Abstract

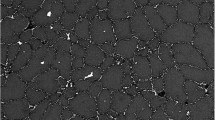

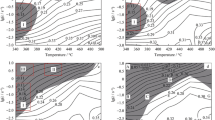

High temperature compression tests for newly developed Al–Zn–Mg alloy were carried out to investigate its hot deformation behavior and obtain deformation processing maps. In the compression tests, cylindrical specimens were deformed at high temperatures (300–500 °C) and strain rates of 0.001–1/s. Using the true stress–true strain curves obtained from the compression tests, processing maps were constructed by evaluating the power dissipation efficiency map and flow instability map. The processing map can be divided into three areas according to the microstructures of the deformed specimens: instability area with flow localization, instability area with mixed grains, and stable area with homogeneous grains resulting from continuous dynamic recrystallization (CDRX). The results suggest that the optimal processing conditions for the Al–Zn–Mg alloy are 450 °C and a strain rate of 0.001/s, having a stable area with homogeneous grains resulting from CDRX.

Similar content being viewed by others

References

W. Miller, L. Zhuang, J. Bottema, A. Wittebrood, P. De Smet, A. Haszler, A. Vieregge, Mater. Sci. Eng. A 280, 37 (2000)

M. Kleiner, S. Chatti, A. Klaus, J. Mater. Process. Technol. 177, 2 (2006)

M. Rokni, A. Zarei-Hanzaki, A.A. Roostaei, H. Abedi, Mater. Des. 32, 2339 (2011)

W. Lee, W. Sue, C. Lin, C. Wu, J. Mater. Process. Technol. 100, 116 (2000)

E. Di Russo, M. Conserva, M. Buratti, F. Gatto, Mater. Sci. Eng. 14, 23 (1974)

H. Zhang, N. Jin, J. Chen, Trans. Nonferrous Metals Soc. China 21, 437 (2011)

Y. Jia, F. Cao, S. Guo, P. Ma, J. Liu, J. Sun, Mater. Des. 53, 79 (2014)

M. Gavgali, B. Aksakal, Mater. Sci. Eng. A 254, 189 (1998)

Y. Prasad, H. Gegel, S. Doraivelu, J. Malas, J. Morgan, K. Lark, D. Barker, Metall. Trans. A 15, 1883 (1984)

O. Sivakesavam, Y. Prasad, Mater. Sci. Eng. A 362, 118 (2003)

Y. Prasad, K. Rao, Mater. Sci. Eng. A 391, 141 (2005)

Y. Prasad, T. Seshacharyulu, Mater. Sci. Eng. A 243, 82 (1998)

J. Jia, K. Zhang, L. Liu, F. Wu, J. Alloys Compd. 600, 215 (2014)

V. Balasubrahmanyam, Y. Prasad, Mater. Sci. Eng. A 336, 150 (2002)

J. Yeom, I. Shim, N. Park, S. Hong, I. Shim, Trans. Mater. Process. 12, 566–571 (2003)

B. Guo, H. Ji, X. Liu, L. Gao, R. Dong, M. Jin, Q. Zhang, J. Mater. Eng. Perform. 21, 1455 (2012)

P. Sivaprasad, S. Mannan, Y. Prasad, R. Chaturvedi, Mater. Sci. Technol. 17, 545 (2001)

H. Liao, Y. Wu, K. Zhou, J. Yang, Mater. Des. 65, 1091 (2015)

S. Yu, K. Jeon, M. Kim, J. Lee, K. Ryu, Metals Mater. Int. 23, 639 (2017)

Y. Lin, L. Li, Y. Xia, Y. Jiang, J. Alloys Compd. 550, 438 (2013)

M. Rajamuthamilselvan, S. Ramanathan, J. Alloys Compd. 509, 948 (2011)

N. Petch, Philos. Mag. 3, 1089 (1958)

T. Watanabe, Mater. Sci. Eng. A 166, 11 (1993)

A. Momeni, K. Dehghani, G. Ebrahimi, J. Alloys Compd. 509, 9387 (2011)

O. Sivakesavam, Y. Prasad, Mater. Sci. Eng. A 362, 118 (2003)

L. Guo, S. Yang, H. Yang, J. Zhang, Chin. J. Aeronaut. 28, 1774 (2015)

I. Watanabe, J. Watkins, H. Nakajima, M. Atsuta, T. Okabe, J. Dent. Res. 76, 773 (1997)

Acknowledgements

This work was supported by the Industrial Strategic Technology Development Program (10062304) funded by the Ministry of Trade, Industry and Energy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jang, B.J., Park, H.S. & Kim, MS. High Temperature Deformation Behavior of Al–Zn–Mg-Based New Alloy Using a Dynamic Material Model. Met. Mater. Int. 24, 1249–1255 (2018). https://doi.org/10.1007/s12540-018-0128-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0128-1