Abstract

In this study, low-velocity impact analysis on glass fibre-reinforced polymer (GFRP) and hybrid laminates is performed through an explicit numerical analysis and relevant experiments. Hybridised composite laminates are fabricated by sandwiching the flexible Polycarbonate sheet between the glass fibre-reinforced polymer laminas. In order to analyse the improvement in the impact resistance of hybrid laminates, low-velocity impact tests are performed on both GFRP and hybrid laminates by dropping an impactor from various pre-defined heights and the absorbed energy in each case is estimated. Results from the numerical analysis are validated with experimental results. Based on the numerical and experimental analysis, variation of the absorbed energy as a function time is estimated. Furthermore, shapes of the damaged areas are also estimated using the experimental specimens. Analysis of results indicates that the hybrid laminates display better energy absorption characteristics before rupture, as compared to the GFRP laminates. For a given energy absorption weight, savings up to 30.77% are observed using polycarbonate-based hybrid composites as compared to the GFRP laminates.

Similar content being viewed by others

References

Balaganesan, G., Khan, V.C.: Energy absorption of repaired composite laminates subjected to impact loading. Compos. B Eng. 98, 39–48 (2016)

Budarapu, P.R., Sudhir, Y.B.S., Brahmanandam, J., Mahapatra, D.R.: Vibration analysis of multi-walled carbon nanotubes embedded in elastic medium. Front. Struct. Civ. Eng. 8(2), 151–159 (2014). https://doi.org/10.1007/s11709-014-0247-9

Budarapu, P.R., Rammohan, B., Vijay, S.K., Satish, B.D., Raghunathan, R.: Aero-elastic analysis of stiffened composite wing structure. J. Vib. Eng. Technol. 8(3), 255–264 (2009)

Kurşun, A., Şenel, M., Enginsoy, H.M., Bayraktar, E.: Effect of impactor shapes on the low velocity impact damage of sandwich composite plate: experimental study and modelling. Compos. B Eng. 86, 143–151 (2016)

Dogan, A., Arikan, V.: Low-velocity impact response of e-glass reinforced thermoset and thermoplastic based sandwich composites. Compos. B Eng. 127, 63–69 (2017)

Hung, P., Lau, K., Cheng, L., Leng, J., Hui, D.: Impact response of hybrid carbon/glass fibre reinforced polymer composites designed for engineering applications. Compos. B Eng. 133, 86–90 (2018)

Sonnenfeld, C., Mendil-Jakani, H., Agogué, R., Nunez, P., Beauchêne, P.: Thermoplastic/thermoset multilayer composites: a way to improve the impact damage tolerance of thermosetting resin matrix composites. Compos. Struct. 171, 298–305 (2017)

Budarapu, P.R., Sudhir Sastry, Y.B., Natarajan, R.: Design concepts of an aircraft wing: composite and morphing airfoil with auxetic structures. Front. Struct. Civ. Eng. 10(4), 394–408 (2016). https://doi.org/10.1007/s11709-016-0352-z

Bouvet, C., Castanié, B., Bizeul, M., Barrau, J.-J.: Low velocity impact modelling in laminate composite panels with discrete interface elements. Int. J. Solids Struct. 46(14–15), 2809–2821 (2009)

Hongkarnjanakul, N., Bouvet, C., Rivallant, S.: Validation of low velocity impact modelling on different stacking sequences of cfrp laminates and influence of fibre failure. Compos. Struct. 106, 549–559 (2013)

Bandaru, A.K., Ahmad, S.: Modeling of progressive damage for composites under ballistic impact. Compos. B Eng. 93, 75–87 (2016)

Sarasini, F., Tirillò, J., D’Altilia, S., Valente, T., Santulli, C., Touchard, F., Chocinski-Arnault, L., Mellier, D., Lampani, L., Gaudenzi, P.: Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. B Eng. 91, 144–153 (2016)

Aktaş, M., Atas, C., Murat İçten, B., Karakuzu, R.: An experimental investigation of the impact response of composite laminates. Compos. Struct. 87(4), 307–313 (2009)

Singh, N.K., Singh, K.K.: Review on impact analysis of frp composites validated by ls-dyna. Polym. Compos. 36(10), 1786–1798 (2015)

Peng, Q., Sun, X., Guan, X., Yidong, M., Jia, Y.: Effect of interlaminar toughness on the low-velocity impact damage in composite laminates. Polym. Compos. 37(4), 1085–1092 (2016)

Rawat, P., Singh, K.K., Singh, N.K.: Numerical investigation of damage area due to different shape of impactors at low velocity impact of gfrp laminate. Mater. Today Proc. 4(8), 8731–8738 (2017)

Gu, G.X., Takaffoli, M., Hsieh, A.J., Buehler, M.J.: Biomimetic additive manufactured polymer composites for improved impact resistance. Extreme Mech. Lett. 9, 317–323 (2016)

Bouhfid, N., Raji, M., Boujmal, R., Essabir, H., Bensalah, M.-O., Bouhfid, R., Qaiss, A.K.: Numerical modeling of hybrid composite materials. In: Modelling of Damage Processes in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, pp. 57–101. Elsevier (2019)

Feraboli, P., Wade, B., Deleo, F., Rassaian, M., Higgins, M., Byar, A.: Ls-dyna mat54 modeling of the axial crushing of a composite tape sinusoidal specimen. Compos. A Appl. Sci. Manuf. 42(11), 1809–1825 (2011)

Gama, B.A., Gillespie Jr., J.W.: Finite element modeling of impact, damage evolution and penetration of thick-section composites. Int. J. Impact Eng. 38(4), 181–197 (2011)

Brown, K., Brooks, R., Warrior, N.: Numerical simulation of damage in thermoplastic composite materials. In: 5th European LSDYNA Users Conference (2005)

Heimbs, S., Heller, S., Middendorf, P., Hähnel, F., Weiße, J.: Low velocity impact on cfrp plates with compressive preload: test and modelling. Int. J. Impact Eng. 36(10–11), 1182–1193 (2009)

Berk, B., Karakuzu, R., Icten, B.M., Arikan, V., Arman, Y., Atas, C., Goren, A.: An experimental and numerical investigation on low velocity impact behavior of composite plates. J. Compos. Mater. 50(25), 3551–3559 (2016)

Hosseinzadeh, R., Shokrieh, M.M., Lessard, L.: Damage behavior of fiber reinforced composite plates subjected to drop weight impacts. Compos. Sci. Technol. 66(1), 61–68 (2006)

Kiani, M., Shiozaki, H., Motoyama, K.: Using experimental data to improve crash modeling for composite materials. In: Composite Materials and Joining Technologies for Composites, vol. 7, pp. 215–226. Springer (2013)

Rawat, P., Singh, K.K.: An impact behavior analysis of cnt-based fiber reinforced composites validated by ls-dyna: a review. Polym. Compos. 38(1), 175–184 (2017)

Sanita, Z.I.K.E., Kalnins, K., Ozolins, O., Knite, M.: An experimental and numerical study of low velocity impact of unsaturated polyester/glass fibre composite. Mater. Sci. 17(4), 384–390 (2011)

Chang, F.-K., Chang, K.-Y.: Post-failure analysis of bolted composite joints in tension or shear-out mode failure. J. Compos. Mater. 21(9), 809–833 (1987)

Tsai, S.W., Edward, M.W.: A general theory of strength for anisotropic materials. J. Compos. Mater. 5(1), 58–80 (1971)

Maio, L., Monaco, E., Ricci, F., Lecce, L.: Simulation of low velocity impact on composite laminates with progressive failure analysis. Compos. Struct. 103, 75–85 (2013)

Boria, S., Pavlovic, A., Fragassa, C., Santulli, C.: Modeling of falling weight impact behavior of hybrid basalt/flax vinylester composites. Procedia Eng. 167, 223–230 (2016)

Thatte, B.S., Chandekar, G.S., Kelkar, A.D., Chaphalkar, P.: Studies on behavior of carbon and fiberglass epoxy composite laminates under low velocity impact loading using ls-dyna. In: 10th International LS-DYNA User’s Conference (2008)

Sudhir, Y.B.S., Budarapu, P.R., Madhavi, N., Krishna, Y.: Buckling analysis of thin wall stiffened composite panels. Comput. Mater. Sci. 96B, 459–471 (2015). https://doi.org/10.1016/j.commatsci.2014.06.007

El Moumen, A., Tarfaoui, M., Lafdi, K., Benyahia, H.: Dynamic properties of carbon nanotubes reinforced carbon fibers/epoxy textile composites under low velocity impact. Compos. B Eng. 125, 1–8 (2017)

Imielińska, K., Guillaumat, L.: The effect of water immersion ageing on low-velocity impact behaviour of woven aramid-glass fibre/epoxy composites. Compos. Sci. Technol. 64(13–14), 2271–2278 (2004)

Li, Z., Khennane, A., Hazell, P.J., Brown, A.D.: Impact behaviour of pultruded gfrp composites under low-velocity impact loading. Compos. Struct. 168, 360–371 (2017)

Mahmoud, B., Torrecilla, M.C., Navarro, P., Marguet, S., Tawk, I., Ferrero, J.-F.: Semi-continuous strategy for the modelling of damage mechanisms in unidirectional composites under low velocity impacts. Compos. B Eng. 130, 147–157 (2017)

Park, H.: Investigation on low velocity impact behavior between graphite/epoxy composite and steel plate. Compos. Struct. 171, 126–130 (2017)

Salvetti, M., Sbarufatti, C., Andrea Gilioli, M., Dziendzikowski, K.D., Manes, A., Giglio, M.: On the mechanical response of cfrp composite with embedded optical fibre when subjected to low velocity impact and cai tests. Compos. Struct. 179, 21–34 (2017)

He, R.W., Shu, C.L., Xiao, Q.Z., Xiao, H.Y.: Study on the delamination behavior of thick composite laminates under low-energy impact. Compos. Struct. 184, 461–473 (2018)

Sudhir, Y.B.S., Budarapu, P.R., Krishna, Y., Devraj, S.: Studies on ballistic impact of the composite panels. Theor. Appl. Fract. Mech. 72, 2–12 (2014). https://doi.org/10.1016/j.tafmec.2014.07.010

Sikdar, S., Banerjee, S.: Identification of disbond and high density core region in a honeycomb composite sandwich structure using ultrasonic guided waves. Compos. Struct. 152, 568–578 (2016)

Bandaru, A.K., Ahmad, S., Bhatnagar, N.: Ballistic performance of hybrid thermoplastic composite armors reinforced with kevlar and basalt fabrics. Compos. A Appl. Sci. Manuf. 97, 151–165 (2017)

Keränen, M., Gnyba, M., Raerinne, P., Kololuoma, T., Maaninen, A., Rantala, J.T.: Synthesis and characterization of optical sol-gel adhesive for military protective polycarbonate resin. J. Sol Gel. Sci. Technol. 31(1–3), 369–372 (2004)

Hsieh, A.J., DeSchepper, D., Moy, P., Dehmer, P.G., Song, J.W.: The effects of pmma on ballistic impact performance of hybrid hard/ductile all-plastic-and glass-plastic-based composites. Technical report, Army Research Lab Aberdeen Proving Ground MD (2004)

Sarva, S., Mulliken, A.D., Boyce, M.C., Hsieh, A.J.: Mechanics of transparent polymeric material assemblies under projectile impact: simulations and experiments. In: Transformational Science and Technology for the Current and Future Force: (With CD-ROM), pp. 227–234. World Scientific (2006)

Sudhir Sastry, Y.B., Kiros, B.G., Hailu, F., Budarapu, P.R.: Impact analysis of compressor rotor blades of an aircraft engine. Front. Struct. Civ. Eng. 13(3), 505–514 (2019)

Her, S.-C., Liang, Y.-C.: The finite element analysis of composite laminates and shell structures subjected to low velocity impact. Compos. Struct. 66(1–4), 277–285 (2004)

ASTM International: Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event. ASTM International (2007)

Mullaoğlu, F., Usta, F., Türkmen, H.S., Kazancı, Z., Balkan, D., Akay, E.: Deformation behavior of the polycarbonate plates subjected to impact loading. Procedia Eng. 167, 143–150 (2016)

Hallquist, J.O., et al.: Ls-dyna keyword user’s manual. Livermore Softw. Technol. Corp. 970, 299–800 (2007)

Acknowledgements

Harshavardhan Shetty would like to thank the computational and experimental facilities provided by PES University to perform the reported numerical and experimental studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Fabrication of GFRP and hybrid laminates

Appendix A: Fabrication of GFRP and hybrid laminates

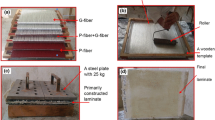

Hybrid laminates of thickness 3 mm are manufactured by sandwiching serrated 2-mm PC sheets in between 0.5-mm GFRP laminates using an adhesive, epoxy resin ‘AV 138 IN’ and hardener ‘HV 998 IN’. The resin ensures the compatibility between the polycarbonate and GFRP. This is particularly required since polycarbonate and GFRP sheets have different adhesive properties. As a result of different characteristics, a resin along with an hardener is used to bond the GFRP and polycarbonate laminates. The selected resin and hardener combination ensures room temperature curing and strong bonding. Furthermore, in order to facilitate the adhesion between GFRP and polycarbonate layers, serrations at \(+ 45 ^\circ\) and \(-45^\circ\) were created on either side of the polycarbonate sheet; see Fig. 14a.

After application of the adhesives, the panel (GFRP/PC) is allowed to cure at room temperature for \(\approx 24 \,\hbox {hours}\). During the curing process, cross-linking between the uniformly distributed adhesive and the laminas can be established. Followed by curing, an adhesive bond shear strength test as per ASTM D1002 standard considering a single lap joint was performed before the impact testing. The GFRP and hybrid laminates prepared for lap joint test are shown in Fig. 14b, where the geometry details of the specimens are highlighted in the front and top schematic views in Fig. 14c, d, respectively. The bonding test is required to validate the strength of the bond such that bond failures during the impact test can be eliminated, thereby avoiding the wrong assessment of the impact test data. Experiments were carried on \(25\times 100 \times 0.5 \,\hbox {mm}^3\) GFRP and \(25\times 100 \times 2 \,\hbox {mm}^3\) polycarbonate specimens, with a bond area of \(25\times 12.5 \,\hbox {mm}^2\); see Fig. 14. The experiments are carried out at the National Analytical Laboratories and Research Center (NALRC), Bangalore, India.

Rights and permissions

About this article

Cite this article

Shetty, H., Sethuram, D., Rammohan, B. et al. Low-velocity impact studies on GFRP and hybrid composite structures. Int J Adv Eng Sci Appl Math 12, 125–141 (2020). https://doi.org/10.1007/s12572-021-00287-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12572-021-00287-9