Abstract

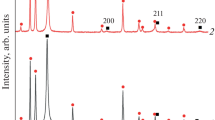

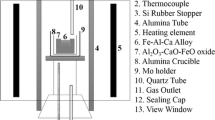

This study investigates the cracking behavior of oxide layers formed on molten metals and alloys including pure zinc, Zn–4 wt%Al (ZAMAK3) and Al–(0.5–2) wt%Ca in dynamic oxidation condition by injecting gas bubbles into the molten metal during the pouring process. The crack characteristics of the oxide layers were studied using a field emission scanning electron microscope. The results show that various stresses initiated from turbulence flow in the molten metal promote the deformation of the oxide layer, particularly at the initial stages of oxidation. Different coefficients of thermal expansion of the oxide layers and the metals can also result in deformation/cracking the oxide layers. Simultaneous aspiration of the molten metal and solidification phenomenon within the casting process may lead to various morphological changes, e.g. folded-, wrinkled- and cracked-oxide layers. In addition, a splitting and reforming phenomenon of multiple oxide layers is observed, called as strips of ‘ruffled tape’. An illustrative mechanism is suggested and discussed quantitatively for the formation of such phenomena. It is assumed that the unique appearance of these strips depends on the formation time and complex stress gradients on the oxide layers.

Graphic Abstract

Similar content being viewed by others

References

J. Campbell, Complete Casting Handbook (Butterworth-Heinemann, Oxford, 2011)

M. Tiryakioğlu, J. Campbell, C. Nyahumwa, Fracture surface facets and fatigue life potential of castings. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 42(6), 1098–1103 (2011)

G.E. Bozchaloei, N. Varahram, P. Davami, S.K. Kim, Effect of oxide bifilms on the mechanical properties of cast Al–7Si–0.3Mg alloy and the roll of runner height after filter on their formation. Mater. Sci. Eng. A 548, 99–105 (2012)

J. Campbell, An overview of the effects of bifilms on the structure and properties of cast alloys. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 37(6), 857–863 (2006)

J. Mi, R. Harding, J. Campbell, Effects of the entrained surface film on the reliability of castings. Metall. Mater. Trans. A 35(9), 2893–2902 (2004)

C. Nayhumwa, N. Green, J. Campbell, Influence of casting technique and hot isostatic pressing on the fatigue of an Al–7Si–Mg alloy. Metall. Mater. Trans. A 32(2), 349–358 (2001)

J. Campbell, Sixty years of casting research. Metall. Mater. Trans. A 46(11), 4848–4853 (2015)

K. Haberl, P. Schumacher, G. Geier, B. Stauder, Characterization of the melt quality and impurity content of an LM25 alloy. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 40(6), 812 (2009)

W. Griffiths, R. Raiszadeh, Hydrogen, porosity and oxide film defects in liquid Al. J. Mater. Sci. 44(13), 3402–3407 (2009)

D. Dispinar, S. Akhtar, A. Nordmark, M. Di Sabatino, L. Arnberg, Degassing, hydrogen and porosity phenomena in A356. Mater. Sci. Eng. A 527(16–17), 3719–3725 (2010)

D. Dispinar, J. Campbell, Critical assessment of reduced pressure test. Part 1: porosity phenomena. Int. J. Cast Metals Res. 17(5), 280–286 (2004)

D. Dispinar, J. Campbell, Porosity, hydrogen and bifilm content in Al alloy castings. Mater. Sci. Eng. A 528(10–11), 3860–3865 (2011)

R. Raiszadeh, W.D. Griffiths, The effect of holding liquid aluminum alloys on oxide film content. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 42(1), 133–143 (2011)

X. Cao, J. Campbell, Effect of precipitation of primary intermetallic compounds on tensile properties of cast Al–11.5Si–0.4Mg alloy, in Transactions of the American Foundry Society and the 104th Annual Castings Congress (2000), pp. 391–400

X. Cao, J. Campbell, The nucleation of Fe-rich phases on oxide films in Al–11.5Si–0.4Mg cast alloys. Metall. Mater. Trans. A 34(7), 1409–1420 (2003)

X. Cao, J. Campbell, The solidification characteristics of Fe-rich intermetallics in Al–11.5 Si–0.4Mg cast alloys. Metall. Mater. Trans. A 35(5), 1425–1435 (2004)

L. Lu, A. Dahle, Iron-rich intermetallic phases and their role in casting defect formation in hypoeutectic Al–Si alloys. Metall. Mater. Trans. A 36(3), 819–835 (2005)

B. Nayebi, M. Divandari, Characteristics of dynamically formed oxide films on molten aluminum. Int. J. Cast Metals Res. 25(5), 270–276 (2012)

B. Nayebi, A. Bahmani, M.S. Asl, A. Rasooli, M.G. Kakroudi, M. Shokouhimehr, Characteristics of dynamically formed oxide films in aluminum–calcium foamable alloys. J. Alloys Compd. 655, 433–441 (2016)

M. Syvertsen, Oxide skin strength on molten aluminum. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 37(3), 495–504 (2006)

C. Garcia-Cordovilla, E. Louis, A. Pamies, The surface tension of liquid pure aluminium and aluminum-magnesium alloy. J. Mater. Sci. 21(8), 2787–2792 (1986)

S. Impey, D. Stephenson, J. Nicholls, Mechanism of scale growth on liquid aluminum. Mater. Sci. Technol. 4(12), 1126–1132 (1988)

J. Campbell, Entrainment defects. Mater. Sci. Technol. 22(2), 127–145 (2006)

B. Nayebi, M. Mehrabian, M.S. Asl, M. Shokouhimehr, Nanostructural approach to the thickening behavior and oxidation of calcium-stabilized aluminum foams. Mater. Chem. Phys. 220, 351–359 (2018)

M. Mehrabian, B. Nayebi, D. Dietrich, T. Lampke, M. Shokouhimehr, Characteristics of dynamically-formed surface oxide layers on molten zinc–aluminum alloys: a multimodality approach. Thin Solid Films 667, 34–39 (2018)

V. Tolpygo, D. Clarke, Wrinkling of α-alumina films grown by oxidation—II. Oxide separation and failur0065. Acta Mater. 46(14), 5167–5174 (1998)

R. Huang, Kinetic wrinkling of an elastic film on a viscoelastic substrate. J. Mech. Phys. Solids 53(1), 63–89 (2005)

G. Wightman, D. Fray, The dynamic oxidation of aluminum and its alloys. Metall. Trans. B 14, 625–631 (1983)

A. Berman, M. Epstein, The kinetics of hydrogen production in the oxidation of liquid zinc with water vapor. Int. J. Hydrogen Energy 25(10), 957–967 (2000)

C. Nyahumwa, N. Green, J. Campbell, Effect of mold-filling turbulence on fatigue properties of cast aluminum alloys. Trans. Am. Foundrymen. Soc. 106, 215–224 (1998)

R. Raiszadeh, W. Griffiths, A method to study the history of a double oxide film defect in liquid aluminum alloys. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 37, 865–871 (2006)

R. Raiszadeh, W. Griffiths, A semi-empirical mathematical model to estimate the duration of the atmosphere within a double oxide film defect in pure aluminum alloy. Trans. B Process Metall. Mater. Process. Sci. 39(2), 298–303 (2008)

M. Aryafar, R. Raiszadeh, A. Shalbafzadeh, Healing of double oxide film defects in A356 aluminium melt. J. Mater. Sci. 45, 3041–3051 (2010)

F.N. Bakhtiarani, R. Raiszadeh, Healing of double-oxide film defects in commercial purity aluminum melt. Trans. B Process Metall. Mater. Process. Sci. 42(2), 331–340 (2011)

S. Amirinejhad, R. Raiszadeh, H. Doostmohammadi, Study of double oxide film defect behaviour in liquid Al–Mg alloys. Int. J. Cast Metals Res. 26(6), 330–338 (2013)

N. Bakhtiarani, R. Raiszadeh, The behaviour of double oxide film defects in Al–4.5wt%Mg melt. J. Mater. Sci. 46(5), 1305–1315 (2011)

F. Khaleghifar, R. Raiszadeh, H. Doostmohammadi, Effect of Ca on the behavior of double oxide film defects in commercially pure aluminum melt. Trans. B Process Metall. Mater. Process. Sci. 46(2), 1044–1051 (2015)

J. Liu, Q. Wang, Y. Qi, Atomistic simulation of the formation and fracture of oxide bifilms in cast aluminum. Acta Mater. 164, 673–682 (2019)

A. Mirak, C. Davidson, J. Taylor, Characterization of fresh surface oxidation films formed on pure molten magnesium in different atmospheres. Corros. Sci. 52(6), 1992–2000 (2010)

H.N. Yoshimura, A.L. Molisani, N.E. Narita, J.L.A. Manholetti, J.M. Cavenaghi, Mechanical properties and microstructure of zinc oxide varistor ceramics, in Materials Science Forum, ed. by L. Salgado, F. Ambrozio Filho (Trans Tech Publications, Stäfa, 2006), pp. 408–413. https://doi.org/10.4028/www.scientific.net/MSF.530-531.408

S.M.A. Azaramehr, M. Divandari, S.H. Arabi, Investigation on thickness of short time oxide films in Al–1Mg and Al–2Mg alloys. Mater. Sci. Technol. 28(11), 1295–1300 (2012)

Acknowledgements

The authors would like to thank Prof. John Campbell (University of Birmingham) for his valuable comments. Moreover, we are also grateful to Hafez Amani (Ph.D. candidate at Amirkabir University of Technology, Tehran, Iran) for his assistance on simulation study.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehrabian, M., Nayebi, B., Bahmani, A. et al. Deformation, Cracking and Fracture Behavior of Dynamically-Formed Oxide Layers on Molten Metals. Met. Mater. Int. 27, 1701–1712 (2021). https://doi.org/10.1007/s12540-019-00537-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00537-3