Abstract

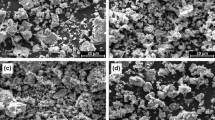

In this paper, three kinds of TiNi alloys, TiNi,Ti3Ni2,Ti2Ni, were prepared by mechanical alloying (MA). The procedures of phase evolution during MA are as follows: elements Ni and Ti → formation of NiTi alloy → amorphization of alloy. For milling 70 h, all three TiNi alloys show typical amorphous character. Oxygen will prevent the amorphization process of TiNi alloys during MA process. Crystallization of amorphous TiNi will take place at about 530 °C. For TiNi, Ti3Ni2, Ti2Ni, the main crystalline phase is TiNi. Ti2Ni + TiNi, Ti2Ni, respectively. For amorphous TiNi base alloys, the initial capacity of Ti2Ni, Ti3Ni2 is higher than TiNi. But it decreases gradually with the charge-discharge process. Capacity of TiNi increases with the cycle process. The capacity of crystallized TiNi alloys is higher than amorphous ones. The initial capacity of Ti2Ni can get 289 mAh/g which is double than amorphous Ti2Ni. But it decreases sharply with the charge-discharge process. After 80 cycle, capacity of Ti2Ni is lower than that of TiNi. As same as amorphous TiNi, capacity of crystallized ones increases gradually with the charge-discharge process.

Similar content being viewed by others

References

Nolan Michael, and Tofailyed A.M., Density functional theory simulation of titanium migration and reaction with oxygen in the early stages of oxidation of equiatomic NiTi alloy, Biomaterials, 2010, 31(13): 3439.

Liu F., Xu J.L., and Wang F.P., Biomimetic deposition of apatite coatings on micro-arc oxidation treated biomedical NiTi alloy, Surface and Coatings Technology, 2010, 204(20): 3294.

Miao W.D., Mi X.J., and Wang X.Q., Effect of different surface treatments on fatigue life of NiTi wires, Materials Science Forum., 2007, 561–565(3): 2265.

Kazuhiro Otsuka, and Ren Xiaobin. Recent developments in the research of shape memory alloys, Intermetallica, 1999, 7(5): 511.

Ye H.Z., Liu R., Li D.Y., and Eadie R., Development of a new wear-resistant material: TiC/TiNi composite, Scripta Material, 1999, 41(10): 1039.

Hitoshi Hiraga, Takashi Inoue, Shigeharu Kamado, Yo Kojima, and Akira Matsunawa C., Fabrication of NiTi intermetallic compound coating made by laser plasma hybrid spraying of mechanically alloyed powders, Surface and Coating Technology, 2001, 139(1): 93.

Yan X.J., Yang D.Z., and Liu X.P., Influence of heat treatment on the fatigue life of a laser-welded NiTi alloy wire, Materials Characterization, 2007, 58(30): 262.

Xu Y.H., Chen C.P., and Wang Q.D., The hydrogen storage properties of Ti-Mn-based C14 Laves Phase intermetallics as hydrogen resource for PEMFC, International Journal of Hydrogen Energy, 2001, 26(6): 593.

Xu Y.H., Chen C.P., and Wang Q.D., Electrochemical behavior of new type Ti3Ni2 hydrogen storage electrode, Rare Metal Materials and Engineering, 2001, 30: 23.

Guo J., Yang K., and Xu L.Q. Hydrogen storage properties of Mg76Ti12Fe12−x Nix (x = 0, 4, 8, 12) alloys by mechanical alloying, International Journal of Hydrogen Energy, 2007, 32(13): 2412.

Rousselot Steeve, Guay Daniel, and Roué Lionel, Comparative study on the structure and electrochemical hydriding properties of MgTi, Mg0.5Ni0.5Ti and MgTi0.5Ni0.5 alloys prepared by high energy ball milling, Journal of Power Sources, 2011, 196(3): 1561.

Harris J.R., Wattis A.D., and Wood J.V., A comparison of different models for mechanical alloying, Acta Mater., 2001, 49(19): 3991.

Jiuczyk M., Jankowska E., Nowak M., and All J., Comp., Nanocrystalline titanium-type metal hydride electrodes prepared by mechanical alloying, Journal of Alloys and Compounds, 2002, 336(1): 265.

Makifuchi Y., Terunama Y., and Naguno M., Structural relaxation in amorphous Ni-Ti alloys prepared by mechanical alloying, Material Science and Engineering, 1997, 226–228: 312.

Suryanarayana C., Mechanical alloying and milling, Progress in Materials Science, 2001, 46(1): 1.

Jiang X.Y., Gao X.P., and Song D.Y., Phase development and crystallization kinetics of NiTi prepared by mechanical alloying, J. Mate. Sci. Tech., 2003, 19(6): 560.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, X., Liu, Q. & Zhang, L. Electrochemical hydrogen storage property of NiTi alloys with different Ti content prepared by mechanical alloying. Rare Metals 30 (Suppl 1), 63–67 (2011). https://doi.org/10.1007/s12598-011-0239-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0239-z