Abstract

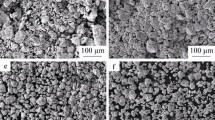

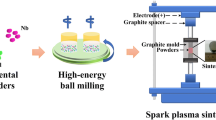

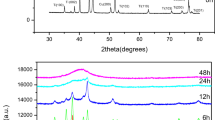

Preparation of high-quality powder blends is the first step for hot-press sintering of Nb-Ti-Si based ultrahigh temperature alloys. In the present work, powder blends of Nb-22Ti-15Si-6Cr-4Hf-3Al-1.5B-0.06Y (at.%) were prepared by ball milling the elemental powder mixtures. The morphology and phase constituents of the powder blends were analyzed by XRD, SEM and EDS techniques. The mechanical alloying process, including diffusion, phase formation and powder deformation was revealed. The results show that supersaturated Nbss (Nb solid solution) formed during the milling process, the deformation of the powders became more serious and thus more crystal defects appeared in the powders with the prolonging of milling time at different rotating speeds. The powder size firstly increased and then decreased, and the size distribution of powders became more uniform with the increase in milling time. A small quantity of nanometer scaled spheroidal particles formed after ball milling for a certain time. It was found that the alloying process was faster upon a higher rotating speed ball milling, but with a lower powder yield.

Similar content being viewed by others

References

Yi D.Q., Li D., Li J., and Zhou M., Powder metallurgy prepares Nb-15Ti-11Al-10Si composites, Rare Metals, 2007, 31: 472.

Nie X.W., Lu S.Q., and Wang K.L., Phase transformations of NbCr2 intermetallics produced by mechanical alloying followed by hot-pressing consolidation, Materials Characterization, 2008, 59: 816.

Ran G., Zhou J.E., Li P.l., Xi S.Q., and Zhang Z.W., Characteristics of high energy ball milling Al-Pb-Si-Sn-Cu nanocrystalline powder, Rare Metal Materials and Engineering, 2004, 33: 1312.

Lu J., Luo F.H., Chen M.J., Mao H.N., and Zhang H., Powder metallurgy Ni-Fe-Al alloys preparation and properties, Metal Heat Treatment, 2008, 33(12): 24.

Bououdina M., and Guo Z.X., Characterization of structural stability of (Ti (H2) + 22Al+23Nb) powder mixtures during mechanical alloying, Materials Science and Engineering. A, 2002, 332: 210.

Lu X., He X.B., and Qu X.H., High-energy ball milling and sintered prepare high-Nb TiAl alloy, Aeronautical Materials, 2009, 29(1): 16.

Chen H., Characteristics of Ti-Al-Si-Nb alloy prepared by mechanical alloying and spark plasma sintering, Metal Materials and Engineering, 2007, 32(7): 1177.

Lou T.P., Ding B.Z., Gu X.J., Li G.S., and Hu Z.Q., Mechanical alloying of Fe-Nb-C materials, Materials Letters, 1996, 28: 129.

Perez R.J., Huang B., Crawford P.J., Sharif A.A., and Lavernia E.J., Synthesis of nanocrystalline Fe-13 at.%B-7 at.%Si by mechanical alloying, Materials Science and Engineering. A, 1995, 204: 217.

Feng Z.X., Xi S.Q., Zhang D.W., and Song X.W., Mechanical alloying Al-Mg-Si-Cu elemental powder characteristics, The Chinese Journal of Nonferrous Metals, 2001, 11: 642.

Ward T.S., Chen W.L., Schoenitz M., Dave R.N., and Dreizin E.L., A study of mechanical alloying processes using reactive milling and discrete element modeling, Acta Materialia, 2005, 53: 2909.

Xiao A.P., Qu X.H., Lei C.M., Zhu B.J., and Huang P.Y., Milling rate and process control agents on Ti-Cr alloys mechanical alloying, Materials Science and Engineering, 2002, 7: 236.

Wang X.L., Wang G.F., and Zhang K.F., Effect of mechanical alloying on microstructure and mechanical properties of hot-pressed Nb-16Si alloys, Materials Science and Engineering. A, 2010, 527: 3253.

Jia D.C., Zhou Y., and Lei T.C., Microstructure and mechanical properties of Al-12Ti-6Nb prepared by mechanical alloying, Materials Science and Engineering. A, 1997, 232: 183.

Kumaran S., Sasikumar T., Arockiakumar R., and Rao T.S., Nanostructured titanium aluminides prepared by mechanical alloying and subsequent thermal treatment, Powder Technology, 2008, 185: 124.

Liu H., Zhou Z.H., Liang B.Y., Jin S.Z., and Zou L.J., Mechanical alloying Ti/Al alloy, Powder Metallurgy Industry, 2005, 15: 8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, T., Guo, X. Morphology and phase constituents of mechanically alloyed Nb-Ti-Si based ultrahigh temperature alloy powders. Rare Metals 30 (Suppl 1), 427–432 (2011). https://doi.org/10.1007/s12598-011-0318-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0318-1