Abstract

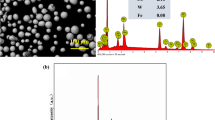

A process has been developed to enable the large-scale production of pure TiO2 films deposited on 316L stainless steel in order to get an easy-to-clean surface. This large-scale process requires an easy aqueous sol–gel procedure for the synthesis of the TiO2 sol. This synthesis has been simplified to facilitate the extrapolation toward an industrial scale. Results of TEM, photocatalytic properties, film hydrophilicity and texture obtained with the simplified aqueous sol–gel synthesis (IsoP–TiO2 synthesis) show similar properties to those obtained with the standard aqueous sol–gel synthesis of TiO2 (HAc–TiO2 synthesis) developed previously. Only, X-ray diffraction patterns showed differences, with the presence of anatase-brookite phases in IsoP–TiO2 synthesis while anatase phase only was observed in HAc–TiO2 synthesis. Both the aqueous sol–gel synthesis of pure TiO2 and the film deposition on steel by roll-coating have been successfully extrapolated to a larger scale. The photocatalytic activity and the hydrophilicity of the film were found to be unchanged when compared to films produced at a laboratory scale, thus validating the production of an efficient easy-to-clean material. Although some problems are still to be solved, this study is a hopeful first step in the development of a large-scale process for self-cleaning steel production.

Graphical Abstract

Similar content being viewed by others

References

Mills A, LeHunte S (1997) J Photochem Photobiol A 108:1

Fujishima A, Hashimoto K, Watanabe T (1999) TiO2 Photocatalysis: Fundamentals and Applications. BKC Inc, Tokyo

Rauf MA, Ashraf SS (2009) Chem Eng J 151:10–18

Houmard M, Riassetto D, Roussel F, Bourgeois A, Berthomé G, Joud JC, Langlet M (2007) Appl Surf Sci 254:1405–1414

Guan K (2005) Surf Coat Technol 191:155–160

Huang T, Huang W, Zhou C, Situ Y, Huang H (2012) Surf Coat Technol 213:126–132

Carp O, Huisman CL, Reller A (2004) Prog Solid State Chem 32:33

Malengreaux CM, Léonard GML, Pirard SL, Ciemeri I, Lambert SD, Pirard JP, Bartlett JR, Heinrichs B (2014) Chem Eng J 243:539

Schubert U (2005) J Mater Chem 15:3701

Malengreaux CM, Timmermans A, Pirard SL, Lambert SD, Pirard JP, Poelman D, Heinrichs B (2012) Chem Eng J 195–196:347

Bartlett JR, Gazeau D, Zemb T, Woolfrey JL (1998) Langmuir 14:3538

Lyonnard S, Bartlett JR, Sizgek E, Finnie KS, Zemb T, Woolfrey JL (2002) Langmuir 18:10386

Sizgek E, Bartlett JR, Brungs MP (1998) J Sol-Gel Sci Technol 13:1011

Malengreaux CM, Douven S, Poelman D, Heinrichs B, Bartlett JR (2014) J Sol-Gel Sci Technol 71:557

Malengreaux C (2013) Modified TiO2-based photocatalytic films and powders produced by aqueous and non-aqueous sol-gel processes for water purification, chap 5. Phd Thesis, University of Liège. http://hdl.handle.net/2268/147251. Accessed 10 Feb 2016

Mahshid S, Askari M, Ghamsari MS (2007) J Mater Process Technol 189:296–300

Chu B (2008) Dynamic light scattering. In: Borsali R, Pecora R (eds) Soft matter characterization. Springer, Netherlands, pp 335–372

Singh KSW, Rouquerol J, Bergeret G, Gallezot P, Vaarkamp M, Koningsberger DC, Datye AK, Niemantsverdriet JW, Butz T, Engelhardt G, Mestl G, Knözinger H, Jobic H (1997) Characterization of solid catalysts: sections 3.1.1–3.1.3. In: Handbook of heterogeneous catalysis. Wiley-VCH Verlag GmbH, pp 427–582

Lecloux AJ (1981) In: Anderson JR, Boudart M (eds) Catalysis: science and technology, vol 2. Springer, Berlin, p 171

Léonard GL-M, Remy S, Heinrichs B (2016) Mater Today Proc 3(2):434–438

Crookes R (2007) Le décapage et la passivation de l’acier inoxydable. Série Matériaux et application, vol 4. Euro Inox

Mills A, McGrady M (2008) J Photochem Photobiol A 193:228–236

Mills A, Hepburn J, Hazafy D, O’Rourke C, Wells N, Krysa J, Baudys M, Zlamal M, Bartkova H, Hill CE, Winn KR, Simonsen ME, Søgaard EG, Banerjee S, Fagan R, Pillai SC (2014) J Photochem Photobiol A 290:63–71

Bockmeyer M, Löbmann P (2006) Chem Mater 18:4478–4485

Léonard GL-M, Malengreaux CM, Mélotte Q, Lambert SD, Bruneel E, Van Driessche I, Heinrichs B (2016) J Environ Chem Eng 4:449–459

Flint SH, Brooks JD, Bremer PJ (2000) J Food Eng 43:235–242

Huang J, Gu Y (2011) Curr Opin Colloid Interface Sci 16:470–481

Parkin IP, Palgrave RG (2005) J Mater Chem 15:1689

Acknowledgments

The authors thank Isabelle Willems and Alain Germeau from Prayon S.A. for the provision of the extrapolation reactor. For their financial support, the authors are grateful to the Ministère de la Région Wallonne Direction Générale des Technologies, de la Recherche et de l’Energie, in relation to the Plan Marshall, and with support from the Pôle MecaTech for the research project “DAO—Durable Aesthetic Outdoor Contract No. 6765.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahy, J.G., Léonard, G.LM., Pirard, S. et al. Aqueous sol–gel synthesis and film deposition methods for the large-scale manufacture of coated steel with self-cleaning properties. J Sol-Gel Sci Technol 81, 27–35 (2017). https://doi.org/10.1007/s10971-016-4020-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4020-5