Abstract

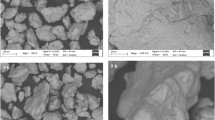

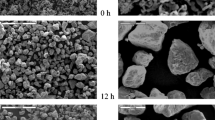

In the current study, Ti-Ni-Cu alloy powders were prepared by mechanical alloying using high-energy planetary ball mill under argon atmosphere. The effects of milling time on the evolution of structure, microstructure, and magnetic properties were analysed. Morphological observations indicated a narrow particle size distribution and homogeneous shape. According to the Rietveld analysis, during early milling stage (1–6 h), the milled powder consists of Ti-based solid solution [HCP-Ti(Ni,Cu)], Ni-based solid solution [FCC-Ni(Ti,Cu)], Cu-based solid solution [FCC-Cu(Ti,Ni)], and amorphous phase (28.52 wt%). For prolonged milling time, the NiTiCu (β19) was achieved from the pre-formed phases. Moreover, microstructural parameters varied considerably with milling time; the crystallite size <L> was found to decrease to the nanoscale range, Ti (41), Ni (21 nm), Cu (16 nm), and β19 (29 nm), while the microstrain <σ2>1/2 increased due to the deformations and defects induced during the milling process. Magnetic measurements indicated that all powders exhibited a ferromagnetic behaviour irrespective of milling time whereas the corresponding magnetic parameters were found very sensitive to the milling time. This was associated with particle size refinement in addition to the phase composition and the amount of the amorphous phase; the higher the percentage of the amorphous phase was, the lower the values of Ms and Mr.

Similar content being viewed by others

References

Tuissi, A., Rondelli, G., Bassani, P.: Plasma arc melting (PAM) and corrosion resistance of pure NiTi shape memory alloys. Shape Mem. Superelast. 1(1), 50–57 (2015)

Witkowska, J., Kaminski, J., Locinski, T.P., et al.: Corrosion resistance of NiTi shape memory alloy after hybrid surface treatment using low-temperature plasma. Vacuum. 137, 92–96 (2017)

Ng, C.H., Nanxi, R., Law, W.C., et al.: Enhancing the cell proliferation performance of NiTi substrate by laser diffusion nitriding. Surf. Coat. Technol. 309, 59–66 (2017)

Sevcikova, J., Pavkova Goldbergova, M.: Biocompatibility of NiTi alloys in the cell behavior. Biol. Met. 30(2), 163–169 (2017)

Piquard, R., D’Acunto, A., Laheurte, P., Dudzinski, D.: Microendmilling of NiTi biomedical alloys, burr formation and phase transformation. Precis. Eng. 38(2), 356–364 (2014)

Thompson, S.A.: An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 33, 297–310 (2000)

Otsuka, K., Ren, X.: Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 50, 511–678 (2005)

Nam, T.H., Saburi, T., Shimizu, K.: Cu-content dependence of shape memory characteristics in Ti-Ni-Cu alloys. Mater. Trans. JIM. 31, 959–967 (1990)

Potapov, P.L., Shelyakov, A.V., Schryvers, D.: On the crystal structure of TiNi-Cu martensite. J. Scr. Mater. 44, 1–7 (2001)

Van Loo, F.J.J., Bastin, G.F., Leenen, A.J.H.: Phase relations in the ternary Ti-Ni-Cu system at 800 and 870 °C. J. Less-Common Met. 57, 111–121 (1978)

Zhang, L., Xie, C., Wu, J.: Martensitic transformation and shape memory effect of Ti–49 at.% Ni alloys. J. Mater. Sci. Eng. A. 438–440, 905–910 (2006)

Xu, Y., Huang, X., Ramirez, A.G.: Crystallization of amorphous NiTiCu thin films. J. Alloys Compd. 480, L13–L16 (2009)

Goryczk, T., Van Humbeeck, J.: Characterization of a NiTiCu shape memory alloy produced by powder technology. J. Achiev. Mater. Manuf. Eng. 17, 65–68 (2006)

Valeanu, M., Lucaci, M., Crisan, A.D., Sofronie, M., Leonat, L., Kuncser, V.: Martensitic transformation of Ti50Ni30Cu20 alloy prepared by powder metallurgy. J. Alloys Compd. 509, 4495–4498 (2011)

Kanchibhotla, S., Munroe, N., Kartikeyan, T.: Amorphization in Ni-Ti-Ta system through mechanical alloying. J. Mater. Sci. 40, 5003–5006 (2005)

Amini, R., Alijani, F., Ghaffari, M., Alizadeh, M., Okyay, A.K.: Quantitative phase evolution during mechano-synthesis of Ti–Ni–Cu shape memory alloys. J. Alloys Compd. 538, 253–257 (2012)

Ghadimi, M., Shokuhfar, A., Zolriasatein, A., Rostami, H.: Morphological and structural evaluation of nanocrystalline NiTiCu shape memory alloy prepared via mechanical alloying and annealing. J. Mater. Lett. 90, 30–33 (2013)

Lutterotti, L.: Microstructure Analysis by MAUD (2016); http://maud.radiographema.com/

Sakher, E., Loudjani, N., Benchiheub, M., Bououdina, M.: Influence of milling time on structural and microstructural parameters of Ni50Ti50 prepared by mechanical alloying using Rietveld analysis. J. Nanomater. 2018, (2018)

Loudjani, N., Benchiheub, M., Bououdina, M.: Structural, thermal and magnetic properties of nanocrystalline Co80Ni20 alloy prepared by mechanical alloying. J. Supercond. Nov. Magn. 29(11), 2717–2726 (2016)

Sakher, E., Loudjani, N., Benchiheub, M., Belkahla, S., Bououdina, M.: Microstructure characterization of nanocrystalline Ni50Ti50 alloy prepared via mechanical alloying method using the Rietveld refinement method applied to the X-ray diffraction. J. Nanosist. Nanomater. Nanotechnol. 15(3), 401–416 (2017)

Li, B.-Y., Rong, L.-J., Li, Y.-Y.: Stress-strain behavior of porous Ni-Ti shape memory intermetallics synthesized from powder sintering. Intermetallics. 8, 643–646 (2000)

Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater. Sci. 46(1–2), 1–184 (2001)

Loudjani, N., Bensebaa, N., Dekhil, L., Alleg, S., Sunol, J.J.: Structural and magnetic properties of Co50Ni50 powder mixtures. J. Magn. Magn. Mater. 323(23), 3063–3070 (2011)

Alijani, F., Amini, R., Ghaffari, M., Alizadeh, M., Okyay, A.K.: Effect of milling time on the structure, micro-hardness, and thermal behavior of amorphous/nanocrystalline TiNiCu shape memory alloys developed by mechanical alloying. J. Mater. Des. 55, 373–380 (2014)

Souilah, S., Alleg, S., Bououdina, M., Sunol, J.J., Hlil, E.K.: Magnetic and structural properties of the nanostructured Cu50Ni50 powders. J. Supercond. Nov. Magn. 30, 1927–1935 (2017)

Herzer, G.: Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 1397–1402 (1990)

Azzaza, S., Alleg, S., Moumeni, H., Nemamcha, A.R., Rehspringer, J.L., Greneche, J.M.: Magnetic properties of nanostructured ball-milled Fe and Fe50Co50 alloy. J. Phys. Condens. Matter. 18, 7257–7272 (2006)

Amini, R., Alijani, F., Ghaffari, M., Alizadeh, M., Okyay, A.K.: Formation of β19′, β2, and amorphous phases during mechano-synthesis of nanocrystalline NiTi intermetallics. J. Powder Technol. 253, 797–802 (2014)

Ghadimi, M., Vanda, M., Sourani, M.A.: Nanocrystalline Ti-Ni-Cu shape memory alloys: metallurgical, mechanical and thermal properties. J. Mater. Lett. 139, 359–363 (2015)

Otsuka, K., Wayman, C.M.: Shape memory materials. Cambridge University Press, Cambridge (1998)

Haider, W., Munroe, N., Pulletikurthi, C., Singh Gill, P.K., Amruthaluri, S.: A comparative biocompatibility analysis of ternary nitinol alloys. J. Mater. Eng. Perform. 18, 760–764 (2009)

Lin, K.-N., Wu, S.-K.: Multi-stage transformation in annealed Ni-rich Ti49Ni41Cu10 shape memory alloy. Intermetallics. 18, 87–91 (2010)

Zheng, Y., Cui, L., Schrooten, J.: Thermal cycling behaviours of a NiTiCu wire reinforced Kevlar/epoxy composite. J. Mater. Lett. 59, 3287–3290 (2005)

Zheng, N., Wang, Q., Cui, C., Yin, F., Jiao, Z., Li, H.: Fabrication and damping behaviors of novel polyurethane/TiNiCu composites. Phys. B Condens. Matter. 582, 411911 (2020)

Shelyakov, A.V., Sitnikov, N.N., Menushenkov, A.P., Koledov, V.V., Irjak, A.I.: Nanostructured thin ribbons of a shape memory TiNiCu alloy. J. Thin Solid Films. 519, 5314–5317 (2011)

Yongqing, F., Hejun, D., Weimin, H., Sam, Z., Min, H.: TiNi-based thin films in MEMS applications. J. Sensors Actuators A. 112, 395–408 (2004)

Shelyakov, A.V., Sitnikov, N.N., Glezer, A.M., Menushenkov, A.P.: Nanostructured shape memory alloys of the TiNi–TiCu system. J. Russ. Acad. Sci. Phys. 74, 1543–1545 (2010)

Ryusuke, H.: Present status of amorphous soft magnetic alloys. J. Magn. Magn. Mater. 215–216, 240–245 (2000)

Qin, F.X., Wang, X.M., Xie, G.Q., Inoue, A.: Distinct plastic strain of Ni–free Ti–Zr–Cu–Pd–Nb bulk metallic glasses with potential for biomedical applications. Intermetallics. 16, 1026–1030 (2008)

Inoue, A.: Stabilization of metallic supercooled liquid and bulk amorphous alloys. J. Acta Mater. 48, 279–306 (2000)

Narushima, T.: Metals for Biomedical Devices, 2nd edn, pp. 495–521. Woodhead Publishing Series in Biomaterials (2019)

Hasegawa, R., Pruess, D.C.: Impact of amorphous metal based transformers on efficiency and quality of electric power distribution. In: Proceedings of the Summer Meeting of IEEE Power Engineering Society Canada, pp. 15–19 (2001)

Smith, C.H.: Application of amorphous magnetic materials at very-high magnetization rates. J. Appl. Phys. 67, 5556–5561 (1990)

Nakayama, H., Uesugi, T., Ezura, E., Ohmori, C., Kanei, Y., Kiba, K., Saito, K., Sato, Y., Sauda, M., Takagi, A., Tanabe, T., Tanabe, Y., Toda, S., Fujieda, M., Matsumura, R., Mori, Y., Yamamoto, M., Yoshii, M.: Summary of the Measurement of Magnetic Materials for JHF RF Cavity. In: (2)-FINMET-, KEK (High Energy Accelerator Research Organization, Japan) Report 98–13 (in Japanese), pp. 1–36 (1999)

Mehnen, L., Pfüitzer, H., Kaniusas, E.: Magnetostrictive amorphous bimetal sensors. J. Magn. Magn. Mater. 215–216, 779–781 (2000)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rezgoun, S., Sakher, E., Chouf, S. et al. Structural, Microstructural, and Magnetic Property Dependence of Nanostructured Ti50Ni43Cu7 Powder Prepared by High-Energy Mechanical Alloying. J Supercond Nov Magn 33, 2059–2071 (2020). https://doi.org/10.1007/s10948-020-05455-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-020-05455-9