Abstract

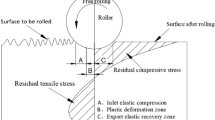

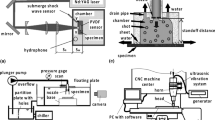

The ultrasonic surface rolling process (USRP) is a strengthening process to improve the surface properties and enhance the mechanical performances of metal materials based on severe plastic deformation and high strain rates. In this study, a three-dimensional numerical model was established to investigate the reconstruction mechanism of surface integrity for the laser additive manufactured 316 L stainless steel (LAMed 316 L) subjected to USRP. The accuracy of the USRP model was confirmed by experimental results of residual stress, microhardness, and surface roughness. The results showed that the static pressure played a crucial role in causing the plastic deformation and strain hardening, followed by the decreased surface roughness, improved microhardness, and induced compressive residual stresses. The introduction of ultrasonic high-frequency impact with the smaller force contributed to the high strain rate plastic deformation and the surface tensile stress release, and improved the plastic deformation efficiency greatly. The reconstructed surface integrity of LAMed 316 L was attributed to the plastic strain, strain hardening, and grain refinement.

Graphical Abstract

Similar content being viewed by others

References

L. Bhandari, V. Gaur, Addit. Manuf. 60, 103227 (2022). https://doi.org/10.1016/j.addma.2022.103227

H. Zhao, C. Zhao, W. Xie, D. Wu, B. Du, X. Zhang, M. Wen, R. Ma, R. Li, J. Jiao, C. Chang, X. Yan, L. Sheng, Mater. (Basel). 16, 3250 (2023). https://doi.org/10.3390/ma16083250

A. Lanzutti, E. Marin, K. Tamura, T. Morita, M. Magnan, E. Vaglio, F. Andreatta, M. Sortino, G. Totis, L. Fedrizzi, Addit. Manuf. 34, 101258 (2020). https://doi.org/10.1016/j.addma.2020.101258

M.J.K. Lodhi, K.M. Deen, M.C. Greenlee-Wacker, W. Haider, Addit. Manuf. 27, 8–19 (2019). https://doi.org/10.1016/j.addma.2019.02.005

E. Liverani, S. Toschi, L. Ceschini, A. Fortunato, J. Mater. Process. Technol. 249, 255–263 (2017). https://doi.org/10.1016/j.jmatprotec.2017.05.042

D. Wu, C. Yu, Q. Wang, F. Niu, G. Ma, H. Wang, C. Zhou, B. Zhang, J. Mater. Process. Technol. 307, 117695 (2022). https://doi.org/10.1016/j.jmatprotec.2022.117695

W. Ouyang, Z. Xu, Y. Chao, Y. Liu, W. Luo, J. Jiao, L. Sheng, W. Zhang, Mater. Charact. 191, 112123 (2022). https://doi.org/10.1016/j.matchar.2022.112123

Q. Xu, X. Yang, J. Liu, D. Jiang, Z. Qiu, Mater. Today Commun. 35, 105932 (2023). https://doi.org/10.1016/j.mtcomm.2023.105932

D. Liu, D. Liu, M. Guagliano, X. Xu, K. Fan, S. Bagherifard, J. Mater. Sci. Technol. 61, 63–74 (2021). https://doi.org/10.1016/j.jmst.2020.05.047

H. Wang, G. Song, G. Tang, Mater. Sci. Eng. A 662, 456–467 (2016). https://doi.org/10.1016/j.msea.2016.03.097

J. Geng, Z. Yan, H. Zhang, Y. Liu, P. Dong, S. Yuan, W. Wang, Adv. Eng. Mater. 23, 2100076 (2021). https://doi.org/10.1002/adem.202100076

Z. Liu, Z. Wang, C. Gao, X. Liu, R. Liu, Z. Xiao, J. Sanderson, Mater. Sci. Eng. A 833, 142352 (2022). https://doi.org/10.1016/j.msea.2021.142352

J.W. Xie, S.Q. Zhang, Y.A. Sun, Y.X. Hao, B.F. An, Q.L. Li, C.A. Wang, Mater. Sci. Eng. A 795, 140004 (2020). https://doi.org/10.1016/j.msea.2020.140004

Z. Liu, C. Gao, X. Liu, R. Liu, Z. Xiao, J. Mater. Process. Technol. 297, 117264 (2021). https://doi.org/10.1016/j.jmatprotec.2021.117264

Y. Chen, T. Lu, X. Chen, B. Sun, N. Yao, K. Li, J. Qiu, X. Hu, X.-C. Zhang, S.-T. Tu, Addit. Manuf. 78, 103887 (2023). https://doi.org/10.1016/j.addma.2023.103887

C. Ma, M.T. Andani, H. Qin, N.S. Moghaddam, H. Ibrahim, A. Jahadakbar, A. Amerinatanzi, Z. Ren, H. Zhang, G.L. Doll, Y. Dong, M. Elahinia, C. Ye, J. Mater. Process. Technol. 249, 433–440 (2017). https://doi.org/10.1016/j.jmatprotec.2017.06.038

Q. Xu, D. Jiang, J. Zhou, Z. Qiu, X. Yang, Surf. Coat. Technol. 454, 129187 (2023). https://doi.org/10.1016/j.surfcoat.2022.129187

J. Sun, Q. Sun, Y. Liu, B. Li, Z. Zhang, B. Xu, S. Xu, Y. Han, Y. Qiao, J. Han, G. Wu, P.K. Chu, J. Mater. Res. Technol. 20, 4378–4391 (2022). https://doi.org/10.1016/j.jmrt.2022.09.011

Y. Liu, L. Wang, D. Wang, J. Mater. Process. Technol. 211, 2106–2113 (2011). https://doi.org/10.1016/j.jmatprotec.2011.07.009

F. Li, B. Zhao, S. Lan, Z. Feng, J. Adv. Manuf. Technol. 106, 1893–1900 (2019). https://doi.org/10.1007/s00170-019-04648-4

Z. Ren, Z. Li, S. Zhou, Y. Wang, L. Zhang, Z. Zhang, Simul. Model. Pract. Theory. 121, 102643 (2022). https://doi.org/10.1016/j.simpat.2022.102643

Y. Li, Y. Ge, J. Lei, W. Bai, D. Sorgente, Adv. Mater. Sci. Eng. 2022, 2905843 (2022). https://doi.org/10.1155/2022/2905843

Y. Liu, X. Zhao, D. Wang, Mater. Sci. Technol. 30, 627–636 (2013). https://doi.org/10.1179/1743284713y.0000000396

Z. Wang, J. Gan, J. He, X. Wang, Y. Yang, M. Shi, X. Ren, Surf. Coat. Technol. 425, 127737 (2021). https://doi.org/10.1016/j.surfcoat.2021.127737

D. Liu, D. Liu, X. Zhang, C. Liu, N. Ao, Mater. Sci. Eng. A 726, 69–81 (2018). https://doi.org/10.1016/j.msea.2018.04.033

G.T. Gray, Annu. Rev. Mater. Res. 42, 285–303 (2012). https://doi.org/10.1146/annurev-matsci-070511-155034

D.L. Foley, S.H. Huang, E. Anber, L. Shanahan, Y. Shen, A.C. Lang, C.M. Barr, D. Spearot, L. Lamberson, M.L. Taheri, Acta Mater. 200, 1–11 (2020). https://doi.org/10.1016/j.actamat.2020.08.047

P. Lin, Y. Hao, B. Zhang, S. Zhang, J. Shen, Mater. Sci. Eng. A 710, 336–342 (2018). https://doi.org/10.1016/j.msea.2017.10.112

Y. Meng, J. Deng, R. Wang, Q. Sun, Z. Zhang, J. Adv. Manuf. Technol. 125, 73–89 (2023). https://doi.org/10.1007/s00170-022-10631-3

K. Dai, J. Villegas, Z. Stone, L. Shaw, Acta Mater. 52, 5771–5782 (2004). https://doi.org/10.1016/j.actamat.2004.08.031

H. Ye, A. Chen, S. Liu, C. Zhang, Y. Gao, Q. Li, J. Lv, J. Chen, H. Guo, Surf. Coat. Technol. 433, 128126 (2022). https://doi.org/10.1016/j.surfcoat.2022.128126

Q. Wei, J. Mater. Sci. 42, 1709–1727 (2007). https://doi.org/10.1007/s10853-006-0700-9

Z. He, J. Yu, B. Cui, S. Zhao, Z. Liu, H. Yu, S. Ding, Trans. Indian Inst. Met. 75, 1113–1123 (2022). https://doi.org/10.1007/s12666-021-02508-y

Acknowledgements

This study is supported by the National Natural Science Foundation of China (No.52001048).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, Q., Yang, X., Liu, J. et al. Reconstruction Mechanism of Surface Integrity for Laser Additive Manufactured 316 L Stainless Steel Subjected to Ultrasonic Surface Rolling Process: Numerical Simulation and Experimental Verification. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01683-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01683-z