Abstract

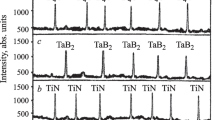

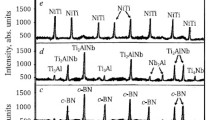

3D micro-cellular structure of Al90Mn9Ce1 / Al2O3 (TiO2, SiC, ZrO2), Fe76Si9B10P5 / Zn0.5Ni0.5Fe2O4 (Co0.5Ni0.5Fe2O4) metal / ceramic system were constructed, based on special sintering mechanism of spark plasma sintering (SPS). The SPS micro local-area temperature field and sintering mechanism at lower macro sintering temperature were analyzed. The microstructure of samples, phase analysis and microstructure of interface were investigated via SEM, XRD and TEM. The results indicate that the 3D micro-cellular structure have been found in the samples, the cellular wall which is nano-ceramic sintered body is uniform, and the alloy cellular body is surrounded by nano-ceramic cellular wall. The infiltration transition area between cellular body and cellular wall implies the combination of interface is fine. Apropos micro-nano-discharge air gap provides interface local transient high temperature. The phase of the composites could maintain small metastable state because of low temperature rapid sintering.

Similar content being viewed by others

References

Wang S.C., Deng Z.X., and Shen W.D., Sound transmission loss characteristics of unbounded orthotropic sandwich panels in bending vibration considering transverse shear deformation, Compos Struct, 2010, 92(12): 2885.

Chen J.M., Hsu C.H., Lin Y.R, Hsiao M.H., and Fey G.T.K., High-power LiFePO4 cathode materials with a continuous nano carbon network for lithium-ion batteries, J. Power Sources, 2008, 184(2): 498.

Matteo P., Massimiliano V., and Claudio B., Effect of porosity of cordierite performs on microstructure and mechanical strength of co-continuous ceramic composites, J. Eur. Ceram. Soc., 2007, 27: 131.

Lee S.P., Chen Y.J., Ho C.M., Chang C.P., and Hong Y.S., A study on synthesis and characterization of the core-shell materials of Mn1−x ZnxFe2O4-Polyaniline, Mat Sci Eng. B, 2007, 143(1–3): 1.

Mamedov V., Spark plasma sintering as advanced PM sintering method, Powd Metall, 2002, 45(4): 322.

Tamburini U.A., Garay J.E., and Munir Z.A., Fast low-temperature consolidation of bulk nanometric ceramic materials, Scripta Mater, 2006, 54: 823.

Zhao Z.K., Yao K.F., and Li J.F., A bulk metal/ceramic composite materal with a celluar structure, Chinese Sci. Bull., 2006, 51(2): 235.

Chun C.H., Lin C.P., Wen S.B., and Shen Y.H., Sintering of aluminum nitride by using alumina crucible and MoSi2 heating element at temperature of 1650 and 1700 °C, Ceram Int, 2009, 35(8): 3455.

Jiang Q., and Lu H.M., Size dependent interface energy and its applications, Surf. Sci. Rep., 2008, 63: 427.

Jiang Q., and Lu H.M., Size-dependent interface energies, J. Mater. Sci. Technol., 2005, 21(suppl. 1): 6.

Jiang Q., Zhao D.S., and Zhao M., Size-dependent interface energy and related interface stress, Acta Mater., 2001, 49: 3143.

Lu H.M., and Jiang Q., Size-dependent surface energies of nanocrystals, J. Phys. Chen. B, 2004, 108: 5617.

Jiang Q., and Shi F.G., Size-dependent initial sintering temperature of ultrafine particles, J. Mater. Sci. Technol., 1998, 14: 171.

Zhang Z., Li J. C., and Jiang Q., Modelling for size-dependent and dimension-dependent melting of nanocrystals, J. Phys. D, 2000, 33: 2653.

Zhang Z., Lu X.X., and Jiang Q., Finite size effect on melting enthalpy and melting entropy of nanocrystals, Physica B, 1999, 270: 249.

Tokita M., Development of large sized ceramic/metal bulk FGM fabricated by spark plasma sintering, Mater Sci. Forum, 1999, 308-311: 83.

Zhang J.X., Zhang G.Z., Zhao S.X., and Song X.Y., Binder-free WC bulk synthesized by spark plasma sintering. J. Alloy Compd., 2009, 479(1–2): 427.

Zhao Z.K., Yao K.F., Jin S.Z., and Li J.F., Bulk Al90Mn9Ce1 alloy with ultra-high strength prepared by spark plasma sintering. Acta Metall. Sin., 2005, 41: 1298.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Li, S., Wang, M. et al. Construction of 3D micro-cellular structure of the metal / ceramic system. Rare Metals 30 (Suppl 1), 604–609 (2011). https://doi.org/10.1007/s12598-011-0355-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0355-z