Abstract

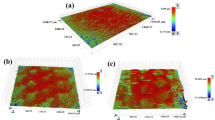

Laser weapons play an important role in the modern high-tech war. And such laser weapon is based on the principle of thermal damage to 'burn' enemy equipment, such as missiles, drones, etc. To investigate the interaction mechanism between laser and common aerospace materials, the microstructure evolution and mechanical response of titanium alloys after laser ablation were studied in detail. The results indicate that in addition to the laser-induced failure zone (ablation area), a significantly large heat-affected zone exists, where the microstructure and mechanical characteristics change. Along the radial direction of the ablation area, the microstructure evolves from coarse lamellar microstructure to needle-like α/α′ with β grain boundary, then to the bimodal microstructure of prior α and secondary α, and finally to the matrix that is mostly made of equiaxed α. Moreover, it is found that needle-like α, refinement grains and high oxygen content are the main reasons for the increase of microhardness. And the oxygen content above the acceptable level and severe segregation of solute elements may be the reasons that finally lead to the indentation cracks. The findings may offer ideas for the design of defensive Ti alloys, as well as the application in laser repair techniques.

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings is all included in the tables and figures.

References

L. Shi, Y. Pei, Q. Yun, Y. Ge, Chin. J. Aeronaut. 36, 442–454 (2022)

C. Peng, F. Lu, C. Xing, in Proceedings of the 9th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, 26-27 August 2017 (IEEE, New York, 2017), pp. 302–307

C. Lyu, R. Zhan, Def. Technol. 18, 678–688 (2022)

J. Stupl, G. Neuneck, Security Challenges 1, 135–153 (2005)

J.A. Holbrook, D.L. Reyes, A systems approach towards high energy laser implementation aboard navy ships, Master’s Thesis, Naval Postgraduate School (2007)

J. Stupl, G. Neuneck, SCI Glob. Secur. 18, 1–60 (2010)

C. Cao, Hangkong Xuebao/Acta Aeronautica et Astronautica Sinica 29, 701–706 (2008)

E. Chikarakara, S. Naher, D. Brabazon, Surf. Coat. Technol. 206, 3223–3229 (2012)

Y. Sun, G. Luo, J. Zhang, C. Wu, J. Li, Q. Shen, L. Zhang, J. Alloys Compd. 741, 918–926 (2018)

J. Xu, J. Zhu, J. Fan, Q. Zhou, Y. Peng, S. Guo, Vacuum 167, 364–373 (2019)

A. Gupta, C.J. Bennett, W. Sun, Eng. Fail. Anal. 140, 106494 (2022)

S. Ningthemba Singh, A.B. Deoghare, Eng. Fail. Anal. 148, 107208 (2023)

D. Zhang, L. Wang, H. Zhang, A. Maldar, G. Zhu, W. Chen, J.-S. Park, J. Wang, X. Zeng, Acta Mater. 189, 93–104 (2020)

T. Marazani, D.M. Madyira, E.T. Akinlabi, Procedia Manuf. 35, 897–902 (2019)

H. Wang, Q. Chao, H.S. Chen, Z.B. Chen, S. Primig, W. Xu, S.P. Ringer, X.Z. Liao, Acta Mater. 235, 118104 (2022)

H. Zhao, C. Zhao, W. Xie, D. Wu, B. Du, X. Zhang, M. Wen, R. Ma, R. Li, J. Jiao, C. Chang, X. Yan, L. Sheng, Materials 16, 66 (2023)

C.P. Ma, Y.C. Guan, W. Zhou, Opt. Lasers Eng. 93, 171–177 (2017)

Y. Li, X. Cheng, Y. Guan, J. Mater. Sci. Technol. 83, 1–6 (2021)

X.D. Ren, W.F. Zhou, F.F. Liu, Y.P. Ren, S.Q. Yuan, N.F. Ren, S.D. Xu, T. Yang, Appl. Surf. Sci. 363, 44–49 (2016)

M.Z. Ge, Y. Tang, Y.K. Zhang, Y. Wang, Surf. Coat. Technol. 444, 128671 (2022)

Y. Fu, N. Guo, B. Zhu, X. Shi, J. Feng, J. Mater. Process. Technol. 275, 116372 (2020)

S. Bashir, M.S. Rafique, A.A. Ajami, C.S. Nathala, W. Husinsky, K. Whitmore, Appl. Phys. A 127, 66 (2021)

J.J.J. Nivas, E. Allahyari, A. Vecchione, Q. Hao, S. Amoruso, X. Wang, J. Mater. Sci. Technol. 48, 180–185 (2020)

S. Xu, Y. Chen, H. Liu, X. Miao, X. Yuan, X. Jiang, Optik 212, 66 (2020)

N. Maharjan, W. Zhou, Y. Zhou, Y. Guan, Appl. Phys. A 124, 66 (2018)

J. Zhao, Z. Zhu, Y. Xu, X. Song, Y. Wang, H. Peng, Y. Wang, J. Zuo, X. Shu, A. Yin, Appl. Sci. 10, 4657 (2020)

S. Zhao, R. Zhang, Y. Chong, X. Li, A. Abu-Odeh, E. Rothchild, D.C. Chrzan, M. Asta, J.W. Morris Jr., A.M. Minor, Nat. Mater. 20, 468–472 (2021)

M. Yan, W. Xu, M.S. Dargusch, H.P. Tang, M. Brandt, M. Qian, Powder Metall. 57, 251–257 (2014)

Y. Chong, M. Poschmann, R. Zhang, S. Zhao, A.M. Minor, Sci. Adv. 6, 4060 (2020)

T. Ahmed, H.J. Rack, Mater. Sci. Eng. A 243, 206–211 (1998)

W.J. Davids, H. Chen, K. Nomoto, H. Wang, S. Babu, S. Primig, X. Liao, A. Breen, S.P. Ringer, Acta Mater. 215, 117131 (2021)

Y. Wang, G. Yang, S. Zhou, C. Sun, B. Li, D. An, S. Zhang, S. Xiu, Mater. Sci. Eng. A 861, 144266 (2022)

J. Luo, H. Wang, C. Xi, H. Zhai, Y. Gu, C. Zhang, Ceram. Int. 47, 4914–4924 (2021)

R. Henry, N. LeRoux, I. Zacharie-Aubrun, J.-M. Gatt, C. Langlois, S. Meille, Mater. Sci. Eng. A 860, 144261 (2022)

H. Wang, Q. Chao, L. Yang, M. Cabral, Z.Z. Song, B.Y. Wang, S. Primig, W. Xu, Z.B. Chen, S.P. Ringer, X.Z. Liao, Mater. Res. Lett. 9, 119–126 (2020)

S.M. Kelly, S.L. Kampe, Metall. Mater. Trans. A 35, 1869–1879 (2004)

J.W. Elmer, T.A. Palmer, J. Wong, J. Appl. Phys. 93, 1941–1947 (2003)

L.E. Murr, E.V. Esquivel, S.A. Quinones, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, F. Medina, D.H. Hernandez, E. Martinez, J.L. Martinez, S.W. Stafford, D.K. Brown, T. Hoppe, W. Meyers, U. Lindhe, R.B. Wicker, Mater. Charact. 60, 96–105 (2009)

Y. Liu, W. Ouyang, H. Wu, Z. Xu, L. Sheng, Q. Zou, M. Zhang, W. Zhang, J. Jiao, J. Mater. Process. Technol. 300, 66 (2022)

Y. Chao, Y. Liu, Z. Xu, W. Xie, L. Zhang, W. Ouyang, H. Wu, Z. Pan, J. Jiao, S. Li, G. Zhang, W. Zhang, L. Sheng, J. Mater. Sci. Technol. 156, 32–53 (2023)

S. Sahoo, O. Licata, B. Mazumder, S. Roy, J. Alloys Compd. 907, 164511 (2022)

Y. Chong, T. Bhattacharjee, N. Tsuji, Mater. Sci. Eng. A 762, 138077 (2019)

Y. Chong, T. Bhattacharjee, J. Yi, S. Zhao, N. Tsuji, Materialia 8, 100479 (2019)

Y. Chong, G. Deng, S. Gao, J. Yi, A. Shibata, N. Tsuji, Scr. Mater. 172, 77–82 (2019)

C. Moussa, M. Bernacki, R. Besnard, N. Bozzolo, IOP Conf. Ser. Mater. Sci. Eng. 89, 012038 (2015)

M. Song, S. Han, D. Min, G. Choi, J. Park, Scr. Mater. 59, 623–626 (2008)

X. Shi, X. Wang, B. Chen, J. Umeda, A. Bahador, K. Kondoh, J. Shen, Mater. Des. 227, 111797 (2023)

W. Shi, S. Lu, J. Shen, B. Chen, J. Umeda, Q. Wei, K. Kondoh, Y. Li, Mater. Sci. Eng. A 830, 142321 (2022)

X. Wang, Y. Zhang, W. Han, Acta Mater. 227, 117686 (2022)

X. Wang, S. Lu, B. Chen, U. Junko, Y. Shibutani, K. Kondoh, J. Shen, Mater. Sci. Eng. A 832, 142449 (2022)

A. I. Kahveci The Effects of Oxygen on the Microstructure and Mechanical Properties of Ti–6Al–4V Alloy (Case Western Reserve Univ., Cleveland, 1989)

H. Conrad, Prog. Mater. Sci. 26, 123–403 (1981)

L. Tang, J. Fan, H. Kou, B. Tang, J. Li, Materials 13, 66 (2020)

H. Wang, Q. Chao, X.Y. Cui, Z.B. Chen, A.J. Breen, M. Cabral, N. Haghdadi, Q.W. Huang, R.M. Niu, H.S. Chen, B. Lim, S. Primig, M. Brandt, W. Xu, S.P. Ringer, X.Z. Liao, Mater. Today 61, 11–21 (2022)

J. Shen, B. Chen, J. Umeda, J. Zhang, Y. Li, K. Kondoh, Mech. Mater. 148, 103519 (2020)

Acknowledgements

The authors appreciate the experimental assistant from the Analytical & Testing Center of Northwestern Polytechnical University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Shi, X., Du, Z. et al. Microstructural Strengthening and Plastic Degradation of Ti–6Al–4V Induced by Laser Ablation. Met. Mater. Int. 30, 895–908 (2024). https://doi.org/10.1007/s12540-023-01558-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01558-9