Abstract

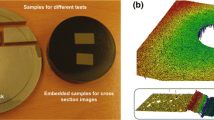

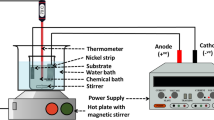

In this study Ni/nano-TiC functional composite coatings were produced by electro-codeposition of TiC nanoparticles (50 nm mean diameter) with nickel on 304L stainless steel support. Coatings were obtained from a Watts classical solution in which TiC nanoparticles were added. The surface morphology, chemical composition, structure, roughness and thickness, were evaluated in relation to the effect of TiC nanoparticles incorporation into Ni matrix. It was found that incorporation of TiC nanoparticles into the nickel matrix produces morphological changes in the deposit and increases the roughness. The fretting wear behavior in wet conditions of the obtained coatings was evaluated on a ball-on-plate configuration. To evaluate the wet fretting wear (tribocorrosion) behavior the open circuit potential was measured before, during and after the fretting tests at room temperature in the solution that simulates the primary water circuit of Pressurized Water Reactors. The results show that Ni/nano-TiC composite coatings exhibited a low friction coefficient, high nanohardness and fretting wear resistance in wet conditions compared with pure Ni coatings.

Similar content being viewed by others

References

R. Sekhar and T. P. Singh, J Mater. Res. Technol. 4, 197 (2015).

X.-H. Qu, L. Zhang, M. Wu and S.-B. Ren, Prog. Nat. Sci. Mater. Int. 21, 189 (2011).

A. S. Verma, S. Kant, N. M. Suri, and N. M. Yashpal, Mater. Today: Proc. 2, 2840 (2015).

A. Liu, M. Guo, M. Zhao, and C. Wang, Surf. Coat. Tech. 201, 7978 (2007).

O. Tazegul, V. Dylmishi, and H. Cimenoglu, Arch. Civ. Mech. Eng. 16, 344 (2016).

J. Wang, L. Li, and W. Tao, Opt. Laser Technol. 82, 170 (2016).

L. Benea, E. Danaila, and J.-P. Celis, Mat. Sci. Eng. A 610, 106 (2014).

D. K. Singh and V. B. Singh, Mat. Sci. Eng. A 532, 493 (2012).

H. Gül, F. Kiliç, S. Aslan, A. Alp, and H. Akbulut, Wear 267, 976 (2009).

G. Parida, D. Chaira, M. Chopkar, and A. Basu, Surf. Coat. Tech. 205, 4871 (2011).

L. Benea, F. Wenger, P. Ponthiaux, and J. P. Celis, Wear 266, 398 (2009).

F. Bratu, L. Benea, and J.-P. Celis, Surf. Coat. Tech. 201, 6940 (2007).

R. K. Saha and T. I. Khan, Surf. Coat. Tech. 205, 890 (2010).

S. T. Aruna, M. Muniprakash, and V. K. William Grips, J. Appl. Electrochem. 43, 805 (2013).

L. Benea, J. Appl. Electrochem. 39, 1671 (2009).

M. Karbasi, N. Yazdian, and A. Vahidian, Surf. Coat. Tech. 207, 587 (2012).

L. Benea, S.-B. Basa, E. Danaila, N. Caron, O. Raquet, P. Ponthiaux, and J.-P. Celis, Mater. Design 65, 550 (2015).

S. Mohajeri, A. Dolati, and S. Rezagholibeiki, Mater. Chem. Phys. 129, 746 (2011).

P. Gyftou, E. A. Pavlatou, and N. Spyrellis, Appl. Surf. Sci. 254, 5910 (2008).

E. A. Pavlatou, M. Stroumbouli, P. Gyftou, and N. Spyrellis, J. Appl. Electrochem. 36, 385 (2006).

D. K. Singh, M. K. Tripathi, and V. B. Singh, J. Electrochem. Soc. 159, 469 (2012).

D. Thiemig and A. Bund, Surf. Coat. Tech. 202, 2976 (2008).

J. A. Calderón, J. E. Henao, and M. A. Gómez, Electrochim. Acta 124, 190 (2014).

M. R.Vaezi, S. K. Sadrnezhaad, and L. Nikzad, Colloid. Surface 315, 176 (2008).

D. K. Singh, M. K. Tripathi, and V. B. Singh, Int. J. Mater. Sci. Appl. 2, 68 (2013).

P. Ponthiaux, F. Wenger, D. Drees, and J. P. Celis, Wear 256, 459 (2004).

A. Berradja, F. Bratu, L. Benea, G. Willems, and J. P. Celis, Wear 261, 987 (2006).

E. Mardare, L. Benea, and J.-P. Celis, Optoelectron Adv. Mater 6, 474 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dănăilă, E., Benea, L., Caron, N. et al. Titanium carbide nanoparticles reinforcing nickel matrix for improving nanohardness and fretting wear properties in wet conditions. Met. Mater. Int. 22, 924–934 (2016). https://doi.org/10.1007/s12540-016-6090-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-6090-x