Abstract

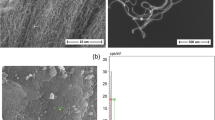

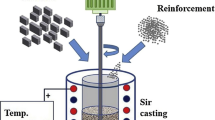

The hot deformation behavior of an A356/Al2O3 composite fabricated by the infiltration method was characterized in the temperature range of 300-500 °C and strain rate range of 0.001-1/s using compressive tests. The composite consists of an Al-Si based matrix and nano-sized Al2O3 particulates. A constitutive model was established based on the hyperbolic sine Arrhenius type equation and its hot workability was evaluated by means of processing maps based on Dynamic Material Modeling. The activation energy for hot deformation was calculated to be 223 kJ/mol, which is higher than the activation energy for self-diffusion of pure aluminum (142 kJ/mol). The optimum processing condition for the hot working of the composite was found to exist at 500 °C with a strain rate of 1/s, where a dynamic recrystallized microstructure was observed and the maximum efficiency was exhibited in the processing map. Voids were frequently detected at 500 °C with lower strain rates, deteriorating the workability of the composite.

Similar content being viewed by others

References

K. Horie, K. Nishizawa, T. Ogawa, S. Akazaki, and K. Miura, The Development of a High Fuel Economy and High Performance Four-Valve Lean Burn Engine (SAE 1992 Transactions), Society of Automotive Engineers, USA (1992).

K. Pramanik, Renew. Energ. 28, 239 (2003).

H. Raheman and A. Phadatare, Biomass Bioenerg. 27, 393 (2004).

P. Rohatgi, J. Kim, N. Gupta, S. Alaraj, and A. Daoud, Compos. Part A-Appl. S. 37, 430 (2006).

S. Chou, J. Huang, D. Lii, and H. Lu, J. Alloy. Compd. 436, 124 (2007).

Z. Luo, Y. Song, and S. Zhang, Scripta Mater. 45, 1183 (2001).

C. Badini, P. Fino, M. Musso, and P. Dinardo, Mater. Chem. Phys. 64, 247 (2000).

N. Movahedi, S. Mirbagheri, and S. Hoseini, Met. Mater. Int. 20, 757 (2014).

S. Park, M. Kim, K. Kim, S. Shin, J. Lee, and K. Ryu, Korean J. Met. Mater. 49, 853 (2011).

Z. Asghar, G. Requena, and E. Boller, Acta Mater. 59, 6420 (2011).

J. Kim, G.-S. Jang, M.-S. Kim, and J.-K. Lee, T. Nonferr. Metal. Soc., 24, 2346 (2014).

A. Momeni and K. Dehghani, Mat. Sci. Eng. A 528, 1448 (2011).

F. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, Scripta Mater. 57, 759 (2007).

H. R. Ashtiani, M. Parsa, and H. Bisadi, Mat. Sci. Eng. A 545, 61 (2012).

E. Cerri, E. Evangelista, A. Forcellese, and H. McQueen, Mat. Sci. Eng. A 197, 181 (1995).

C. Sellars and W. McTegart, Acta Mater. 14, 1136 (1966).

H. McQueen and N. Ryan, Mat. Sci. Eng. A 322, 43 (2002).

S. Yu and M. Kim, Metals 6, 32 (2016).

S. Lee and M. Kim, Met. Mater. Int. 22, 579 (2016).

T. Lundy and J. Murdock, J. Appl. Phys. 33, 1671 (1962).

J. Shao, B. Xiao, Q. Wang, Z. Ma, Y. Liu, and K. Yang, Mat. Sci. Eng. A 527, 7865 (2010).

Y. V. R. K. Prasad, H. L. Gegel, S. M. Doraivelu, J. C. Malas, J. T. Morgan, K. A. Lark, et al. Metall. Trans. A 15, 1883 (1984).

S. V. S. Narayana Murty and B. N. Rao, J. Mater. Sci. Lett. 17, 1203 (1998).

Y. Prasad and T. Seshacharyulu, Mat. Sci. Eng. A 243, 82 (1998).

P. Cavaliere, E. Cerri, and P. Leo, Compos. Sci. Technol. 64, 1287 (2004).

G. Ganesan, K. Raghukandan, R. Karthikeyan, and B. Pai, Mat. Sci. Eng. A 369, 230 (2004).

A. Whitehouse and T. Clyne, Composites 24, 256 (1993).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, SB., Jeon, KS., Kim, MS. et al. Microstructure and hot deformation behavior of A356/Al2O3 composite fabricated by infiltration method. Met. Mater. Int. 23, 639–647 (2017). https://doi.org/10.1007/s12540-017-6676-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6676-y