Abstract

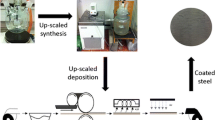

In this paper, a novel method of infiltration of TiO2 nanoparticles into the coating of the cellulose and rutile shielded metal arc welding electrode is shown. Tensile properties and strength of weld metals were correlated to the chemical composition of the weld metals, ferrite type, and non-metallic inclusion type, size and composition. As infiltration time is increased in the cellulose electrodes, the non-metallic inclusion count increases and their size decreases. They act as inoculants and lead to the replacement of Widmanstaetten with the finegrained acicular ferrite which increases the mechanical properties of the welds. The modification of rutile electrodes with low and medium infiltration time also refines the microstructure and increases the mechanical properties. Specimens welded with rutile electrodes infiltrated at maximum duration exhibited the lowest mechanical properties due to the relatively large non-metallic inclusions that act as void nucleation sites and the appearance of large grain allotriomorphic ferrite in the weld metal.

Similar content being viewed by others

References

R. Zhang and L. Gao, Mater. Res. Bull. 36, 1957 (2001).

J. Yang, S. Mei, and J. M. F. Ferreira, J. Am. Ceram. Soc. 84, 1696 (2001).

B. Wetzel, P. Rosso, F. Haupert, and K. Friedrich, Eng. Fract. Mech. 73, 2375 (2006).

S. H. Nedjad and A. Farzaneh, Scr. Mater. 57, 937 (2007).

M. Kiviö, L. Holappa, and T. Iung, Metall. Mater. Trans. B 41, 1194 (2010).

S. St-Laurent and G. L’Esperance, Mater. Sci. Eng. A 149, 203 (1992).

D. Zhang, H. Terasaki, and Y. Komizo, Acta. Mater. 58, 1369 (2010).

J. -S. Byun, J. -H. Shim, J. -Y. Suh, Y.-J. Oh, Y. W. Cho, J.-D. Shim, and D. N. Lee, Mater. Sci. Eng. A 319-321, 326 (2001).

J. S. Byun, J. H. Shim, and Y. W. Cho, Scr. Mater. 48, 449 (2003).

J. A. Gianetto, N. J. Smith, J. T. MCGrath, and J. T. Bowker, J. Weld. J. 11, 407 (1992).

S. S. Babu, Curr. Opin. Solid. State. Mater. Sci. 8, 267 (2004).

A. F. Gourgues, H. M. Flower, and T. C. Lindley, Mater. Sci. Technol. 16, 26 (2000).

M. Díaz-Fuentes, A. Iza-Mendia, and I. Gutiérrez, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 34A, 2505 (2003).

M. Fattahi, N. Nabhani, M. R. Vaezi, and E. Rahimi, Mater. Sci. Eng. A 528, 8031 (2011).

T. K. Pal, Mater. Sci. Appl. 02, 1285 (2011).

N. Greenwood and A. Earnshaw, Chemistry of the Elements, 2nd ed., pp. 961–962, Butterworth-Heinemann, Woburn (1997).

J. H. Shim, Y. J. Oh, J. Y. Suh, Y. W. Cho, J. D. Shim, J. S. Byun, and D. N. Lee, Acta. Mater. 49, 2115 (2001).

D. P. Fairchild, J. Y. Koo, N. V. Bangaru, M. L. Macia, D. L. Beeson, and A. Ozekcin, U. S. Patent, No.6565678 (2003).

D. Broek, Eng. Fract. Mech. 5, 55 (1973).

R. Smallman, R. J. Bishop, Modern Physical Metallurgy and Materials Engineering, 6th ed., p. 212, Butterworth Heinemann, Woburn (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balos, S., Sidjanin, L., Dramicanin, M. et al. Modification of cellulose and rutile welding electrode coating by infiltrated TiO2 nanoparticles. Met. Mater. Int. 22, 509–518 (2016). https://doi.org/10.1007/s12540-016-5637-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-5637-1