Abstract

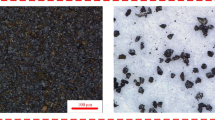

In order to eliminate the disposal issues of toxic chemicals in chemical mechanical planarization, a water-based ultra-polishing experiment with alumina abrasives was investigated for silicon wafer based on Box-behnken theory. It was found that the material removal rate (MRR) was sensitive to pH value, more sensitive to the slurry flow rate, and most sensitive to the oxidizer concentration. Under the optimal conditions of oxidizer concentration (0.44%), slurry flow rate (71.86 mL/min), and natural pH (pH: 7), the highest MRR was derived. Finally, a confuse-understanding of pH on material removal was addressed as well. It was pointed out that the increase in pH leads to the initial decrease in MRR, followed by a rapid increase as pH exceeds 11.

Similar content being viewed by others

References

Zantye, P. B., Kumar, A., and Sikder, A. K., “Chemical Mechanical Planarization for Microelectronics Applications,” Materials Science and Engineering: R: Reports, Vol. 45, No. 3, pp. 89–220, 2004.

Wang, T., Lu, X., Zhao, D., He, Y., and Luo, J., “Optimization of Design of Experiment for Chemical Mechanical Polishing of a 12-Inch Wafer,” Microelectronic Engineering, Vol. 112, pp. 5–9, 2013.

Chen, S., Lei, H., and Chen, R., “Preparation of Porous Alumina/ Ceria Composite Abrasive and Its Chemical Mechanical Polishing Behavior,” Journal of Vacuum Science & Technology B, Vol. 31, No. 2, Paper No. 021804, 2013.

Nolan, L. M. and Cadien, K. C., “Chemically Enhanced Synergistic Wear: A Copper Chemical Mechanical Polishing Case Study,” Wear, Vol. 307, No. 1, pp. 155–163, 2013.

Lee, H., Park, Y., Lee, S., and Jeong, H., “Effect of Wafer Size on Material Removal Rate and Its Distribution in Chemical Mechanical Polishing of Silicon Dioxide Film,” Journal of Mechanical Science and Technology, Vol. 27, No. 10, pp. 2911–2916, 2013.

Lee, H. S., Jeong, H. D., and Dornfeld, D. A., “Semi-Empirical Material Removal Rate Distribution Model for SiO2 Chemical Mechanical Polishing (CMP) Processes,” Precision Engineering, Vol. 37, No. 2, pp. 483–490, 2013.

Lee, H., Park, S., and Jeong, H., “Evaluation of Environmental Impacts during Chemical Mechanical Polishing (CMP) for Sustainable Manufacturing,” Journal of Mechanical Science and Technology, Vol. 27, No. 2, pp. 511–518, 2013.

Lei, H., Bu, N., Chen, R., Hao, P., Neng, S., et al., “Chemical Mechanical Polishing of Hard Disk Substrate with a-Alumina-GPolystyrene Sulfonic Acid Composite Abrasive,” Thin Solid Films, Vol. 518, No. 14, pp. 3792–3796, 2010.

Estragnat, E., Tang, G., Liang, H., Jahanmir, S., Pei, P., and Martin, J., “Experimental Investigation on Mechanisms of Silicon Chemical Mechanical Polishing,” Journal of Electronic Materials, Vol. 33, No. 4, pp. 334–339, 2004.

Manivannan, R. and Ramanathan, S., “The Effect of Hydrogen Peroxide on Polishing Removal Rate in CMP with Various Abrasives,” Applied Surface Science, Vol. 255, No. 6, pp. 3764–3768, 2009.

Song, X., Yang, H., Zhang, X., Liu, H., Qiu, G., and Tang, M., “Effects of H2O2 on Electrochemical Characteristics of Silicon Wafers during Chemical Mechanical Polishing,” Journal of the Electrochemical Society, Vol. 155, No. 11, pp. C530–C533, 2008.

Choi, W., Abiade, J., Lee, S.-M., and Singh, R. K., “Effects of Slurry Particles on Silicon Dioxide CMP,” Journal of the Electrochemical Society, Vol. 151, No. 8, pp. G512–G522, 2004.

Belongia, B. M., Haworth, P. D., Baygents, J. C., and Raghavan, S., “Treatment of Alumina and Silica Chemical Mechanical Polishing Waste by Electrodecantation and Electrocoagulation,” Journal of the Electrochemical Society, Vol. 146, No. 11, pp. 4124–4130, 1999.

Corlett, G., “Targeting Water Use for Chemical Mechanical Polishing,” Solid State Technology, Vol. 43, No. 6, pp. 201–202, 2000.

Kuan, W.-H. and Hu, C.-Y., “Chemical Evidences for the Optimal Coagulant Dosage and pH Adjustment of Silica Removal from Chemical Mechanical Polishing (CMP) Wastewater,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, Vol. 342, No. 1, pp. 1–7, 2009.

de Luna, M. D. G. and Liu, J. C., “Combined Treatment of Polishing Wastewater and Fluoride-Containing Wastewater from a Semiconductor Manufacturer,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, Vol. 347, No. 1, pp. 64–68, 2009.

Dakubo, F., Baygents, J. C., and Farrell, J., “Hydrogen Peroxide Removal from Chemical–Mechanical Planarization Wastewater,” IEEE Transactions on Semiconductor Manufacturing, Vol. 25, No. 4, pp. 623–629, 2012.

Ferreira, S. L. C., Bruns, R. E., Ferreira, H. S., Matos, G. D., David, J. M., et al., “Box-Behnken Design: An Alternative for the Optimization of Analytical Methods,” Analytica Chimica Acta, Vol. 597, No. 2, pp. 179–186, 2007.

Yang, Y.-K. and Chang, T.-C., “Experimental Analysis and Optimization of a Photo Resist Coating Process for Photolithography in Wafer Fabrication,” Microelectronics Journal, Vol. 37, No. 8, pp. 746–751, 2006.

Douglas, C., “Design and Analysis of Experiments,” Wiley, New York, pp. 63–97, 2001.

Mahajan, U., Bielmann, M., and Singh, R., “Dynamic Lateral Force Measurements during Chemical Mechanical Polishing of Silica,” Electrochemical and Solid-State Letters, Vol. 2, No. 2, pp. 80–82, 1999.

Luo, J. and Dornfeld, D., “Effects of Abrasive Size Distribution in Chemical Mechanical Planarization: Modeling and Verification,” IEEE Transactions on Semiconductor Manufacturing, Vol. 16, No. 3, pp. 469–476, 2003.

Wang, Y., Zhao, Y. W., and Gu, J., “A New Nonlinear-Micro-Contact Model for Single Particle in the Chemical-Mechanical Polishing with Soft Pad,” Journal of Materials Processing Technology, Vol. 183, No. 2-3, pp. 374–379, 2007.

Wang, Y., Zhao, Y., and Chen, X., “Chemical Mechanical Planarization from Macro-Scale to Molecular-Scale,” Materials and Manufacturing Processes, Vol. 27, No. 6, pp. 641–649, 2012.

Wang, Y., Zhao, Y., An, W., Ni, Z., and Wang, J., “Modeling Effects of Abrasive Particle Size And Concentration on Material Removal at Molecular Scale in Chemical Mechanical Polishing,” Applied Surface Science, Vol. 257, No. 1, pp. 249–253, 2010.

Zhao, Y. and Chang, L., “A Micro-Contact and Wear Model for Chemical-Mechanical Polishing of Silicon Wafers,” Wear, Vol. 252, No. 3, pp. 220–226, 2002.

Seidel, H., Csepregi, L., Heuberger, A., and Baumgärtel, H., “Anisotropic Etching of Crystalline Silicon in Alkaline Solutions I. Orientation Dependence and Behavior of Passivation Layers,” Journal of the Electrochemical Society, Vol. 137, No. 11, pp. 3612–3626, 1990.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, YG., Chen, Y. & Zhao, YW. Chemical mechanical planarization of silicon wafers at natural pH for green manufacturing. Int. J. Precis. Eng. Manuf. 16, 2049–2054 (2015). https://doi.org/10.1007/s12541-015-0266-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0266-z