Abstract

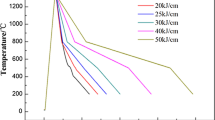

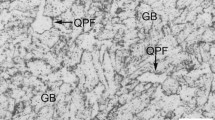

The objective of this paper is to study the effect of peak temperature on the microstructure and impact toughness property in the simulated heat-affected zones (HAZs) of American Petroleum Institute (API) X90 pipeline steel. Simulated HAZs were produced at different peak temperatures (Tp) from 650 to 1350 °C with a heat input of 25 kJ/cm. With a decreasing Tp, the grains become significantly refined, and the granular bainite (GB) increases at the expense of lath bainite (LB). When the peak temperature is 1350 °C, the crack initiator martensite/austenite (M/A) constituents are coarse and distribute along the prior austenite grain boundaries with a short rod-shaped morphology, while the coarse grain heat-affected zone (CGHAZ) has the lowest impact energy of 269.67 J. The subcritical HAZ (Tp=650 °C) has a similar microstructure to the base material and has the best impact energy of 336.33 J. When Tp = 950 °C, LB disappears, and the grains become refined due to complete recrystallization, resulting in a higher toughness property than that at Tp = 850 °C. The lowest microhardness occurs at Tp = 850 °C because of the coarsening of precipitates and some PF.

Similar content being viewed by others

Data Availability

All data generated or used during the study are included in the submitted article.

References

L. Lan, Z. Chang, X. Kong et al., Phase transformation, Microstructure, and Mechanical Properties of X100 Pipeline Steels Based on TPCP and HTP Concepts, J. Mater. Sci., 2017, 52, p 1661–1678.

X. Wang, X. Li, S. Wu et al., Effect of austenitic state on the multi-phase control in X90 pipeline steel with high Nb content, Mater. Today: Proc., 2015, 2, p S701–S706.

G. Yuan, W. Hu, X. Wang et al., The relationship between microstructure, crystallographic orientation, and fracture behavior in a high strength ferrous alloy, J. Alloy Compd., 2017, 695, p 526–539.

M.C. Zhao, K. Yang and Y. Shan, The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel, Mater. Sci. Eng. A, 2002, 335(1–2), p 14–20.

I.D.S. Bott, L.F.G.D. Souza, J.C.G. Teixeira et al., High-strength steel development for pipelines: a brazilian perspective, Metall. Mater. Trans. A, 2005, 36(2), p 443–454.

J.Y. Yoo, S.S. Ahn, D.H. Seo et al., New development of high grade X80 to X120 pipeline steels, Mater. Manuf. Process, 2011, 26, p 154–160.

W. Zhao, W. Wang, S. Chen et al., Effect of simulated welding thermal cycle on microstructure and mechanical properties of X90 pipeline steel, Mater. Sci. Eng. A, 2011, 528, p 7417–7422.

B. Wang, L. Wang, Y. Jiang et al., Microstructure and mechanical behavior of X90 bend using local induction bending, T. Indian I. Metals, 2017, 70(1), p 1–10.

L. Wang, B. Wang and P. Zhou, Misorientation, grain boundary, texture and recrystallization study in X90 hot bend related to mechanical properties, Mater. Sci. Eng .A, 2018, 711, p 588–599.

C. Li, Y. Wang, T. Han et al., Microstructure and toughness of coarse grain heataffected zone of domestic X70 pipeline steel during in-service welding, J. Mater. Sci., 2011, 46, p 727–733.

A. Lambert-Perlade, T. Sturel, A.F. Gourgues et al., Mechanisms and modeling of cleavage fracture in simulated heat-affected zone microstructures of high-strength low alloy steel, Metall. Mater. Trans. A, 2004, 35, p 1039–1053.

K. Poorhaydari and D.G. Ivey, Precipitate alterations in the heat-affected zone of a Grade 100 microalloyed steel, J Mater Sci, 2011, 46, p 4953–4963.

T. Gladman, Physical Metallurgy of Microalloyed Steels, Cambridge University Press, Cambridge, 1997, p 218

S.H.M. Anijdan and S. Yue, The effect of cooling rate, and cool deformation through strain induced transformation, on microstructural evolution and mechanical properties of microalloyed steels, Metall. Mater. Trans A, 2012, 43, p 1140–1162.

H.F. Lan, L.X. Du, Q. Li et al., Improvement of strength-toughness combination in austempered low carbon bainitic steel: the key role of refining prior austenite grain size, J. Alloy. Compd., 2017, 710, p 702–710.

B. Guo, F. Lei, Q. Wang et al., The role of the bainitic packet in control of impact toughness in a simulated CGHAZ of X90 pipeline steel, Metals., 2016, 6(11), p 256.

P. Zhou, B. Wang, L. Wang et al., Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel, Mater. Sci. Eng. A, 2018, 722, p 112–121.

S. Moeinifar, A.H. Kokabi and H.R.M. Hosseini, Effect of tandem submerged arc welding process and parameters of Gleeble simulator thermal cycles on properties of the intercritically reheated heat affected zone, Mater. Des., 2011, 32, p 869–876.

S. Moeinifar, A.H. Kokabi and H.R.M. Hosseini, Influence of peak temperature during simulation and real thermal cycles on microstructure and fracture properties of the reheated zones, Mater. Des., 2010, 31, p 2948–2955.

C. Li, Y. Wang and Y. Chen, Influence of peak temperature during in-service welding of api x70 pipeline steels on microstructure and fracture energy of the reheated coarse grain heat-affected zones, J. Mater. Sci., 2011, 46, p 6424–6431.

H. Xie, L.X. Du, J. Hu et al., Effect of thermo-mechanical cycling on the microstructure and toughness in the weld CGHAZ of a novel high strength low carbon steel, Mater. Sci. Eng .A, 2015, 639, p 482–488.

J.F. Lancaster, Metallurgy of Welding, 3rd ed. George Allen & Unwin, London, 1954.

J.C. Lippold, Welding Metallurgy and Weldability, Wiley, Hoboken, 2015.

H.K. Sung, D.H. Lee, S.Y. Shin et al., Effect of finish cooling temperature on microstructure and mechanical properties of high-strength bainitic steels containing Cr, Mo, and B, Mater. Sci. Eng. A, 2015, 624, p 14–22.

S.D. Bhole, J.B. Nemade, L. Collins and C. Liu, Effect of nickel and molybdenum additions on weld metal toughness in a submerged arc welded HSLA line-pipe steel, J. Mater. Process Tech., 2006, 173(1), p 92–100.

H.S. Zurob, G. Zhu, S.V. Subramanian et al., Analysis of the effect of Mn on the recrystallization kinetics of high Nb steel: an example of physically-based alloy design, Transactions Iron Steel Inst. Jpn., 2005, 45(5), p 713–722.

M. Díaz-Fuentes, A. Iza-Mendia and I. Gutiérrez, Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction Study of their toughness behavior, Metall. Mater. Trans. A., 2003, 34(11), p 2505–2516.

S. Shanmugam, N.K. Ramisetti, R.D.K. Misra et al., Microstructure and high strength-toughness combination of a new 700 MPa Nb-microalloyed pipeline steel, Mater. Sci. Eng. A, 2008, 478, p 26–37.

Y.T. Shin, S.W. Kang and H.W. Lee, Fracture characteristics of TPCP and QT steel weldments with respect to crack length, Mater. Sci. Eng. A, 2006, 434(1), p 365–371.

B. Hwang, G.K. Yang, S. Lee et al., Effective grain size and charpy impact properties of high-toughness X70 pipeline steels, Metall. Mater. Trans. A, 2005, 36(8), p 2107–2114.

W.B. Lee, S.G. Hong, C.G. Park et al., Influence of Mo on precipitation hardening in hot rolled HSLA steels containing Nb, Scr Mater, 2000, 43, p 319–324.

J. Hu, L.X. Du, H. Xie et al., Effect of weld peak temperature on the microstructure, hardness, and transformation kinetics of simulated heat affected zone of hot rolled ultra-low carbon high strength Ti–Mo ferritic steel, Mater. Des., 2014, 60, p 302–309.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, L., Zhou, P., Hu, Y. et al. Microstructure and Impact Toughness Property of API X90 Heat-Affected Zones at Different Peak Temperatures. J. of Materi Eng and Perform 30, 5787–5798 (2021). https://doi.org/10.1007/s11665-021-05827-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05827-9