Abstract

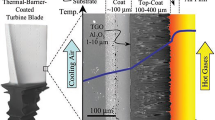

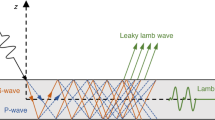

Thermal barrier coatings (TBCs) are widely used in turbine blade for protection of superalloy substrate. Interfacial debonding will lead to serious safety accidents of aircrafts and should be detected in advance. Vibrothermography (VT) and long pulse thermography (LPT) are two kinds of effective non-destructive techniques. In this paper, the two methods were used for defect detection in TBCs. Artificial debonding defects with diameter from 5 mm to 2 mm were fabricated. The results show that both VT and LPT can be successfully used to identify defects with diameter larger than 2 mm. The thermal contrast of the two methods reduces with the decreasing size of debonding defect, and there is a higher thermal contrast in VT than that in LPT, when a proper ultrasonic excitation frequency is selected in VT. Measurement accuracy is investigated by comparing the defect area, which shows that the average value of the relative error is reasonable except for defects with small size. The lateral thermal diffusion effect and imperfect manufacturing process of artificial debonding may be the main causes for the relative error. In addition, parameters of each method should be optimized for better defect detection in TBCs.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Padture, N.P., Gell, M., Jordan, E.H.: Thermal barrier coatings for gas-turbine engine applications. Science 296, 280–284 (2002). https://doi.org/10.1126/science.1068609

Cernuschi, F., Bison, P.: Thirty Years of thermal barrier coatings (TBC), photothermal and thermographic techniques: best practices and lessons learned. J. Therm. Spray Technol. https://doi.org/10.1007/s11666-022-01344-w

Zhu, J., et al.: Progress and trends in non-destructive testing for thermal barrier coatings based on infrared thermography: a review. J. Nondestruct. Eval. 41, 49 (2022). https://doi.org/10.1007/s10921-022-00880-3

Jiao, D.-C., Liu, Z.-W., Zhu, W.-Y., Xie, H.-M.: Exact localization of debonding defects in thermal barrier coatings. AIAA J. 56, 3691–3700 (2018). https://doi.org/10.2514/1.J056806

Zheng, X., Chen, H., Ma, Z.: Shakedown boundaries of multilayered thermal barrier systems considering interface imperfections. Int. J. Mech. Sci. 144, 33–40 (2018). https://doi.org/10.1016/j.ijmecsci.2018.05.016

Liu, Z., Jiao, D., Shi, W., Xie, H.: Linear laser fast scanning thermography NDT for artificial disbond defects in thermal barrier coatings. Opt. Express 25, 31789–31800 (2017). https://doi.org/10.1364/OE.25.031789

Quattrocchi, A., Freni, F., Montanini, R.: Comparison between air-coupled ultrasonic testing and active thermography for defect identification in composite materials. Nondestruct. Test. Eval. 36, 97–112 (2021). https://doi.org/10.1080/10589759.2019.1699084

Hedayatrasa, S., Segers, J., Poelman, G., Verboven, E., Van Paepegem, W., Kersemans, M.: Vibrothermographic spectroscopy with thermal latency compensation for effective identification of local defect resonance frequencies of a CFRP with BVID. NDT E Int. 109, 102179 (2020). https://doi.org/10.1016/j.ndteint.2019.102179

Yong, L., Chen, Z., Mao, Y., Yong, Q.: Quantitative evaluation of thermal barrier coating based on eddy current technique. NDT E Int. 50, 29–35 (2012). https://doi.org/10.1016/j.ndteint.2012.04.006

Arai, Y., Inoue, R.: Detection of small delamination in mullite/Si/SiC model EBC system by pulse thermography. J. Adv. Ceram. 8, 438–447 (2019). https://doi.org/10.1007/s40145-019-0327-3

Doshvarpassand, S., Wu, C., Wang, X.: An overview of corrosion defect characterization using active infrared thermography. Infrared Phys. Technol. 96, 366–389 (2019). https://doi.org/10.1016/j.infrared.2018.12.006

Zhuo, L., Yang, X., Zhu, J., Huang, Z., Chao, J., Xie, W.: Size determination of interior defects by reconstruction of subsurface virtual heat flux for step heating thermography. NDT E Int. 133, 102734 (2023). https://doi.org/10.1016/j.ndteint.2022.102734

Huang, Z., et al.: Non-destructive evaluation of uneven coating thickness based on active long pulse thermography. NDT E Int. 130, 102672 (2022). https://doi.org/10.1016/j.ndteint.2022.102672

Dong, L., et al.: Effects of crack surface roughness on crack heat generation characteristics of ultrasonic infrared thermography. Infrared Phys. Technol. 106, 103262 (2020). https://doi.org/10.1016/j.infrared.2020.103262

Pech-May, N.W., Oleaga, A., Mendioroz, A., Omella, A.J., Celorrio, R., Salazar, A.: Vertical cracks characterization using lock-in thermography: I infinite cracks. Meas. Sci. Technol. 25, 115601 (2014). https://doi.org/10.1088/0957-0233/25/11/115601

Wei, Q., et al.: Experimental and numerical investigation on detection fatigue crack in metallic plate by vibro-thermography. Infrared Phys. Technol. 126, 104347 (2022). https://doi.org/10.1016/j.infrared.2022.104347

Ibarra-Castanedo, C., Genest, M., Piau, J.-M., Guibert, S., Bendada, A., Maldague, X.P.V.: Active infrared thermography techniques for the nondestructive testing of materials. In: Ultrasonic and Advanced Methods for Nondestructive Testing and Material Characterization, pp. 325–348. World Scientific (2007)

Sun, J.G., Benz, J.: Flash duration effect in one-sided thermal imaging. AIP Conf. Proc. 760, 650–654 (2005). https://doi.org/10.1063/1.1916737

Sun, J.G., Kulkarni, A., Fry, A.T.: Pulsed thermal imaging for non-destructive evaluation of hot gas path coatings in gas turbines. Mater. High Temp. 1–15 (2020). https://doi.org/10.1080/09603409.2020.1824853

Bu, C., Liu, G., Zhang, X., Tang, Q.: Debonding defects detection of FMLs based on long pulsed infrared thermography technique. Infrared Phys. Technol. 104, 103074 (2020). https://doi.org/10.1016/j.infrared.2019.103074

Almond, D.P., Angioni, S.L., Pickering, S.G.: Long pulse excitation thermographic non-destructive evaluation. NDT E Int. 87, 7–14 (2017). https://doi.org/10.1016/j.ndteint.2017.01.003

Mabrouki, F., Thomas, M., Genest, M., Fahr, A.: Frictional heating model for efficient use of vibrothermography. NDT E Int. 42, 345–352 (2009). https://doi.org/10.1016/j.ndteint.2009.01.012

Solodov, I., Bai, J., Bekgulyan, S., Busse, G.: A local defect resonance to enhance wave-defect interaction in nonlinear spectroscopy and ultrasonic thermography (2012)

Segers, J., Kersemans, M., Hedayatrasa, S., Calderon, J., Van Paepegem, W.: Towards in-plane local defect resonance for non-destructive testing of polymers and composites. NDT E Int. 98, 130–133 (2018). https://doi.org/10.1016/j.ndteint.2018.05.007

Fernandes, H., Zhang, H., Figueiredo, A., Ibarra-Castanedo, C., Guimarares, G., Maldague, X.: Carbon fiber composites inspection and defect characterization using active infrared thermography: numerical simulations and experimental results. Appl. Opt. 55, D46–D53 (2016). https://doi.org/10.1364/AO.55.000D46

Katunin, A., Wronkowicz-Katunin, A., Wachla, D.: Impact damage assessment in polymer matrix composites using self-heating based vibrothermography. Compos. Struct. 214, 214–226 (2019). https://doi.org/10.1016/j.compstruct.2019.02.003

Xu, C., Xie, J., Huang, W., Chen, G., Gong, X.: Improving defect visibility in square pulse thermography of metallic components using correlation analysis. Mech. Syst. Signal Process. 103, 162–173 (2018). https://doi.org/10.1016/j.ymssp.2017.09.030

Wei, Y., Zhang, S., Luo, Y., Ding, L., Zhang, D.: Accurate depth determination of defects in composite materials using pulsed thermography. Compos. Struct. 267, 113846 (2021). https://doi.org/10.1016/j.compstruct.2021.113846

Park, H., Choi, M., Park, J., Kim, W.: A study on detection of micro-cracks in the dissimilar metal weld through ultrasound infrared thermography. Infrared Phys. Technol. 62, 124–131 (2014). https://doi.org/10.1016/j.infrared.2013.10.006

Busse, G., Wu, D., Karpen, W.: Thermal wave imaging with phase sensitive modulated thermography. J. Appl. Phys. 71, 3962–3965 (1992). https://doi.org/10.1063/1.351366

Otsu, N.: A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 9, 62–66 (1979). https://doi.org/10.1109/TSMC.1979.4310076

Ptaszek, G., Cawley, P., Almond, D., Pickering, S.: Artificial disbonds for calibration of transient thermography inspection of thermal barrier coating systems. NDT E Int. 45, 71–78 (2012). https://doi.org/10.1016/j.ndteint.2011.09.008

Acknowledgements

The authors are grateful for financial support from the National Natural Science Foundation of China (Grant No. 11972014), the Natural Youth Science Foundation of Jiangsu Province (Grant No. BK20210740) and the National Key Laboratory of Science and Technology on Advanced Composites in Special Environments (JCKYS2020603C014).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Li, C., Zhuo, L., Zhu, J. (2024). Detection of Debonding Defects in Thermal Barrier Coatings by Long Pulse and Vibro-Thermography. In: Burduk, A., Batako, A.D.L., Machado, J., Wyczółkowski, R., Dostatni, E., Rojek, I. (eds) Intelligent Systems in Production Engineering and Maintenance III. ISPEM 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-44282-7_12

Download citation

DOI: https://doi.org/10.1007/978-3-031-44282-7_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-44281-0

Online ISBN: 978-3-031-44282-7

eBook Packages: EngineeringEngineering (R0)