Abstract

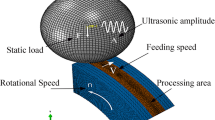

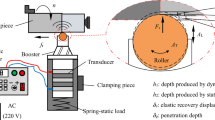

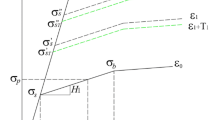

In order to study the effects of ultrasonic rolling pressure on the surface characteristics of titanium alloy Ti-6AL-4V (TC4), a theoretical model of ultrasonic rolling pressure and residual stress was established on the basis of Hertz theory. The effect of different ultrasonic rolling pressures on residual stress was simulated by ABAQUS software. Compared with the ultrasonic rolling TC4 tests, the variation trend of the simulation results closely matched results obtained from physical testing. That is, when other processing parameters were constant, the surface residual stress first increased and then decreased with the increase of the rolling pressure, and the residual stress value was the largest at a rolling pressure of 600 N. The physical tests showed that the surface roughness reached a minimum when the rolling pressure was 600 N, and after it had exceeded 800 N, the surface was damaged and cracks appeared. This showed that the ultrasonic rolling pressure process parameters could achieve good processing effects within a certain range, but adverse effects were generated if this range was exceeded.

Similar content being viewed by others

References

Ellyson B, Brochu M, Brochu M (2017) Characterization of bending vibration fatigue of SLM fabricated Ti-6Al-4V. Int J Fatigue 99:25–34

Mohsan AUH, Liu Z, Padhy GK (2017) A review on the progress towards improvement in surface integrity of Inconel 718 under high pressure and flood cooling conditions. Int J Adv Manuf Technol 91:107–125

Singh R, Khamba JS (2007) Investigation for ultrasonic machining of titanium and its alloys. Journal of Materials Processing Technology 183:363–367

Zhao ZY (2005) Investigation and development status of the application technology to improve fatigue behavior of high strength alloys. Eng Sci 7(3):90–94

Li L, Li SJ, Tang AF, Li Y (2014) Vibration cutting analysis of axially moving diamond wire saw excited by transverse ultrasonic wave. Acta Armamentarii 35(10):1651–1658

Kumar J, Khamba JS, Mohapatra SK (2008) An investigation into the machining characteristics of titanium using ultrasonic machining. Int J Mach Mach Mater 3:143–161

Xu XC, Liu DX, Zhang XH, Liu CS, Liu D, Zhang WC (2019) Influence of ultrasonic rolling on surface integrity and corrosion fatigue behavior of 7B50-T7751 aluminum alloy. Int J Fatigue 125:237–248

Thamizhmanii S, Omar BB, Saparudin S, Hasan S (2008) Surface roughness investigation and hardness by burnishing on titanium alloy. J Achiev Mater Manuf Eng 28(2):139–142

Bozdana AT, Gindy NNZ (2008) Comparative experimental study on effects of conventional and ultrasonic deep cold rolling processes on Ti-6Al-4V. Mater Sci Technology 24(11):1378–1384

Bozdana AT, Gindy NNZ, Li H (2005) Deep cold rolling with ultrasonic vibrations a new mechanical surface enhancement technique. Int J Mach Tools Manuf 45(6):713–718

Li L, Zhu YL, Lv GY, Huang YL, Bai C (2008) Study on ultrasonic deep rolling surface mechanical enhancement technique of TC4 titanium alloy. Journal of Materials Engineering 10(11):68–74

Lv GY, Zhu YL, Li L, Han XG (2007) The effect of ultrasonic deep rolling (UDR) on surface topography and surface roughness of TC4 titanium alloy. China Surf Eng 20(4):38–41

Nalla RK, Altenberger I, Noster U, Liu GY, Scholtes B, Ritchie RO (2003) On the influence of mechanical surface treatments-deep rolling and laser shock peening-on the fatigue behavior of Ti-6AL-4V at ambient and elevated temperatures. Materials Science and Engineering A 355(1):216–230

Liu Y, Wang LJ, Wang DP (2011) Finite element modeling of ultrasonic surface rolling process. J Mater Process Technol 211:2106–2113

Ren K, Yue W, Zhang HY (2018) Surface modification of Ti6Al4V based on ultrasonic surface rolling processing and plasma nitriding for enhanced bone regeneration. Surf Coating Technol 349:602–610

Ao N, Liu DX, Zhang XH, Liu CS, Yang J, Liu D (2019) Surface nanocrystallization of body-centered cubic beta phase in Ti–6Al–4V alloy subjected to ultrasonic surface rolling process. Surface and Coatings Technology 361:35–41

Zhang M, Tang HX (2014) Research on improvement of parts surface properties by ultrasonic auxiliary rolling processing. Electromach Mould 4(2):60–62

Hou Y (2009) Finite element analysis of bending stress of face gear drive on the basis of Hertz contact stress distribution. Nanjing University of Aeronautics and Astronautics 32-38

Funding

The study received financial support from The National Natural Science Foundation of China (51475148 and U1604255).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, F., Zhao, B., Lan, S. et al. Experiment and simulation of the effect of ultrasonic rolling on the surface properties of Ti-6Al-4V. Int J Adv Manuf Technol 106, 1893–1900 (2020). https://doi.org/10.1007/s00170-019-04648-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04648-4