Abstract

Biodegradable metals have received limited attention for application in transdermal drug delivery, although metallic microneedles (MNs) and iontophoresis have been thoroughly researched for this purpose. Here, we present Mg as a salient candidate for an MN electrode. Its metallic properties enable the application of voltage to enhance the diffusion of charged drug molecules, while hydrogen gas generated during Mg corrosion prevents its application to electrodes. The Mg MN electrode was fabricated using a nanosecond laser, and the amount of hydrogen gas were measured with applied potential during iontophoresis. Accordingly, an appropriate potential window for iontophoresis was established based on the combined effect of enhanced drug diffusion by applied electric potential and impediment from hydrogen generation. The dye permeation tests of the Mg MN on the porcine skin demonstrated the combined effect of the Mg MN and iontophoresis. The dye migration decreased at higher voltages due to excess hydrogen generation and the corrosion of needle tips, both making the diffusion of charged dye molecules along the Mg MN surface harder. These results demonstrate optimal potential range of Mg MN electrodes for transdermal drug delivery with an electric field and bubble generation during iontophoresis.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Transdermal drug delivery (TDD) is a painless method for systemically transporting molecular drugs into the skin. [1] It provides a possible alternative to the traditional drug delivery methods such as oral administration or hypodermic injection by overcoming the various limitations including allergic reactions, risks of infection, needle phobia, bleeding, and psychological stress to patients [2,3,4,5,6] and providing direct absorption via microcirculation with less limitation on pH requirements, susceptibility to enzymes, and complicated metabolism. [7,8,9,10] However, as the natural permeation of the foreign molecules through the skin is extremely slow, [11, 12] advanced transdermal strategies with maximized drug flux but minimal invasion are necessary.

Microneedles (MNs) are the best fit for these ambivalent requirements: as a minimally invasive method with negligible pain, the MNs create microchannels through which drugs can travel into the skin. [13] Moreover, MNs can easily be combined with the iontophoresis mechanism and effectively deliver charged drug molecules. [14, 15] Biocompatible metals like stainless steel or titanium are used for MNs, with sufficient mechanical strength and excellent electric conductivity to apply an electric field to charged drug molecules. [14, 16,17,18,19,20] Despite the advantages, these metals can cause allergic reactions, local anaphylaxis inflammation, or pigmentation by releasing toxin ions if the MNs got broken inside the skin. [21, 22]

The Mg-based materials are good candidates to overcome the challenges mentioned above, especially the danger of broken MNs, and have already been actively studied for their safety in the fields of orthopedics, dental, and cardiology. [23, 24] As metallic materials, they have sufficient strength to penetrate the skin and can be used as electrodes. Nevertheless, they have not been significantly considered as MN electrodes for iontophoresis due to the severe corrosion generating hydrogen gas in vivo, far different from conventional electrochemical electrode materials.

Herein, we report the application of Mg as electrochemical electrodes for iontophoretic MNs: the hydrogen generation behavior on both Mg anode and Mg cathode (Fig. 1) was thoroughly analyzed as a function of applied voltage together with the dye migration in the porcine skin model to determine the optimum potential range for enhanced TDD. These investigations are essential to overcome the difficulties arising from the application of electrochemically active Mg to electrodes: the efficiency of drug delivery is proportional to the strength of the electric field, but high voltage can trigger cell or skin damage. [25, 26] Also, as vigorous hydrogen generation may hinder the migration of the drug molecules along the surface of the Mg MNs and microchannels around them, the optimization for precise control of electric potential is essential.

2 Experimental

2.1 Fabrication of the Mg MN

The Mg plate was polished up to 2000 grit and cleaned in an ultrasonic bath with absolute ethanol. The polished Mg plate was cut into 6 × 2 MN arrays using a fiber nanosecond laser (Biolino series, Laservall, China), and each needle had a length and width of 1000 μm and 500 μm, respectively. The laser system was set up with a pulse duration of 8 ns at a central wavelength of 1070 nm. The laser power was 20 W, the spot diameter was 60 μm, and the scanning speed was 1000 mm s−1. Each needle was erected by pushing the straight pin and sterilized in an ultrasonic bath with absolute ethanol and acetone, respectively, before use.

2.2 Penetration Test of the Mg MN

Porcine skin was used for the penetration and dye permeation tests of the Mg MN. Porcine samples were acquired from a local butcher shop and immediately stored at − 80 °C until further analysis. Before the experiment, the porcine sample was thawed to room temperature by immersing in a 1 × phosphate-buffered saline solution (PBS, pH 7.4, Welgene) to prevent surface drying. Then, the porcine sample was thoroughly cleaned with deionized water to remove subcutaneous fat, and cut into 2 × 2 cm slabs with a thickness of 3 ± 0.2 mm. PDMS (Sylgard 184, Dow Corning, USA) resin was used as a support structure for the Mg MNs on the porcine sample. First, the PDMS resin was mixed with a curing agent at a ratio of 10:1 (v/v). Air bubbles trapped in the PDMS were removed using vacuum equipment, and the mixture was cured at 70 °C overnight. The red fluorescent dye solution was prepared by dissolving Rhodamine B (0.2 mg, 0.44 mM) (Sigma Aldrich, USA) in ethanol. The Mg MN was dipped into the dye solution and placed on the porcine sample at a distance of 3 mm. Then, the coated Mg MNs were pushed by a finger for a while to enable penetration into the porcine sample, followed by pressing with PDMS to secure it for 1 h. The porcine skin marked by the Mg MN was verified with a digital camera, and the depth of a single puncture was investigated using a 3D microscope (OLS5000, Olympus, Japan).

2.3 Potential Measurement of the Mg and Mg Alloys Electrodes

Mg rectangular electrodes were used for the potential level measurement, H2 generation test, and H2O2 generation test. The electrodes were fabricated by cutting the polished plate in a 1.5 × 1 cm rectangular shape using a fiber nanosecond laser and sterilized in an ultrasonic bath with absolute ethanol and acetone, respectively. The potential of the electrodes was measured using a potentiostat (VersaSTAT 3, AMETEK, USA) with the Mg electrode, Ag/AgCl, and Pt plate as the working electrode, reference electrode, and counter electrode, respectively, in 1 × PBS solution (pH 7.4). Then, the working electrode was connected to the DC power supply (RDP-305, SMART, Korea) as an anode or cathode. The potential of the Mg alloy electrodes was measured in the same manner.

2.4 H2 Generation Test of the Mg and Mg Alloy Electrodes

The Mg rectangular electrodes were attached with long electrical lines, and the attaching part was thoroughly enveloped by a commercial epoxy resin. Then, the two electrodes were connected to the DC power supply as an anode and a cathode, respectively, and soaked in 1 × PBS solution (pH 7.4). The system was covered with an upside downed funnel, and the hydrogen gas generated during immersion of the Mg electrodes under applied voltage was collected in the column part of the funnel. The volume change was observed and converted to the amount of hydrogen gas generated. The H2 generation test of the Mg alloy electrodes was performed in the same manner.

2.5 H2O2 Generation Test of the Mg Electrodes

Two Mg rectangular electrodes as the anode and cathode were connected to the DC power supply, and the voltage was applied to the electrodes in 1 × PBS solution (pH 7.4) for 1 h. The 50 μL working samples captured at certain times and the 50 μL H2O2 standard solutions to draw a linear curve of the H2O2 concentration were seeded into a 96-well black plate. Subsequently, 50 μL Mater Mix of the Fluorimetric Hydrogen Peroxide Assay Kit (Sigma Aldrich, USA) was added to each well and incubated for 10 min. Fluorescence was measured using a microplate reader (GloMax® Discover, PromegaTM, USA) with an excitation wavelength of 540 nm and an emission wavelength of 590 nm. The fluorescence intensity values were converted into the concentration of H2O2 generated.

2.6 Dye Permeation Test on the Porcine Skin

The porcine sample was coated by dropping the red dye solution of Rhodamine B (0.44 mM). Two Mg MNs were placed on the drop-cast porcine sample at a distance 3 mm and connected to the DC power supply as an anode and a cathode. Then, the Mg MNs were manually pushed for a while to enable penetration into the porcine sample, followed by pressing with PDMS to secure it for 1 h under applied voltage. Then, the Mg MN-treated porcine skin was fixed with formaldehyde (4%) for 30 min, embedded in a frozen section compound (FSC 22 ® Clear, Leica) medium, and stored at − 80 °C overnight. The frozen sample was then cut using a single edged knife to obtain cross-sectional images of the MN insertion site.

2.7 Area Analysis for Dye Migration

Cross-sectional images of the porcine samples inserted with the Mg MNs were analyzed to quantify dye permeation during iontophoresis. Each image was uniformly cut at a certain area in the vicinity of the Mg MN anode, and the area of the dye distribution was analyzed by Image J software. The results are presented as the mean ± SD. Statistical analysis was performed using one-way (ANOVA) with Tukey’s test using Origin software.

2.8 Mg MN Characterization

The Mg MNs after insertion into the porcine sample during the 1 h period of iontophoresis was washed with deionized water and dried. Subsequently, the Mg MN samples were coated with a thin layer of platinum prior to imaging. SEM (Inspect F 50, FEI Company, USA) images were captured at an acceleration voltage of 10 kV. Then, the elemental composition of the Mg MNs was analyzed using EDS (Octane Silicon Drift Detector, AMETEK EDAX, USA) attached to the SEM instrument.

3 Results and Discussion

3.1 Fabrication and Penetration Test of the Mg MN

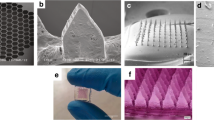

The Mg MN electrodes were readily fabricated with a fiber nanosecond laser (Fig. 2a). For successful transdermal drug delivery, the MNs should be able to penetrate at least 150 μm into the skin. [27] However, as the average depth of skin penetration is only 10%–30% of the total needle length, [28] the Mg MNs were designed with a length and width of 1000 μm and 500 μm respectively, in 6 × 2 arrays (Fig. 2b). To analyze the penetration behavior of the Mg MNs, they were tested with porcine skin samples. The Mg MNs were dipped into the dye solution (Rhodamine B, 0.44 mM) for visualization and inserted into the porcine skin. After removal of Mg MNs, the porcine sample showed microchannels marked with Rhodamine B after 1 h (Fig. 2c). The depth of a single puncture on the porcine skin was investigated with 3D microscopy (Fig. 2d and e). The indented mark was about 290 μm deep after 1 h of the MN insertion (Fig. 2f), which was about 30% of the total MN length. So, it can be concluded that pure Mg MNs have sufficient strength to penetrate the skin and form microchannels for drug transport.

a the fabrication process of the Mg microneedles, b optical images of the 6 × 2 array of Mg microneedles, c visualization of microchannel created by the Mg microneedles with Rhodamine B into the porcine samples (scale bar: 2 mm), d close up image (scale bar: 200 μm), e 3D depth microscopy profile image (scale bar: 200 μm) and f the average depth of a single puncture on the porcine sample stained by Rhodamine B after 1 h of the Mg microneedle insertion (Mean ± SD, n = 10)

3.2 Establishment of Applied Potential Range as the Mg MN Electrodes

In the iontophoresis application, as Mg MN electrodes act as anode and cathode or alternately, it is necessary to analyze electrochemical reactions such as Mg corrosion and hydrogen evolution at each electrode according to the applied voltage. As ease of use is one of the main advantages of MNs, an electrochemical study was conducted assuming a direct current (DC) voltage of an alkaline battery, as shown in Figure S1. Figure 3a shows the potential levels of each Mg electrode when voltage was applied. Compared to the open-circuit potential (OCP) of pure Mg (− 1.58 V in PBS solution), the potential of the Mg anodes slightly moved in the positive direction, while the levels of the Mg cathodes significantly moved in the negative direction based on the OCP level as the applied voltage increased. The potential difference between anode and cathode was almost identical to the applied voltage. The direction to which the potential moved was influenced by overpotential, which increased with increasing current density according to the Tafel equation. (η: overpotential, A: Tafel slope, i: current density, and i0: exchange current density). [29]

Hence, the greater the voltage applied, the more vigorous became the chemical reaction on the Mg electrodes.

The H2 generated on the Mg electrodes was measured as a function of applied voltage. The H2 generation increases as the applied voltage increases (Fig. 3b). [30] Initially, H2 was rapidly generated on the surface of Mg electrodes, and the amount gradually decreased over time (Figure S2). [31,32,33,34] The H2 amount after 30 min, 1 h, and 2 h was rearranged as a function of applied voltage for the establishment of the optimum potential range (Fig. 3c). At an applied voltage of 1.2 V or higher, H2 was very rapidly generated, and the electrodes got completely dissolved between 1 and 2 h and further measurement was impossible. In the applied voltage range up to 1.0 V, H2 generation for 30 min and 1 h slowly increased with the increment of the applied voltage. So, up to 1.0 V, it can be expected that the H2 generation would not be too vigorous to prevent the transport of drugs along the surface of Mg MNs or microchannel around MNs and their diffusion in the tissue.

Practically, alloys are more commonly used than pure Mg because of their superior corrosion resistance and strength. Mg-Ca-Zn alloys have been actively studied as biomaterials due to their excellent biocompatible and biodegradable properties, in addition to their controlled corrosion rate and strength. [35,36,37] As an example study, Mg-0.05Ca-1Zn was selected and its potential levels and amount of H2 were measured in the same way as pure Mg under the applied voltage. The potential levels of the Mg-0.05Ca-1Zn electrodes shifted in a similar manner to pure Mg electrodes (Figure S3). The H2 generation on Mg-0.05Ca-1Zn electrodes increased as the applied voltage increased (Fig. 4a), but it is noteworthy that the amount of H2 with 1.2 V was almost identical to that on pure Mg with 1.0 V and did not show abrupt increment up to 1.4 V (Fig. 4b). So, it can be inferred that Mg-0.05Ca-1Zn alloy MNs may show identical or superior performance to Mg MNs up to 1.2 V and even be used at 1.4 V. By far, we assumed H2 evolution as an obstacle to drug delivery. However, adequate H2 generation could physically drive the drugs into the skin more effectively. [38] Therefore, a suitable voltage range should be decided by comprehensively considering the driving effect of the applied voltage and the accelerating or hindering effect of H2 generation on the drug molecules.

3.3 Dye Permeation Test on the Porcine skin

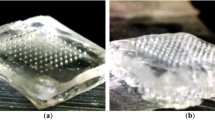

To test the efficacy of Mg electrodes for iontophoresis and determine the optimum voltage range, the dye permeation test was performed with anodic and cathodic Mg MNs using Rhodamine B solution, instead of actual drugs. [28, 39,40,41] The solution was loaded by a drop-casting method on the porcine skin surface. The Mg MN electrodes were attached to the dye-loaded porcine sample, and voltage was applied for 1 h (Fig. 5a). The resultant iontophoresis effect was clearly visible with the naked eyes (Fig. 5b): in control samples (0 V), the dye moved into the skin only by diffusion, whereas the dye migrated deeper and farther with applied voltage. Previously, iontophoresis studies have been conducted at a current density of 0.2–0.5 mA cm−2 on MN electrodes to avoid human skin damage. [15, 17, 42,43,44] In this study, the application of 0.8 V corresponds to the above-mentioned range as a current density of 0.43 mA cm−2 without notable change by time (Figure S4). Statistical analysis of the dyed area was conducted due to the roughness and irregularity of the porcine skin surface. In the optical cross-section images near the Mg MN anode, the dyed region was extracted and quantified using ImageJ software. The process is described in Figure S5 in detail. The dyed areas under applied voltage were larger than those of the control group only depending on the intrinsic diffusion without voltage (Fig. 5c). The dye was delivered to a wider area with the increment of applied voltage, but the dyed area decreased at 1.4 V. It can be concluded that the dye-driving effect by applied voltage was dominant within a mild H2 generation range (~ 0.5 ml cm−2 for 1 h), but higher voltages (1.4 V ~) leading to active H2 generation (more than 2 ml cm−2 for 1 h) interrupted dye migration rather than driving it farther during iontophoresis.

a Schematic illustration of experimental set up of the dye migration test during iontophoretic investigations, b optical cross-sections images of the porcine samples after 1 h of insertion under the applied potential (scale bar: 1 mm), c area change curve of dye migration after 1 h of insertion under the applied potential (One-way ANOVA with Turkey’s test Mean ± SD n = 5, n.s = no significant *p < 0.05, **p < 0.01, ***p 0.001, ****p < 0.0001), d schematic illustration of dye migration by the electrical field on anode without or with the applied potential, e optical images of dye migration on porcine samples by the electrical field near the anode after 1 h of insertion under the applied potential (scale bar: 1 mm)

During iontophoresis, the migration of positively charged Rhodamine B dye is strongly influenced by the electric field. It was expected that the dye evenly permeates into the porcine sample without applied voltage (control), whereas when voltage is applied (potential), the dye near the anode would dominantly migrates toward the direction of the cathode (Fig. 5d). In Fig. 5e, the red color of the dye remained on the surface in the control, but the dye near the anode was asymmetrically pushed to the cathode by the electric field. It is noteworthy that the dye moved further toward the cathode at 0.8 V and showed a paler color than at 0.2 V because the same amount of dye solution should permeate farther with a stronger electric field.

3.4 Characterization of the Mg MN Electrode after Iontophoresis

The scanning electron microscopy (SEM) images show a considerable difference between the anodic and cathodic Mg MN electrodes after they had been attached to the porcine sample at 0.8 V for 1 h. While the needle tip of the anode got corroded and disappeared (Fig. 6a i), the shape of the cathode was almost retained during the iontophoresis (Fig. 6a ii). The energy dispersive spectroscopy (EDS) results showed that the amount of oxygen was much higher in the anode (Table S1a). The SEM images in Fig. 6b show the corroded Mg MN anodes with different applied voltages. As the applied voltage increased, the corrosion became severer and a more amount of oxygen was detected (Table S1b). Specifically, only the tip of the needle disappeared at 0.8 V showing the maximum dyed area, whereas, at 1.4 V, the needle almost disappeared during the 1 h period. As previously discussed, dye migration decreased at 1.4 V, which was attributed to the abrupt increase of the H2 generation during iontophoresis. Considering the anode image at 1.4 V (Fig. 6b), it can also be inferred that it became harder as time elapsed for the dye diffusion into the porcine skin along the anodic MNs which got corroded and gradually disappeared.

a SEM images of i) the Mg microneedle anode and ii) the Mg microneedle cathode after 1 h of insertion into the porcine sample under 0.8 V (scale bar: 100 μm), b SEM images of the Mg microneedle anodes after 1 h of insertion into the porcine samples under the applied potential (scale bar: 100 μm), c H2 generation curve on each pure Mg electrode under the applied potential for 1 h, d schematic illustration of the H2 and H2O2 generation mechanism on each pure Mg electrode

Like other iontophoresis studies, [42, 44] Rhodamine B dye was used to conveniently visualize the electric field effect in this study. However, many the drug molecules have a negative charge, [45, 46] then they would go to the anodes from the cathode during iontophoresis. So, the H2 generation at each Mg electrode was separately measured as shown in Fig. 6c. As the applied voltage increased, the H2 generation at the cathode increased, but much less than that at the anode. For example, the amount of H2 generated on the cathode at 1.6 V was less than that on the anode at 1.2 V. This implies that negatively charged drugs can be delivered using the Mg MNs with applied voltage up to 1.6 V, due to the slow H2 generation rate and cathodic MNs maintaining their shape for 1 h. Hydrogen peroxide (H2O2) was also generated by the Mg corrosion (Figure S6). With the increment of applied voltage, i.e. increased H2 generation, the amount of H2O2 decreased, and this seems to be the pH change by Mg ions (Fig. 6d). [47,48,49,50]

4 Conclusion

In summary, biocompatible and biodegradable Mg electrodes were studied for enhancing TDD by combining MN technology and iontophoresis. The Mg MNs formed microchannels deep enough for drug delivery into the skin. Then, during iontophoresis, the potential levels of Mg and Mg-based alloy were measured and their optimum voltage ranges were established based on the amount of H2 generation. The dye permeation test on the porcine skin samples obviously proved the efficacy of the Mg electrodes for iontophoresis. The dye migrated farther as the applied voltage increased, but the dye transport was hindered by excessive H2 generation and MN corrosion at a high applied voltage, 1.4 V. By analyzing the H2 generation and MN corrosion at each electrode, they clearly indicate that the Mg MNs are adequate for iontophoretic TDD regardless of the polarity of the drugs. In addition, it is expected that this study would serve as an opportunity to further expand the application of biodegradable metals even to various electrochemical applications.

5 Associated Content

Supporting information for this article is given via a link at the end of the document.

References

M.R. Prausnitz, R. Langer, Nat. Biotechnol. 26, 1261 (2008)

A.P. Raphael, M.L. Crichton, R.J. Falconer, S. Meliga, X. Chen, G.J.P. Fernando, H. Huang, M.A.F. Kendall, J. Control. Release 225, 40 (2016)

Y.-H. Park, S.K. Ha, I. Choi, K.S. Kim, J. Park, N. Choi, B. Kim, J.H. Sung, Biotechnol. Bioproc. E. 21, 110 (2016)

S. Indermun, R. Luttge, Y.E. Choonara, P. Kumar, L.C. du Toit, G. Modi, V. Pillay, J. Control. Release 185, 130 (2014)

C. Wiraja, Y. Zhu, D.C.S. Lio, D.C. Yeo, M. Xie, W. Fang, Q. Li, M. Zheng, M. Van Steensel, L. Wang, C. Fan, C. Xu, Nat. Commun. 10, 1147 (2019)

K.B. Vinayakumar, P.G. Kulkarni, M.M. Nayak, N.S. Dinesh, G.M. Hegde, S.G. Ramachandra, K. Rajanna, J. Micromech. Microeng. 26, 065013 (2016)

B.W. Barry, Eur. J. Pharm. Sci. 14, 101 (2001)

E.E.L. Tanner, A.M. Curreri, J.P.R. Balkaran, N.C. Selig-Wober, A.B. Yang, C. Kendig, M.P. Fluhr, N. Kim, S. Mitragotri, Adv. Mater. 31, 1901103 (2019)

K.J. Krieger, N. Bertollo, M. Dangol, J.T. Sheridan, M.M. Lowery, E.D. O’Cearbhaill, Microsyst. Nanoeng. 5, 42 (2019)

W.Y. Jeong, M. Kwon, H.E. Choi, K.S. Kim, Biomater. Res. 25, 24 (2021)

A. Arora, M.R. Prausnitz, S. Mitragotri, Int. J. Pharm. 364, 227 (2008)

M.R. Prausnitz, S. Mitragotri, R. Langer, Nat. Rev. Drug Disc. 3, 115 (2004)

M.R. Prausnitz, Adv. Drug Deliv. Rev. 56, 581 (2004)

C.S. Kolli, J. Xiao, D.L. Parsons, R.J. Babu, Drug Dev. Ind. Pharm. 38, 571 (2012)

Y. Bai, V. Sachdeva, H. Kim, P.M. Friden, A.K. Banga, Ther. Deliv. 5, 525 (2014)

S.-J. Kim, J.-H. Shin, J.-Y. Noh, C.-S. Song, Y.-C. Kim, Drug Deliv. Transl. Res. 6, 486 (2016)

N.D. Singh, A.K. Banga, J. Drug Target. 21, 354 (2013)

P.R. Miller, M. Moorman, R.D. Boehm, S. Wolfley, V. Chavez, J.T. Baca, C. Ashley, I. Brener, R.J. Narayan, R. Polsky, MRS Advances 4, 1417 (2019)

K. Tsuchiya, S. Jinnin, H. Yamamoto, Y. Uetsuji, E. Nakamachi, Precis. Eng. 34, 461 (2010)

E.R. Parker, M.P. Rao, K.L. Turner, N.C. MacDonald, Bulk titanium microneedles with embedded microfluidic networks for transdermal drug delivery, in 19th IEEE International Conference on Micro Electro Mechanical Systems. Istanbul, 22–26 January 2006 (IEEE, Piscataway, 2006), pp. 498–501

E.K. Brooks, R.P. Brooks, M.T. Ehrensberger, Mater. Sci. Eng. C 71, 200 (2017)

J. Yang, J.L. Guo, A.G. Mikos, C. He, G. Cheng, Ann. Biomed. Eng. 46, 1229 (2018)

X. Li, W. Zhang, W. Lin, H. Qiu, Y. Qi, X. Ma, H. Qi, Y. He, H. Zhang, J. Qian, G. Zhang, R. Gao, D. Zhang, J. Ding, ACS Appl. Mater. Interfaces. 12, 15703 (2020)

F. Witte, F. Feyerabend, P. Maier, J. Fischer, M. Störmer, C. Blawert, W. Dietzel, N. Hort, Biomaterials 28, 2163 (2007)

M.J. Pikal, Adv. Drug Deliv. Rev. 46, 281 (2001)

D.S. Bernardi, C. Bitencourt, D.S.C. da Silveira, E.L.C.M. da Cruz, M.A. Pereira-da-Silva, L.H. Faccioli, R.F.V. Lopez, Nanomed. Nanotechnol. Biol. Med. 12, 2439 (2016)

S. Pradeep Narayanan, S. Raghavan, Int. J. of Adv. Manufact. Technol. 104, 3327 (2019)

J. Li, B. Liu, Y. Zhou, Z. Chen, L. Jiang, W. Yuan, L. Liang, PLoS ONE 12, e0172043 (2017)

H.-K. Kim, J.-W. Jang, Met. Mater. Int. 10, 439 (2004)

C.D. Lee, C.S. Kang, K.S. Shin, Met. Mater. Int. 7, 385 (2001)

S. Thomas, N.V. Medhekar, G.S. Frankel, N. Birbilis, Curr. Opin. Solid State Mater. Sci. 19, 85 (2015)

A. Maltseva, V. Shkirskiy, G. Lefèvre, P. Volovitch, Corros. Sci. 153, 272 (2019)

W. Zhang, Q. Liu, Y. Chen, G. Wan, Mater. Lett. 232, 54 (2018)

S. Bender, J. Goellner, A. Heyn, S. Schmigalla, Mater. Corros. 63, 707 (2012)

Y. Pan, S. He, D. Wang, D. Huang, T. Zheng, S. Wang, P. Dong, C. Chen, Mater. Sci. Eng. C 47, 85 (2015)

C. Gong, X. He, X. Yan, Corrosion behavior of Mg–Ca–Zn alloys with high Zn content. J. Phys. Chem. Solids 152, 109952 (2021)

P.-R. Cha, H.-S. Han, G.-F. Yang, Y.-C. Kim, K.-H. Hong, S.-C. Lee, J.-Y. Jung, J.-P. Ahn, Y.-Y. Kim, S.-Y. Cho, J.Y. Byun, K.-S. Lee, S.-J. Yang, H.-K. Seok, Sci. Rep. 3, 2367 (2013)

M.A. Lopez-Ramirez, F. Soto, C. Wang, R. Rueda, S. Shukla, C. Silva-Lopez, D. Kupor, D.A. McBride, J.K. Pokorski, A. Nourhani, N.F. Steinmetz, N.J. Shah, J. Wang, Adv. Mater. 32, 1905740 (2020)

M. Bok, Y. Lee, D. Park, S. Shin, Z.-J. Zhao, B. Hwang, S.H. Hwang, S.H. Jeon, J.-Y. Jung, S.H. Park, J. Nah, E. Lim, J.-H. Jeong, Nanoscale 10, 13502 (2018)

M. Bok, Z.-J. Zhao, S. Jeon, J.-H. Jeong, E. Lim, Sci. Rep. 10, 2027 (2020)

A. Ullah, C.M. Kim, G.M. Kim, Royal Soc. Open Sci. 5, 171609 (2018)

M.J. Garland, E. Caffarel-Salvador, K. Migalska, A.D. Woolfson, R.F. Donnelly, J. Control. Release 159, 52 (2012)

R.R. Burnette, B. Ongpipattanakul, J. Pharm. Sci. 77, 132 (1988)

V. Kumar, A.K. Banga, Int. J. Pharm. 434, 106 (2012)

G. Stagni, M.E. Ali, D. Weng, Int. J. Pharm. 274, 201 (2004)

M. Sznitowska, S. Janicki, Polski Merkur. Lek. 7, 58 (2000)

J. Lim, M.R. Hoffmann, Chem. Eng. J. 374, 958 (2019)

G. Jeong, H.W. Hwang, M. Chae, S.H. Hong, J. Park, Y. Han, H. Jeon, Y.-C. Kim, S.-K. Kang, H.W. Jang, J.-Y. Sun, M.-R. Ok, Langmuir 38, 8003 (2022)

S.Y. Park, Y.W. Jung, S.H. Hwang, G.H. Jang, H. Seo, Y.-C. Kim, M.-R. Ok, Met. Mater. Int. 24, 657 (2018)

K.-M. Moon, H.-R. Cho, M.-H. Lee, S.-K. Shin, S.-C. Koh, Met. Mater. Int. 13, 211 (2007)

Acknowledgements

This work was supported by the grant of the Ministry of Trade, Industry, and Energy of the Korean Government (project no. 10065241), a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT (2020R1A2C2007156), and the Korea Health Technology R&D Project through the Korea Health Industry Development Institute (KHIDI) funded by the Ministry of Health & Welfare, Republic of Korea (grant no. HI17C0471).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jeong, G., Han, HS., Jeon, H. et al. Biodegradable Mg Electrodes for Iontophoretic Transdermal Drug Delivery. Met. Mater. Int. 29, 2084–2092 (2023). https://doi.org/10.1007/s12540-022-01345-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01345-y