Abstract

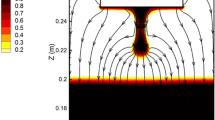

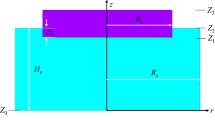

A transient three-dimensional (3D) model is developed for understanding the electromagnetism, heat transfer and phase change in electroslag remelting (ESR) furnace with triple-electrode. The electromagnetic fields are solved by Maxwell’s equations using the finite element method. The temperature field and phase change are modeled by the enthalpy approach. A reasonable agreement is obtained between experiment and simulation. The electric current flows from one electrode into the slag and comes out from other two electrodes. Most electric current travels through the slag near the slag/ingot interface. A great amount of the Joule heating is generated by the slag and a higher value is found in the slag around the three electrodes. The highest temperature is located at the center of the slag layer. Increase in the current causes the increase in the Joule heating. A hotter slag and a deeper metal pool therefore are formed. The total Joule heating in the slag increases with more slag, while the average Joule heating density reduces. The metal pool depth increases and then decreases with the increasing slag thickness, and the deepest metal pool is obtained at the slag thickness of 200 mm. The power efficiency and the slag temperature reduce with the increasing electrode immersion depth. A shallower electrode immersion depth is a better choice for the ESR process with triple-electrode.

Similar content being viewed by others

Abbreviations

- \(\vec A\) :

-

magnetic potential vector

- \(\vec B\) :

-

magnetic flux density

- C l :

-

specific heat of liquid metal

- C S :

-

specific heat of solid metal

- \(\vec E\) :

-

electric field intensity

- \(\vec F\) :

-

Lorentz force

- f l :

-

liquid fraction

- H :

-

enthalpy

- \(\vec J\) :

-

current density

- k eff :

-

effective thermal conductivity

- Q :

-

Joule heating

- T :

-

temperature

- t :

-

time

- ρ :

-

density

- σ :

-

electrical conductivity

References

Hernandez-Morales, B., and Mitchell, A., “Review of Mathematical Models of Fluid Flow, Heat Transfer, and Mass Transfer in Electroslag Remelting Process,” Ironmaking & Steelmaking, Vol. 26, No. 6, pp. 423–438, 1999.

Li, J., Wu, M., Ludwig, A., and Kharicha, A., “Simulation of Macrosegregation in a 2.45-Ton Steel Ingot using a Three-Phase Mixed Columnar-Equiaxed Model,” International Journal of Heat and Mass Transfer, Vol. 72, pp. 668–679, 2014.

Založnik, M. and Combeau, H., “Thermosolutal Flow in Steel Ingots and the Formation of Mesosegregates,” International Journal of Thermal Sciences, Vol. 49, No. 9, pp. 1500–1509, 2010.

Ferng, Y. M., Chieng, C. C., and Pan, C., “Numerical Simulations of Electro-Slag Remelting Process,” Numerical Heat Transfer, Vol. 16, No. 4, pp. 429–449, 1989.

Gu, J. P. and Beckermann, C., “Simulation of Convection and Macrosegregation in a Large Steel Ingot,” Metallurgical and Materials Transactions A, Vol. 30, No. 5, pp. 1357–1366, 1999.

Weber, V., Jardy, A., Dussoubs, B., Ablitzer, D., Rybéron, S., et al., “A Comprehensive Model of the Electroslag Remelting Process: Description and Validation,” Metallurgical and Materials Transactions B, Vol. 40, No. 3, pp. 271–280, 2009.

Ludwig, A., Kharicha, A., and Wu, M., “Modeling of Multiscale and Multiphase Phenomena in Materials Processing,” Metallurgical and Materials Transactions B, Vol. 45, No. 1, pp. 36–43, 2014.

Jardy, A., Ablitzer, D., and Wadier, J. F., “Magnetohydronamic and Thermal Behavior of Electroslag Remelting Slags,” Metallurgical Transactions B, Vol. 22, No. 1, pp. 111–120, 1991.

Fezi, K., Yanke, J., and Krane, M. J., “Modeling Macrosegregation during Electroslag Remelting of Alloy 625,” Proc. of the International Symposium on Liquid Metal Processing and Casting (LMPC), pp. 151–158, 2013.

Dong, Y., Jiang, Z., Liu, H., Chen, R., and Song, Z., “Simulation of Multi-Electrode Esr Process for Manufacturing Large Ingot,” ISIJ International, Vol. 52, No. 12, pp. 2226–2234, 2012.

Li, B., Wang, B., and Tsukihashi, F., “Modeling of Electromagnetic Field and Liquid Metal Pool Shape in an Electroslag Remelting Process with Two Series-Connected Electrodes,” Metallurgical and Materials Transactions B, Vol. 45, No. 3, pp. 1122–1132, 2014.

Kharicha, A., Ludwig, A., and Wu, M., “Shape and Stability of the Slag/Melt Interface in a Small Dc Esr Process,” Materials Science and Engineering: A, Vols. 413-414, pp. 129–134, 2005.

Mitchell, A. and Hernandez-Morales, B., “Electromagnetic Stirring with Alternating Current during Electroslag Remelting,” MTB, Vol. 21, No. 4, pp. 723–731, 1990.

Mitchell, A., “Solidification in Remelting Processes,” Materials Science and Engineering: A, Vols. 413-414, pp. 10–18, 2005.

Kelkar, K. M., Patankar, S. V., and Mitchell, A., “Computational Modeling of the Electroslag Remelting (ESR) Process Used for the Production of Ingots of High-Performance Alloys,” Proc. of the International Symposium on Liquid metal Processing and Casting, pp. 137–144, 2005.

Dilawari, A. H. and Szekely, J., “Heat Transfer and Fluid Flow Phenomena in Electroslag Refining,” Metallurgical Transactions B, Vol. 9, No. 1, pp. 77–87, 1978.

Biro, O. and Preis, K., “On the Use of the Magnetic Vector Potential in the Finite-Element Analysis of Three-Dimensional Eddy Currents,” IEEE Transactions on Magnetics, Vol. 25, No. 4, pp. 3145–3159, 1989.

Li, B., Wang, F., and Tsukihashi, F., “Current, Magnetic Field and Joule Heating in Electroslag Remelting Processes,” ISIJ International, Vol. 52, No. 7, pp. 1289–1295, 2012.

Zhao, R., Gosselin, L., Fafard, M., and Ziegler, D. P., “Heat Transfer in Upper Part of Electrolytic Cells: Thermal Circuit and Sensitivity Analysis,” Applied Thermal Engineering, Vol. 54, No. 1, pp. 212–225, 2013.

Wang, Q., Zhao, R., Fafard, M., and Li, B., “Three-Dimensional Magnetohydrodynamic Two-Phase Flow and Heat Transfer Analysis in Electroslag Remelting Process,” Applied Thermal Engineering, Vol. 80, pp. 178–186, 2015.

Wang, Q., He, Z., Li, B., and Tsukihashi, F., “A General Coupled Mathematical Model of Electromagnetic Phenomena, Two-Phase Flow, and Heat Transfer in Electroslag Remelting Process including Conducting in the Mold,” Metallurgical and Materials Transactions B, Vol. 45, No. 6, pp. 2425–2441, 2014.

Yanke, J. and Krane, M. J. M., “A Parametric Study of Slag Skin Formation in Electroslag Remelting,” Proc. of the International Symposium on Liquid Metal Processing and Casting, pp. 71–78, 2013.

Hugo, M., Dussoubs, B., Jardy, A., Escaffre, J., and Poisson, H., “Impact of the Solidified Slag Skin on the Current Distribution during Electroslag Remelting,” Proc. of the International Symposium on Liquid Metal Processing and Casting, pp. 79–85, 2013.

Patel, A. D., “Effect of Electrode Pipe and Mold Current on Electromagnetic Fields in Esr,” Proc. of International Symposium on Liquid Metal Processing and Casting LMPC, pp. 95–100, 2007.

Kharicha, A., Schutzenhofer, W., Ludwig, A., Tamer, R., and Wu, M., “On the Importance of Electric Currents Flowing Directly into the Mould During an Esr Process,” Steel Research International, Vol. 79, No. 8, pp. 632–636, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Qi, F., Wang, F. et al. Numerical investigation on electromagnetism and heat transfer in electroslag remelting process with triple-electrode. Int. J. Precis. Eng. Manuf. 16, 2467–2474 (2015). https://doi.org/10.1007/s12541-015-0317-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0317-5