Abstract

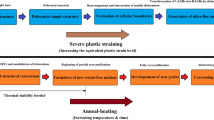

Deformation mode and restoration of face-centered cubic (FCC) metal (Al, Ni, and Cu) particles subjected to kinetic spraying (KS) were investigated. The FCC metal particles were accelerated to supersonic velocity by high pressure process gas, and collided with substrates or previously deposited coating layer. The high velocity impact of in-flight particles and their successive deposition leads to severe plastic deformation at ultra-high strain rate and the dissipation of heat energy from the plasticity. Accordingly, highly strained interface undergoes restoration to stabilize strained area during KS. Although Al, Ni, and Cu have equivalent slip systems {111} 〈110〉, the different physical and metallurgical properties of the FCC metals differentiate the deformation mode and lead to variations in static recovery and recrystallization rates. The deformation and restoration behavior of KS FCC metals are discussed, taking into account the physical and metallurgical factors such as stacking fault energy, dislocation mobility, diffusivity, and melting point.

Similar content being viewed by others

References

L. Ajdelsztajn, B. Jodoin, J. Kim, G. Kim, J. Schoenung, and J. Mondoux, Metall. Mater. Trans. A 36, 657 (2005).

K. Kang, S. Yoon, Y. Ji, and C. Lee, Mater. Sci. Eng. A 486, 300 (2008).

A. Hall, L. Brewer, and T. Roemer, J. Therm. Spray Technol. 17, 352 (2008).

T. Schmidt, F. Gärtner, and H. Kreye, J. Therm. Spray Technol. 15, 488 (2006).

F. Gärtner, T. Stoltenhoff, T. Schmidt, and H. Kreye, J. Therm. Spray Technol. 15, 223 (2006).

S. Zahiri, D. Fraser, and M. Jahedi, J. Therm. Spray Technol. 18, 16 (2009).

S. Klinkov, V. Kosarev, and M. Rein, Aerosp. Sci. Technol. 9, 582 (2005).

P. C. King, S. Zahiri, and M. Jahedi, Metall. Mater. Trans. A 40, 2115 (2009).

W. A. Li, C. Zhang, X. Guo, C. J. Li, and H. Liao, Appl. Sur. Sci. 254, 517 (2007).

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Acta Mater. 51, 4379 (2003).

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Acta Mater. 54, 729 (2006).

R. C. Dykhuizen, M. F. Smith, D. L. Gilmore, R. A. Neiser, X. Jiang, and S. Sampath, J. Therm. Spray Technol. 8, 559 (1999).

M. Grujicic, C. L. Zhao, W. S. DeRosset, and D. Helfritch, Mater. Design 25, 681 (2004).

M. Grujicic, J. R. Saylor, D. E. Beasley, W. S. DeRosset, and D. Helfritch, Appl. Sur. Sci. 219, 211 (2003).

W. Y. Li, H. Liao, C. J. Li, G. Li, C. Coddet, and X. Wang, Appl. Sur. Sci. 253, 2852 (2006).

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, Acta Mater. 56, 4858 (2008).

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H. J. Kim, and C. Lee, Acta Mater. 57, 5654 (2009).

Y. Xiong, K. Kang, G. Bae, S. Yoon, and C. Lee, Appl. Phys. Lett. 92, 194101 (2008).

C. Borchers, F. Gärtner, T. Stoltenhoff, H. Assadi, and H. Kreye, J. Appl. Phys. 93, 10064 (2003).

C. Borchers, F. Gärtner, T. Stoltenhoff, and H. Kreye, J. Appl. Phys. 96, 4288 (2004).

C. Borchers, F. Gärtner, T. Stoltenhoff, and H. Kreye, Acta Mater. 53, 2991 (2005).

T. H. Steenkiste, J. R. Smith, and R. E. Teets, Sur. Coat. Technol. 154, 237 (2002).

T. H. Steenkiste, and J. R. Smith, et al., Sur. Coat. Technol. 111, 62 (1999).

C. J. Li, W. Y. Li, and Y. Y. Wang, Sur. Coat. Technol. 198, 469 (2005).

F. J. Humphreys, and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed., Pergamon Press, London, (2004).

R. C. Dykhuizen, and M. F. Smith, J. Therm. Spray Technol. 7, 205 (1998).

P. Rosakis, A. Roskis, G. Rvichandran, and J. Hodowany, J. Mech. Phys. Soli. 48, 581 (2000).

R. C. Pond, and L. M. F. Garcia-Garcia, Electron Microscopy and Analysis, Proceeding of the Institute of Physics Electron Microscopy and Analysis Group Conference. IOP, Cambridge, England (1982).

S. Kibey, J. B. Liu, D. D. Johson, and H. Sehitoglu, Acta Mater. 55, 6843 (2007).

W. Z. Han, G. M. Cheng, S. X. Li, S. D. Wu, and Z. F. Zhang, Phys. Rev. Lett. 101, 1105 (2008).

I. M. Robertson, Philos. Mag. A 54, 821 (1986).

P. Haasen, and A. King, Z. Metallkd. 51, 722 (1960).

M. A. Meyers, O. Vöhringer, and V. A. Lubarda, Acta Mater. 49, 4025 (2001).

E. El-Danaf, S. R. Kalidindi, and R. D. Doherty, Metall. Mater. Trans. A 30, 1223 (1999).

M. A. Meyers, D. J. Benson, O. Vöhringer, B. K. Kad, Q. Xue, and H. H. Fu, Mater. Sci. Eng. A 322, 194 (2002).

O. Vöhringer, Z. Metallkd. 67, 535 (1976).

P. R. Thornton and T. E. Mitchell, Phil. Mag. 7, 361 (1962).

W. B. Choi, L. Li, V. Luzin, R. Neiser, T. Gnaupel-Herold, H. J. Prask, S. Sampath, and A. Gouldstone, Acta Mater. 55, 857 (2007).

Y. Zou, W. Qin, E. Irissou, J. G. Legoux, S. Yue, and J. A. Szpunar, Scripta Mater. 61, 899 (2009).

L. E. Murr, K. P. Staudhammer, and M. A. Meyers, Metallurgical and Materials Applications of Shock-Wave and High Strain Rate Phenomena, 1st ed., Elsevier, Amsterdam, (1995).

Y. Xu, J. Zhang, Y. Bai, and M. A. Meyers, Metall. Mater. Trans. A 39, 811 (2008).

U. Andrade, M. A. Meyers, K. S. Vecchio, and A. H. Chokshi, Acta Metall. 42, 3183 (1994).

M. A. Meyers, J. C. LaSalvia, V. F. Nesterenko, Y. J. Chen, and B. K. Kad, Proc. ReX 96., Monterey, USA (1996).

M. A. Meyers, V. F. Nesterenko, J. C. LaSalvia, and Q. Xue, Mater. Sci. Eng. A 317, (2001).

H. P. Stüwe, A. F. Padilha, and F. Siciliano, Mater. Sci. Eng. A 333, 361 (2002).

X. X. Yu and C. Y. Wang, Acta Mater. 57, 5914 (2009).

A. S. Argon and W. C. Moffatt, Acta Metall. 29, 293 (1981).

A. M. Brown and M. F. Ashby, Acta Metall. 28, 1085 (1980).

W. G. Johnston and J. J. Gilman, J. Appl. Phys. 30, 129 (1959).

E. H. Kwon, Sung Ho Cho, J. W. Han, C. Lee, and H. J. Kim, Met. Mater. Int. 11, 377 (2005).

D. A. Porter and K. E. Eastering, Phase Transformations in Metals and Alloys, 2nd ed., Nelson Thornes, Cheltenham (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, K., Bae, G. & Lee, C. Restoration of face-centered cubic metals subjected to kinetic spraying. Met. Mater. Int. 19, 283–293 (2013). https://doi.org/10.1007/s12540-013-2024-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-2024-z