Abstract

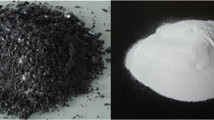

A new style Ni-containing alumina ceramic based network skeleton with excellent high-temperature structural stability was designed and prepared by die-molding and sintering. Subsequently, three-dimensional network alumina/steel metal matrix composites (MMCs) were produced successfully by pressureless infiltration of steel melt into the network skeletons at 1600 °C in vacuum. The obtained MMCs were observed by SEM, EDS and XRD, respectively. Finally, bending strength and fretting wear behavior of the MMCs were investigated.

Similar content being viewed by others

References

Lemster K., Graule T., and Kuebler J., Processing and microstructure of metal matrix composites prepared by pressureless Ti-activated infiltration using Fe-base and Ni-base alloys, Mater. Sci. Eng. A., 2005, 393(1–2): 229.

Pavese M., Fino P., Valle M., and Badini C., Preparation of C4 ceramic/metal composites by reactive metal penetration of commercial ceramics, Compd. Sci. Tech., 2006, 66: 350.

Imbeni V., Hutchings I.M., and Breslin M.C., Abrasive wear behaviour of an Al2O3-Al co-continuous composite, Wear, 1999, 233: 462.

Chang H., Binner J., and Higginson R., Dry sliding wear behaviour of Al(Mg)/Al2O3 interpenetrating composites pro duced by a pressureless infiltration technique, Wear, 2010, 268(1–2): 166.

Matteo P., Paolo F., Daniele U., and Claudio B., High cycle fatigue study of metal-ceramic co-continuous composites, Scripta. Mater., 2006, 55: 1135.

Lemster K., Delporte M., Graule T., and Kuebler J., Activation of alumina foams for fabricating MMCs by pressureless infiltration, Ceram. Inter., 2007, 33(7):1179.

Lemster K., Graule T., Minghetti T., Schelle C., and Kuebler J., Mechanical and machining properties of X38CrMoV5-1/Al2O3 metal matrix composites and components, Mater. Sci. Eng. A., 2006, 420: 296.

Vasic S., Grobéty B., Kuebler J., and Graule T., Activation mechanism and infiltration kinetic for pressureless melt infiltration of Ti activated Al2O3 preforms by high melting alloy, Adv. Eng. Mater., 2009, 11: 658.

Nakashima K., Takihira K., Mori K., and Shinozaki N., Wettability of Al2O3 substrate by liquid iron-effects of oxygen in liquid iron and purity of Al2O3 substrate, Jpn. Inst. Metals., 1991, 55(11): 1199.

Ernst B., Haag S., and Burgard M., Pure nickel coating on a mesoporous alumina membrane: Preparation by electroless plating and characterization, Surf. Coat. Technol., 2006, 201(6): 2166.

Lin H.T., Wang S.C., Huang J.L., and Chang S.Y., Processing of hot pressed Al2O3-Cr2O3/Cr-carbide nanocomposite prepared by MOCVD in fluidized bed, J. Eur. Ceram. Soc., 2007, 27: 4759.

Wittig D., Aneziris C.G., Graule T., and Kuebler J., Mechanical properties of three-dimensional interconnected alumina/steel metal matrix composites, J. Mater. Sci., 2009, 44: 572.

Bai M.W. and Xue Q.J., Study of fretting wear of Al-Fe-Ce-SiC composites, Scripta. Mater., 1996, 35(2): 169.

Rybiaka R., Fouvrya S., and Bonnet B., Fretting wear of stainless steels under variable temperature conditions: Introduction of a ‘composite’ wear law, Wear, 2010, 268: 413.

Jiang J., Stott F.H., and Stack M.M., The role of triboparticulates in dry sliding wear, Tribol. Int., 1998, 31: 245.

Godet M., Third-bodies in tribology, Wear, 1990, 136(1): 29.

Yao Junping, Wang Weiwei, and Yang Bin, Dry friction and wear properties of aluminum matrin composites reinforced with 3D-network ceramics, The Chinese Journal of Nonferrous Metals, 2004, 14(5): 766.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, W., Han, M. & Yang, S. Processing and mechanical properties of three-dimensional network alumina ceramic/alloy steel composites. Rare Metals 30 (Suppl 1), 588–594 (2011). https://doi.org/10.1007/s12598-011-0352-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0352-z