Abstract

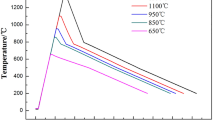

In this study, heat affected zone (HAZ) specimens were fabricated by applying flux-cored arc welding (FCAW) and submerged arc welding (SAW) processes to steel plate with a thickness of 100 mm and yield strength of 460 MPa for use in offshore platforms. The correlation between microstructure and Charpy absorbed energy was investigated, and fracture mechanisms were analyzed. As distance from the fusion line increases, heat input and cooling rate decrease, making it difficult to form low-temperature transformation microstructures in HAZ specimens and increasing the grain size of quasi-polygonal ferrite. The FCAW process is advantageous for low-temperature transformation microstructures because it has a lower heat input and a faster cooling rate than the SAW process. Plastic deformation and ductile fracture occurred at low temperatures in fine acicular ferrite and quasi-polygonal ferrite regions of HAZ specimens, but brittle fractures occurred in bainitic ferrite, granular bainite, and coarse quasi-polygonal ferrite regions. The unit crack path in the brittle fracture region was similar to the grain size. In other words, as the volume fraction of fine acicular ferrite and quasi-polygonal ferrite increased in HAZ specimens, Charpy absorbed energy at low temperature increased.

Graphic Abstract

-

100 mm thick steel plate with yield strength of 460 MPa for offshore platforms is fabricated by TMCP.

-

The SAW and FCAW HAZ specimens are consisted of AF, QPF, and small amounts of GB, BF, and secondary phases. Secondary phases are evenly distributed of the HAZ specimens. So the average Charpy absorbed energy at − 20 °C of the SAW and FCAWHAZ are very high at 100 and 230 J, respectively.

-

Plastic deformation occurred around the AF grain, leading to ductile fracture, while brittle fracture occurred without plastic deformation around the BF and GB grains, resulting in long unit crack paths.

Similar content being viewed by others

References

T. Araki, Atlas for Bainitic Microstructures (ISIJ, Tokyo, 1992), pp. 1−100

H.K.D.H. Bhadeshia, Mater. Sci. Eng. A378, 34 (2004)

G. Huang, K.M. Wu, Met. Mater Int. 17, 847 (2011)

C. Yu, T.C. Yang, C.Y. Huang, R.K. Shiue, Metall. Mater. Trans. A 47A, 4777 (2016)

Offshore Standard, Metallic materials, DNV-GL-OS-B101. (DNVGL, Norway, 2015), pp. 1–69

X. Di, M. Tong, C. Li, C. Zhao, D. Wang, Mater. Sci. Eng. A 743, 67 (2019)

B. Hwang, C.G. Lee, S.J. Kim, Metall. Mater. Trans. A 42A, 717 (2011)

Y.T. Shin, H.W. Lee, Met. Mater Int. 18, 863 (2012)

J.S. Lee, S.H. Jeong, D.Y. Lim, J.O. Yun, M.H. Kim, Met. Mater Int. 16, 827 (2012)

C. Pandey, M.M. Mahapatra, P. Kumar, A. Giri, Met. Mater Int. 23, 900 (2017)

Z. Yao, G. Xu, Z. Jiang, J. Tian, Q. Yuan, H. Ma, Met. Mater Int. 25, 1151 (2019)

Design of Offshore Steel Structures, General-LRFD method, DNVGL-OS-C101 (DNVGL, Norway, 2011), pp. 1–85

J. Moon, S.-J. Kim, C. Lee, Mater. Sci. Eng. A 528, 7658 (2011)

X. Li, Y. Fan, X. Ma, S.V. Subramanian, C. Shang, Mater. Des. 67, 457 (2015)

Y. You, C. Shang, L. Chen, S. Subramanian, Mater. Des. 43, 485 (2013)

V.G. Haugen, B.R.S. Rogne, O.M. Akselsen, C. Thaulow, Mater. Des. 59, 135 (2014)

I. Kim, H. Nam, M. Lee, D. Nam, Y. Park, N. Kang, Metals 8, 638 (2018). https://doi.org/10.3390/met8080638

X.J. Di, X. An, F.J. Cheng, D.P. Wang, X.J. Guo, Sci. Technol. Weld. Join. 21, 366 (2016)

AWS Welding Handbook, Welding process part 1. (American Welding Society, Miami, 1997), pp. 1–680

O.M. Akselsen, J.K. Solberg, O. Grong, Scand. J. Metall. 17, 194 (1988)

H.U. Hong, J. Weld. Join. 28, 4 (2010)

I. Hwang, H. Yun, D. Kim, M. Kang, Y.-M. Kim, Met. Mater Int. 24, 149 (2018)

I. Tamura, H. Sekine, T. Tanaka, C. Ouchi, Thermomechanical Processing of High-Strength Low-Alloy Steels (Butterworth-Heinemann, Oxford, 1988), pp. 80–100

S.W. Thompson, D.J. Colvin, G. Krauss, Metall. Mater. Trans. A 21A, 1493 (1990)

G. Krauss, S.W. Thompson, ISIJ Int. 35, 937 (1995)

H.K.D.H. Bhadeshia, Mater. Sci. Eng. A A378, 34 (2004)

C. Capdevila, F.G. Caballero, C. Garcia de Andres, ISIJ Int. 42, 894 (2003)

K.W. Andrew, J. Iron Steel Inst. 203, 721 (1965)

C.Y. Kung, J.J. Raymond, Metall. Trans. 13A, 328 (1982)

H. Ohtani, S. Okaguchi, Y. Fujishiro, Y. Ohmori, Metall. Trans. A 21A, 877 (1990)

M. Diaz-Fuentes, A. Iza-Mendia, I. Gutierrez, Metall. Mater. Trans. A 34A, 2505 (2003)

Y.M. Kim, S.Y. Shin, H. Lee, B. Hwang, S. Lee, N.J. Kim, Metall. Mater. Trans. 38A, 1731 (2007)

D. Deng, S. Kiyoshima, Comput. Mater. Sci. 62, 23 (2012)

H. Qiu, M. Enoki, Y. Kawaguchi, T. Kishi, ISIJ Int. 40, 34 (2000)

Acknowledgements

This work was supported by a Korea Evolution Institute of Industrial Technology (KEIT) grant funded by the Korean government (MOTIE) (No. 10063532, Development of steel application technologies against ice-induced crashworthiness and arctic temperature high toughness). This work was partly supported by a Korea Institute for Advancement of Technology (KIAT) grant funded by the Korean government (MOTIE) (No. P0002007, The Competency Development Program for Industry Specialist).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, D., Lee, H., Cho, SK. et al. Microstructure and Charpy Impact Properties of FCAW and SAW Heat Affected Zones of 100 mm Thick Steel Plate for Offshore Platforms. Met. Mater. Int. 26, 867–881 (2020). https://doi.org/10.1007/s12540-020-00626-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00626-8