Abstract

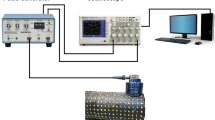

Adoption of thermal barrier coatings (TBC) will help to improve the durability and thermal efficiency of turbine engines. Delamination of TBC owing to thermally grown metal oxides is a critical issue that needs periodical evaluation to ensure safety and effective maintenance for the financial benefits of industry. In this paper, a methodical approach using ultrasonic C-scan technique for quantitative evaluation of partial delamination area in TBC specimens was investigated. Preliminary studies were conducted using acoustic simulations and the experiments were carried out on a set of coin shaped TBC specimens prepared using plasma spray technique and isothermally degraded at 1100 °C for 25 h, 50 h, 100 h, and 150 h. Ultrasonic C-scans were performed using pulse echo technique with incident ultra sound radiation inclined normal to the surface of base metal of TBC system. Delamination maps of respective specimens were formulated from ultrasonic signals through proper signal processing and analysis techniques and the degree of delamination was evaluated with the help of existed mathematical model. The simulation results shows good agreement with the experimental data and this approach shows ability to estimate the degree of delamination from base metal surface.

Similar content being viewed by others

References

Lepeshkin, A. (2012). Investigations of thermal barrier coatings for turbine parts. Ceramic Coatings: Applications in Engineering. https://doi.org/10.5772/31354.

Miller, R. (1987). Current status of thermal barrier coatings: an overview. Surface and Coatings Technology. https://doi.org/10.1016/0257-8972(87)90003-X.

Kim, D. J., Shin, I. H., Koo, J. M., Seok, C. S., & Lee, T. W. (2010). Failure mechanisms of coin-type plasma-sprayed thermal barrier coatings with thermal fatigue. Surface and Coatings Technology. https://doi.org/10.1016/j.surfcoat.2010.08.130.

Xu, R., Fan, X., & Wang, T. J. (2016). Mechanisms governing the interfacial delamination of thermal barrier coating system with double ceramic layers. Applied Surface Science. https://doi.org/10.1016/j.apsusc.2016.02.180.

Kramera, S., Faulhaber, S., Chambers, M., Clarke, D. R., Levia, C. G., Hutchinson, J. W., et al. (2008). Mechanisms of cracking and delamination within thick thermal barrier systems in aero-engines subject to calcium-magnesium-alumino-silicate (CMAS) penetration. Materials Science and Engineering A. https://doi.org/10.1016/j.msea.2008.01.006.

Madhwal, M., Jordanb, E. H., & Gella, M. (2004). Failure mechanisms of dense vertically-cracked thermal barrier coatings. Materials Science and Engineering A. https://doi.org/10.1016/j.msea.2004.05.061.

Hutchinson, J., & Evans, A. (2002). On the delamination of thermal barrier coatings in a thermal gradient. Surface and Coatings Technology. https://doi.org/10.1016/S0257-8972(01)01451-7.

Evans, A. G., Mumm, D. R., & Hutchinson, J. W. (2001). Mechanisms controlling the durability of thermal barrier coatings. Progress in Materials Science. https://doi.org/10.1016/S0079-6425(00)00020-7.

Bumgardner, C., Croom, B., & Li, X. (2017). High temperature delamination mechanisms of thermal barrier coatings: In-situ digital image correlation and finite element analyses. Acta Materialia. https://doi.org/10.1016/j.actamat.2017.01.061.

Zhang, J., & Desai, V. (2005). Evaluation of thickness, porosity and pore shape of plasma sprayed TBC by electrochemical impedance spectroscopy. Surface and Coating Technology. https://doi.org/10.1016/j.surfcoat.2004.06.019.

Zhou, M., Yao, W. B., Yang, X. S., Peng, Z. B., Li, K. K., Dai, C. Y., et al. (2014). In-situ and real-time tests on the damage evolution and fracture of thermal barrier coatings under tension: A coupled acoustic emission and digital image correlation method. Surface and Coatings Technology. https://doi.org/10.1016/j.surfcoat.2013.12.010.

Fan, X., Xu, R., & Wang, T. J. (2014). Wang Interfacial delamination of double-ceramic-layer thermal barrier coating system. Ceramics International. https://doi.org/10.1016/j.ceramint.2014.05.095.

Li, Y., Chen, Z., Mao, Y., & Qi, Y. (2012). Quantitative evaluation of thermal barrier coating based on eddy current technique. NDT&E International. https://doi.org/10.1016/j.ndteint.2012.04.006.

Fahr, B. Rogé, & Thornton, J. (2006). Detection of thermally grown oxides in thermal barrier coatings by nondestructive evaluation. Journal of Thermal Spray Technology. https://doi.org/10.1361/105996306X92587.

He, Y., et al. (2014). An investigation into eddy current pulsed thermography for detection of corrosion blister. Corrosion Science. https://doi.org/10.1016/j.corsci.2013.09.001.

Zhang, D., Yating, Yu., et al. (2016). Thickness measurement of multilayer conductive coatings using multi frequency eddy current techniques. Nondestructive Testing and Evaluation. https://doi.org/10.1080/10589759.2015.1081903.

Jayaraj, B., Desai, V. H., Lee, C. K., & Sohn, Y. H. (2004). Electrochemical impedance spectroscopy of porous ZrO2–8 wt% Y2O3 and thermally grown oxide on nickel aluminide. Materials Science and Engineering A. https://doi.org/10.1016/j.msea.2004.01.005.

Jing, W., Guon, H., Abbas, M., & Gong, S. (2012). Evaluation of plasma sprayed YSZ thermal barrier coatings with the CMAS deposits infiltration using impedance spectroscopy. Progress in Natural Science: Materials International. https://doi.org/10.1016/j.pnsc.2011.12.007.

Yang, F., & Xiao, P. (2009). Nondestructive evaluation of thermal barrier coatings using impedance spectroscopy. International Journal of Applied Ceramic Technology. https://doi.org/10.1111/j.1744-7402.2008.02304.x.

Song, S. H., & Xiao, P. (2003). An impedance spectroscopy study of high-temperature oxidation of thermal barrier coatings”. Materials Science and Engineering B. https://doi.org/10.1016/S0921-5107(02)00397-5.

Harmsworth, P. D., & Stevens, R. (1992). Phase composition and properties of plasma-sprayed zirconia thermal barrier coatings. Journal of Materials Science. https://doi.org/10.1007/BF02403868.

Knotek, O., Loffler, F., & Beele, W. (1993). Diffusion barrier design against rapid interdiffusion of MCrAlY and Ni-base material. Surface and Coatings Technology,61, 6–13.

Koo, J. M., & Seok, C. S. (2004). Design technique for improving the durability of top coating for thermal barrier of gas turbine. Journal of Korean Society for Precision Engineering. https://doi.org/10.7736/KSPE.2014.31.1.15.

Fukuchi, T., Ozeki, T., Okada, M., & Fujii, T. (2016). Nondestructive inspection of thermal barrier coating of gas turbine high temperature components. IEEJ Transactions on Electrical and Electronic Engineering. https://doi.org/10.1002/tee.22255.

Kim, H. J., Song, S. J., & Schmerr, L. W. (2014). Modeling ultrasonic pulse echo signals from a flat-bottom hole in immersion testing using a multi-gaussian beam. Journal of Nondestructive Evaluation. https://doi.org/10.1023/B:JONE.0000045217.48147.f6.

Doane, D. P., & Lori, E. S. (2011). Measuring skewness: A forgotten statistic? Journal of Statistics Education. https://doi.org/10.1080/10691898.2011.11889611.

Brown, S. Measures of shape: Skewness and kurtosis. https://brownmath.com/stat/shape.htm#Kurtosis.

Acknowledgements

This subject is supported by Korea Ministry of Environment (MOE) as ‘Public Technology program (No. 2016000700003) based on Environmental policy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kishore, M.B., Lee, HG., Abera, A.G. et al. Quantitative Evaluation of Partial Delamination in Thermal Barrier Coatings Using Ultrasonic C-scan Imaging. Int. J. Precis. Eng. Manuf. 21, 157–165 (2020). https://doi.org/10.1007/s12541-019-00143-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00143-8