Abstract

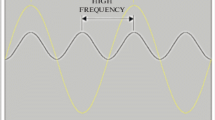

Carburization that takes place in HP steel tubes in pyrolysis furnaces coils is an undesirable event, as it negatively affects mechanical and resistance to corrosion properties. This has been an important factor for the study and development of non-destructive methodologies aiming at maintaining structural integrity. In this work, non-destructive testing using ultrasound was employed for specimen with varying carburization degrees, in order to characterize them. The results allowed for the development of a correlation between the thickness of the carburized layer and of the half height bandwidth of the backwall echo frequency spectra.

Similar content being viewed by others

References

Silveira, T.L., May, I.: Reformer furnaces: materials, damage mechanisms and assessment. Arab. J. Sci. Eng. Sect. B 31(2C), 99–119 (2006)

Silveira TF, Silveira TL, Almeida LH, Moreira MF (2002) Microestrutura de tubos de forno de pir´olise desativados após 91.000 h de operação resultados da metalografia ótica, in: 6a -Conferência Sobre Tecnologia de Equipamentos—COTEC Salvador, Brasil

Silva, I.C., Rebello, J.M.A., Bruno, A.C., Jacques, P.J., Nysten, B., Dille, J.: Structural and magnetic characterization of a carburized cast austenitic steel. Scripta Mater. 59(9), 1010–1013 (2008). https://doi.org/10.1016/j.scriptamat.2008.07.015

Guo, J., Cao, T., Cheng, C., Meng, X., Zhao, J.: The relationship between magnetism and microstructure of ethylene pyrolysis furnace tubes after a long-term service. Microsc. Microanal. 24(5), 478–487 (2018). https://doi.org/10.1017/S1431927618015180

Shi, S., Lippold, J.C.: Microstructure evolution during service exposure of two cast, heat-resisting stainless steels—hp–nb modified and 20–32nb. Mater. Charact. 59(8), 1029–1040 (2008). https://doi.org/10.1016/j.matchar.2007.08.029

Petkovic-Luton, R., Ramanarayanan, T.A.: Mixed-oxidant attack of hightemperature alloys in carbon-and oxygen-containing environments. Oxid. Met. 34(5–6), 381–400 (1990). https://doi.org/10.1007/BF00664423.13

Chun, C.M., Desai, S., Hershkowitz, F., Ramanarayanan, T.A.: Materials challenges in cyclic carburizing and oxidizing environments for petrochemical applications. Mater. Corros. 65(3), 282–295 (2014). https://doi.org/10.1002/maco.201307059

Shen, L.M., Gong, J.M., Liu, H.S.: Carburisation layer evolution of fe–cr–ni alloy in furnace after long term service: experimental study and numerical prediction. Mater. High Temp. 31(2), 148–154 (2014). https://doi.org/10.1179/1878641313Y.0000000002

Lian, X., Chen, X., Chen, T., Ye, J., Sun, J.: Carburization analysis of ethylene pyrolysis furnace tubes after service. Proc. Eng. 130, 685–692 (2015). https://doi.org/10.1016/j.proeng.2015.12.298

Majumdar, A.K., Blanckenhagen, P.V.: Magnetic phase diagram of Fe80–xNixCr20 (10 ≤ x ≤ 30) alloys. Phys. Rev. B 29(7), 4079 (1984). https://doi.org/10.1103/PhysRevB.29.4079

Stevens, K.J., Parbhu, A., Soltis, J., Stewart, D.: Magnetic force microscopy of a carburized ethylene pyrolysis tube. J. Phys. D Appl. Phys. 36(2), 164–168 (2002). https://doi.org/10.1088/0022-3727/36/2/315

Li, T.F.: High temperature oxidation and hot corrosion of metals. Chemical Industry Press, Beijing (2003)

Khodamorad, S.H., Haghshenas, D.F.: Inspection of carburization and ovalness in ethylene cracking tubes by using a semi-robot. Eng. Fail. Anal. 25, 81–88 (2012). https://doi.org/10.1016/j.engfailanal.2012.04.006

McLeod, A.C., Bishop, C.M., Stevens, K.J., Kral, M.V.: Microstructure and carburization detection in hp alloy pyrolysis tubes. Metall. Microstruct. Anal. 4(4), 273–285 (2015). https://doi.org/10.1007/s13632-015-0210-8

Silva, I.C., Silva, R.S., Rebello, J.M.A., Bruno, A.C., Silveira, T.F.: Characterization of carburization of hp steels by non destructive magnetic testing. NDT E Int. 39(7), 569–577 (2006). https://doi.org/10.1016/j.ndteint.2006,03(004)

Silva, I.C., Silva, L.L., Silva, R.S., Rebello, J.M.A., Bruno, A.C.: Carburization of ethylene pyrolysis tubes determined by magnetic measurements and genetic algorithm. Scr. Mater. 56(4), 317–320 (2007). https://doi.org/10.1016/j.scriptamat.2006.09.004

Kasai, N., Ogawa, S., Oikawa, T., Sekine, K., Hasegawa, K.: Detection of carburization in ethylene pyrolysis furnace tubes by a C core probe with magnetization. J. Nondestr. Eval. 29(3), 175–180 (2010). https://doi.org/10.1007/s10921-010-0075-3

Kumar, A., Jayakumar, T., Raj, B.: Ultrasonic spectral analysis for microstructural characterization of austenitic and ferritic steels. Philos. Mag. A 80(11), 2469–2487 (2000). https://doi.org/10.1080/01418610008216486

Carmo CBF, Rodrigues LFM, Cruz FDC, Filho EFS, Albuquerque MC, da Silva IC, Farias CT (2016) Support vector machines applied to the identification of carburized hp steels using ultrasonic nondestructive testing. In: 19th World Conference on Nondestructive Testing, Munich

Rodrigues, L.F., Cruz, F.C., Oliveira, M.A., Filho, E.F.S., Albuquerque, M.C., Silva, I.C., Farias, C.T.: Carburization level identification in industrial hp pipes using ultrasonic evaluation and machine learning. Ultrasonics 94, 145–151 (2019). https://doi.org/10.1016/j.ultras.2018.10.005

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Santos, Y.T.B., Coelho, R.E., da Silva, I.C. et al. Method to Determine the Thickness of the Carburized Layer of Pyrolysis Furnace Tubes Using Ultrasound Technique. J Nondestruct Eval 39, 3 (2020). https://doi.org/10.1007/s10921-019-0646-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-019-0646-x