Abstract

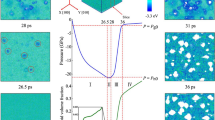

Deformation twins have a major role in the microstructure evolution of hexagonal close packed (HCP) metals. Voids are common defects in metals and have a significant impact on their properties. In this work, using molecular dynamics, a tension simulation of single-crystal titanium (Ti) with different void sizes under uniaxial stress conditions was performed. The results showed that the evolution and dominance of the \(\left\{ {10\bar 12} \right\}\) twin system using the Henning potential was not consistent with the Schmid criterion when the single-crystal Ti contained void defects. From a microscopic perspective, the authors analyzed the relationship between the nucleation and growth of twins and the emission of dislocation loops. The authors found that the existence of voids not only contributes to the emission of dislocation loops but also hinders the movement of these loops. With the increase in void size, the peak dislocation density of \({{\bf{V}}_{\bf{2}}}:\left\{ {10\bar 12} \right\}\left\langle {\bar 1101} \right\rangle\) partial dislocation loops decreased. This work is helpful to further investigate the nucleation and evolution of tension twins and to form an effective growth criterion for twins to study the twinning process of HCP metals during plastic deformation.

Similar content being viewed by others

References

M.J. Donachie: Titanium: A Technical Guide, 2nd ed. (ASM International, Materials Park, Ohio, 2000).

C. Leyens and M. Peters: Titanium and Titanium Alloys: Fundamentals and Applications (Wiley-VCH Verlag GmbH & Co., 2003). IBSN: 3-527-30534-3.

M. Niinomi: Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 243, 231 (1998).

H. Conrad: Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 26, 123 (1981).

P.G. Partridge: The crystallography and deformation modes of hexagonal close-packed metals. Metall. Rev. 12, 169 (1967).

I. Kim, J. Kim, D. Shin, X. Liao, and Y. Zhu: Deformation twins in pure titanium processed by equal channel angular pressing. Scr. Mater. 48, 813 (2003).

L. Xiao: Twinning behavior in the Ti–5 at.% Al single crystals during cyclic loading along [0001]. Mater. Sci. Eng. A 394, 168 (2005).

M. Yoo: Twinning and mechanical behavior of titanium aluminides and other intermetallics. Intermetallics 6, 597 (1998).

J.W. Christian and S. Mahajan: Deformation twinning. Prog. Mater. Sci. 39, 1 (1995).

S. Rawat and N. Mitra: Molecular dynamics investigation of c-axis deformation of single crystal Ti under uniaxial stress conditions: Evolution of compression twinning and dislocations. Comput. Mater. Sci. 141, 19 (2018).

C. Barrett, M. Tschopp, and H. El Kadiri: Automated analysis of twins in hexagonal close-packed metals using molecular dynamics. Scr. Mater. 66, 666 (2012).

S.J. Lainé and K.M. Knowles: \(\left\{ {11\bar 24} \right\}\) deformation twinning in commercial purity titanium at room temperature. Philos. Mag. 95, 2153 (2015).

J. Zhang and S.P. Joshi: Phenomenological crystal plasticity modeling and detailed micromechanical investigations of pure magnesium. J. Mech. Phys. Solids 60, 945 (2012).

D.R. Askeland and P.P. Phule: The Science and Engineering of Materials (Springer, 2003). IBSN: 978-94-009-1842-9.

A. Needleman: Void growth in an elastic-plastic medium. J. Appl. Mech. 39, 964 (1972).

J. Koplik and A. Needleman: Void growth and coalescence in porous plastic solids. Int. J. Solids Struct. 24, 835 (1988).

P-H. Sung and T-C. Chen: Studies of crack growth and propagation of single-crystal nickel by molecular dynamics. Comput. Mater. Sci. 102, 151 (2015).

K. Zhao, C. Chen, Y. Shen, and T. Lu: Molecular dynamics study on the nano-void growth in face-centered cubic single crystal copper. Comput. Mater. Sci. 46, 749 (2009).

T. Tang, S. Kim, and M. Horstemeyer: Molecular dynamics simulations of void growth and coalescence in single crystal magnesium. Acta Mater. 58, 4742 (2010).

R. Aghababaei and S.P. Joshi: Micromechanics of tensile twinning in magnesium gleaned from molecular dynamics simulations. Acta Mater. 69, 326 (2014).

S. Rawat and S.P. Joshi: Effect of multiaxial loading on evolution of \(\left\{ {101\bar 2} \right\}\) twinning in magnesium single crystals. Mater. Sci. Eng., A 659, 256 (2016).

Y. Liu, N. Li, S. Shao, M. Gong, J. Wang, R. McCabe, Y. Jiang, and C. Tomé: Characterizing the boundary lateral to the shear direction of deformation twins in magnesium. Nat. Commun. 7, 11577 (2016).

Z. Yang, G. Zhang, and J. Zhao: Molecular dynamics simulations of void effect of the copper nanocubes under triaxial tensions. Phys. Lett. A 380, 917 (2016).

S. Rawat and N. Mitra: Evolution of tension twinning in single crystal Ti under compressive uniaxial strain conditions. Comput. Mater. Sci. 141, 302 (2018).

L. Bao, C. Schuman, J.S. Lecomte, M.J. Philippe, X. Zhao, and C. Esling: A study of twin variant selection and twin growth in titanium. Adv. Eng. Mater. 13, 928 (2011).

S. Godet, L. Jiang, A. Luo, and J. Jonas: Use of Schmid factors to select extension twin variants in extruded magnesium alloy tubes. Scr. Mater. 55, 1055 (2006).

J.D. Honeycutt and H.C. Andersen: Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J. Phys. Chem. 91, 4950 (1987).

V. Lubarda, M. Schneider, D. Kalantar, B. Remington, and M. Meyers: Void growth by dislocation emission. Acta Mater. 52, 1397 (2004).

T. Ohashi: Crystal plasticity analysis of dislocation emission from micro voids. Int. J. Plast. 21, 2071 (2005).

S. Traiviratana, E.M. Bringa, D.J. Benson, and M.A. Meyers: Void growth in metals: Atomistic calculations. Acta Mater. 56, 3874 (2008).

A.H. Cottrell and B. Bilby: Dislocation theory of yielding and strain ageing of iron. Proc. Phys. Soc. Sect. A 62, 49 (1949).

A. Cottrell and B. Bilby: L.X. A mechanism for the growth of deformation twins in crystals. London, Edinburgh Dublin Philos. Mag. J. Sci. 42, 573 (1951).

R. Hennig, T. Lenosky, D. Trinkle, S. Rudin, and J. Wilkins: Classical potential describes martensitic phase transformations between the α, β, and ω titanium phases. Phys. Rev. B 78, 054121 (2008).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995).

N.S. Martys and R.D. Mountain: Velocity Verlet algorithm for dissipative-particle-dynamics-based models of suspensions. Phys. Rev. E 59, 3733 (1999).

D.J. Evans and B.L. Holian: The Nose–Hoover thermostat. J. Chem. Phys. 83, 4069 (1985).

A. Stukowski, V.V. Bulatov, and A. Arsenlis: Automated identification and indexing of dislocations in crystal interfaces. Modell. Simul. Mater. Sci. Eng. 20, 085007 (2012).

A. Stukowski: Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2009).

Acknowledgments

The authors would like to deeply appreciate the support from the National Natural Sciences Foundation of China (11572191, 51701117, and 51779139) and the Shanghai Science and Technology Committee Foundation (17411962200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, Y., Chen, X. & Feng, M. Effect of void defect on c-axis deformation of single-crystal Ti under uniaxial stress conditions: Evolution of tension twinning and dislocations. Journal of Materials Research 34, 3699–3706 (2019). https://doi.org/10.1557/jmr.2019.279

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.279