Abstract

Future crewed space missions will make use of hybrid life support systems to sustain human presence in space and on other planetary bodies. Plants fulfill essential roles in those systems such as carbon dioxide removal, oxygen production, and food production. The systems required to grow plants in space, so-called space greenhouses, are complex and need to be built as efficient as possible. Thereby, the resources mass, volume, energy, and crewtime required to grow a certain amount of food are essential because these parameters define the effectiveness of the space greenhouse. However, the required resources depend on the size of the greenhouse which in turn depends on the productivity of the crops which in turn depend on the cultivation conditions. The output of such a system can be calculated using the Modified Energy Cascade plant production model, which can simulate the food output depending on the cultivation conditions. Traditionally, life support systems are evaluated using the Equivalent System Mass method, which can determine the cost effective life support architecture for a given mission scenario. By combining both, the influence of the cultivation conditions inside the space greenhouse on the effectiveness of the complete system can be investigated. It seems counterintuitive first, but it is more effective to increase the energy per area provided to the plants in the form of light. Although that increases the electrical energy demand per area, the reduction in required cultivation area and, therefore, system size leads to a more efficient system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Humanity needs to develop space greenhouses to grow plants to produce food during long duration exploration mission for its endeavors to venture farther into space. In the past, several small plant cultivation systems have been part of space stations to test the response of plants to microgravity and to test the technologies necessary to sustain plants [1]. VEGGIE [2] and the Advanced Plant Habitat [3] onboard the ISS are the latest systems of this kind. To contribute to the life support needs of humans (e.g., food, oxygen), a space greenhouse needs to be substantially larger. Analogue test facilities such as NASA’s Biomass Production Chamber [4], the South Pole Food Growth Chamber [5], and the EDEN ISS greenhouse in Antarctica [6, 7] are testing the operation of such larger facilities on Earth.

Determining the costs of launching and operating a greenhouse is necessary to compare it to more conventional physical–chemical life support systems. While this is rather simple for the latter, because of the static or semi-static production behavior of physical–chemical systems, evaluating the costs of a space greenhouse is more complex. This is caused by the dynamic biological behavior of plants. During their development stages, plants require and produce different amounts of resource which is also dependent on the crop species. But even when the crops and the associated cultivation area are known, the production rate can be further influenced by the environmental conditions in which the plants are cultivated.

The modified energy cascade (MEC) plant production simulation model can be used to simulate the effects of environmental conditions on the production rate of a wide range of crops [8].

The equivalent system mass (ESM) method is used to compare life support options to determine the most cost-effective technology [9]. Therefore, the ESM calculates a single mass value which incorporates also energy and cooling demand, volume, and crewtime. These values are transformed to a mass value by mission-specific conversion ratios. The ESM has been used, among others, to evaluate a Mars mission life support architecture [10], food processing equipment [11], and to compare sunlight versus electrical illumination in a plant production facility [12].

By combining the ESM method and the MEC plant production model, it is possible to simulate the effects of different production rates on the greenhouse ESM value. The difference in production rates can be caused by varying the environmental conditions. Thereby, the influence of the illumination intensity and the level of carbon dioxide in the atmosphere are dominant. By optimizing both, the yield per area of the greenhouse can be increased, which in turn influences all ESM parameters and consequently, affects the costs of plant production during a space exploration mission.

2 Methods

2.1 Simulation model

A comprehensive system dynamic model of a hybrid life support system [13] has been used for the research of this paper. This model combines a crew model, a plant cultivation model, several physical–chemical life support system models, and a habitat model for conducting dynamic simulations of life support architectures. The model also has the capabilities to run sensitivity and perturbation analyses.

For the research presented in this paper, only the plant cultivation simulation part of the hybrid life support system model has been used, which is described in the following chapter.

2.2 Modified energy cascade crop production model

The Modified Energy Cascade (MEC) crop production model was developed to calculate biomass production and transpiration rates depending on environmental conditions (e.g., light intensity, carbon dioxide concentration). The model is based on a multivariate polynomial regression of experimental data and links plant metabolic and growth processes on a general level.

The model was first created in 1995 and named Energy Cascade model [14]. This first model simulated the growth of wheat but did not include formulas for transpiration. The model was then evolved to the Top-level Energy Cascade (TLEC) model in 2000 [15], which increased the number of crop species to nine, including most of the preferred cultivars at that time. Furthermore, the formulas in the model were adapted to better fit the experimental observations. The TLEC also included formulas for canopy transpiration. In 2002, the TLEC was improved to the MEC by adjusting the formulas again and by adding the calculation of daily oxygen production [16]. All MEC formulas, parameters and also lists of the allowed ranges of the environmental input parameters (see Table 1) are documented elsewhere [17]. The MEC model exists for nine different crops: dry bean, lettuce, peanut, white potato, rice, soybean, sweet potato, tomato, and wheat.

2.3 Equivalent system mass

The equivalent system mass (ESM) is an evaluation tool for life support systems and is used to determine which of several system options with the same performance has the lowest launch mass for a defined mission. For the evaluation, different performance values such as volume (V), power demand (P), cooling demand (C), crewtime (CT), and logistics mass (L) are converted by being multiplied with mission-specific constants (Veq, Peq, Ceq, CTeq) to a mass value and added to the actual system mass (M) to form the ESM value (see Eq. 1). The crewtime calculation also includes the mission duration (D) [18].

The following analysis assumes a Mars surface mission. Therefore, typical values as defined by Anderson et al. [17] (specifically table 3.4 in this reference) with the conversion parameters shown in Table 2 and ESM values for crop production as shown in Table 3 were used for the calculations.

The values for Peq and Ceq represent only one of several technology options. The Peq value used in the calculations of this paper is for nuclear static thermoelectric power production. Peq has a range of 54–338 kg/kW depending on the technology used. Ceq depends on the location. For Mars surface, the range is 121–145 kg/kW.

The logistics mass in Table 3 only accounts for lamp spare parts (e.g., ballasts) and those only for high-pressure sodium lamps. Other consumables such as substrate, nutrient salts, and cleaning agents are not accounted for. The EDEN ISS project or the plant growth chambers on board the ISS (Veggie and APH) might provide up-to-date values for consumables in the near future. For the calculations of this paper, the logistics mass was excluded from the ESM formula.

The thermal control value equals the power demand value. The power demand value consists of two components, an electrical illumination value (2.175 kW/m2, assuming 1000 μmol/(m2 s)) and a value for the remaining equipment of the plant growth chamber (0.44 kW/m2). While the latter is adequate and is also used for the following analysis, the value for electrical illumination is outdated because it is based on high-pressure sodium lamps. The rapidly evolving development of plant growth LED lamps results in a much lower power demand per square meter.

Equation 2 is used to determine the power demand per square meter for LED lamps (PLED) for different illumination levels (PPF). Therefore, the PPF value is converted to Watts per square meter and multiplied by the efficiency of converting electrical energy to light energy within PAR of the LED lamps (ρPAR-e).

The conversion ratio for PAR intensity per square meter to power per square meter of 0.22 (W s)/µmol is normally used to convert the PAR fraction of sunlight [19]. This conversion ratio is a reasonable assumption for the calculation in this paper although for LEDs the conversion ratio are slightly different. However, the conversion ratio depends on the specific spectrum of the LED lamps. A lot of research is currently going on the field of plant illumination with LED lamps and different spectrums are investigated. Therefore, a more general conversion ratio for sunlight PAR was used in this paper instead of a specific LED spectrum.

Table 4 shows power demand values for plant growth LED lamps assuming a conversion efficiency of 0.35 which is well in the limits of current LED technology. Compared to the power demand value of 2.175 kW/m2 for high-pressure sodium lamps at 1000 μmol/(m2 s), the value for LED lamps (0.629 kW/m2) is less than one third for the same light intensity.

The new power demand value P as a function of PPF is, therefore, calculated as the following:

With these assumptions, Eq. 1 is modified to an ESM equation (Eq. 4) for the trade-off analysis. Equation 4 calculates an ESM value per produced biomass as function of PPF with A(PPF) being the cultivation area required to produce one kilogram of biomass:

2.4 Simulation inputs

This chapter lists the inputs used to run the simulations with the MEC crop production model. A number of parameters are defined as constants for the simulations:

-

The photoperiod H is set to the nominal value H0 for each crop species.

-

The relative humidity (RH) inside the greenhouse is set to 0.75.

-

The temperature during illumination (Tlight) is set to the nominal value for each crop species.

-

The growth cycles of all crop species include a germination period of five days at the beginning of the growth cycle.

-

Crops are harvested at the nominal time of crop maturity (tM).

The light intensity (PPF) and the CO2 concentration are varied within the limits of each crop species as defined in Table 1. The CO2 level has been varied for all crop species in four steps (330, 700, 1000 and 1300 ppm). The boundaries for the variable PPF are different for the nine crop species. Therefore, each crop species has different intervals of PPF assigned for the simulations, see Table 5.

3 Results

3.1 Effects of carbon dioxide concentration and light intensity on crop productivity

The daily oxygen production (DOP), the total crop biomass (TCB), and the water accumulation rate are all functions of the daily carbon gain (DCG). While all of the mentioned variables are simulated for each variable combination, only the graphs of the daily carbon gain are shown in the following. All effects of variations in PPF and CO2 explained on the daily carbon gain also apply to the daily oxygen production, total crop biomass, and water accumulation rate of the different crop species.

The graphs in Figs. 3, 4 show the daily carbon gain for each crop species for all combinations of CO2 and PPF. In general, one can say that an increase in CO2 or PPF leads to a higher daily carbon gain. However, the increase is not linear and with higher values of CO2 and PPF, the increase levels off indicating the approach to the maximum production capacity. The effect of increased CO2 alone while keeping the PPF constant is relatively low compared to the effects of increased PPF for a constant CO2 level. This indicates that the more limiting factor to a high daily carbon gain is the light energy provided to the plants. However, the combination of the highest allowed PPF and the highest allowed CO2 usually achieves the highest daily carbon gain.

Lettuce has the lowest daily carbon gain of all nine crop species, which results from the relatively small size and low plant density during cultivation of the plants and, therefore, their smaller total production capacity compared to the other eight species. Furthermore, the upper limit for the PPF with 500 μmol/(m2 s) is much lower than for the other plants. Dry bean, lettuce, tomato, white potato, peanut, and soybean all have their highest daily carbon gain values between 6.5 and 11 g/(m2 days), while sweet potato has a highest daily carbon gain of around 20 g/(m2 days). Rice and wheat have an even higher upper limit of daily carbon gain of 27 and 35 g/(m2 days), respectively, because of the higher limit for the PPF input of 2000 μmol/(m2 s).

In general, an increase of CO2 from 1000 to 1300 ppm for a defined PPF level is very small or almost non-existent, e.g., lettuce daily carbon gain from 6.37 to 6.48 g/(m2days). This corresponds very well with the typically assumed CO2 level for closed environment agriculture of 1000 ppm.

White potato, peanut, and soybean show a different behavior for high PPF (600, 800, 1000), then the other crop species. Their increase in daily carbon gain from 600 to 800 μmol/(m2 s) is very small and from 800 to 1000 μmol/(m2 s) almost negligible. This indicates that those three plant species have already approached their maximum production capacity at medium light intensities.

The daily transpiration rate (DTR) is not a function of daily carbon gain, but a function of PPF/CO2. Consequently, the daily transpiration rate graphs (Figs. 5, 6) decline with increasing PPF and CO2 levels. Similar to the daily carbon gain behavior, dry bean, lettuce, tomato, white potato, peanut, and soybean form the groups of crops having a much lower daily transpiration rate than sweet potato, rice, and wheat. Also similar to the daily carbon gain calculations, the daily transpiration rates for white potato, peanut, and soybean at high PPF levels show almost no difference between 600, 800 and 1000 μmol/(m2 s).

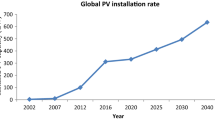

3.2 Trade-off between ESM per total crop biomass and different illumination intensities with electrically produced light

Achieving high values of PPF is usually done with electrical illumination. Consequently, an increase in PPF always means an increase in electrical energy demand and, therefore, more launch mass for the energy supply system which leads to a higher ESM. However, an increase in delivered light energy means higher productivity per cultivation area and, therefore, a smaller plant production facility to produce the same amount of biomass. A smaller plant production facility means less launch mass and volume and a smaller ESM. This results in a competition between increased energy demand for increased productivity versus structural mass and volume reduction caused by the productivity increase.

A CO2 level of 1000 ppm is used for the ESM trade-off calculations. This value is usually assumed as the nominal value for the CO2 level of closed environment agriculture. While the model allows a higher level of up to 1300 ppm for all crop species, the increase in production from 1000 to 1300 ppm is rather small, as shown in the previous chapter.

The value A(PPF) in Eq. 4 represents the cultivation area required to produce one kilogram of biomass. This value is crop specific and a function of PPF and can be determined from the DCG values calculated in the previous chapter. The value D is usually the mission duration. However, for the following analysis, this value represents the life cycle time of each crop.

Table 6 shows as an example the calculation results for dry bean. One can see that when the PPF doubles, the power demand per square meter (P) also doubles because P has a linear dependency on PPF. The cultivation area A, however, has a non-linear dependency on PPF and decreases with an increase in PPF. The ESM values power and cooling are a function of PPF and A. Since A is also a function of PPF, the ESM for power and cooling does not increase with increasing values of PPF, because the resulting reduction in cultivation area required for the production of one kilogram of total crop biomass also reduces the total power and cooling demand. The ESM values for mass, volume, and crewtime are a function of A alone and, therefore, decrease with an increase of PPF.

Tables with the values of the ESM calculation for the other eight crops of the MEC can be found in “Appendix” in Tables 7, 8, 9, 10, 11, 12, 13, 14.

Figures 1 and 2 show the total ESM values as a function of PPF for all nine crop species of the MEC at a CO2 level of 1000 ppm. The positive effect on reducing the ESM of an increased PPF is visible for all crops. White potato, peanut, and sweet potato show a different behavior than the other plants. Their lowest total ESM is not at the highest PPF value like for the other six crop species, but at around 800 μmol/(m2 s).

4 Discussion

There is clearly a benefit of increasing light intensity for plant cultivation in space to reduce the ESM and, therefore, launch cost. Although this means an increased energy demand per cultivation area, the advantages of a faster growth and a higher yield outweigh the higher resource demand (in terms of ESM). Nevertheless, one should keep in mind that the ESM is designed to evaluate life support system technologies, which does not necessarily include plant cultivation systems. Comparing two physical–chemical life support technologies for the same function (e.g., supply of oxygen) is straightforward and rather easy using ESM. However, because plant-based life support systems naturally fulfill different life support functions simultaneously (e.g., supply of oxygen, reduction of carbon dioxide), those systems cannot be compared to a single physical–chemical technology option. A comparison at the system or architecture level would be more adequate. Furthermore, plant cultivation in a closed environment also provides qualitative benefits such as increased mood of the crew [20], which is not easily accounted for.

Plants are not technical systems such as other life support technologies. Especially, influencing the metabolism by changing environmental conditions (e.g., increased light intensity) can lead to a variety of changes in the plant’s produce beyond the mere increase of yield. An increase in light intensity does not only affect the growth rate and the yield of the plants but can also affect the texture and taste of the produced food. This is especially true for leafy greens, such as lettuce. The leaves can become thicker and harder. The taste gets more bitter, up to a point where the taste of the produce is not acceptable anymore [20, 21]. This means that even when the ESM is lower at higher light intensities, lower intensities are more favorable to produce a tasty lettuce. The concentration of secondary plant ingredients (e.g., antioxidants) is also influenced by the light intensity. Here a higher light intensity can be beneficial to produce more valuable compounds [23, 24].

This paper focuses on a Mars surface mission. The same calculations can be made for a lunar surface mission. The absolute values are then lower compared to the Mars surface scenario; because the ESM penalty values for power, volume, and cooling are lower for lunar surface missions, only the crewtime penalty is higher, but this value has only very little influence. The trends of the graphs of the lunar mission scenario are the equal to the ones of the Mars surface scenario.

One should note that the ESM total values shown in this paper should not be used for plant selection evaluation. It is assumed here that all crops have the same structural mass and volume requirement per square meter. In a space greenhouse, the structure of the different plant compartments will be adapted to the morphology and size of the crop cultivated. This would lead to different structure mass and volume penalty for each crop species. The crewtime for tending plants is also different for each crop species (e.g., lower for lettuce, higher for tomato). However, these crop-specific values for mass, volume penalty, and crewtime penalty are not available in the current literature. With the current values, small plants (e.g., lettuce) have a much higher total ESM value than tall plants. Although the total ESM values for all crop species are based on the same mass, volume, and crewtime values and, therefore, not ideal, the general trend of a lower total ESM with higher PPF remains the same.

5 Summary

This paper presented the results of calculating ESM values for plant-based food production in space for varying light intensities. The goal of this investigation was to understand the effects of higher intensities on the ESM of each crop. Therefore, the MEC model was used to simulate plant development under different conditions. As a conclusion, one can say that the positive effect of a reduced cultivation area, caused by an increased light intensity, on the total ESM is greater than the negative effect of an increased power and cooling demand for illumination. This means that in principle an increase in light intensity makes plant cultivation systems more efficient, in terms of ESM. Nevertheless, one also needs to keep in mind the effects on the plant-produced food caused by the increase in light intensity which means that the ESM value cannot be the only value used to evaluate a plant production system. Other factors such as taste, texture, and appearance of the produce are equally important.

Abbreviations

- ESM:

-

Equivalent system mass

- PPF:

-

Photosynthetic photon flux

- A:

-

Cultivation area

- M:

-

Mass

- V:

-

Volume

- P:

-

Electrical power

- C:

-

Cooling power

- CT:

-

Crewtime

- TLEC:

-

Top-level energy cascade

- MEC:

-

Modified energy cascade

References

Zabel, P., Bamsey, M., Schubert, D., Tajmar, M.: Review and analysis of over 40 years of space plant growth systems. Life Sci. Space Res. 10, 1–16 (2016)

Morrow, R.C., Wetzel, J.P., Richter, R.C., Crabb, T.M.: Evolution of space-based plant growth technologies for hybrid life support systems. In: 47th International Conference on Environmental Systems, Charleston, South Carolina (2017)

Morrow, R.C., Richter, R.C., Tellez, G., Monje, O., Wheeler, R.M., Massa, G., Dufour, N., Onate, B.: A new plant habitat facility for the ISS. In: 46th international conference on environmental systems, Vienna, Austria (2016)

Wheeler, R.M., Mackowiak, C.L., Stutte, G.W., Sager, J.C., Yorio, N.C., Ruffe, L.M., Fortson, R.E., Dreschel, T.W., Knott, W.M., Corey, K.A.: NASA's biomass production chamber: A testbed for bioregenerative life support studies. Adv. Space Res. 18, 215–224 (1996)

Patterson, R.L., Giacomelli, G.A., Kacira, M., Sadler, P.D., Wheeler, R.M.: Description, operation and production of the South Pole Food Growth Chamber. Acta Hortic. 2012, 589–596 (2012)

Zabel, P., Zeidler, C., Vrakking, V., Dorn, M., Schubert, D.: Biomass production of the EDEN ISS space greenhouse in Antarctica during the 2018 experiment phase. Front. Plant Sci. 2020, 5 (2020)

Zabel, P., Bamsey, M., Zeidler, C., Vrakking, V., Schubert, D., Romberg, O.: Future exploration greenhouse design of the EDEN ISS project. In: 47th international conference on environmental systems, Charleston, South Carolina (2017)

Cavazzoni, J.: Using explanatory crop models to develop simple tools for advanced life support system studies. Adv. Space Res. 34, 1528–1538 (2004)

Levri, J.A., Vaccari, D.A., Drysdale, A.E.: Theory and application of the equivalent system mass metric. In: 30th international conference on environmental systems, Toulouse, France (2000)

Drysdale, A.E., Ewert, M.K., Hanford, A.J.: Life support approaches for Mars missions. Adv. Space Res. 31, 51–61 (2003)

Perchonok, M.H., Cooper, M.R., Catauro, P.M.: Mission to Mars: food production and processing for the final frontier. Annu. Rev. Food Sci. Technol. 3, 311–330 (2012)

Drysdale, A.E., Nakamura, T., Yorio, N., Sager, J., Wheeler, R.: Use of sunlight for plant lighting in a bioregenerative life support system—equivalent system mass calculations. Adv. Space Res. 42, 1929–1943 (2008)

Zabel, P., Tajmar, M.: A system dynamics model of a hybrid life support system. In: 49th international conference on environmental systems, Boston, USA (2019)

Volk, T., Bugbee, B., Wheeler, R.: An approach to crop modeling with the energy cascade. Life Support Biosphere Sci. 1, 119–127 (1995)

Jones, H., Cavazzoni, J.: Top-level crop models for advanced life support analysis. In: 30th international conference on environmental systems, Toulouse, France (2000)

Jones, H., Cavazzoni, J., Keas, P.: Crop models for varying environmental conditions. In: 32nd international conference on environmental systems, San Antonio, Texas (2002)

Anderson, M.S., Ewert, M.K., Keener, J.F., Wagner, S.A.: Life support baseline values and assumptions document, NASA (2015)

Levri, J.A., Fisher, J.W., Jones, H.W., Drysdale, A.E., Ewert, M.K., Hanford, A.J., Hogan, J.A., Joshi, J.A., Vaccari, D.A.: Advanced life support equivalent system mass guidelines document, NASA (2003)

Langhans, R.W., Tibbitts, T.W. (eds.): Plant Growth Chamber Handbook. Iowa Agricultural and Home Economics Experiment Station, Ames (1997)

Haeuplik-Meusburger, S., Paterson, C., Schubert, D., Zabel, P.: Greenhouses and their humanizing synergies. Acta Astronaut. 96, 138–150 (2014)

Zhang, M., Whitman, C.M., Runkle, E.S.: Manipulating growth, color, and taste attributes of fresh cut lettuce by greenhouse supplemental lighting. Sci. Hortic. 252, 274–282 (2019)

Holmes, S.C., Wells, D.E., Pickens, J.M., Kemble, J.M.: Selection of heat tolerant lettuce (Lactuca sativa L) cultivars grown in deep water culture and their marketability. Horticulturae 5, 50 (2019)

Pérez-Lopéz, U., Sgherri, C., Miranda-Apodaca, J., Micaello, F., Lacuesta, M., Mena-petite, A., Quartacci, M.F., Munoz-Rueda, A.: Concentration of phenolic compounds is increased in lettuce grown under high light intensity and elevated CO2. Plant Physiol. Biochem. 123, 233–241 (2018)

Pérez-Lopéz, U., Miranda-Apodaca, J., Munoz-Rueda, A., Mena-petite, A.: Lettuce production and antioxidant capacity are differentially modified by salt stress and light intensity under ambient and elevated CO2. J. Plant Physiol. 170, 1517–1525 (2013)

Acknowledgements

Open Access funding provided by Projekt DEAL. The work of this paper was part of the author’s PhD dissertation. The author thanks Prof. Martin Tajmar (Technical University Dresden) for his support and supervision of the dissertation. The author is also grateful for having received a NPI fellowship from the European Space Agency (ESA) between 2013 and 2016 to co-fund his PhD work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Figs. 3 , 4 , 5 , 6 and Tables 7 , 8, 9, 10, 11, 12, 13,14.

,

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zabel, P. Influence of crop cultivation conditions on space greenhouse equivalent system mass. CEAS Space J 13, 3–15 (2021). https://doi.org/10.1007/s12567-020-00317-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12567-020-00317-5