Abstract

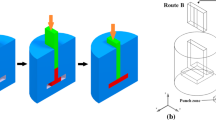

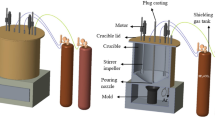

In this study, first, AZ80 magnesium alloy and AZ80/SiC nanocomposite were manufactured through a stir casting approach. Then built samples underwent five passes of DECLE process at a constant temperature of 300 °C. Changes in microstructures, hardness, and tensile strength were measured in the annealed alloy and nanocomposites as well as samples with 1, 3, and 5 passes of DECLE to determine the effects of sic. strengthening nanoparticles and number of the DECLE passes. Results show that there is a most significant decrease in grain size due to adding the nanoparticles. The microstructure of the initial AZ80 samples made by large grains and inhomogeneous structure with an average grain size of 60.3 µm. After five DECEL passes for samples with nanoparticles, the structure is turned into fine and homogenous grains with an average size of 4.5 µm. Along with this decreasing trend in the grain size, hardness shows a 20.7% increasing. The results of the uniaxial tensile test show that yield strength and ultimate tensile strength have increased respectively from 74 to 131.8 MPa for initial samples to 113 and 221.9 MPa in nanocomposites. Finally, their values reach to 191.3 and 288.3 MPa after applying five passes of DECLE process. The results indicate that it is possible to significantly improve the microstructure and mechanical properties of the AZ80 magnesium alloy through enriching by nanoparticles. Using severe plastic deformation processes such as DECLE can induce a further decrease in grain size and significant improvement in the mechanical properties without causing changes in the samples’ dimensions.

Graphic Abstract

Similar content being viewed by others

References

S. Huang, M. Lu, S. Luo, H. He, Y. Yi, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00452-7

E. Maleki, F. Shahri, M. Emamy, Met. Mater. Int. 12, pp. 1–13, (2019)

G. Yarkadaş, H. Şevik, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00560-4

L. Chen, Y. Yao, Acta Metall. Sin. (English Lett. 27, 762 (2014)

K.K. Deng, J.C. Li, J.F. Fan, X.J. Wang, K. Wu, B.S. Xu, Acta Metall. Sin. (English Lett. 27, 885 (2014)

M. Gupta, W.L.E. Wong, Mater. Charact. 105, 30 (2015)

B. Saleh, J. Jiang, A. Ma, D. Song, D. Yang, Q. Xu, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00491-0

J. Zhao, J. Fu, B. Jiang, A. Tang, H. Sheng, T. Yang, G. Huang, D. Zhang, F. Pan, Met. Mater. Int. 19, pp. 1–3, (2019)

J. Kubásek, D. Dvorský, J. Veselý, P. Minárik, M. Zemková, D. Vojtěch, Acta Metall. Sin. (English Lett. 32, 321 (2019)

Y. Huang, T.G. Langdon, Mater. Today 16, 85 (2013)

V.V. Popov, E.N. Popova, Mater. Trans. 60, 1209 (2019)

X.G. Qiao, T. Ying, M.Y. Zheng, E.D. Wei, K. Wu, X.S. Hu, W.M. Gan, H.G. Brokmeier, I.S. Golovin, Mater. Charact. 121, 222 (2016)

K.B. Nie, K.K. Deng, X.J. Wang, T. Wang, K. Wu, Mater. Charact. 124, 14 (2017)

W. Liao, B. Ye, L. Zhang, H. Zhou, W. Guo, Q. Wang, W. Li, Mater. Sci. Eng. A 642, 49 (2015)

R.B. Figueiredo, T.G. Langdon, Mater. Sci. Eng. A 503, 141 (2009)

S.M. Masoudpanah, R. Mahmudi, Mater. Des. 31, 3512 (2010)

A. Heczel, F. Akbaripanah, M.A. Salevati, R. Mahmudi, Á Vida, J. Gubicza, J. Alloys Compd. 763, 629 (2018)

B. Talebanpour, R. Ebrahimi, K. Janghorban, Mater. Sci. Eng. A 527, 141 (2009)

B. Talebanpour, R. Ebrahimi, Mater. Des. 30, 1484 (2009)

W. Guo, Q.D. Wang, B. Ye, M.P. Liu, T. Peng, X.T. Liu, H. Zhou, Mater. Sci. Eng. A 540, 115 (2012)

F. Fereshteh-Saniee, N. Fakhar, F. Karami, R. Mahmudi, Mater. Sci. Eng. A 673, 450 (2016)

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, T.G. Langdon, Scr. Mater. 35, 143 (1996)

N. Fakhar, F. Fereshteh-Saniee, R. Mahmudi, Trans. Nonferrous Met. Soc. China 26, 3081 (2016)

ASTM E384-17, A.S.T.M. Int. West Conshohocken, PA (2017). https://doi.org/10.1520/E0384-17

A. Matin, F. Saniee, H.R. Abedi, Mater. Sci. Eng. A 625, 81 (2015)

H. Khoshzaban Khosroshahi, F. Saniee, H.R. Abedi, Mater. Sci. Eng. A 595, 284 (2014)

H.Z. Ye, X.Y. Liu, J. Mater. Sci. 39, 6153 (2004)

V.V. Popov, E.N. Popova, A.V. Stolbovskiy, Mater. Sci. Eng. A 539, 22 (2012)

J. Bai, F. Xue, S.N. Alhajeri, T.G. Langdon, Mater. Sci. Forum 667–669, 391 (2010)

S.A. Alsubaie, Y. Huang, T.G. Langdon, J. Mater. Res. Technol. 6, 378 (2017)

S.M. Masoudpanah, R. Mahmudi, Mater. Sci. Eng. A 526, 22 (2009)

R. Seifi, M.A. Kazemi, Fatigue Fract. Eng. Mater. Struct. 41, 1758 (2017)

S. Sankaranarayanan, R.K. Sabat, S. Jayalakshmi, S. Suwas, A. Almajid, M. Gupta, J. Compos. Mater. 49, 3045 (2015)

P. Chen, Y. Sun, J. Jiang, A. Ma, Q. Lv, Chinese J. Nonferrous Met. 12, 140 (2002)

W.L.E. Wong, M. Gupta, Adv. Eng. Mater. 8, 735 (2006)

M. De Cicco, H. Konishi, G. Cao, H. Choi, L.-S. Turng, J.H. Perepezko, S. Kou, R. Lakes, X. Li, Metall. Mater. Trans. A 40, 3038 (2009)

E.O. Hall, Proc. Phys. Soc. Sect. B 64, p. 747, (1951).

N.J. Petch, J. Iron Steel Inst. 174, 25 (1953)

Z. Zhang, D.L. Chen, Scr. Mater. 54, 1321 (2006)

D.P. Mondal, N.V. Ganesh, V.S. Muneshwar, S. Das, N. Ramakrishnan, Mater. Sci. Eng. A 433, 18 (2006)

Z. Zhang, D.L. Chen, Mater. Sci. Eng. A 483–484, 148 (2008)

F.-D. Dumitru, O.F. Higuera-Cobos, J.M. Cabrera, Mater. Sci. Eng. A 594, 32 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salevati, M.A., Imam, A., Seifi, R. et al. Investigating the Microstructure, Hardness and Tensile Behavior of Magnesium AZ80 Alloy and AZ80/SiC Nanocomposite Manufactured Through Dual Equal Channel Lateral Extrusion (DECLE). Met. Mater. Int. 27, 3538–3549 (2021). https://doi.org/10.1007/s12540-020-00694-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00694-w