Abstract

Automated material handling systems (AMHSs) are widely utilized in general manufacturing processes. The precision motion control and wear resistance of rolling parts of an AMHS are important factors to ensure sufficient reliability of the final product. Polyurethanes are widely used in the manufacturing process due to their superior damage resistance and adequate rolling friction properties. In this work, friction and wear behaviors of polyurethane O-ring rollers sliding against a glass plate specimen were investigated with respect to sliding speed, temperature and relative humidity. A pin-on-reciprocating sample tribotester in an environmental chamber was used to assess the friction and wear properties of the polyurethane O-rings. It was found that the wear resistance increased for higher sliding speed, higher temperature, and lower relative humidity conditions. The results of this work are expected to provide optimized O-ring transfer equipment operating conditions to improve the productivity of the TFT-LCD manufacturing process.

Similar content being viewed by others

References

Jang, Y. J. and Choi, G. H., “Introduction to Automated Material Handling Systems in LCD Panel Production Lines,” Proc. of the 2006 IEEE International Conference on Automation Science and Engineering, pp. 223–229, 2006.

Lee, T. G., Yu, J. S., Jung, H. J., Kim, J.-H., and Kim, J. H., “Development of the Air Floating Conveyor System for the Large Glass Sheet,” Journal of the Korean Society of Manufacturing Technology Engineers, vol. 22, no. 4, pp. 635–642, 2013.

Won, M.-S., Amanov, A., Kim, H.-J., Yun, W.-S., Joo, W.-G., and Kim, D.-E., “Evaluation of the Mechanical and Tribological Properties of a TFT-LCD Panel,” Tribology International, vol. 73, pp. 95–100, 2014.

Ko, H. J., Kim, J. H., and Cho, W., “A Study of LCD Transfer System using Thereof,” Proc. of KSPE Conference, vol. 2008, pp. 411–412, 2008.

Kim, J., Hwang, J., Chung, H., and Kim, N., “Study on Micro Deformation of Automobile Roof with Mastic Sealer after Oven Process,” Int. J. Precis. Eng. Manuf., vol. 15, no. 4, pp. 649–654, 2014.

Choi, C.-H., Kim, D.-H., and Lee, C.-M., “A Study on the Development of a Deformable Rubber Variable Preload Device,” Int. J. Precis. Eng. Manuf., vol. 15, no. 12, pp. 2685–2688, 2014.

Chung, C., Chen, Y.-J., Chen, P.-C., and Chen, C.-Y., “Fabrication of Pdms Passive Micromixer by Lost-Wax Casting,” Int. J. Precis. Eng. Manuf., vol. 16, no. 9, pp. 2033–2039, 2015.

Jin, K., Jeong, T., Kim, T., Kim, N., and Kim, B., “Analysis and Design for Reducing Residual Stress and Distortion after Ejection of Injection Molded Part with Metal-Insert,” Int. J. Precis. Eng. Manuf., vol. 15, no. 12, pp. 2533–2542, 2014.

Moon, S.-I., Cho, I.-J., Woo, C.-S., and Kim, W.-D., “Study on Determination of Durability Analysis Process and Fatigue Damage Parameter for Rubber Component,” Journal of Mechanical Science and Technology, vol. 25, no. 5, pp. 1159–1165, 2011.

Meckel, W. Goyert, W. Wieder, W., and Wussow, H. G., “Thermoplastic Polyurethane Elastomers,” Carl Hanser Verlag, pp. 15–39, 2004.

Kim, J. Y., Choi, H.-J., and Woo, C.-S., “Nanoscale Thin Film Transfer using Elastomer-Covered Roll with Buffer Cavities,” Int. J. Precis. Eng. Manuf., vol. 15, no. 4, pp. 711–716, 2014.

Elango, N., Faudzi, A. A. M., Hassan, A., and Rusydi, M. R. M., “Experimental Investigations of Skin-Like Material and Computation of Its Material Properties,” Int. J. Precis. Eng. Manuf., vol. 15, no. 9, pp. 1909–1914, 2014.

Lyu, M.-Y. and Choi, T. G., “Research Trends in Polymer Materials for Use in Lightweight Vehicles,” Int. J. Precis. Eng. Manuf., vol. 16, no. 1, pp. 213–220, 2015.

Lee, S. H., Yoo, S. S., Kim, D. E., Kang, B. S., and Kim, H. E., “Accelerated Wear Test of Fkm Elastomer for Life Prediction of Seals,” Polymer Testing, vol. 31, no. 8, pp. 993–1000, 2012.

Paglicawan, M. A., Kim, B. S., Basilia, B. A., Emolaga, C. S., Marasigan, D. D., and Maglalang, P. E. C., “Plasma-Treated Abaca Fabric/Unsaturated Polyester Composite Fabricated by Vacuum-Assisted Resin Transfer Molding,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 1, no. 3, pp. 241–246, 2014.

Kim, H., Kim, R.-U., Chung, K.-H., An, J.-H., Jeon, H.-G., and Kim, B.-J., “Effect of Test Parameters on Degradation of Polyurethane Elastomer for Accelerated Life Testing,” Polymer Testing, vol. 40, pp. 13–23, 2014.

Cho, M. and Choi, H.-J., “Optimization of Surface Texturing for Contact Between Steel and Ultrahigh Molecular Weight Polyethylene under Boundary Lubrication,” Tribology Letters, vol. 56, no. 3, pp. 409–422, 2014.

Lee, H.-J. and Park, K., “Development of Composite Micro-Patterns on Polymer Film using Repetitive Ultrasonic Imprinting,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 1, no. 4, pp. 341–345, 2014.

Sim, K., Lee, Y.-B., Song, J. W., Kim, J.-B., and Kim, T. H., “Identification of the Dynamic Performance of a Gas Foil Journal Bearing Operating at High Temperatures,” Journal of Mechanical Science and Technology, vol. 28, no. 1, pp. 43–51, 2014.

Tong, V.-C. and Hong, S.-W., “Characteristics of Tapered Roller Bearing Subjected to Combined Radial and Moment Loads,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 1, no. 4, pp. 323–328, 2014.

Kurniawan, R. and Ko, T. J., “Friction Reduction on Cylindrical Surfaces by Texturing with a Piezoelectric Actuated Tool Holder,” Int. J. Precis. Eng. Manuf., vol. 16, no. 5, pp. 861–868, 2015.

Chung, C. H., Chen, Y. J., Chen, P. C., and Chen, C. Y., “Fabrication of Pdms Passive Micromixer by Lost-Wax Casting,” Int. J. Precis. Eng. Manuf., vol. 16, no. 9, pp. 2033–2039, 2015.

Moon, B. J., Kim, J., and Lee, S. K., “Suppression of Thermal Crown of Heating Roll for Large Area Thermal Imprint with Consideration of Thermal Resistance between Roll and Shaft,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 2, no. 4, pp. 315–323, 2015.

Prakash, S. and Kumar, S., “Fabrication of Microchannels on Transparent Pmma using Co2 Laser (10.6 μm) for Microfluidic Applications: An Experimental Investigation,” Int. J. Precis. Eng. Manuf., vol. 16, no. 2, pp. 361–366, 2015.

Ahn, D. G., “Research Trends of Metallic Sandwich Plates with Single Layer Periodically Repeated Metallic Inner Structures (Prmis) -Focused on Design, Manufacturing and Formability,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 2, no. 4, pp. 377–391, 2015.

Moon, S. K., Tan, Y. E., Hwang, J., and Yoon, Y. J., “Application of 3D Printing Technology for Designing Light-Weight Unmanned Aerial Vehicle Wing Structures,” Int. J. Precis Eng. Manuf.-Green Tech., vol. 1, no. 3, pp. 223–228, 2014.

Weise, H., Kowalewsky, H., and Wenz, R., “Behaviour of Elastomeric Seals at Low Temperature,” Vacuum, vol. 43, no. 5-7, pp. 555–557, 1992.

Burnay, S. G. and Hitchon, J. W., “Prediction of Service Lifetimes of Elastomeric Seals during Radiation Ageing,” Journal of Nuclear Materials, vol. 131, no. 2-3, pp. 197–207, 1985.

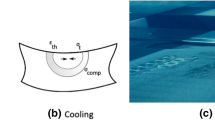

George, A. F., Strozzi, A., and Rich, J. I., “Stress Fields in a Compressed Unconstrained Elastomeric O-Ring Seal and a Comparison of Computer Predictions and Experimental Results,” Tribology International, vol. 20, no. 5, pp. 237–247, 1987.

Dragoni, E. and Strozzi, A., “Analysis of an Unpressurized, Laterally Restrained, Elastomeric O-Ring Seal,” Journal of Tribology, vol. 110, no. 2, pp. 193–200, 1988.

Green, I. and English, C., “Analysis of Elastomeric O-Ring Seals in Compression using the Finite Element Method,” Tribology Transactions, vol. 35, no. 1, pp. 83–88, 1992.

Deleau, F., Mazuyer, D., and Koenen, A., “Sliding Friction at Elastomer/Glass Contact: Influence of the Wetting Conditions and Instability Analysis,” Tribology International, vol. 42, no. 1, pp. 149–159, 2009.

Ettles, C. M. M. and Shen, J. H., “The Influence of Frictional Heating on the Sliding Friction of Elastomers and Polymers,” Rubber Chemistry and Technology, vol. 61, no. 1, pp. 119–136, 1988.

Vinogradov, G., Yel'kin, A., Bartenev, G., and Bubman, S., “Effect of Normal Pressure on Temperature and Rate Dependences of Elastomer Friction in the Glass Transition Region,” Wear, vol. 23, no. 1, pp. 33–38, 1973.

Elleuch, R., Elleuch, K., Salah, B., and Zahouani, H., “Tribological Behavior of Thermoplastic Polyurethane Elastomers,” Materials & Design, vol. 28, no. 3, pp. 824–830, 2007.

Burr, B. H. and Marshek, K. M., “An Equation for the Abrasive Wear of Elastomeric O-Ring Materials,” Wear, vol. 81, no. 2, pp. 347–356, 1982.

Kim, H.-J. and Kim, D.-E., “Nano-Scale Friction: A Review,” Int. J. Precis. Eng. Manuf., vol. 10, no. 2, pp. 141–151, 2009.

Kim, H.-J., Yoo, S.-S., and Kim, D.-E., “Nano-Scale Wear: A Review,” Int. J. Precis. Eng. Manuf., vol. 13, no. 9, pp. 1709–1718, 2012.

Sung, I.-H., Kim, H. J., and Yeo, C. D., “First Observation on the Feasibility of Scratch Formation by Pad–Particle Mixture in CMP Process,” Applied Surface Science, vol. 258, no. 20, pp. 8298–8306, 2012.

Yeo, C.-D., Lee, J., and Polycarpou, A. A., “Dynamic Adhesive Forces in Rough Contacting Bodies including Normal and Sliding Conditions,” Journal of Adhesion Science and Technology, vol. 26, no. 24, pp. 2709–2718, 2012.

Argibay, N. and Sawyer, W. G., “Low Wear Metal Sliding Electrical Contacts at High Current Density,” Wear, Vols. 274–275, pp. 229–237, 2012.

Meckel, W., Goyert, W., Wieder, W., and Wussow, H. G., “Thermoplastic Polyurethane Elastomers,” in: Thermoplastic Elastomers, 3rd Ed., Holden, G., Kricheldorf, H. R., and Quirk, R. P., (Eds.,), Carl Hanser Verlag, pp. 15–39, 2004.

Roberts, A. D. and Othman, A. B., “Rubber Adhesion and the Dwell Time Effect,” Wear, vol. 42, no. 1, pp. 119–133, 1977.

Hays, D., “The Physics of Tire Traction: Theory and Experiment,” Springer Science & Business Media, 2013.

Barquins, M., “Sliding Friction of Rubber and Schallamach Waves-A Review,” Materials Science and Engineering, vol. 73, pp. 45–63, 1985.

Persson, B. N. J. and Volokitin, A. I., “Rubber Friction on Smooth Surfaces,” The European Physical Journal E, vol. 21, no. 1, pp. 69–80, 2006.

Yahiaoui, M., Denape, J., Paris, J.-Y., Ural, A. G., Alcalà, N., and Martinez, F. J., “Wear Dynamics of a TPU/Steel Contact under Reciprocal Sliding,” Wear, vol. 315, no. 1, pp. 103–114, 2014.

Hwang, D. H., Sung, I. H., and Kim, D. E., “The Effects of Relative Material Properties on the Friction and Wear Behavior of Pure Metals,” Journal of the Korean Society of Tribologists & Lubrication Engineers, vol. 14, no. 2, pp. 10–20, 1998.

Elleuch, R., Elleuch, K., Abdelounis, H. B., and Zahouani, H., “Surface Roughness Effect on Friction Behaviour of Elastomeric Material,” Materials Science and Engineering: A, vol. 465, no. 1, pp. 8–12, 2007.

Hill, D. J. T., Killeen, M. I., O'Donnell, J. H., Pomery, P. J., St John, D., and Whittaker, A. K., “Laboratory Wear Testing of Polyurethane Elastomers,” Wear, vol. 208, no. 1, pp. 155–160, 1997.

Mercer, A. P. and Hutchings, I. M., “The Influence of Atmospheric Humidity on the Abrasive Wear of Metals,” Wear, vol. 103, no. 3, pp. 205–215, 1985.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, DH., Yoo, SS., Kim, HJ. et al. Surface damage behavior of polyurethane O-rings in automated material handling system for glass panels. Int. J. Precis. Eng. Manuf. 17, 43–50 (2016). https://doi.org/10.1007/s12541-016-0006-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0006-z