Abstract

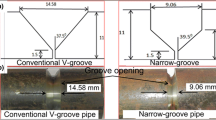

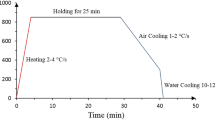

The effect of weld groove design and heat treatment on microstructure evolution and Charpy toughness of P91 pipe weldments was studied. The P91 pipe weldments were subjected to subcritical post weld heat treatment (760 °C-2 h) and normalizing/tempering conditions (normalized-1040 °C/40 min, air cooled; tempered 760 °C/2 h, air cooled) were employed. The influence of subsequent PWHT and N&T treatment on the microstructure of various zone of P91 pipe weldments were also investigated. The present investigation also described the effect of PWHT and N&T treatment on hardness, grain size, precipitate size, inter-particle spacing and fraction area of precipitates present in each zone of P91 pipe weldments. The result indicated great impact of heat treatment on the Charpy toughness and microstructure evolution of P91 weldments. The N&T treatment was found to be more effective heat treatment compared to subsequent PWHT. Charpy toughness value was found to be higher for narrow-groove design as compared to conventional V-groove design.

Similar content being viewed by others

References

V. T. Paul, S. Saroja, and M. Vijayalakshm, J. Nucl. Mater. 378, 273 (2008).

B. S. Dutt, M. N. Babu, G. Shanthi, S. Venugopal, G. Sasikala, and A. K. Bhaduri, J. Nucl. Mater. 421, 15 (2012).

T. Shrestha, M. Basirat, I. Charit, G. P. Potirniche, K. K. Rink, and U. Sahaym, J. Nucl. Mater. 423, 110 (2012).

C. Pandey, A. Giri, and M. M. Mahapatra, Mat. Sci. Eng. A 664, 58 (2016).

P. K. Parida, A. Gupta, and S. Saibaba, J. Nucl. Mater. 432, 450 (2013).

M. E. Angiolini, G. Aiello, P. Matheron, L. Pilloni, and G. M. Giannuzzi, J. Nucl. Mater. 472, 215 (2016).

C. Pandey and M. M. Mahapatara, J. Mater. Eng. Perform. 25, 2195 (2016).

B. Silwal, L. Li, A. Deceuster, and B. Griffiths, Weld. J. 91, 80 (2013).

T. Watanabe, M. Tabuchi, M. Yamazaki, H. Hongo, and T. Tanabe, Int. J. Pres. Ves. Pip. 83, 63 (2006).

B. Arivazhagan, S. Sundaresan, and M. Kamaraj, J. Mater. Process. Tech. 209, 524 (2009).

C. Pandey, N. Saini, M. M. Mahapatra, and P. Kumar, Int. J. Hydrogen Energ. 41, 17695 (2016).

C. Pandey and M. M. Mahapatra, J. Mater. Eng. Perform. 25, 2761 (2016).

S. Spigrarelli and E. Quadrini, Mater. Design 23, 547 (2002).

M. E. Abd El-Azim, O. E. El-Desoky, H. Ruoff, F. Kauffmann, and E. Ross, Mater. Sci. Tech. 29, 1027 (2013).

M. Abd El-Rahman Abd El-Salam, I. El-Mahallawi, and M. R. El-Koussy, Int. Heat Treatment Surface Eng. 7, 32 (2013).

G. C. Bodine, C. Chakravarti, C. M. Owens, B. W. Roberts, D. M. Vandergriff, and C. T. Ward, ORNL/Sub-4291/1, TRMCD-015, Oak Ridge National Laboratory, USA (1977).

M. L. Santella, R. W. Swindeman, R. W. Reed, and J. M. Tanzosh, Martensite Formation in 9 Cr-1 Mo Steel Weld Metal and Its Effect on Creep Behavior, http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.526.9089&rep=rep1&type=pdf (accessed June 23, 2017).

W. F. Newell, Weld J. 89, 33 (2001).

M. L. Santella, R. W. Swindeman, R. W. Reed, and J. M. Tanzosh, Proc. 6th Int. Conf. on:Trends in Welding Research, pp.713–718, ASM International. EPRI, USA (2002).

M. Sireesha, S. Sundaresan, and S. K. Albert, J. Mater. Eng. Perform. 10, 320 (2001).

C. Pandey, A. Giri, M. M. Mahapatra, and P. Kumar, Met. Mater. Int. 23, 148 (2017).

C. Pandey, A. Giri, and M. M. Mahapatra, Mat. Sci. Eng. A 657, 173 (2016).

C. Pandey and M. M. Mahapatra, P. I. Mech. E, DOI: 10.1177/0954408916656678 (2016).

Y. Wang, R. Kannan, and L. Li, Mater. Charact. 118, 225 (2016).

P. Mayr and H. Cerjak, T. Indian I. Metals 63, 131 (2010).

D. A. Porter and K. E. Esterling, Introduction to the Physical Metallurgy of Welding, 2ed., pp.1–11, Chapmanand Hall, London, UK (1991).

T. Kojima, K. Hayashi, and Y. Kajita, ISIJ Int. 35, 1284 (1995).

C. Pandey and M. M. Mahapatra, T. Indian I. Metals 69, 1657 (2016).

C. Pandey, M. M. Mahapatra, P. Kumar, and N. Saini, Mat. Sci. Eng. A 685, 39 (2017).

B. Arivazhagan and B. kamraj, A Study on Influence of d- Ferrite Phase on Toughness of P91 Steel Welds, https://www.steel-grips.com/articles/2013/sg13004.pdf (accessed July, 14, 2017).

Y. Silwal, L. Li, A. Deceuster, and B. Griffiths, Weld. J. 92, 80 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, C., Mahapatra, M.M., Kumar, P. et al. Microstructure characterization and charpy toughness of P91 weldment for as-welded, post-weld heat treatment and normalizing & tempering heat treatment. Met. Mater. Int. 23, 900–914 (2017). https://doi.org/10.1007/s12540-017-6850-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6850-2