Abstract

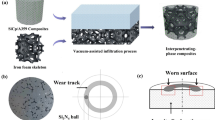

A new style Ni-containing alumina ceramic foam based continuous three-dimensional interconnected skeleton was prepared by impregnating a polymeric sponge with aqueous ceramic slurry. Subsequently, alumina ceramic foam/steel metal matrix composites (MMCs) were prepared successfully by sand mold casting technique. The microstructure and mechanical properties of MMCs were investigated by SEM, EDS and compressive test. The results show that the depth of infiltration is about 40 μm to the bonding interface of ceramic/steel and the fracture strength σ max and plastic strain limit ɛ p of composite are 520 MPa and 11.2%, respectively. The fretting wear mechanism of MMCs is mainly performed at the oxidative wear mode with lower load/friction frequency and the predominant oxidation wear together with slight adhesive wear and abrasive wear multiple mode with higher load/friction frequency. Moreover, the infiltration bonding and continuous three-dimensional interconnected ceramic skeleton play a vital role in the stability of the bonding interface and excellent mechanical properties.

Similar content being viewed by others

References

GURTSANACH J, ESTOURNÈS C, WEIBEL A, PEIGENEY A, CHEVALLIER G, LAURENT C. Spark plasma sintering as a reactive sintering tool for the preparation of surface-tailored Fe-FeAl2O4-Al2O3 nanocomposites [J]. Scr Mater, 2009, 60(4): 195–198.

HUANG D, CHEN W P, ZHANG S Y. Dry friction and wear performance of SiC 3D continuous ceramic frame reinforced 7075A1alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 54–58.

YUAN B, LIU J X, ZHANG G J, KAN Y M, WANG P L. Silicon nitride/boron nitride ceramic composites fabricated by reactive pressureless sintering [J]. Ceram Int, 2009, 35(6): 2155–2159.

MLANFREDI D, PAVESE M, BIAMINO S, FINO P, BADINI C. NiAl(Si)/Al2O3 co-continuous composites by double reactive metal penetration into silica reforms[J]. Composits Sci Tech, 2008, 16(4): 580–583.

EDUARDO D R. Co-continuous composites for high-temperature applications [J]. Mater Sci Eng A, 2007, 463(1): 115–121.

WANG Z, SONG M, SUN C, XIAO D, HE Y. Effect of extrusion and particle volume fraction on the mechanical properties of SiC reinforced Al-Cu alloy composites [J]. Mater Sci Eng A, 2010, 527(24/25): 6537–6542.

KHODAEI M, ENAYATI M H, KARIMZADEH F. Mechanochemically synthesized Fe3Al -Al2 O3 nanocomposite [J]. J Alloys Compd, 2009, 467(1/2): 159–162.

LI J, ZONG B Y, WANG Y M. Experiment and modeling of mechanical properties on iron matrix composites reinforced by different types of ceramic particles [J]. Mater Sci Eng A, 2010, 527(29/30): 7545–7551.

SONG M, HE Y H, FANG S F. Yield stress of SiC reinforced aluminum alloy composites [J]. J Mater Sci, 2010, 45(15): 4097–4110.

FENG S R, TANG H B, ZHANG S Q, WANG H M. Microstructure and wear resistance of laser clad TiB-TiC/TiNi-Ti2Ni intermetallic coating on titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1667–1673

SRDAN V, BERNARD G, JAKOB K, PHILIPPE K, THOMAS G. Experimental models for activation mechanism of pressureless infiltration in the non-wetting steel-alumina MMC System [J]. Adv Eng Mater, 2008, 10(5): 471–475

LIU G W, VALENZA F, MUOLO M L. Survey on wetting of SiC by molten metals [J]. Ceram Int, 2010, 36(4): 1177–1188.

LEMSTER K, GRAULE T, MINGHETTI T, SCHELLE C, KUEBLER J. Mechanical and machining properties of X38CrMoV5-1/Al2O3 metal matrix composites and components [J]. Mater Sci Eng A, 2006, 420(1/2): 296–305.

YANG S F, CHEN W P, HAN M Y, YANG C, ZHU D Z. Bonding mechanism of X10CrNi18-8 with Ni/Al2O3 composite ceramic by pressureless infiltration [J]. Journal of Central South University, 2011, 18(4): 953–959.

ZHANG S Y, QU S G, Li Y Y, CHEN W P. Friction and wear behaviour of brake pads dry sliding against semi-interpenetrating network ceramics/al-alloy composites [J]. Tribol Lett, 2010, 38(2): 135–146.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51271080) supported by the National Natural Science Foundation of China; Project(2012JSSPITP1968) supported by the Innovative Foundation for Students of Jiangsu Province, China; Project(CKJB201204) supported by the Innovation Fund of Nanjing Institute of Technology, China

Rights and permissions

About this article

Cite this article

Yang, Sf., Chen, Wp., Wang, Zy. et al. Processing and mechanical properties of network ceramic/steel composites by pressureless infiltration. J. Cent. South Univ. 21, 2560–2566 (2014). https://doi.org/10.1007/s11771-014-2212-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2212-0