Abstract

Mine blasting has adopted machine learning (ML) into its practices with the aims of performance optimization, better decision-making process, and work safety. This study is aimed at reviewing the status of ML method applications to mine blasting issues. One of the most important observations of this research highlights the developed ML methods such as hybrids/ensembles, outperforming the other methods at 61% of the sample of case studies. The first section provides a background on the application of ML methods in mining. Two sections of the review provide the trends in the application of ML methods and the utilization of input parameters in surface and underground blasting problems. The appraisal reveals an increase of hybrid/ensemble or highly developed ML methods for the top four blast issues on the surface (72%) and underground (45%). The sample of studies reviewed indicated through graphical/statistical means a continuing increase in hybrids/ensembles’ use mirrored by high research output for the top four surface blast issues. This is contrasted by a low rate of research in underground blasting, under the encountered operational conditions applied. Regarding the input parameters, controllable parameters (blast design and geometry) were recognized to be steadily used in surface blasting for the top four surface blast issues, along with less involvement from the uncontrollable parameters (geological and geotechnical parameters). On the contrary, underground blasting has a slight involvement of the uncontrollable parameters more than the controllable parameters, in the top four blast issues. In the final section of this paper, the review offers a discussion of the current state of research under the encountered limits and where the efforts should be focused concerning ML methods applied, input parameters involved, and the challenges faced. Such high levels of performances are in demand in a highly complex mining environment. Persistent research, and development of mining employees’ technological skills alongside an increased awareness among mining industry of the benefits of highly developed ML techniques, is greatly needed at this stage. This would establish the role of highly developed ML methods in improving both the blasting process and the overall decision-making and mining management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Mine blasting optimization

Optimization of the blasting supported by a better decision-making process continues to be the goal of every mining operation. Several methods have been applied to this process, yet it is to achieve the most accurate and proactive method. The following subsections give an overview of the path taken by mine blast optimization to achieve its goal(s).

Mine blasting

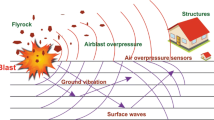

The main objective of mine blasting is to separate the ore from the host rock or burden and produce processible fragments suitable for downstream processes. The blasting mechanism is extremely complex; it involves very high temperatures and pressures through chemical reactions. The exothermic reaction will result in producing high pressures up to around 20 GPa, which generates the separation of the ore from the host rock (Jang and Topal 2013). Blasting comes with the advantage of being the most cost-effective rock breakage method (Jang and Topal 2013). However, it is often associated with side effects or environmental issues such as fly rocks, seismic activity, air blast, and blast vibration. These side effects also reflect negatively on the operations in the form of added investments to lessen their influence and most importantly maintain the workers’ safety and the condition of the surroundings. Conventional approaches such as empirical method/equations and mathematical/statistical models were employed to predict the issues as a matter of proactiveness, therefore, aiming to optimize the blasting and minimize the negative effects of the issues in question. Conventional methods are hindered by their limited capabilities. For instance, empirical models are limited to no more than two input parameters at a time and cannot simultaneously predict more than one output, incapable to include the geological conditions, constrained to analyzing datasets along with specific geometries, and restricted by their inability to verify the non-linear relationships between the increased number of input parameters (Dumakor-Dupey et al. 2021). Thus, it called for an alternative course of action, ML.

Machine learning and review of mining application

To achieve safe, smart, sustainable mining operations, researchers paid great interest in artificial intelligence (AI) and its branches (Jang and Topal 2014). AI is a technique that allows recreating human-like cognitive abilities to automate tasks and processes (Franco-Sepúlveda et al. 2019). ML is a division of AI, whereby the existing data are used to forecast or react to impending data (Ali and Frimpong 2020). ML is relevant where it is not feasible, or even possible, to write algorithms to perform a task (Ali and Frimpong 2020). ML has several applications such as pattern recognition, computational statistics, medical diagnosis, and spam filtering (Ali and Frimpong 2020). Examples of autonomous learning methods are regression; neural nets; decision trees; expert system; gradient boost (GB); extreme gradient boost (XGBoost), and support vector machines (SVM). ML employs computer algorithms to examine and learn from data, perform tasks, and make decisions or projections founded on the data run (Dumakor-Dupey et al. 2021). Depending on the structure of available data being analyzed, ML models are considered supervised learning, unsupervised learning, or reinforcement learning based on the organization of data analyzed (Dumakor-Dupey et al. 2021). They can support a better decision-making process for a well-performing operation with such capabilities. Several mining-related practices, e.g., exploration, mining method selection, equipment selection, hard rock support, and blasting, have adopted ML techniques. A myriad of case studies was reviewed by Jang and Topal (Jang and Topal 2014), Franco-Sepúlveda et al. (Franco-Sepúlveda et al. 2019), and Ali and Frimpong (Ali and Frimpong 2020), which covered ML applications to surface and underground mining. As perceived from the reviews, there is an increased attention to optimize the blasting processes; however, the invested interests are not balanced for both sides (surface and underground). The reviews gave little explanation on the trends and the direction of the ML application in this area of interest. This allows us to pursue a few questions: how did mining optimization research attain the current position; what type of change; when the change occurs; how the ML prediction models’ input parameters influence the optimization exercises; and how do we see future of research in this area given the current developments. To grasp the impact of trends of ML application on blasting issues, the following two sections offer an overview of the current/previous applications of ML methods in surface and underground blasting. The analysis shall provide an evaluation of the technological developments’ trends in addressing mine blasting issues under the current research capabilities. The following final section compromises a discussion of the trends observed to present conclusions and recommendations for future references.

Machine learning applications in surface mine blasting

Through the review of research papers over the past decade or earlier, surface mining has the biggest share of ML applications in research, mainly due to its simple and structured nature (Dumakor-Dupey et al. 2021; Jang and Topal 2014; Franco-Sepúlveda et al. 2019; Ali and Frimpong 2020). ML has been employed to boost surface mining practices including the blasting process to eliminate/minimize its environmental effects. The methods used were mostly exhibited in a comparative path, whereby one primary ML technique is compared against others. The most used ML techniques were hybrid/ensemble ML methods, followed by artificial neural networks (ANN), others, support vector machine (SVM), and fuzzy logic as indicated in Fig. 1. Four blast issues have the most attention, and they are blast vibration, fly rocks, rock fragmentation/particle size, and back break, as exhibited by Fig. 2. ML applications to surface blasting appear to be experiencing a high yearly production of research case studies, especially from the mid-2010s to the early-2020s, as shown in Fig. 3, which may confirm the notion of surface mining having the most attention from researchers in terms of development and utilization. Considering the state of research, the following sub-sections demonstrate the trends of ML techniques regarding the top four surface blast issues. This trends’ analysis will give a brief account of the frequency and size of the use of the adopted ML techniques and the transformation from one dominating technique to another per blast issue. Additionally, an evaluation of the trends in input parameters’ utilization per top blast issue will be concisely explained. This is followed by a brief description of the lowest-ranked surface blast issues and the trends of ML techniques applied to them.

Machine learning applications to surface blast vibrations

Blasting-induced vibrations are a major environmental issue that has been extensively covered by researchers, as exhibited in Table 1. To understand the effect of blast vibrations, it is essential to explain the way they are generated. As detailed by Singh and Singh, at the time of the blast and as other researchers indicated, only 20–30% of the energy is used for the rock breakage. The remainder of the blast energy is transformed into dynamic stresses generated by the abrupt acceleration of the rock mass by the blasting pressures. A stress wave is transmitted to the surrounding rock mass and consequently sets up a wave motion in the ground. The rock mass is broken in a variety of manners, e.g., crushing, radial cracking, and reflection breakage in the presence of a free face by the strain energy transmitted by the wave. The stress wave increases through the medium in the form of elastic waves, oscillating the particle through which it travels. The stress wave spreads through the medium in the form of elastic waves, oscillating the particle through which it travels. These stress waves are called PPV (particle peak velocity) in the elastic zone, which carefully confirms the viscoelastic behavior. The wave motion spreads away from the blasting point in all directions and gets diminished due to the dispersal of fixed energy far from the source (Singh and Singh 2005). Blast vibrations can negatively affect the surroundings of the operations through the initial disturbance and the aftershocks. Traditionally, researchers addressed the issue via the usage of geophones and/or seismometers as indicated by the Department of Mines and Petroleum of Western Australia to detect and record the vibrations or seismic activity generated in or from the mining area (http://www.dmp.wa.gov.au/News/Seismic-survey-gets-underway-25226.aspx). However, there was a need for proactiveness. Mining activity areas are usually situated in bushlands with protected fauna, flora, and heritage sites. In some cases, mining operations are near towns, e.g., KCGM’s super pit in Kalgoorlie-Western Australia is located near the suburb of Williamstown (https://www.abc.net.au/news/2022–03-11/teary-goodbye-first-williamstown-house-falls-northern-star/100900516). Blasting activities are restricted on their levels of vibrations by the regulatory limits to decrease the impact on structures, lessen the possibilities of seismic, and optimize the blasting performances. Additionally, empirical, mathematical, and statistical models were utilized to predict the blast vibrations as a preventative method. However, they were not offering satisfying forecasts due to their limitations. ML techniques based on their exceptional capabilities were considered as an alternative where they are utilized to predict the blast vibrations. Researchers applied several ML techniques such as artificial neural networks (ANN), support machine vectors, (SVM), and fuzzy logic, dating from the mid-2000s up to the late-2010s as depicted by the issue dates of case studies in the references section. However, it was a rather inconsistent output research-wise. Despite the variable research output, it puts some emphasis on their ability to give out acceptable and accurate results that kept them being engaged for over a decade. Hybrid/ensemble ML methods took the leading position, being applied in mine blasting studies from the late-2000s and early-2010s. The real thrive of hybrids/ensembles came in the mid-2010s and remaining, with a noticed increased research output as depicted in Fig. 3. The performance of prediction models depended predominantly on controllable parameters (blast geometry and explosive) more than uncontrollable parameters (geological and geotechnical). From the analysis, it was found that several controllable parameters were consistently used for the purpose (see Table 1), and they are displayed in Fig. 4. The top three parameters are monitoring distance (MD), burden (B), and spacing (S). Other parameters were used, e.g., stemming (T), specific charge (Q), and powder factor (q); however, they were deemed of less significance as exhibited in Fig. 4 with their reduced frequent use. The significance of some of the most used controllable parameters was explained by Singh and Singh (Singh and Singh 2005). As a top parameter, MD importance comes from its main objective of observing and recording the distance covered by the vibration to the affected points, e.g., boundaries, structures, and buildings (Singh and Singh 2005). Regarding burden, if the burden is higher than the gases produced, the gas confined in the bottom of the hole is more than the optimum time. The energy of the explosive not used in fragmentation and throw will increase ground vibration. If the spacing and burden ratio is more than one, this increases the fragmentation. If more energy is consumed in fragmentation, consequently, less energy is consumed to generate ground vibration. The impact of explosives was highlighted by the relatively frequent use of max. charge per delay (Wmax) and charge per delay (W), coming in fourth and fifth positions. Singh and Singh (https://www.abc.net.au/news/2022–03-11/teary-goodbye-first-williamstown-house-falls-northern-star/100900516) shed a light on the significance of explosives in the generation of blast vibrations. As for explosives, the ground vibration characteristics rely on the maximum charge per delay rather than the total explosive blasted. Some explosives like ANFO can generate higher gaseous energy than shock energy which induces higher amplitude air blast overpressures and lower ground vibrations. On the other hand, explosives with a lower velocity of detonation (VoD) generate significant vibrations compared to explosives with higher gaseous energy than shock energy, but a rather lower vibration. In terms of the least used parameters, e.g., stemming (T) and powder factor (q/Q), and stemming length in the generation of blast vibrations, notwithstanding their limited use, they still hold important role. The objective of stemming is to confine the explosive gases, to allow enough time to fracture the ground (Singh and Singh 2005) A long stemming length may improve the ground vibrations due to long confinement and high pressure, developed in blast holes (https://www.abc.net.au/news/2022–03-11/teary-goodbye-first-williamstown-house-falls-northern-star/100900516). Powder factor as explained by Orica (https://www.orica.com/products-services/resources/blasting-principles#.Y6E1OOxBy3I) is the quantity of explosives per unit volume or unit mass of rock fragmented/broken. This highlights the emphasis in the case studies on the amounts of the charge used to determine the intensity of the blast rather than on the resulting amounts of broken mass rock. For uncontrollable parameters such as rock density, rock quality, rock compressive strength, tensile strength, and modulus of elasticity, they were variably used for the purpose as depicted in Table 1.

Machine learning applications to fly rock phenomenon

Fly rock events can be described as the uncontrolled abrupt throw or movement of loose rock fragments/pieces discharged from blasting, and that can travel distances beyond the blasting zone(s) as the abrupt throw or movement of rock fragments/pieces because of the explosive energy (Dumakor-Dupey et al. 2021; Zhou et al. 2021a; Guo et al. 2021). Blast-induced fly rocks can cause an unmitigated impact on the surroundings as blasted rock fragments may go beyond the pile limits/blasting zone. As previously stated, researchers concluded that 70–80% of the total blast energy is wasted because of improper use of explosive energy; this leads to the occurrence of blast vibrations, air-overpressure, and especially fly rocks (Dumakor-Dupey et al. 2021; Singh and Singh 2005). Fly rocks are a dangerous issue that has the potential to cause harm and injury to mine workers, capital equipment, and others within the blasting radius. For instance, in 2018 and as reported by the Australasian Mine Safety Journal (The%20flyrock%20incident, metres%20from%20the%20blast%20site. xxxx), a fly rock incident occurred in a quarry in Albury-NSW in Australia. Fly rocks from a blast conducted by a contractor damaged three light vehicles parked a short distance and put seven people at risk of being struck in the exclusion zone. The incident was unreported for several months. The cause of the ejection of the fly rocks has not been determined at the time. Fly rocks come in a variety of shapes and sizes. The sizes of the fly rocks are directly proportionate to the blast hole diameter, the bigger the blast diameter, the larger the fly rocks’ size. The initial velocity of the throw is indirectly propionate to the fly rocks’ dimensions (Guo et al. 2021). The mechanisms of fly rocks generation shown in Fig. 5 were briefly described by Amini et al. (Amini et al. 2012). Rifling transpires due to inadequate stemming, causing blast gases to go up the blast hole with the least resistance, resulting in stemming ejection. Cratering occurs at a weakened layer caused by a previous blasting from the bench above. Blast gases easily stream with force into the air and propagate cracks in this weakened area. Face bursting eventuates when the explosive charges are present in adjoining weakened major geological structures orezone (Amini et al. 2012).

General cases of fly rocks mechanism from a column charged blast hole (Guo et al. 2021)

Fly rocks can be attributed to several factors according to Guo et al. (Guo et al. 2021). These factors may include incorrect loading and disposal of blast-hole, inadequate burden, aberrancy in the rock mass and geology structures, questionable firing delay, half-finished stemming, failure to use proper blasting cubbyhole, corrupt connections, and inadequate sentry of the blast area. Previously, researchers addressed the issue, through empirical equations such as the ones developed by Lundborg et al. (Lundborg 1981) and Gupta (Gupta 1980). The equations’ role was to predict the flying distance of the fly rocks, to establish a buffer and/ or exclusion zones to protect the workers, and the surrounding equipment, etc. However, these methods have not given researchers any confidence in their performances due to their incapability to forecast within 400-m throw distance due to the occasional poor decision on the rock conditions and failure deal with the complexities of the whole process (Jamei et al. 2021). Added to that, the site-specific nature of empirical methods because of the applicability of statistical data solely for certain areas where the measurements occurred (Jamei et al. 2021). To overcome the limitations of empirical models/equations, attempts have been made to minimize the prediction of the fly rock distance via ML techniques. Artificial neural networks (ANN) and other ML techniques were primarily the best performers in fly rock distances’ predictions for a brief period (early-2010s to mid-2010s, and a single appearance in 2021) as demonstrated in Table 2 and the studies’ issue dates in the references section. Researchers shifted their attention toward the use of hybrid/ensemble ML methods from the mid-2010s onwards. The performance of the prediction models was restricted to several input parameters. Fly rocks’ distance predictions are still influenced more by controllable (blast design and geometry) rather than uncontrollable factors (geological and geotechnical factors) as observed in Table 2. From the analysis, the most influencing and consistent input parameters are displayed in Fig. 6. Bearing in mind the mine sites’ differences, the top three parameters burden (B), stemming (T) and spacing (S) continue to dominate. Regarding the explosives, powder factor (q) and charge per delay (W) were included in pursuit of determining the amount of rock fragmented and the intensity of the explosion occurring such event. The least used of the blast design parameters are blast hole depth (Hde), blast hole diameter (Hdi), and maximum charge per delay (Wmax). The insignificant engagement of blast hole diameters and depth raises questions on their neglect despite the substantial impact on the size of the fly rocks as afore mentioned. Wmax sat the bottom of the least used, though it relates to the explosive energy discharged and founded on the maximum amount of explosive in use. Regarding uncontrollable parameters, georgical and rock mechanical parameters were minimally used for the purpose as noticed in Table 2, despite their potential influence on the event.

Machine learning applications to rock fragmentation

The primary goal of blasting in surface mining is to separate ore from the burden; the resulting fragmentations should have a size suitable for the loading, haulage, and downstream processes. For that purpose, ML techniques were involved in the prediction of rock fragmentation and particle size distribution in several published research articles. The topic was pursued by researchers and comes in the third place. As a matter of proactiveness, rock fragmentation size prediction was pursued by researchers via theoretical and empirical models (Jia et al. 2022). The blasting process is non-linear and hard to detect its intricacies. These theoretical and empirical methods have their boundaries, being founded on certain assumptions, and only a few influencing factors were considered (Jia et al. 2022). Hence, fragmentation sizes’ prediction needed a boost, which came from ML applications. ML applications with their exceptional computing, regression, and classification powers can overcome such difficulties encountered. Table 3 and the references section show that artificial neural networks (ANN) were the most used from the early-2010s to the early-2020s. However, it was a variable output of research of one study per year. Other ML techniques like fuzzy logic and GPR had short-lived roles in 2009 and 2018. In the late-2010s the topic was revitalized, and from that point, researchers persisted with the use of hybrid/ensemble ML methods. Despite the interest shown, it did not match the research output quantity, one to two studies per year. A moderate boost in research came in the late-2010s by the cases (Parvin Faraji et al. 2018; Duah et al. 2019; Mojtahedi et al. 2019; Ohadi et al. 2020; Fang et al. 2021; Xie et al. 2021). In 2021 and 2022, hybrids/ensembles were used as primary and secondary techniques, respectively. Jia et al. (Jia et al. 2022) attributed the appearance of this event primarily to three factors, rock mechanical characteristics, blasting parameters, and charging technology. These factors were represented through the prediction models’ input parameters and most used exhibited in Table 3, respectively. Regarding the most used parameters, Fig. 7 displays the most used ones. Coming as the top three parameters, burden (B), stemming (T), and spacing(S) were the leading parameters. Figure 7 highlights the drive toward optimizing the explosives’ energy through the inclusion of charge per delay (W) and powder factor (q) parameters for better fragmentations output. This inclusion of these two parameters is based on 30% or less of the explosive energy consumed for fragmentation. Less stress was given to other blast design parameters, e.g., charge per delay (Wmax), blast hole diameter (Hdi), and blast hole depth (Hde). This noteworthy minimal usage of these parameters may raise questions on their feasibility, despite their influences as previously stated in the preceding blast issues. Regarding the geological and rock mechanical parameters (see Table 3), they were not included at the same level as the blast design and geometry parameters, despite their potential impact on the process.

Machine learning applications to back break

Back break can be defined as damages beyond the limits of the rear row of holes in a blast pattern (Monjezi and Dehghani 2008). As shown in Fig. 8, the occurrence of back breaks can lead to rock fallings, mine wall instability, and improper fragmentation (Sharma et al. 2022). Sharma et al. (Sharma et al. 2022) stated the causative factors of back breaks, and it may include longer stemming length on stiff benches, improper/insufficient delay timing, increasing number of rows in a blast round, low stiffness ratio, and excessive burden. Efforts were invested to find a solution for this problem, though the prediction of the back break from the blast data. Empirical methods were applied to the issue; however, it was hindered by the increased number and problematic relations of effective parameters (Monjezi and Dehghani 2008). ML methods provided alternative path to address the issue in question. As observed from Table 4 and the references section, the path to resolution started in the late-2000s and late early-2010s with artificial neural networks (ANN) in two cases (Monjezi et al. 2010) and (Sayadi et al. 2013). Support vector machine (SVM) was utilized once in the study (Khandelwal and Monjezi 2012) in the early-2010s. A lack of steady research output is observed from the timeline indicated in the references section. The topic was revitalized in the mid-2010s, using hybrid/ensemble ML methods by the case (Esmaeili et al. 2014) onwards. Since then, predictions of back break are relatively more reliant on them rather than applying an individual ML approach (Fig. 9). Sharma et al. (Sharma et al. 2022) identified the influential parameters in the generation of back break, and they were stemming (T), burden (B), spacing (S), and depth of the hole (Hde). In this sample of studies, the powder factor/specific charge (q/Q) parameter was found to be more in place of the parameter Hde. Blast hole diameter (Hdi) and charge per delay (W) were found at the bottom of the input parameters. This is irrespective of their potential effect on blast’s intensity and outcomes as perceived from the former blast issues. The geological and rock mechanical characteristic parameters (uncontrollable parameters) were the least used as seen in Table 4, notwithstanding their potential influence on the event.

Back breaks observed at the crust of bench in Tehran Cement (Hasanipanah et al. 2017a)

Machine learning applications to other surface blasting issues

Surface blasting has other matter problems to address such as air blast pressure, barrier wall, and blast deign and performance. ML techniques have also been applied to those issues as shown in Table 5. The other areas of research are as shown in Table 5, the blasting issues, blast wall barrier (Remennikov and Rose 2007), and blast design parameters (Rezaei et al. 2012; Khandelwal and Singh 2013; Mishra et al. 2018). The first three studies employed ANN as the main ML technique, while the fourth study employed both ANN and random forest (RF) for the purpose, respectively. Unfortunately, no further studies were provided to assist with additional analysis for the matters. Air overpressure or airblasts appear to be an issue relatively better covered than the other blasting problems on the same level. Airblasts are described by Dumakor-Dupey et al. (Dumakor-Dupey et al. 2021) as explosion-induced large shock waves that are diverted horizontally by density disparities in the atmosphere. The atmospheric pressure waves of air blasts include both high audible frequency and subaudible low-frequency sound. Air blasts can affect structures nearby the blast zone by shaking windows and the roofing materials. To avoid the negative effects of the air blast, empirical models/equations were employed for prediction of airblasts. However, they faced the same unsatisfactory results encountered with the top four issues (Dumakor-Dupey et al. 2021). Researchers turned their attention to ML methods to overcome the negatives of empirical models. The use of hybrid/ensemble ML methods in forecasting airblasts came in the mid-2010s by Hajihassani et al. (2014) and carried on to the early-2020s by Nguyen et al. 2020b. From that point, hybrid/ensemble ML methods maintained course as the main ML technique for airblasts’ prediction. Regarding input parameters, only two input parameters dominated the scene as seen in Table 5 and Fig. 10 were the most used: max charge per delay (Wmax) and monitoring distance (MD). Max charge per delay (Wmax) is an indicative of the explosive energy released based on the maximum amount of explosive charge per delay, resulting in airblasts. Monitoring distance (MD) is significant for measuring the distance traveled by the shock wave to the affected points in the blast zone or beyond. However, unlike the previous top blast issues and despite their significance in the generation of airblasts as previously stated, burden (B), stemming (T), and spacing (S) were less included in the predictions.

Applications of machine learning in underground mine blasting

The very nature of underground operations and their relative complexities make it difficult for researchers to apply ML (Musingwini 2016). Regardless of the challenges, researchers continue to focus their energies on minimizing/eliminating the blasting linked issues such as seismic events and poor fragmentations. The research literature witnessed how researchers took advantage of the powerful classification and regression capabilities of ML techniques. Like surface blasting, the comparative approach emerged to be the most involved way, with individual applications of ML techniques at a lesser rate. The most frequently applied methods are hybrid/ensemble ML methods, artificial neural networks (ANN) and support vector machine (SVM), as shown in Fig. 10. The top four underground blast issues handled by ML methods are blast vibration, overbreak/underbreak, blast performance, and stope failure, as exhibited by Fig. 11. ML applications to underground blasting appear to be experiencing a low yearly production of research case studies as shown in Fig. 12. The only beneficiary topic is underground blast vibrations, which had the most attention, especially between the 2019s and the 2020s. This may confirm the notion of underground blasting has a rather less than ordinary consideration from researchers primarily due to its very nature. This presents a cause for concern from a long-term benefit perspective. The following sub-sections will demonstrate the trends of ML techniques in relation to the top four underground blast issues. This trend investigation will give a brief account of the size of the use of the adopted ML technique(s), conversion from one dominating ML technique to another, and the tendencies of the input parameters impacting predictions, per each of the top four underground blast issues.

Machine learning application to underground mine blast vibration

Underground-induced vibrations are a natural companion of underground blasting. If they are not minimized and controlled, vibrations can negatively affect the surrounding of the operations and most importantly the workers’ safety. Xu et al. (Xu et al. 2019) stated that underground blast vibrations may result in rib spalling, rock burst, and collapse in the underground developments or works. Sensing and recording of the generated vibrations are one primary tool as aforementioned in surface blast vibrations. However, proactivity become a priority. To lessen the unfavorable influences of vibrations, empirical models such as USBM predictor, Langefors–Kihlstrom model, Bureau of Indian Standards criteria, and CMRI predictor (Xu et al. 2019) involved only two parameters: maximum charge per delay (Wmax) and monitoring distance. The empirical model overlooked other influencing parameters such as spacing (S), burden (B), hole depth (Hde), hole diameter (Hdi), powder factor (q), number of holes (Nh), number of delays (Nd), and rock mass parameters (Xu et al. 2019). This deficiency in the empirical models led to the introduction ML techniques to predict blast vibration ML techniques which were considered as a preventative measure due to their exceptional computational capabilities, and the advantage of involving more than two parameters per model. The topic has been addressed by researchers via several ML techniques as revealed in Table 6. Individual techniques such as artificial neural networks (ANN) produced three studies in the mid-2000s (Lu 2005), and in early 2020s (Paneiro and Rafael 2021; Kumar et al. 2021b), respectively. This prevalence of ANN was not consistent; hybrid/ensemble ML methods reigned starting the late-2010s onwards, which may confirm their status established by Zhang et al. (Zhang et al. 2020b) through engaging eXtreem Gradient Boosting (XGBoost). Like surface blast vibrations, monitoring distance (MD) is leading the way, as depicted in Fig. 13. On same level but less regularly, spacing (S), charge per delay (W), max.charge per delay (Wmax), burden (B), and powder factor (q) are used to address the issue. In terms of uncontrollable parameters (geological and rock mechanical properties), they were minimally used except for the cases (Lu 2005; Kumar et al. 2021b; Rao et al. 2021).

Machine learning application to predict overbreak and underbreak phenomena

Overbreaks and underbreaks are unpredictable and inventible occurrences associated with underground drilling and blasting (Jang and Topal 2013). Overbreaks can be defined as an excess of the drilled and blasted/excavated area of rock past the theoretical contour in an excavation (Jang and Topal 2013). This surplus rock requires to be removed to attain the final profile of the tunnel/heading. In terms of underground mining, overbreak and underbreak have undesirable effects like unplanned ore dilution shown in Fig. 14 (Jang et al. 2020).

Overbreak and underbreak effect-unplanned dilution (Jang et al. 2020)

Several causative factors are to be considered when demonstrating overbreak. The causative factors to overbreaks and underbreaks can be categorized into blasting geology-geotechnical, stope design, and operational errors (Jang and Topal 2013). Practical avoidance methods were proposed to diminish the influence of overbreak and underbreak which may include (i) addition of extra holes to make up for the unconcentrated charge at the perimeter, (ii) avoidance of drilling at and toward discontinuities, (iii) decreasing holes in the case of the extreme weak geological zone, and (iv) delay control use at the boundaries and the buffer line to lessen the overbreak (Dumakor-Dupey et al. 2021). Besides the above-mentioned preventative methods, to manage overbreak and underbreak, an establishment of a predictor empirical model was considered. However, the idea did not gain any momentum due to two factors: (i) the complex nature of the prediction of overbreak and (ii) the compound relationship between the causative factors and overbreak is not clear (Mottahedi et al. 2018).

ML prediction models with their exceptional capabilities offered as an alternative approach and have been gaining some momentum over time. Artificial neural network (ANN) maintained its number one position as the technique employed with a 100% share of the applications in a limited number of cases (Jang et al. (Jang et al. 2020), Jang et al. (Jang et al. 2015), Jang et al. (Jang et al. 2019)). The cases were produced in the mid-2010s and the late-2010s, with gaps of 4 to 5 years. Alternatives to ANN are yet to be applied to the blasting issue in question. From the long-term perspective, it is a matter of concern. Regarding the input parameters utilized, as observed from Table 7 and Fig. 15, the first and the last case studies share some of the blast design input parameters, e.g., blast hole diameter (Hdi), angle difference between the hole and the wall (AWH), aspect ratio of stope [W/H], SPT: tons of stope planned [tons], and SAR: aspect ratio of stope [W/H]. As for the second case, it only involves more geological and geotechnical parameters (uncontrollable parameters) rather than blast parameters.

Machine learning application to underground blast performance

To gage the effectiveness of the blast design in achieving its indented function with the least number of problems, a performance measure is required. For that purpose, researchers undertook the mission to assess the wellness of the underground blast practices. One case was released in the late-2000s (Jiang et al. 2009) in which a hybrid/ensemble ML method was employed for the purpose. The authors (Jiang et al. 2009) stated that only two methods were previously used for the purpose, and they are blasting crater test method and small-scale industrial test and a variety of individual ML methods, e.g., ANN, to optimize the blasting parameters. The first method relied on engineering geologic condition and existing mining structure parameters. The methods employed faced obstacles. For instance, blasting crater and small-scale industrial test is time consuming and requires large manpower, material, and financial resources. Regarding intelligent methods, artificial neural network (ANN) makes it hard to guarantee accuracy; genetic algorithm (GA) coding is more difficult and prone to “premature” phenomenon. Thus, it was essential to find an alternative way: hybrids/ensembles. The authors (Jiang et al. 2009) resorted to use of hybrid/ensemble rough set base-artificial neural networks (RS-ANN) to predict the consumption of explosives (kg/t). The input parameters were f coefficient, rock bulk density [kg/cm3], blast hole diameter (Hdi), blast hole depth (Hde), the smallest resistance line divided by hole diameter (W/d) value, and spacing (S). No more cases were found, which should be considered prudently for the future benefit of the issue in question.

Machine learning application to underground stope failure

Stope failure is major concern for underground mining in terms of safety. The causes of the event were briefly described by Bourmas and Tsakiri (Bourmas and Tsakiri 2009). Stope failure comes from the sagging of the hanging wall because of geotechnical factors (rockfalls or bursts) and rock blasting factors. The sagging if uncontrolled is followed by rockfalls or bursts. As practical measure, the authors suggested the installation of dowels to increase stopes’ stability and help the hanging wall support its weight. The pattern and density of the installation is reliant on the visual inspection and geotechnical experience of the shift supervisor (Bourmas and Tsakiri 2009). In the only case study found, the stope failure criterion only employed decision tree (DT), an ensemble, for the purpose in the late-2000s by Bourmas and Tsakiri (Bourmas and Tsakiri 2009). The input failure parameters were stope surface area (m2), distance between the stope centroid and the blast face (m), and the number of explosives (kg). The output of the DT was the effect on the cohesion of the rock mass: low, intermediate, and high. Unfortunately, no additional cases were discovered, due to the scarcity of research papers on this subject or other underground blast-related areas. It is not possible to give a full picture of their progress in terms of ML applications and consequently trends.

Discussion and conclusions

The study presented is aimed at reviewing the status of ML method applications to mine blasting issues. The trends of ML applications give us a snapshot of the status of research and development, in the field, from the pros and cons perspectives. The review reveals a surge in the use of the of highly developed ML methods as best performers (61% of the sample) for both surface and underground blasting. The dominance was achieved over the last decade research wise. A progress in surface blasting optimization through the use of highly developed ML methods has been achieved and shall be able continued given the right means and conditions. Added to that, the bigger participation of uncontrollable parameters, the more added value to the predictions sought and putting into account the complexities of the operational conditions. Underground blasting optimization still faces a tougher uphill battle as a result of the operational challenges encountered and low rates of research as depicted by the analysis. This is despite the slight high involvement of well-developed ML methods such as hybrids/ensembles, in the researchers’ perspective to the blasting process.

ML techniques can be considered a game changer in a highly data-driven complex mining environment and a suitable tool to the inevitable adoption of automated mining. To uphold the case for highly developed ML methods, more energies are required to (i) boost the awareness of technological developments, (ii) further the cooperation between research institutions and mining companies, and (iii) improve technological skill development among mining employees, thus ascertaining their vital role to offer better optimization practices and ensure the longevity and prosperity of the mining industry.

Change history

23 February 2023

Missing Open Access funding information has been added in the Funding Note.

References

Ali D, Frimpong S (2020) Artificial intelligence, machine learning and process automation: existing knowledge frontier and way forward for mining sector. Artif Intell Rev 53(8):6025–6042. https://doi.org/10.1007/s10462-020-09841-6

Álvarez-Vigil AE, González-Nicieza C, López Gayarre F, Álvarez-Fernández MI (2012) Predicting blasting propagation velocity and vibration frequency using artificial neural networks. Int J Rock Mech Min Sci 55:108–116. https://doi.org/10.1016/j.ijrmms.2012.05.002

Amini H, Gholami R, Monjezi M, Torabi SR, Zadhesh J (2012) Evaluation of fly rocks phenomenon due to blasting operation by support vector machine. Neural Comput Appl 21(8):2077–2085. https://doi.org/10.1007/s00521-011-0631-5

Amiri M, Bakhshandeh Amnieh H, Hasanipanah M, Mohammad Khanli L (2016) A new combination of artificial neural network and K-nearest neighbors models to predict blast-induced ground vibration and air-overpressure. Eng Comput 32(4):631–644. https://doi.org/10.1007/s00366-016-0442-5

Bahrami A, Monjezi M, Goshtasbi K, Ghazvinian A (2011) Prediction of rock fragmentation due to blasting using artificial neural network. Eng Comput 27(2):177–181. https://doi.org/10.1007/s00366-010-0187-5

Bayat P, Monjezi M, Rezakhah M, Armaghani DJ (2020) Artificial neural network and firefly algorithm for estimation and minimization of ground vibration induced by blasting in a mine. Nat Resour Res 29(6):4121–4132. https://doi.org/10.1007/s11053-020-09697-1

Bourmas G, Tsakiri M (2009) Using decision trees to build a failure criterion for an underground mine. In (Vol. 1, pp. 845–850). Sofia: Surveying Geology & Mining Ecology Management (SGEM)

Chakraborty AK, Guha P, Chattopadhyay B, Pal S, Das J (2004) A fusion neural network for estimation of blasting vibration, Berlin, Heidelberg

Dauji S (2020) Prediction accuracy of underground blast variables: decision tree and artificial neural network. Intl J Earthq Impact Eng 3(1). https://doi.org/10.1504/IJEIE.2020.105382

Dehghani H, Shafaghi M (2017) Prediction of blast-induced fly rocks using differential evolution algorithm. Eng Comput 33(1):149–158. https://doi.org/10.1007/s00366-016-0461-2

Dindarloo, S. R. (2015). Peak particle velocity prediction using support vector machines: a surface blasting case study. Journal of the Southern African Institute of Mining and Metallurgy, 115, 637–643. Retrieved from http://www.scielo.org.za/scielo.php?script=sci_arttext&pid=S2225-62532015000700012&nrm=iso

Ding X, Hasanipanah M, Nikafshan Rad H, Zhou W (2021) Predicting the blast-induced vibration velocity using a bagged support vector regression optimized with firefly algorithm. Eng Comput 37(3):2273–2284. https://doi.org/10.1007/s00366-020-00937-9

Duah P, Abbaspour H, Kansake B, Drebenstedt C (2019) Unraveling the capability of artificial intelligence for prediction of rock fragmentation

Dumakor-Dupey NK, Arya S, Jha A (2021) Advances in blast-induced impact prediction—a review of machine learning applications. Minerals 11(6):601

Esmaeili M, Osanloo M, Rashidinejad F, Aghajani Bazzazi A, Taji M (2014) Multiple regression, ANN and ANFIS models for prediction of backbreak in the open pit blasting. Eng Comput 30(4):549–558. https://doi.org/10.1007/s00366-012-0298-2

Fang Q, Nguyen H, Bui X-N, Nguyen-Thoi T (2020) Prediction of blast-induced ground vibration in open-pit mines using a new technique based on imperialist competitive algorithm and M5Rules. Nat Resour Res 29(2):791–806. https://doi.org/10.1007/s11053-019-09577-3

Fang Q, Nguyen H, Xuan-Nam B, Nguyen-Thoi T, Zhou J (2021) Modeling of rock fragmentation by firefly optimization algorithm and boosted generalized additive model. Neural Comput Appl 33(8):3503–3519. https://doi.org/10.1007/s00521-020-05197-8

Fattahi H, Hasanipanah M (2021) An integrated approach of ANFIS-grasshopper optimization algorithm to approximate fly rocks D in mine blasting. Eng Computhttps://doi.org/10.1007/s00366-020-01231-4

Fişne A, Kuzu C, Hüdaverdi T (2011) Prediction of environmental impacts of quarry blasting operation using fuzzy logic. Environ Monit Assess 174(1):461–470. https://doi.org/10.1007/s10661-010-1470-z

Franco-Sepúlveda G, Del Rio-Cuervo JC, Pachón-Hernández MA (2019) State of the art about metaheuristics and artificial neural networks applied to open pit mining. Resour Policy 60:125–133. https://doi.org/10.1016/j.resourpol.2018.12.013

Gao W, Karbasi M, Hasanipanah M, Zhang X, Guo J (2018) Developing GPR model for forecasting the rock fragmentation in surface mines. Eng Comput 34(2):339–345. https://doi.org/10.1007/s00366-017-0544-8

Ghasemi E, Amini H, Ataei M, Khalokakaei R (2012) Application of artificial intelligence techniques for predicting the fly rocks D caused by blasting operation. Arab J Geosci 7(1):193–202. https://doi.org/10.1007/s12517-012-0703-6

Ghasemi E, Ataei M, Hashemolhosseini H (2013) Development of a fuzzy model for predicting ground vibration caused by rock blasting in surface mining. J Vib Control 19(5):755–770. https://doi.org/10.1177/1077546312437002

Ghasemi E, Amnieh HB, Bagherpour R (2016) Assessment of backbreak due to blasting operation in open pit mines: a case study. Environ Earth Sci 75(7):552. https://doi.org/10.1007/s12665-016-5354-6

Guo H, Zhou J, Koopialipoor M, Jahed Armaghani D, Tahir MM (2021) Deep neural network and whale optimization algorithm to assess fly rocks induced by blasting. Eng Comput 37(1):173–186. https://doi.org/10.1007/s00366-019-00816-y

Gupta R (1980) Surface blasting and its impact on environment. Impact of mining on environment. Ashish Publishing House, New Delhi, 23-24

Hajihassani M, Jahed Armaghani D, Sohaei H, Tonnizam Mohamad E, Marto A (2014) Prediction of airblast-overpressure induced by blasting using a hybrids/ensembles artificial neural network and particle swarm optimization. Appl Acoust 80:57–67. https://doi.org/10.1016/j.apacoust.2014.01.005

Han H, Jahed Armaghani D, Tarinejad R, Zhou J, Tahir MM (2020) Random forest and Bayesian network techniques for probabilistic prediction of fly rocks induced by blasting in quarry sites. Nat Resour Res 29(2):655–667. https://doi.org/10.1007/s11053-019-09611-4

Handar KR, Sastry VR, Hegde C (2017) A critical comparison of regression models and artificial neural networks to predict ground vibrations. Geotech Geol Eng, 35(2), 573-583https://doi.org/10.1007/s10706-016-0126-3

Hasanipanah M, Jahed Armaghani D, Khamesi H, Bakhshandeh Amnieh H, Ghoraba S (2016) Several non-linear models in estimating air-overpressure resulting from mine blasting. Eng Comput 32(3):441–455. https://doi.org/10.1007/s00366-015-0425-y

Hasanipanah M, Shahnazar A, Arab H, Saeid Bagheri G, Amiri M (2017a) Developing a new hybrids/ensembles-AI model to predict blast-induced backbreak. Eng Comput 33(3):349–359. https://doi.org/10.1007/s00366-016-0477-7

Hasanipanah M, Shahnazar A, Bakhshandeh Amnieh H, Jahed Armaghani D (2017b) Prediction of air-overpressure caused by mine blasting using a new hybrids/ensembles PSO-SVR model. Eng Comput 33(1):23–31. https://doi.org/10.1007/s00366-016-0453-2

Hasanipanah M, Keshtegar B, Thai D-K, Troung N-T (2020) An ANN-adaptive dynamical harmony search algorithm to approximate the fly rocks resulting from blasting. Eng Computhttps://doi.org/10.1007/s00366-020-01105-9

https://www.orica.com/products-services/resources/blasting-principles#.Y6E1OOxBy3I ( accessed 20/12/22)

Huang J, Koopialipoor M, Jahed AD (2020) A combination of fuzzy Delphi method and hybrids/ensembles ANN-based systems to forecast ground vibration resulting from blasting. Scientific Reports (Nature Publisher Group), 10(1). https://doi.org/10.1038/s41598-020-76569-2

Iphar M, Yavuz M, Ak H (2008) Prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neuro-fuzzy inference system. Environ Geol 56(1):97–107. https://doi.org/10.1007/s00254-007-1143-6

Jahed Armaghani D, Hasanipanah M, Tonnizam Mohamad E (2016) A combination of the ICA-ANN model to predict air-overpressure resulting from blasting. Eng Comput 32(1):155–171. https://doi.org/10.1007/s00366-015-0408-z

Jahed Armaghani D, Hasanipanah M, Mahdiyar A, Abd Majid MZ, Bakhshandeh Amnieh H, Tahir M (2018) Airblast prediction through a hybrids/ensembles genetic algorithm-ANN model. Neural Comput Appl, 29. doi:https://doi.org/10.1007/s00521-016-2598-8

Jahed Armaghani D, Kumar D, Samui P, Hasanipanah M, Roy B (2020) A novel approach for forecasting of ground vibrations resulting from blasting: modified particle swarm optimization coupled extreme learning machine. Eng Computhttps://doi.org/10.1007/s00366-020-00997-x

Jamei M, Hasanipanah M, Karbasi M, Ahmadianfar I, Taherifar S (2021) Prediction of fly rocks induced by mine blasting using a novel kernel-based extreme learning machine. J Rock Mech Geotech Eng 13(6):1438–1451. https://doi.org/10.1016/j.jrmge.2021.07.007

Jang H, Topal E, Kawamura Y (2015) Unplanned dilution and ore loss prediction in longhole stoping mines via multiple regression and artificial neural network analyses. Journal of the Southern African Institute of Mining and Metallurgy, 115, 449–456. Retrieved from http://www.scielo.org.za/scielo.php?script=sci_arttext&pid=S2225-62532015000500018&nrm=iso

Jang H, Kawamura Y, Shinji U (2019) An empirical approach of overbreak resistance factor for tunnel blasting. Tunn Undergr Space Technol, 92, 103060. https://doi.org/10.1016/j.tust.2019.103060

Jang H, Taheri S, Topal E, Kawamura Y (2020) Illumination of contributing parameters of uneven break in narrow vein mine, Cham

Jang H, Topal E (2013) Optimizing overbreak prediction based on geological parameters comparing multiple regression analysis and artificial neural network. Tunn Undergr Space Technol 38:161–169. https://doi.org/10.1016/j.tust.2013.06.003

Jang H, Topal E (2014) Review article: a review of soft computing technology applications in several mining problems. Appl Soft Comput 22:638–651. https://doi.org/10.1016/j.asoc.2014.05.019

Jia Z, Song Z, Fan J, Jiang J (2022) Prediction of blasting fragmentation based on GWO-ELM. Shock Vib 2022:7385456. https://doi.org/10.1155/2022/7385456

Jiang F, Zhou K, Deng H, Li X, Zhong Y (2009, 12–14 Dec. 2009) An optimized model for blasting parameters in underground mines’ deep-hole caving based on rough set and artificial neural network. Paper presented at the 2009 Second International Symposium on Computational Intelligence and Design

Jiang Z, Xu H, Chen H, Gao B, Jia S, Yu Z, Zhou J (2021) Indirect determination approach of blast-induced ground vibration based on a hybrids/ensembles SSA-optimized GP-based technique. Adv Civil Eng, 2021. https://doi.org/10.1155/2021/6694918

Jong SC, Ong DEL, Oh E (2021) State-of-the-art review of geotechnical-driven artificial intelligence techniques in underground soil-structure interaction. Tunn Undergr Space Technol, 113, 103946. https://doi.org/10.1016/j.tust.2021.103946

Kalaivaani PT, Akila T, Tahir MM, Munir A, Aravindhan S (2020) A novel intelligent approach to simulate- the blast-induced fly rocks based on RFNN combined with PSO. Eng Comput 36(2):435–442. https://doi.org/10.1007/s00366-019-00707-2

Ke B, Nguyen H, Bui X-N, Costache R (2021) Estimation of ground vibration intensity induced by mine blasting using a state-of-the-art hybrids/ensembles autoencoder neural network and support vector regression model. Natl Resour Reshttps://doi.org/10.1007/s11053-021-09890-w

Khandelwal M (2011) Blast-induced ground vibration prediction using support vector machine. Eng Comput (lond) 27:193–200. https://doi.org/10.1007/s00366-010-0190-x

Khandelwal M, Monjezi M (2012) Prediction of backbreak in open-pit blasting operations using the machine learning method. Rock Mech Rock Eng 46(2):389–396. https://doi.org/10.1007/s00603-012-0269-3

Khandelwal M, Singh TN (2009) Prediction of blast-induced ground vibration using artificial neural network. Int J Rock Mech Min Sci 46(7):1214–1222. https://doi.org/10.1016/j.ijrmms.2009.03.004

Khandelwal M, Singh TN (2013) Application of an expert system to predict maximum explosive charge used per delay in surface mining. Rock Mech Rock Eng 46(6):1551–1558. https://doi.org/10.1007/s00603-013-0368-9

Khandelwal M, Armaghani DJ, Faradonbeh RS, Yellishetty M, Majid MZ, Abd, Monjezi M (2017) Classification and regression tree technique in estimating peak particle velocity caused by blasting. Eng Comput, 33(1), 45-53https://doi.org/10.1007/s00366-016-0455-0

Kumar S, Mishra AK, Choudhary BS (2021a) Prediction of back break in blasting using random decision trees. Engineering with Computershttps://doi.org/10.1007/s00366-020-01280-9

Kumar S, Chandra Dutta S, Goswami K, Mandal P (2021b) Vulnerability assessment of building structures due to underground blasts using ANN and non-linear dynamic analysis. J Build Eng, 44, 102674. https://doi.org/10.1016/j.jobe.2021.102674

Longjun D, Xibing L, Ming X, Qiyue L (2011) Comparisons of random forest and support vector machine for predicting blasting vibration characteristic parameters. Procedia Eng 26:1772–1781. https://doi.org/10.1016/j.proeng.2011.11.2366

Lu Y (2005) Underground blast induced ground shock and its modelling using artificial neural network. Comput Geotech 32(3):164–178. https://doi.org/10.1016/j.compgeo.2005.01.007

Lu X, Hasanipanah M, Brindhadevi K, Bakhshandeh Amnieh H, Khalafi S (2020) ORELM: a novel machine learning approach for prediction of fly rocks in mine blasting. Nat Resour Res 29(2):641–654. https://doi.org/10.1007/s11053-019-09532-2

Lundborg N (1981) The probability of flyrock; SveDeFo: Stockholm; Sweden

Manoj K, M, M. (2013) Prediction of fly rocks in open pit blasting operation using machine learning method. Intl J Min Sci Technol, 23(3), 313-316https://doi.org/10.1016/j.ijmst.2013.05.005

Marto A, Hajihassani M, Danial Jahed A, Mohamad ET, Ahmad Mahir M (2014) A novel approach for blast-induced fly rocks prediction based on imperialist competitive algorithm and artificial neural network. Sci World J, 2014. https://doi.org/10.1155/2014/643715

Mehrdanesh A, Monjezi M, Khandelwal M, Bayat P (2021) Application of various robust techniques to study and evaluate the role of effective parameters on rock fragmentation. Eng Computhttps://doi.org/10.1007/s00366-021-01522-4

Mishra AK, Ramteke SV, Sen P, Verma AK (2018) Random forest tree based approach for blast design in surface mine. Geotech Geol Eng 36(3):1647–1664. https://doi.org/10.1007/s10706-017-0420-8

Mojtahedi SFF, Isa E, Hasanipanah M, Bonakdari H, Hassan Bakhshandeh A (2019) Proposing a novel hybrids/ensembles intelligent model for the simulation of particle size distribution resulting from blasting. Eng Comput 35(1):47–56. https://doi.org/10.1007/s00366-018-0582-x

Monjezi M, Dehghani H (2008) Evaluation of effect of blasting pattern parameters on back break using neural networks. Int J Rock Mech Min Sci 45:1446–1453. https://doi.org/10.1016/j.ijrmms.2008.02.007

Monjezi M, Rezaei M, Yazdian Varjani A (2009) Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int J Rock Mech Min Sci 46(8):1273–1280. https://doi.org/10.1016/j.ijrmms.2009.05.005

Monjezi M, Rezaei M, Yazdian A (2010) Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Syst Appl 37(3):2637–2643. https://doi.org/10.1016/j.eswa.2009.08.014

Monjezi M, Bahrami A, Varjani A, Sayadi AR (2011) Prediction and controlling of fly rocks in blasting operation using artificial neural network. Arab J Geosci 4:421–425. https://doi.org/10.1007/s12517-009-0091-8

Mottahedi A, Sereshki F, Ataei M (2018) Development of overbreak prediction models in drill and blast tunneling using soft computing methods. Eng Comput, 34. doi:https://doi.org/10.1007/s00366-017-0520-3

Murlidhar BR, Kumar D, Jahed Armaghani D, Mohamad ET, Roy B, Pham BT (2020) A novel intelligent ELM-BBO technique for predicting D of mine blasting-induced fly rocks. Nat Resour Res 29(6):4103–4120. https://doi.org/10.1007/s11053-020-09676-6

Musingwini C (2016) Optimization in underground mine planning - developments and opportunities. J South Afr Inst Min Metall, 116, 809–820. Retrieved from http://www.scielo.org.za/scielo.php?script=sci_arttext&pid=S2225-62532016000900003&nrm=iso

Nguyen H, Bui X-N, Moayedi H (2019a) A comparison of advanced computational models and experimental techniques in predicting blast-induced ground vibration in open-pit coal mine. Acta Geophys 67(4):1025–1037. https://doi.org/10.1007/s11600-019-00304-3

Nguyen H, Xuan-Nam B, Hoang-Bac B, Cuong Dao T (2019b) Developing an XGBoost model to predict blast-induced peak particle velocity in an open-pit mine: a case study. Acta Geophys 67(2):477–490. https://doi.org/10.1007/s11600-019-00268-4

Nguyen H, Bui X-N, Choi Y, Lee CW, Armaghani DJ (2021) A novel combination of whale optimization algorithm and support vector machine with different kernel functions for prediction of blasting-induced fly-rock in quarry mines. Nat Resour Res 30(1):191–207. https://doi.org/10.1007/s11053-020-09710-7

Nguyen H, Bui X-N, Nguyen-Thoi T, Ragam P, Moayedi H (2019c) Toward a state-of-the-art of fly-rock prediction technology in open-pit mines using EANNs model. Appl Sci, 9(21), 4554. Retrieved from https://www.Dpi.com/2076-3417/9/21/4554

Nguyen H, Choi Y, Bui X-N, Nguyen-Thoi T (2020a) Predicting blast-induced ground vibration in open-pit mines using vibration sensors and support vector regression-based optimization algorithms. Sensors, 20(1), 132. Retrieved from https://www.Dpi.com/1424-8220/20/1/132

Nguyen H, Bui X-N, Tran Q-H, Van Hoa P, Nguyen D-A, Hoa LTT, ... Moayedi H (2020b) A comparative study of empirical and ensemble machine learning algorithms in predicting air over-pressure in open-pit coal mine. Acta Geophysica, 68(2), 325–336. doi:https://doi.org/10.1007/s11600-019-00396-x

Nikafshan Rad H, Bakhshayeshi I, Wan Jusoh WA, Tahir MM, Foong LK (2020) Prediction of fly rocks in mine blasting: a new computational intelligence approach. Nat Resour Res 29(2):609–623. https://doi.org/10.1007/s11053-019-09464-x

Ohadi B, Sun X, Esmaieli K, Consens MP (2020) Predicting blast-induced outcomes using random forest models of multi-year blasting data from an open pit mine. Bull Eng Geol Env 79(1):329–343. https://doi.org/10.1007/s10064-019-01566-3

Paneiro G, Rafael M (2021) Artificial neural network with a cross-validation approach to blast-induced ground vibration propagation modeling. Underground Space 6(3):281–289. https://doi.org/10.1016/j.undsp.2020.03.002\

Parvin Faraji A, Monjezi M, Jafar Khademi H, Danial Jahed A (2018) Optimization of fly rocks and rock fragmentation in the Tajareh limestone mine using metaheuristics method of firefly algorithm. Eng Comput 34(2):241–251. https://doi.org/10.1007/s00366-017-0535-9

Peng K, Zeng J, Armaghani DJ, Hasanipanah M, Chen Q (2021) A novel combination of gradient boosted tree and optimized ANN models for forecasting ground vibration due to quarry blasting. Natural Resources Researchhttps://doi.org/10.1007/s11053-021-09899-1

Qiu Y, Zhou J, Khandelwal M, Yang H, Yang P, Li C (2021) Performance evaluation of hybrids/ensembles WOA-XGBoost, GWO-XGBoost and BO-XGBoost models to predict blast-induced ground vibration. Eng Comput. doi:https://doi.org/10.1007/s00366-021-01393-9

Rao D, Shi X, Zhou J, Yu Z, Gou Y, Dong Z, Zhang J (2021) An expert artificial intelligence model for discriminating microseismic events and mine blasts. Appl Sci 11(14):6474. https://doi.org/10.3390/app11146474

Remennikov AM, Rose TA (2007) Predicting the effectiveness of blast wall barriers using neural networks. Int J Impact Eng 34(12):1907–1923. https://doi.org/10.1016/j.ijimpeng.2006.11.003

Rezaei M, Monjezi M, Yazdian Varjani A (2011) Development of a fuzzy model to predict fly rocks in surface mining. Saf Sci 49(2):298–305. https://doi.org/10.1016/j.ssci.2010.09.004

Rezaei M, Monjezi M, Ghorbani Moghaddam S, Farzaneh F (2012) B prediction in blasting operation using rock geomechanical properties. Arab J Geosci 5(5):1031–1037. https://doi.org/10.1007/s12517-010-0269-0

Rezaeineshat A, Monjezi M, Mehrdanesh A, Khandelwal M (2020) Optimization of blasting design in open pit limestone mines with the aim of reducing ground vibration using robust techniques. Geomech Geophys Geo-Energy Geo-Resour 6(2):40. https://doi.org/10.1007/s40948-020-00164

Saghatforoush A, Monjezi M, Shirani Faradonbeh R, Jahed Armaghani D (2016) Combination of neural network and ant colony optimization algorithms for prediction and optimization of fly rocks and back-break induced by blasting. Eng Comput 32(2):255–266. https://doi.org/10.1007/s00366-015-0415-0

Sayadi A, Monjezi M, Talebi N, Khandelwal M (2013) A comparative study on the application of various artificial neural networks to simultaneous prediction of rock fragmentation and backbreak. J Rock Mech Geotech Eng 5(4):318–324. https://doi.org/10.1016/j.jrmge.2013.05.007

Shang Y, Nguyen H, Bui X-N, Tran Q-H, Moayedi H (2020) A novel artificial intelligence approach to predict blast-induced ground vibration in open-pit mines based on the firefly algorithm and artificial neural network. Nat Resour Res 29(2):723–737. https://doi.org/10.1007/s11053-019-09503-7

Sharma M, Agrawal H, Choudhary BS (2022) Multivariate regression and genetic programming for prediction of backbreak in open-pit blasting. Neural Comput Appl 34(3):2103–2114. https://doi.org/10.1007/s00521-021-06553-y

Singh TN, Singh V (2005) An intelligent approach to prediction and control ground vibration in mines. Geotech Geol Eng 23(3):249–262. https://doi.org/10.1007/s10706-004-7068-x

Taheri K, Hasanipanah M, Saeid Bagheri G, Muhd Zaimi Abd M (2017) A hybrids/ensembles artificial bee colony algorithm-artificial neural network for forecasting the blast-produced ground vibration. Eng Comput, 33(3), 689-700https://doi.org/10.1007/s00366-016-0497-3

https://www.amsj.com.au/flyrock-incident-damages-vehicles-during-blast/#:~:text=and%20South%20Australia.-,The%20flyrock%20incident,metres%20from%20the%20blast%20site. (Accessed 2/05/2022)

Tonnizam Mohamad E, Jahed Armaghani D, Hasanipanah M, Murlidhar BR, Alel MN, Asmawisham (2016) Estimation of air-overpressure produced by blasting operation through a neuro-genetic technique. Environ Earth Sci, 75(2), 1-15https://doi.org/10.1007/s12665-015-4983-5

Wade C, Glynn K (2020) Hands-on gradient boosting with XGBoost and scikit-learn: perform accessible machine learning and extreme gradient boosting with Python

Wei HX, Zhu J (2011) Study on application of support vector machine to prediction of blasting vibration velocity. Appl Mech Mater 71–78:4155. https://doi.org/10.4028/www.scientific.net/AMM.71-78.4155

Wen T-X, Qi L, Shao L-S (2015) Predicting blasting vibration characteristic parameters in open-pit mining based on Logistic-ELM. Comput Eng Design, 36(10), 2791–2795. https://doi.org/10.16208/j.issn1000-7024.2015.10.036

Xie C, Nguyen H, Bui X-N, Choi Y, Zhou J, Nguyen-Trang T (2021) Predicting rock size distribution in mine blasting using various novel soft computing models based on meta-heuristics and machine learning algorithms. Geoscience Frontiers, 12(3), 101108. https://doi.org/10.1016/j.gsf.2020.11.005

Xu S, Li Y, Liu J, Zhang F (2019) Optimization of blasting parameters for an underground mine through prediction of blasting vibration. J Vib Control 25(9):1585–1595. https://doi.org/10.1177/1077546319829938

Xu S, Chen T, Liu J, Zhang C, Chen Z (2021) Blasting vibration control using an improved artificial neural network in the ashele copper mine. Shock and Vibration, 2021. https://doi.org/10.1155/2021/9949858

Xuan-Nam B, Nguyen H, Tran Q-H, Dinh-An N, Hoang-Bac B (2021) Predicting ground vibrations due to mine blasting using a novel artificial neural network-based cuckoo search optimization. Nat Resour Res 30(3):2663–2685. https://doi.org/10.1007/s11053-021-09823-7

Xue X, Yang X, Li P (2017) Evaluation of ground vibration due to blasting using fuzzy logic. Geotech Geol Eng 35(3):1231–1237. https://doi.org/10.1007/s10706-017-0162-7

Yu Z, Shi X, Zhou J, Chen X, Miao X, Teng B, Ipangelwa T (2020a) Prediction of blast-induced rock movement during bench blasting: use of gray wolf optimizer and support vector regression. Nat Resour Res 29(2):843–865. https://doi.org/10.1007/s11053-019-09593-3

Yu C, Koopialipoor M, Murlidhar BR, Mohammed AS, Armaghani DJ, Mohamad ET, Wang Z (2021) Optimal ELM–Harris Hawks optimization and ELM–Grasshopper optimization models to forecast peak particle velocity resulting from mine blasting. Nat Resour Res 30(3):2647–2662. https://doi.org/10.1007/s11053-021-09826-4

Yu Z, Shi X, Zhou J, Gou Y, Huo X, Zhang J, Armaghani DJ (2020b) A new multikernel relevance vector machine based on the HPSOGWO algorithm for predicting and controlling blast-induced ground vibration. Eng Computhttps://doi.org/10.1007/s00366-020-01136-2

Zhang W, Zhang R, Wu C, Goh ATC, Lacasse S, Liu Z, Liu H (2020b) State-of-the-art review of soft computing applications in underground excavations. Geosci Front 11(4):1095–1106. https://doi.org/10.1016/j.gsf.2019.12.003

Zhang H, Zhou J, Jahed Armaghani D, Tahir MM, Pham BT, Huynh VV (2020a) A combination of feature selection and random forest techniques to solve a problem relate-d to blast-induced ground vibration. Applied Sciences, 10(3), 869. Retrieved from https://www.Dpi.com/2076-3417/10/3/869

Zhongya Z, Xiaoguang J (2018) Prediction of peak velocity of blasting vibration based on artificial neural network optimized by dimensionality reduction of FA-MIV. Math Probl Eng 2018:8473547. https://doi.org/10.1155/2018/8473547

Zhou J, Shi X, Li X (2016) Utilizing gradient boosted machine for the prediction of damage to residential structures owing to blasting vibrations of open pit mining. J Vib Control 22(19):3986–3997. https://doi.org/10.1177/1077546314568172

Zhou J, Qiu Y, Khandelwal M, Zhu S, Zhang X (2021a) Developing a hybrids/ensembles model of Jaya algorithm-based extreme gradient boosting machine to estimate blast-induced ground vibrations. Intl J Rock Mech Min Sci, 145, 104856. https://doi.org/10.1016/j.ijrmms.2021.104856

Zhou J, Dai Y, Khandelwal M, Monjezi M, Yu Z, Qiu Y (2021b) Performance of hybrids/ensembles SCA-RF and HHO-RF models for predicting backbreak in open-pit mine blasting operations. Natl Resour Reshttps://doi.org/10.1007/s11053-021-09929-y

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abd Elwahab, A., Topal, E. & Jang, H. Review of machine learning application in mine blasting. Arab J Geosci 16, 133 (2023). https://doi.org/10.1007/s12517-023-11237-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-023-11237-z