Abstract

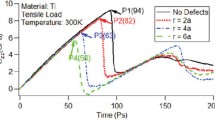

In this paper, we report deformation behavior during tension followed by compression loading for Nickel and Nickel-Tungsten alloy (15 at% W) single crystals using molecular dynamics simulations to investigate the role of W on the dislocation evolution in Ni-W alloy. The stress-strain responses of single crystals under uniaxial tension followed by compression loading after different pre-strains (i.e. 0.10 and 0.20 true strains for pure Ni; 0.10 and 0.24 true strains for Ni-15 at% W alloy) are simulated at strain rate of 108 s−1 and at the temperature of 300 K. Dislocation mobility, dislocation-dislocation interaction and dislocation-twin interactions are thoroughly investigated to evaluate their influence on deformation behaviour during reverse loading. Slip dominated deformation mechanism prevails during forward loading but both twin and slip are found to be operative during reverse loading for Ni single crystal. It is observed that the dominant deformation mechanism is twin for both forward and reverse loading in case of Ni-15 at% W alloy single crystal.

Similar content being viewed by others

References

O. Younes and E. Gileadi, Electrochem. Solid St. 3, 543 (2000).

O. Younes, L. Zhu, Y. Rosenberg, Y. Shacham-Diamand, and E. Gileadi, Langmuir 17, 8270 (2001).

L. Zhu, O. Younes, N. Ashkenasy, Y. Shacham-Diamandand, and E. Gileadi, Appl. Surf. Sci. 200, 1 (2002).

O. Younes-Metzler, L. Zhu, and E. Gileadi, Electrochim. Acta 48, 2551 (2003).

S. Yao, S. Zhao, H. Guo, and M. Kowaka, Corrosion 52, 183 (1996).

P. Schloßmacher and T. Yamasaki, Microchim. Acta 132, 309 (2000).

N. Sulitanu, J. Magn. Magn. Mater. 231, 85 (2001).

N. D. Sulitanu, Mater. Sci. Eng. B-Adv. 95, 230 (2002).

P. Lammel, L. D. Rafailovic, M. Kolb, K. Pohl, A. H. Whitehead, G. Grundmeierand, and B. Gollas, Surf. Coat. Tech. 206, 2545 (2012).

P. Indyka, E. Beltowska-Lehman, L. Tarkowski, A. Bigosand, E. García-Lecina, J. Alloy. Compd. 590, 75 (2014).

T. Yamasaki, P. Schloßmacher, K. Ehrlichand, and Y. Ogino, Nanostruct. Mater. 10, 375 (1998).

Z. Zhongand and S. J. Clouser, Surf. Coat. Tech. 240, 380 (2014).

N. Atanassov, K. Gencheva, and M. Bratoeva, Plat. Surf. Finish. 84, 67 (1997).

O. Younes and E. Gileadi, J. Electrochem. Soc. 149, C100 (2002).

Z. Zhong and S. J. Clouser, Surf. Coat. Tech. 240, 380 (2014).

C. A. Schuh, T. G. Nieh, and H. Iwasaki, Acta Mater. 51, 431 (2003).

Y. Lu, C. Peng, Y. Ganesan, J. Y. Huangand, and J. Lou, Nanotechnology 22, 355702 (2011).

C. H. Lin, H. Ni, X. Wang, M. Chang, Y. J. Chao, J. R. Deka, and X. Li, Small 6, 927 (2010).

J. Y. Huang, H. Zheng, S. X. Mao, Q. Liand, and G. T. Wang, Nano lett. 11, 1618 (2011).

M. T. McDowell, A. M. Leachand, and K. Gall, Model. Simul. Mater. Sc. 16, 045003 (2008).

R. Komanduri, N. Chandrasekaran, and L. M. Raff, Int. J. Mech. Sci. 43, 2237 (2001).

P. Wang, W. Chou, A. Nie, Y. Huang, H. Yaoand, and H. Wang, J. Appl. Phys. 110, 093521 (2011).

S. J. A. Koh and H. P. Lee, Nanotechnology 17, 3451 (2006).

N. Yedla, M. Srinivas, S. Ghosh, and B. Majumdar, Intermetallics 18, 2419 (2010).

W. D. Wang, C. L. Yi, and K. Q. Fan, T. Nonferr. Metal. Soc. 23, 3353 (2013).

C. S. Tiwary, S. Chakraborty, D. R. Mahapatra, and K. Chattopadhyay, J. Appl. Phys. 115, 2035021 (2014).

M. Jo, Y. M. Koo, and S. K. Kwon, Met. Mater. Int. 21, 227 (2015).

Y. Zhang and H. Huang, Nanoscale Res. Lett. 4, 34 (2009).

J. Han, M. Park, A. Lee, D. Sohn, J. Park, and S. Im, Met. Mater. Int. 20, 899 (2014).

X. L. Ma and W. Yang, Nanotechnology 14, 1208 (2003).

N. Y. Park, P. R. Cha, Y. C. Kim, H. K. Seok, S. H. Han, S. C. Lee, S. Cho, and H. Jung, Met. Mater. Int. 15, 447 (2009).

S. Pal, D. Z. Kamal, N. Yedla, and K. Dutta, J. Comput. Theor. Nanos. 12, 2264 (2015).

N. Yedla, M. Meraj, P. Gupta, V. Sarat, A. J. Kabi, and S. Pal, Metall. Res. Technol. 112, 505 (2015).

S. Plimpton, J. Comput. Phys. 117, 1 (1995).

A. Stukowski, Model. Simul. Mater. Sc. 18, 015012 (2010).

A. Stukowski, Model. Simul. Mater. Sc. 20, 045021 (2012).

X. W. Zhou, R. A. Johnson, and H. N. G. Wadley, Phys. Rev. B 69, 1441131 (2004).

L. J. Meng, X. Y. Peng, K. W. Zhang, C. Tang, and J. X. Zhong, J. Appl. Phys. 111, 0243031 (2012).

H. Choi, E. K. Lee, and Y. C. Chung, Curr. Appl. Phys. 11, S400 (2011).

C. L. Kelchner, S. J. Plimpton, and J. C. Hamilton, Phys. Rev. B 58, 11085 (1998).

R. Komanduri, N. Chandrasekaran, and L. M. Raff, Int. J. Mech. Sci. 43, 2237 (2001).

Z. X. Wu, Y. W. Zhang, M. H. Jhon, J. R. Greer, and D. J. Srolovitz, Acta Mater. 61, 1831 (2013).

R. L. Penn and J. F. Banfield, Science 281, 969 (1998).

J. Godet, S. Brochard, L. Pizzagalli, P. Beauchamp, and J. M. Soler, Phys. Rev. B 73, 0921051 (2006).

J. C. Williams, A. W. Thompson, and R. G. Baggerly, Scripta Metall. Mater 8, 625 (1974).

R. E. Stoltz and A. G. Pineau, Mater. Sci. Eng. 34, 275 (1978).

M. Sundararaman, W. Chen, R. P. Wahi, A. Wiedenmann, W. Wagner, and W. Petry, Acta. Metall. Mater. 40, 1023 (1992).

M. Arzaghi, B. Beausir, and L. S. Tóth, Acta Mater. 57, 2440 (2009).

Y. T. Zhu, X. Z. Liao, and X. L. Wu, Prog. Mater. Sci. 57, 1 (2012).

G. I. Taylor, Proceedings of the Royal Society of London. Series A, Containing Papers of a Mathematical and Physical Character, pp.362–387, Royal Society, London (1934).

V. V. Bulatov, L. L. Hsiung, M. Tang, A. Arsenlis, M. C. Bartelt, W. Cai, J. N. Florando, M. Hiratani, M. Rhee, G. Hommes, T. G. Pierce1, and T. D. de La Rubia, Nature 440, 1174 (2006).

T. Yamasaki, P. Schloßmacher, K. Ehrlich, and Y. Ogino, Nanostruct. Mater. 10, 375 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meraj, M., Yedla, N. & Pal, S. Role of W on the dislocation evolution in Ni-W alloy during tension followed by compression loading. Met. Mater. Int. 22, 373–382 (2016). https://doi.org/10.1007/s12540-016-5551-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-5551-6