Abstract

Grain drying is a vital operation in preparing finished grain products such as flour, drinks, confectioneries and infant food. The grain drying kinetics is governed by the heat and mass transfer process between the grain and the environment. Incomplete, improper and over-drying are crucial to the grain quality and negatively influence the acceptance of the grain by the consumers. Dried grain moisture content is a critical factor for developing grain drying systems and selecting optimal performance by researchers and the grain processing industry. Many grain drying technologies such as fluidised bed dryers, fixed bed dryers, infrared dryers, microwave dryers, vacuum dryers and freeze dryers have been used in recent years. To improve the drying process of grain, researchers have combined some drying technologies such as microwave + hot air, infrared + hot air and microwave + a fluidised bed dryer. Also, they introduce some treatments such as ultrasound dielectric and dehumidification. These methods enhance the dryer performance, such as higher moisture removal, reduced processing time, higher energy efficiency and nutrient retention. Therefore, this review focused on the drying conditions, time, energy consumption, nutrient retention and cost associated with the reduction of moisture content in grain to a suitable safe level for further processing and storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Grains are divided into three main categories: oil seeds, legumes and cereals, as shown in Fig. 1. They are among the world’s most important staple foods, making up a significant portion of the human diet (~ 34.4%) and animal feed (~ 65%) (FAO, IFAD, UNICEF, WFP and WHO [1], OECD/FAO, [2]). Edible oils are produced from oilseeds such as melon, rapeseed, soybean, peanut, sunflower seed and cotton seeds. They are the most prevalent oilseeds grown worldwide. Pulses are the type of grains that come from the Fabaceae or Leguminosae family. Peas, chickpeas, lentils, kidney beans, broad beans and navy beans are among the dry seed devoured as a pulse plant product. Rice, wheat, corn, millet, sorghum, oat, sorghum and rye belong to the cereals which are among the seeds of grass in the Poaceae family [3–5]. Grains are important sources of vitamins, minerals, fibres, crude fat, proteins, essential fatty acids, carbs and inorganic elements, all of which are important for human health [6]. Daily consumption of white and brown rice contributes 334 to 341 kcal to the total dietary energy gained by the human body [7]. Rice, wheat, corn, peas, beans, peanuts and sunflower seeds are the widely consumed grains. In contrast, less consumed grains include cottonseeds, rapeseeds, chickpeas, rye and sorghum. However, all the grains are good sources of nutritional composition such as carbs, protein, minerals and vitamins (Guerrieri and Cavalleto [8]).

Dried grains are used as a raw material for producing various valuable products such as alcoholic and non-alcoholic drinks, extracts, beverages and vinegar. Flour is another commercially available dried grain product, such as rice flour, wheat flour, sorghum flour, cowpea flour and bean flour. It is usually used for making baked food such as cakes, bread, pastries and cookies. In addition, grain flour is essential in producing other food such as noodles, snacks, spaghetti confectionery and baby food [9]. Consumption of grain-based food offers balanced nourishment and aids in treating various ailments caused by nutritional deficiencies. From an environmental standpoint, including plant-based foods in the human diet, with a focus on legumes, cereals and seeds as a sustainable alternative to protein intake, could reduce the environmental impact of food [3]. Such plant-based foods emit fewer greenhouse gases and are highly reliable protein and other nutrient sources [10]. Nonetheless, different factors such as plant cultivars, seed quality and planting procedures significantly impact the quality of the finished grain products [11]. However, these pre-harvest factors have less impact than the drying process of grains [11].

Drying is the most widely used preservation method and the most diversified unit activity in agricultural grain processing [12] and serves as a pre-process to other main processes [13]. The drying process significantly affects the quality of dried grains. It plays a vital role and has a significant impact on the performance of milling and grinding operations [14]. The drying process include a combination of heat, moisture and momentum interactions in which the moisture in the grain is decreased to a desirable level (e.g. 8.5 to 13.0% for rice, 8.0–13.5% for corn, 8.0–15% for beans and 4.5 to 7% for peanuts [15], ASAE-D245.5, 2001; [16]. Several drying methods and different processing conditions, such as heat intensity, air velocity, drying duration and the initial condition, could significantly affect the quality of the final dried products, such as high moisture, cracks, burnt grains, etc. [17]. For instance, fungal development, germination, respiration and mould growth in dried grain is associated with high grain moisture. This makes it inappropriate for long-term storage [18]. If the moisture content of a properly dried grain is less than 9%, it can be kept for more than a year [15]. Freshly harvested grains have high moisture levels (20 to 36%). Before it can be marketed or used as feed or seed, the moisture content must be reduced to less than 15% for extended storage [19]. Grain post-harvest losses can be reduced by 2 to 5% by selecting a proper drying technology (Nguyen [20]).

Drying of grain accounts for a large portion (27 to 70%) of industrial energy usage, depending on the final product of the process [21]. An efficient drying process is critical to the grain processing industries [22]. Currently, the drying operations must satisfy the demand of both grain farmers and processors. This includes the request for high-quality products, adherence to government energy regulations, increased production capacity and improved economic and eco-friendly practices [23]. In pursuit of this goal, researchers have investigated the potential of combined drying procedures. The hybrid dryers involve a technique where two or more drying method mechanisms are combined into one operation. Also, additional treatments such as ultrasound, vibration and dehumidification can be combined with the drying procedures. Although grain drying technologies have been recently improved and enhanced, to date, grain dryers perform at the peak of their potential with constraints. Therefore, this study reviews the fundamentals of the drying process, the drying conditions, time, energy consumption, nutrient retention and cost for effective drying of the three different classes of grains namely: cereal, legumes and oilseed, over the last 5 years.

Fundamentals of the Grain Drying Process

Moisture and Phase Change

Moisture and its phase shift are found in a variety of engineering and biotechnological applications where heat and mass exchange are inextricably linked. In the drying phenomenon, the water is evaporated from a product and the water vapour is removed from the dryer at the same time [24, 25]. Similar to grain moisture removal, partial evaporation of the liquid phase occurs inside the substrate and the exposed surface. The liquid is transformed into a vapour phase that is evacuated from the substrate. Removal of the reducing moisture level facilitates postharvest handling and avoids microbiological deterioration, hence, improves the nutrient retention and economic value of the grain.

The primary characteristic that guides the drying of agricultural grains is the combination of heat transfer (environment to grain) and moisture migration (grains to the environment). The temperature, relative humidity, velocity, moisture and solid elements of the grain determine the heat and mass transfer during grain drying. The physicochemical properties such as texture, size, minerals and proximate composition of the grain have a huge impact on the drying kinetics of the material [26]. The moisture loss of the grains during the drying process is sensitive to the number of grain layers subjected to the drying process and quantifies the process by the moisture ratio profile of the dried grain under different layers (D). The path of moisture migration is shown in Fig. 2(a) and the corresponding temperature profile of the grain during the drying process is illustrated in Fig. 2(b) [27].

Moisture ratio-time (a) and temperature–time (b) relationship pattern for the grain drying process. D = different dryer layers [27]

Mass Transfer

The moisture inside biological products can be classified as vacuolar, cytoplasmic, extracellular water and others. The transformation between different moisture types has been defined as a function of changes in cell structure during drying by considering the variation in mass because of moisture migration. The moisture has been further classified into four categories: highly mixed water, combined water, free water and others [28]. Due to its comprehensive theoretical foundation, this categorisation approach is currently frequently employed. Although the influence of this moisture class is not addressed during the drying process, the mass transfer regulates the transition of this within the several moisture-binding kinds in the grain and the surroundings [29]. During the drying process of grain, the air-grain mass transfer is described by a mass kinetic equation [30]. The reduction of the grain moisture content to a safe storage level involves mass transfer processes of which kinetics are defined in several studies based on the mass of the grain before and after drying. The magnitude of the transfer phenomenon in grain drying is quantified based on the instantaneous moisture content (time-dependent moisture content), moisture ratio, drying rate and equilibrium moisture content which are determined from Eqs. 1−4, respectively [15, 27, 31].

where MCwb and MCdb are the moisture content on a wet and dry basis (%) respectively, Ww is the grain wet mass (g) and Wd is the grain dry mass (g).

where MR is the moisture ratio (dimensionless), Mg is the grain moisture at a specific time (%), Me is the equilibrium moisture content (%) and Mo is the initial moisture content (%).

where DR is the drying rate (%/s), Mg is the grain moisture at a specific time (%), Mo is the initial moisture content (%),tg is the specific drying time (s) and t0 is initial drying time (s).

where Me is the equilibrium moisture content (%), T is the temperature (K), RH is the relative humidity and a, b and c are the constant parameter.

Diffusion regulates the movement of moisture vapour throughout the drying period. Liquid diffusion through a porous solid media and molecular diffusion are the main examples of diffusion in grain drying. Effective moisture diffusivity is a term that describes how fast the moisture moves. The moisture diffusion is usually calculated using Fick's second rule of diffusion Eq. (5) [32].

where dm is the change in moisture content (%), dt change in time (s), Deff is the effective moisture diffusivity (m2/s) and m is the moisture content (%).

There are easy analytical solutions to Fick’s equation: When the size reduction is insignificant or not considered, internal movement is the principal resistance, with no exterior movement resistance, and influences the external and internal heat transmission, with the initial thermal transient being ignored. For distinct geometrics: slab, cylinder and sphere, the solution of the Fickian diffusion equation with a one-dimensional standpoint is shown in Eq. 6−8 respectively [33–35].

where MR is the moisture ratio (dimensionless), Mg is the grain moisture at a specific time (%), Me is the equilibrium moisture content (%), Mo is the initial moisture content (%), Deff is the effective moisture diffusivity (m2/s) and L is the slap thickness (m).

where MR is the moisture ratio (dimensionless), Mg is the grain moisture at a specific time (%), Me is the equilibrium moisture content (%), Mo is the initial moisture content (%), Deff is the effective moisture diffusivity (m2/s), β is the root of the Bassel function

where MR is the moisture ratio (dimensionless), Mg is the grain moisture at a specific time (%), Me is the equilibrium moisture content (%), Mo is the initial moisture content (%), Deff is the effective moisture diffusivity (m2/s) and r is the radius of cylinder or sphere (m).

Equation 9 expresses the relationship between the effective moisture diffusivity and the mass transfer coefficient [36–38].

where hm is the mass transfer coefficient, Pr is the Prandtl number, Re is the Reynold number and Sc is the Schmidt number.

The relationship between the mass flow rate of air molecules and the grain drying rate is shown in Eq. 9. This gives the link between the air molecules in the drying system and the grain moisture migration throughout the drying process [30]. Using the Lewis law to define fluid transport in a biological material (Eq. 10), the sensitivity of the moisture content of the grain to time (drying rate) is calculated as illustrated in Eq. 11 [15, 30, 38].

where ρa is the density of the air (kg/m3), Va is the volume of the air (m3), εo is the void ratio, x is the depth of the drying layer (m), ρg is the density of the grain (kg/m3), dm is the change in moisture content (%) and dt is the change in time (s).

Me is the equilibrium moisture content (%), Mo is the initial moisture content (%), tg is the specific drying time (s), dm is the change in moisture content (%) and dt is the change in time (s).

During the grain drying process, the air-mass conservation of the drying system is represented in Eq. 12.

where Xa is the humidity of air (kg/kg dry basis), εo is the void ratio, x is the depth of drying layer (m), Va is the volume of the air (m3), ρa is the density of the air (kg/m3), ρg is the density of the grain (kg/m3), Me is the equilibrium moisture content (%), Mo is the initial moisture content (%), tg is the specific drying time (s) and t0 is initial drying time (s).

Heat Transfer

The temperature difference between the grain and the immediate surroundings is used to study heat transmission during grain drying. They act as a driving force that monitors heat transfer from a hot (heating) situation to a cooler zone (grain). The modes of heat transmission during grain drying include conduction, convection and radiation [30]. Regardless of the drying system, both conduction and convection modes of heat transfer occur in grain drying. The energy transmission during grain drying is governed by the following phenomena: (1) external heat transfer from the drying chamber to the grain surface via conduction or convention; (2) internal heat transfer within the grain to conduct the necessary energy for the transformation of water into vapour, energy via conduction; (3) internal water is transferred either in liquid or vapour phases by various processes including capillarity for liquid form, and molecular diffusivity for both liquid and vapour phases. Mechanisms are regulated by the gradients of respectively water content and partial vapour pressure as driving forces. (4) External vapour transport from the surface of the grains towards the exit is the principal driving force of dehydration [30, 38]. The internal energy of the grain during the drying process is a function of the amount of heat necessary to increase the temperature of the grain to a specified level and the energy required for the evaporation of moisture from the grain is indicated in Eq. 13.

where hc is the heat transfer coefficient (W/m2K), A is the surface area, L is the latent heat of vaporisation (J/kg), mg is the mass of the grain (kg), Cg is the specific heat capacity of the grain (Jkg−1 K−1), m is the mass of moisture removed from grain (g), Ta is the air temperature (K) and Tg is the grain temperature (K).

The heat transfer rate, which is the most important variable in simulating the space and time-dependence of heat transmission, is defined as shown in Eq. 14−16 for the conductive, convective and radiative modes of heat transfer, respectively [32, 39, 40].

where qcond is the heat transfer rate (W/m2), A is the surface area of the grain (m2), k is the thermal conductivity (W/mK), dT is the change in temperature and dx is the change in the drying layer.

where qconv is the heat transfer rate (W/m2), hc is the heat transfer coefficient (W/m2K), Pr is the Prandtl number, Re is the Reynold number, x is the depth of drying layer (m) and m and n are constant parameters.

where qrad is the radiative heat transfer rate (W/m2), σ is the Stefan-Boltzmann constant (5.67 × 10−8 W/m2K4), A is the surface area of the grain (m2), f is the shape factor, ε is the emittance of the source of radiation, Ts is the temperature from the source of radiation (K) and Tg is the grain temperature (K).

Energy Efficiency and Energy Consumption

Grain drying is one of the most energy-intensive unit operations during grain processing. According to industrial statistics, the drying process in the developed world accounted for between 10 and 20% of all industrial energy use. The performance efficiency of the dryer hinges on the quality of the dried product and the energy consumption [41]. The energy needed for grain drying is significantly influenced by the latent heat of vaporisation of water, which has a huge energy value (2257 kJ/kg), as well as the sensible heat that must be removed from the dryer. In most conventional dryers, the heat required to raise the temperature of the products and evaporate the moisture is defined in Eq. 17 [23].

where EU is the energy required for the grain drying (J), mp is the mass of the dried grain product (kg), Cp is the specific heat capacity of the dried grain product (kJ/kg), mw is the mass of the moisture removed from the grain (kg), Cw is the specific heat capacity of the moisture (kg) and L is the latent heat of vaporisation of moisture (kJ/kg).

Furthermore, the projected efficiency of the dryer is significantly reduced by bad dryer design and inadequate insulation [23]. The operating principle underpins the estimation of the energy usage of a grain dryer. According to Eq. 18, the amount of electrical energy used to dry grains relies on the power rating of the heater and the drying duration [42].

where E is the energy consumption (J), P is the power rating of the heater (kW) and t is the drying time (h). The energy consumption is sometimes estimated based on the specific heat of dry air, mass flow rate and temperature difference as shown in Eq. 19 [43].

where \({Q}_{a}\) is the airflow rate (m3/s), \({C}_{a}\) is the specific heat (kJ/kg/°C), \(\Delta T\) is the change in temperature and t is the drying time (h).

In a convective and fluidised hot air dryer, Eq. 20 includes the power rating of the blower in the overall energy usage throughout the drying process [38].

where Ph is the rated power of the heating source and Pb is the rated power of the blower. For direct and indirect-fired furnace dryers, burning biomass provides the heat needed for the drying process. Equation 21 defines the thermal energy used by the dryer [38].

where Mb is the mass of the biomass (kg) and Sb is the calorific value of the biomass (J/kg), P is the power rating of the blower (kW) (P = 0 in the direct-fired furnace) and t is the drying time. According to Eq. 22, the energy consumption of steam dryer is determined by the gravimetric characteristics and heating value of the gas (mostly Liquefied petroleum gas (LPG) [42].

Where \({\rho }_{a}\) is the density of the gas (kg/m3), \({V}_{g}\) is the volume of the gas and HHV is the heating value of the gas.

Energy efficiency is typically the bedrock for grain dryer performance effectiveness. Energy efficiency measurements can be obtained instantaneously (at a specified time) or cumulatively throughout the drying process. Equation 23 provides a general definition of energy efficiency [44].

where \(\eta\) is the energy efficiency (%), EU is the required energy and EC is the consumed energy.

Other equations have been considered to measure the energy effectiveness of dryers, such as the microwave vacuum dryer, convective solar dryer [45] and hot air dryer [44], which are each depicted in Eqs. 24−26.

where \(\eta\) is the energy efficiency (%), td is the drying time, P is the microwave power (kW), M is the mass of the grain (kg), \({m}_{0}\) is the initial moisture content (g/g) and me is the final moisture content (g/g).

where \(\eta\) is the energy efficiency (%), \({A}_{c}\) is the area of the solar collector (m2) and Isr is the intensity of solar radiation (W/m2).

where \(\eta\) is the energy efficiency (%), \({T}_{i}\) is the input temperature (K), \({T}_{2}\) is the output temperature (K) and \({T}_{w}\) is the ambient temperature (K).

To determine the performance of the dryer during drying grains, specific moisture extraction rate (SMER), specific energy consumption (SEC) and the energy payback time (EPBT) in Eqs. 27−29 are other important energy-related indicators [36, 46, 47].

where SMER is the specific moisture extraction (kg/kJ), \(\lambda\) is the mass of moisture removed (kg) and E is the energy consumed (kJ).

where SEC is the specific energy consumption (\({\mathrm{kJ}/\mathrm{kg}}_{\mathrm{mosture}}\) or \({\mathrm{kJ}/\mathrm{kg}}_{\mathrm{grains}}\)), E is the energy consumed (kJ) and m is the mass of moisture removed or mass of grain (kg).

where EPBT is the energy payback time (years), Ec is the total energy required for producing a dryer (kWh) and Eout is the annual energy output of the dryer (kWh).

Table 1 shows the energy performance of recent grain drying studies. There is a dearth of information available regarding the efficiency of other grain dryers over the last 5 years. Most of the studies concerned corn, green peas, paddy and soya beans, with corn and paddy being the most significant. The energy efficiency of convective hot air dryers ranged from 26.52 to 71.75% and 50.30 to 59.80% for corn [44] and paddy [38], respectively. The specific energy consumption in convective bin drying of corn ranged from 4.4 to 5.3 MJ/ kgH20 [36] and a higher value was reported for fluidised dryers [46]. In convective hot air drying of green peas, the specific energy consumption was 142.73 MJ/kgH20. The combination of infrared and microwave heating with the hot air-drying method reduced the SEC by 54.3% and 75.3%, respectively [48]. The significant reduction in the SEC was accredited to the pronounced reduction in the drying time by the combined methods. In contrast, the infrared [49] and microwave dryer [50] had a higher SEC compared to the convective drying for the paddy [38, 51].

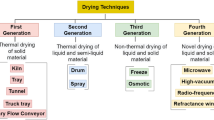

Grain Drying Technology

There are many types of grain drying technology, and the choice of drying technology in the grain processing industries depends on moisture removal, energy consumption, time-saving and nutrient retention. Incomplete and over-drying of grain are detrimental to grain nutrient retention [44, 51]. The critical moisture content level of dried grain is presented in Table 2. When the final moisture content of the dried grain is higher than the range of critical moisture levels, the grain drying process is incomplete. Therefore, the dried grain is susceptible to mould growth, insect infestation and high-quality deterioration [55–57]. The dried grains with lesser moisture content compared to the range of critical moisture content levels are overdried and the grains are liable to lose their nutritional value and germination potential [58, 16].

Cereal Drying

The application of different drying technologies for the reduction of moisture of cereal grain over the last 5 years is summarised in Table 3. The three main drying methods used for drying cereals are thin layer, deep bed and continuous flow drying methods. The analysed cereals in this study include barley, corn, germinated brown rice, millet, paddy, sorghum and wheat.

Barley/Sorghum/Millet

From Table 3, barley, sorghum and millet were dried in a fluidised bed dryer. The moisture content of the grains reduced the moisture content of the grains to < 10%db in ~ 33 min. The region in which drying took place in the fluidised bed dryer was referred to as the zone of desorption. It indicated the maximum altitude at which the heated inflow gas in the dryer became saturated. At this point, the heated gas could not remove moisture from the grains. The zone of desorption varied with the type of grain (maximum of 140 mm for barley, 110 to 150 for sorghum, 212 for millet). It therefore determines the capacity and height of the dryer. Other factors that were significantly correlated to the zone of desorption and moisture removal capacity of the dryer included the inflow temperature, mass flow rate and saturation temperature of the gas [61]. In a continuous belt dryer with variable heat supply, the drying kinetics of barley was studied based on the temperature distribution in the grain layer and the allowable range of thermal-humidity conditions. The dryer was constructed with a changeable grain layer height in the drying chambers and a particular grain load per gas distribution and this allowed homogeneous grain drying energy use. The grain moisture content was reduced by the drying system from about 22% after harvesting to ~ 13% [62].

Corn

The effective drying of corn in recent years has been achieved using convective drying (mixed-flow dryer, laboratory oven, open-air sun drying), microwave dryer, microwave vacuum dryer, fluidised bed dryer and heat pump dryer. Recently, corn drying gained the most attention and covers ~ 35% of the drying studies on cereal in the last 5 years (Table 3). In the convective dryer, temperature and air velocity are correlated to the moisture reduction of corn. The moisture content of corn was reduced from 22 to 10%wb and this took roughly 80 min of drying time. The small quantity of corn and continuous increase in temperature was reported as the main reason for the shorter drying time in a laboratory-scale tower dryer [63]. The drying air temperature had the greatest impact on the starch content and ethanol output of corn grains during processing [65]. The first and second principles of thermodynamics were used to optimise cereal (corn) grain dryers using transient spatial–temporal analysis. A time-adaptive radial basis function was used to solve the models. Comprehensive sensitivity analysis revealed that the incumbent moisture content and air velocity affect the quantitative temporal profiles of the output air temperature, moisture content, integrated energy and exergy efficiency. The exergy recovery of the dryer was highly related to high drying temperatures (The most essential factor) and faster drying times. The specific moisture extraction rate was suitable for designing in-bin or low-temperature dryers in terms of applicability [36].

The total drying time of corn grain was 12 h and 35 min in a convection dryer under a dried air temperature of 40 °C [66]. In microwave drying, the drying time was reduced to 5 h under a microwave intensity of 0.6 W/g. Microwave drying under 0.6 W/g had no significant effect on the colour and size of dried corn compared to convective drying. A lower drying time (< 70 min) was achieved with a 60 °C air temperature and a microwave intensity of 1.2 W/g but the colour and size were compromised [66]. The microwave drying of corn via heat transfer through a porous and double-porous medium was modelled using the three-dimensional electromagnetic model. The geometry considered the entire microwave oven, with pilled corn serving as an example of double porous media. The installation of an active pellet bed was an added advantage for the modelling of microwave drying of pilled corn monitored with computer vision techniques as shown in Fig. 3. The double-porous model outperformed the porous model in terms of accuracy [68].

Setup of microwave drying of pilled corn monitored with computer vision technique [68]

In a fluidised bed-shelled core dryer, the drying time, moisture content, specific energy consumption and quality characteristics such as ultimate compressive strength, toughness, shrinkage and colour of corn kernels were investigated. The drying factors were used to forecast characteristics using artificial neural network (ANN) simulation model, and the colour and shrinkage were assessed using non-destructive techniques (machine vision). Lower-frequency ultrasound demonstrated better penetration at lower temperatures resulting in a considerable decrease in drying time. The use of ultrasound lowered the final compressive strength and the specific energy consumption of the drying process. The dried corn was toughened, and this played a key role in shrinkage and colour change, the developed ANN model made good predictions [46].

Germinated Brown Rice

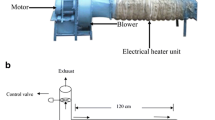

Hot air, microwave and a fluidised bed dryer have been recently employed drying technologies for the drying of germinated brown rice. In the last 5 years, germinated brown rice has occupied ~ 9% of the selected drying studies on cereal (Table 3). In a hot air dryer, a three-dimensional body model was fitted into the geometry of the brown rice kernel using image processing techniques. The hot air temperature was identified as the single most important element influencing the brown rice drying process. In the modelling of the drying process, the largest difference between the simulated and the experimental data was roughly 8% during the drying process at 40 °C. The temperature difference in the rice kernel only lasted a few minutes during the early drying time [32]. In the continuous fluidised bed dryer, a drying temperature of around 130 °C was determined to be the most efficient and cost-effective drying condition for paddy when compared to the conventional approach. The energy consumption of the dryer at the optimal temperature was 1.13 MJ/kg and the operating cost was 0.17 USD/kg. The gelatinisation, head brown rice output and hardness of the cooked germinated brown rice were satisfactory [42].

The microwave (1 to 3 W/g) drying properties of germinated brown rice were investigated using a continuous belt microwave dryer (Fig. 4). To simulate moisture evaporation, the microwave energy was transformed into thermal energy within the layer of germinated brown rice during the early drying time. The microwave intensity was proportional to the grain temperature and the moisture removal from the germinated brown rice. The overall energy usage of the microwave dryer was strongly dependent on the drying time, grain temperature and microwave intensity. An increase in the end temperature of the dried germinated brown rice signified higher microwave energy consumption. A decrease in the drying time of brown rice indicates less microwave energy input and lower thermal consumption. The temperature transmission pattern of the germinated brown rice layer was in the order of rising >> constant >> re-rising stages for all the microwave intensities [77].

Paddy

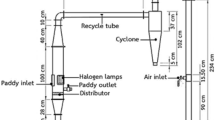

Convective hot air dryers (mixed flow dryers, hot air dryers, industrial LSU dryers and in-bin dryers), fixed bed dryers, fluidised bed dryers, microwave rotary drum dryers and infrared dryers were the drying technologies employed for the moisture removal from paddy in the last five years. Paddy drying is the second most studied cereal after corn, and it covers ~ 27% of the drying studies concerning cereal (Table 3). The convective hot air dryer was the most commonly used. Three drying parameters, namely temperature, air velocity and relative humidity, were reported as the factors that influenced moisture removal in the convective dryer [38, 51, 70, 74]. In 7 h, the industrial paddy dryer at Louisiana State University (LSU) reduced the moisture content of the paddy to 14%wb. The specific electrical and thermal energy of the industrial LSU dryer ranged from 0.34 to 0.51 and 14.41 to 28.81 MJ/kg respectively. The drying efficiency and exergy efficiency of the dryer increased from 50.30 to 59.80% and 43.63 to 67.21% respectively with an increase in the air outflow [38]. The fluidised bed and fixed bed dryers with desiccant (silica gel) and dehumidifier (Fig. 5) improved the rate of moisture removal in paddy. About 87% to 90% of the moisture was eliminated within 30 min of starting the drying process. The moisture removal of the fluidised bed was 15% greater than the fixed bed at 60 °C without dehumidification [71].

Fluidised bed dryer with dehumidifier and desiccant [71]

The modelling and simulation of the drying process of paddy were carried out using neural networks and numerical methods in recent years. For the neural network, the working mechanism of a continuous grain dryer and the principle of grain drying (heat and mass transfer mechanism) were modelled. The model used a backward propagation neural network (BPNN). According to the BPNN, the moisture content of the dried grain was mostly affected by the pace at which the dryer discharged the grain. The developed neural network model effectively regulated the grain dryer performance by considering the nonlinearity, robust coupling and hysteresis of the parameters utilised in defining the grain drying process, which makes it a precise management of the drying system challenges. The comparison of the experimental findings with the analysis from the BPNN intelligent control system demonstrated that the produced intelligence had the benefit of higher stability and noise management [70].

In a thin infrared layer, the drying process of rice was simplified based on infinity and zero penetration depth models and the impact of penetration on the drying parameters of the dried rice kernel. Both models successfully forecast the temperature and moisture content (MC) of the brown rice during drying. This was due to the highest temperature difference across the rice kernel in both models being consistently less than 15 °C and thermal stresses caused by non-uniform temperature was not significant. Changes in temperature and moisture throughout the drying process induced stress on the grain on the surface of the endosperm and the middle of the grain. The highest MC in the endosperm was found near its surface, where it reached 190 m−1 at 110 s, and the maximum stress was found at the same location, where it hit 7 MPa at 160 s a few seconds later [75].

The head rice yield (HRY), strength and appearance (colour and size) are the commonly used parameters for quantifying dried paddy quality and a few studies have addressed nutrient retention of the dried paddy. The appearance of the paddy tends to diminish due to hot air drying at a high temperature of 80 °C in an attempt to shorten the drying time [78]. The head rice yield of dried paddy in a mixed-flow dryer varied from 50 to 54% respectively. This was posed as a positive prospect of quality improvement of the dried product and improvement in the energetic and exergies response of the dryer [38]. The humidified hot air produced better quality dried paddy (greater HRY and a lower number of white belly grains) than the hot air in the fluidised bed dryer [79]. The milling quality and hardness of the paddy were improved by 38.76 to 55.19% and 20 to 33% under hot air or fluidised bed drying by replacing the conventional parboiling treatment with a superheated steam treatment [73]. Using zero dehumidification improved the whiteness of milled paddy under a fluidised bed dryer at 60 °C. Dehumidification gave a high head rice yield of 64.6% in the fluidised bed dryer at 40 °C, whereas zero dehumidification gave a higher head rice yield (HRY = 66.7%) in fixed bed drying [71].

Wheat

Convective and fixed bed dryers have been recently used for the drying of wheat in the last 5 years. Wheat drying occupies ~ 9% of the recent drying studies of cereal. In convective drying, low-field nuclear-magnetic-resonance (LF-NMR) relaxation time measurements were used to track the moisture content of wheat during drying. The surface water was the dominant source of water loss during the first drying phase. Water flowed in both directions between the components. Water migration was also influenced by the wheat moisture content and the proportions of the five water components. In addition, the high temperature was to produce a high drying rate throughout the drying process. Using a thermal oscillatory method with an early drying temperature of 80 °C and then switching to 70 °C reduced the heat consumption by 4.81% while increasing the drying time by 9.61% [28].

For the fixed bed dryer, a robust model based on Fick’s law was built for the drying of wheat grains. The model worked for temperatures ranging from 17 to 87 °C with ultimate moisture concentrations of 10 to 25% db. When compared to the more stringent model, ignoring internal temperature gradients, exterior mass transfer resistance, and the difference between grain and air temperature saved 18% of execution time. However, simulations using a simpler model that merely used the average moisture content of the grain gave a lower drying rate (De-Mattos et al. 2020).

Legume Drying

The recent drying methods and technologies applied for the safe drying process of legumes are summarised in Table 4. The table depicts the method used for the drying process as well as the simulation and modelling techniques that were adopted for the proper understanding of the intrinsic behaviour of legume grains during the drying process. The analysed legumes include broad beans, red kidney beans, chickpeas and green peas.

Beans

Vacuum and hot air dryers are the recent drying technologies applied for bean drying. Approximately 42% of the drying studies on legumes focused on bean drying over the last 5 years. In the vacuum dryer, the vacuum pressure and the low temperature are highly correlated with the moisture content of the dried bean grains. The cellular-level morphological alterations of broad bean seeds during dehydration in a low-temperature vacuum dryer in Fig. 6 was analysed using an SEM-based approach. The cell size and shape distribution of the seeds was significantly altered with the dehydration duration and moisture content. During dehydration, the overall change in cell size and distribution at 8 °C was more uniform. Higher temperatures induced higher contraction in more cells, due to cell rupture. Smaller cells were less prone to shrinkage and distortion during dehydration. A strong correlation of 0.96 was observed between moisture loss and shrinkage [85]. The effect of diffusion on the seed structure during the drying process at a low temperature and vacuum pressure was observed in the experiment. The drying period was decreased, and the drying rate was improved when the temperature and vacuum degree was raised from 0 to 8 °C and 95 to 99 kPa respectively. Lowering the thickness of the beans, the vacuum degree had a significant impact on the shrinkage, with an equilibrium moisture content of 5 to 11%, and the effective moisture diffusivity varies from 0.65 to 2.97 × 10−10 m2 [35]. Also considered were the shrinkage and irregular shapes in the 3D finite element of red kidney beans under different drying conditions. The relationships between the transient heat and mass transfer coefficients, transient water diffusivity, temperature and moisture content were estimated. It was discovered that there was a strong relationship between the transient heat and mass transfer coefficients, moisture diffusivity and ratio coefficients. The Lewis number was 27, and the ratio of transient heat over mass transfer coefficient at 30 and 40 °C was 10,765 Jm3/K and 10,729 Jm3/K at 50 °C [87].

Static and dynamic methods were used to investigate the sorption isotherms and the drying characteristics of red kidney beans. Sorption was observed at 10 to 60 °C temperature and 32 to 91% relative humidity (RH). The drying characteristics were investigated using a thin layer dryer with an air temperature of 30 to 50 °C and RH of 35 to 50%. The modified Chung-Pfost and modified Guggeheim-Anderson-deBoer (GAB) equation provided the best fit for the sorption isotherms. The Henderson and Pabis model, as well as the page model, provided the best fit for the thin layer drying data [34].

Pea

In pea drying, the drying system such as hot air, fluidised bed, microwave, infrared, freeze, hot air + microwave and hot air + infrared dryer was used in the last 5 years. Pea drying has recently gained the most attention and covers ~ 58% of the total drying studies on the legume. In a convective dryer, the greenness of the pea decreased with increased drying temperature. The relative crystallinity decreased from 23 at 50 °C to 19% at 70 °C. Conversely, as the drying temperature was raised, the in vitro digestibility of both carbohydrates and protein in the green pea flour increased. The protein was denaturalised, and its digestibility rose from 76.26% at 50 °C to 85.87% at 70 °C [81]. In the fluidised bed dryer, the shrinkage of the peas in real-time and offline mode was tracked using computer vision (Fig. 7) during the drying process. The method recognised and analysed only seeds that were built to compute the average area, perimeter and diameter at precise intervals during the drying process. The offline approach indicated a continuous increase in shrinkage. The output of the real-time shrinkage curve in the first 15 min was highly similar to those of the offline curves. A high deviation was recorded between the two methods during the later drying time [80].

Fluidised grain measurement using machine vision A real-time B offline [80]

Two treatments, namely cooking and ultrasound treatment, have been noted as the recent methods of improving the drying process of peas. The cooking was correlated with the glycaemic indices (GI) digestible starch (RDS), slowly digested starch (SDS), and resistant starch (RS) of pea and chickpea grains. The combination of high-temperature cooking and drying kept the starch in the peas and chickpeas at 68.58% and 61.99% of dry matter, respectively, with increased RDS and reduced RS. The GI of The HCHD peas (59.02) and chickpeas (49.15) were significantly higher than those processed by low-temperature cooking and drying (peas: 32.63; chickpeas: 31.91) [84]. The drying temperature and ultrasound power + frequency in an ultrasonic-assisted heat pump dyer (Fig. 8) were examined for the drying kinetics and the germination index of pea seed. The drying kinetics of pea seed was improved by using high temperature and ultrasound treatment which reduced the drying time and increased the diffusion coefficient from 3.5 × 10−11 to 57 × 10−11 m2/s. The page model had the most potential for modelling the drying curve under a variety of experimental settings. The use of high ultrasonic power increased the germination percentage and index, as well as gave a reduction in the mean germination time of the seed [83].

Ultrasound-assisted heat pump dryer [83]

Comparing the drying kinetics of the green pea under the sun, hot air, freeze and microwave drying to the hybrid drying technology (hot air + microwave and hot air + infrared), the page model had the best performance in predicting the drying kinetics of the green pea. The HA-MW and FD techniques yielded the fastest and slowest drying period respectively [48]. The drying behaviour of green peas in the combined infrared and hot-air dryer was forecast using the finite element method (FEM). The developed mathematical model produced a predicted average moisture content that was reasonably close to the experimental data with a low error value: RMSE = 2.18 and MAPE = 5.08% [82].

Oil Seed Drying

The primary purpose of drying the oilseed was to reduce the moisture content to a specific level and enhance the oil yield and maintain the oil quality of the dried seed oil extraction or expelling. The recent drying methods and technologies applied for drying the oilseed to a safe moisture level are shown in Table 5. The analysed oilseed included groundnut, melon, rapeseed, soybean and sunflower.

Groundnuts

In groundnut drying, natural drying methods such as open sun drying, solar drying and open-air drying are unquestionably the most cost-effective strategy for groundnut drying. However, the naturally dried ground nuts are liable to contamination and low nutrient retention due to long drying and exposure to the ambient environment [96]. In the last 5 years, ~ 25% of the drying studies on oilseed have focused on groundnut. Recently, a study examined the forced convective mode for seed drying to obtain higher-quality seeds. The influence of the weight on convective heat and mass transfer ranged from 0.61 to 1.10 W/m2 °C, and it improved in proportion to the amount of the groundnut [96]. The heat transfer coefficient of ground nut drying in an indoor forced convective dryer was between 2.4 and 2.5 W/m2 °C [97]. The value reduced to the range of 0.41 to 1.85 W/m2 °C in a forced convective greenhouse dryer. Sahdev et al. (89, 90 formulated a Lewis model for thin layer drying of groundnuts under a natural and forced convection greenhouse dryer and found the heat transfer coefficient reduced with increasing wire mesh size. Drying ground nuts to a safe storage moisture level of 8 to 11% using a natural, forced and indoor forced convective greenhouse dryer had a payback period of approximately 1.66, 1.72 and 4.67 years respectively. The dryer satisfied the requirement of greenhouse drying with reduced CO2 and provided a premium reason to decrease pollution emissions [47].

Melon

Melon seeds were dried in a combined fluidised bed and microwave drying system. The seeds had a moisture diffusivity ranging from 6.51 × 10−10 to 6.59 × 109 m2/s and rose with increased air temperature and microwave power. The percentage of melon seed shrinkage ranged from 15.09 to 46.99%. In the model study, the Aghbashloo et al. model accurately described the moisture ratio of the seed based on the drying time with 0.991 < < R2 < < 1.000; 0.000 < < χ2 < < 0.002 and 0.023 < < RMSE < < 0.823 (Golpour et al. [33]).

Rapeseed

Ren et al. [91] explored the impact of microwave (MW) drying on rapeseed oil yield and microstructure, as well as the differences in oxidative stability, tocopherol content and flavour attributes of rapeseed oils extracted via cold press and solvent-based methods. The moisture content of the rapeseed was amended to 15% and the seed was subjected to MW power of 200 to 600 W. MW power increased the oil yield by 9 to 23% and the total tocopherol content by 17 to 23% when compared to the rapeseed that was not subjected to MW power. The effect of dielectric treatment on the drying characteristics of rapeseed and the physicochemical attributes of cold-pressed oil were studied by Xu et al. [92]. Before oil extraction, the rape seeds were adjusted to 15% moisture content and subjected to dielectric treatment via a cold press at a frequency of 27 to 2450 MHz for 22 to 45 min. The temperature rising rate of the 2450 MHz dielectric heat was the highest, but temperature distribution was the most non-uniform. Oil extraction yields were increased by 12.28%, 17.25% and 22.08% for 27, 915 and 2450 MHz dielectric treatment, respectively compared to the untreated sample.

Soybean

Soybean drying is the most studied oilseed drying method over the last 5 years. It covers about 42% of the drying studies on oilseed. The drying of soybean was recently studied using convective, in-bin drying, automatic furnace dryer, pulse-spouted vacuum microwave, pulse-spouted microwave and microwave vacuum dryers. In a convective dryer, the air temperature and velocity modulation are directly related to the drying rates of soybean as a proportion of vaporised moisture in intermittent and convectional operation conditions with similar energy consumption. Under intermittent operation, higher drying rates were obtained, and a validated model could be reasonably used to forecast temperature and moisture content profiles. According to the simulation, the optimal modulation patterns of the air qualities were a function of several system parameters, including the incumbent temperature and moisture content of both the soybean and air. However, when the dryer was at a high temperature and used a consistently low velocity, there was a tendency to lower energy usage [54]. In the simulation of in-bin drying and the storage of soybean with various fan control options and drying methodologies were applied. The fan control techniques, air flow rates, harvest date and moisture content of soybean are the key factors that determine the drying time. The non-difference qualified level of the soybean was revealed in the layer-by-layer statistical analysis since the total average relative deviation was even less than 10% and the overall chi-square was 0.88 [94]. Cao et al. [86] explored the drying kinetics and predicted the quality of dried green soybean using several modified microwave drying procedures. When compared to the fresh sample, the microwave freeze-dried green soybean exhibited a minor difference in the bright colour, and its drying time was the longest of all the procedures. The bright colour values of the pulse-spouted vacuum microwave, pulse-spouted microwave and microwave vacuum dryer were 79.77, 71.43 and 55.45, respectively, with a slight difference in drying time. Based on product quality enhancement, pulse-spouted vacuum microwaves and pulse-spouted microwave dryers outperformed the microwave vacuum dryers. Quequeto et al. [22] studied the performance of soybean grain drying quality using an automatic furnace dryer fed with eucalyptus chips. After drying, the average moisture content of the grains decreased from 14.47 to 12.11%wb. The dryer efficiency for drying the grains was 75.61%, and the fuel consumption was 21.78 kg of chips per tonne of dry grains. To remove 1.0 kg of water, the specific energy consumption was 11,871.80 kJ. Drying in general did not degrade the ultimate quality of the soybeans.

Sunflower

In a hot air dryer, the drying kinetics of sunflower seeds was studied. The effectiveness of the drying process was defined based on the effect of temperature (45 to 75 °C) on the oil yield. The effective diffusivity and isosteric heat desorption were produced by an increase in the drying temperature, interfering with the physical qualities of the grain and lowering the yield and quality of the extracted oil. The Wang and Singh model was chosen as the most appropriate model to forecast the drying kinetics. Sunflower grain effective water diffusivity ranged from 2.83 × 10−6 to 2.93 × 10−6 m2/s and the physical properties of the sunflower grains were affected by drying air temperatures. The Correa et al. model better fitted the volumetric shrinkage data of the sunflower grain. The use of raffia packaging mitigated the deleterious impacts of drying and storage conditions. The drying temperature of 45 °C, the storage temperature of 20 °C and 60% RH gave higher oil yield for the grain [95].

Future Trends

Food grain drying studies in recent years have been cantered on reducing grain moisture content while retaining grain nutrients with maximised energy utilisation. The loss of nutrients and quantity during the drying process contributes noticeably to the total postharvest loss of grain. Therefore, the search for knowledge on sustainable ways of reducing postharvest losses is still inevitable [12].

With a basic overview of grain drying kinetics and the capacity of the dryer, a convective hot air dryer is mostly used to achieve the appropriate moisture reduction of grains. Several studies improved the drying process by focusing on the modification of the convective dryer. Future research should explore the ways of improving the drying process by modifying the properties of the grain, either by grain pre-treatment or modification of the drying process pattern, which could be a good catalyst for the process when improved or advanced drying systems are not available, accessible or economical.

Despite several attempts (such as ultrasonic, desiccant and vacuum-assisted drying) to improve process quality and lower the energy consumption during the processing of grain to a final product, the grain drying process continues to consume the most energy in the grain processing line. Therefore, further research should consider the utilisation of spent energy exiting the grain drying system for other purposes such as material tempering and converting to electrical energy to reduce the processing cost.

It is important to note that a real-time and online monitoring system is less considered in grain drying studies. Despite the current trend in the adoption of online monitoring systems, several studies focused on the modelling and simulation of the grain drying process, where the relationship between the drying parameters and drying performance such as nutrient retention, time and energy consumption were addressed using different offline methods [85]. Further research should consider real-time modelling and simulation using an online monitoring system through virtually controlled devices or sensors such as cameras, e-noses, acoustic sensors and thermal sensors. This could be integrated into the grain drying system to save energy and the cost of grain drying.

In several studies, the best drying parameters such as heat intensity, air velocity and treatments were primarily chosen based on selected drying performance. Meanwhile, grain drying kinetics is highly connected to all the responses such as dried grain quality, time, energy consumption and processing cost associated with the drying process. Therefore, future studies should investigate the adoption of optimisation of the global drying process to identify the ideal drying conditions that concurrently meet all the goals of the drying process.

Conclusion

Several drying techniques have been applied to different grain classes, namely: cereals, legumes, and oilseeds in the recent years. The goal of grain drying is to increase the shelf life of grain and retain the nutrient in the grain while saving the cost of production and energy consumption during the drying process. Therefore, this study reviewed the grain drying process over recent years and concluded that the drying parameters, drying conditions and optimum moisture removal capacity significantly affect the quality of the dried grains. Compared to the untreated conventional drying method, the quality of grains was improved by the application of treatments such as superheated steam (~ 55% of milling quality and ~ 33% hardness of rice), ultrasound (~ 13% of shrinkage compressive strength), humidification (increased head rice yield and lower grain chalkiness) and dielectric frequency (~ 22% of oil yield).

Improper, incomplete and over-drying of grains are detrimental to the quality of the grains. Dried grain with moisture content above the range of the critical moisture level shows incomplete drying. Partially dried grains are susceptible to mould growth, insect infestation and high-quality deterioration. The dried grains with moisture content below the critical moisture content level are over dried and the grains are liable to lose their nutritional value and germination potential.

The design and evaluation of different drying technologies for grain drying processes, such as fluidised bed dryers, fixed bed dryers, vacuum dryers, infrared dryers, microwave dryers and hybrid dryers (a combination of two or more different drying technologies), have shown a significant contribution to time, cost savings and efficient drying processes. Convective hot air was found to be the most time and energy-consuming drying method while more energy was saved during the drying process using a microwave (84%), infrared (~ 67%), microwave + hot air (~ 75%) and infrared + hot air (~ 54%) drying method.

Data Availability

The available data that are related to this study were included in the article.

References

FAO, IFAD, UNICEF, WFP, WHO (2020) The state of food security and Nutrition in the World 2020. Transforming food systems for affordable healthy diets. Rome, FAO, pp 124–128. https://doi.org/10.4060/ca9692en

OECD/FAO (2021) OECD-FAO Agricultural outlook 2021–2023, OECD Publishing. Paris, pp 50–53. https://doi.org/10.1787/19428846-en

Garrido-Galand S, Asensio-Grau A, Calvo-Lerma J, Heredia A, Andres A (2021) The potential of fermentation on nutritional and technological improvement of cereal and legume flours: a review. Food Res Int 145(April). https://doi.org/10.1016/j.foodres.2021.110398

Wang S, Chao C, Cai J, Niu B, Copeland L, Wang S (2020) Starch-lipid and starch-lipid-protein complexes: a comprehensive review. Comprehensive Reviews in Food Science and Food Safety 19(3):1056–1079

Wu H, Rui X, Li W, Xiao Y, Zhou J, Dong M (2018) Whole-grain oats (Avena sativa L.) as a carrier of lactic acid bacteria and a supplement rich in angiotensin I- converting enzyme inhibitory peptides through solid-state fermentation. Food Funct 9(4):2270–2281. https://doi.org/10.1039/c7fo01578j.

Hassan G, Shabbir MA, Ahmad F, Pasha I, Aslam N, Ahmad T, Rehman A, Manzoor MF, Inam-Ur-Raheem M, Aadil RM (2021) Cereal processing waste, an environmental impact and value addition perspectives: A comprehensive treatise. Food Chem 363:130352. https://doi.org/10.1016/j.foodchem.2021.130352

Carcea M (2021) Value of wholegrain rice in a healthy human nutrition. Agriculture 11(8):1–11. https://doi.org/10.3390/agriculture11080720

Guerrieri N, Cavaletto M (2018). Cereals proteins. In: Proteins Food Process. Elsevier, pp 223–244

Anunciacao PC, de Morais CL, Gomes JVP, Della Lucia CM, Carvalho CWP, Galdeano MC et al (2017) Comparing sorghum and wheat whole-grain breakfast cereals: sensorial acceptance and bioactive compound content. Food Chem 221:984–989

Fasolin LH, Pereira RN, Pinheiro AC, Martins JT, Andrade CCP, Ramos PL, Vicente AA (2019) Emergent food proteins–Towards sustainability, health and innovation. Food Res Int 125:108586. https://doi.org/10.1016/j.foodres.2019.108586

Zareef M, Arslan M, Hassan MM, Ahmad W, Ali S, Li H, Chen Q (2021) Recent advances in assessing qualitative and quantitative aspects of cereals using nondestructive techniques: a review. Trends Food Sci Technol 116:815–828. https://doi.org/10.1016/j.tifs.2021.08.012

Hashim N, Onwude DI, Maringgal B (2022) Technological advances in postharvest management of food grains. In Res Technol Adv Food Sci pp. 371–406. https://doi.org/10.1016/B978-0-12-824369-5.00016-6. Elsevier Inc

Satpati B, Koley C, Datta S (2020b) Nonlinear model of pneumatic conveying dryer for economic process control. Drying Technol 38(11):1516–1537. https://doi.org/10.1080/07373937.2019.1648286

Balandran-Quintana RR (2018) Recovery of proteins from cereal processing by-products. In Sustainable recovery and reutilization of cereal processing by-products. Elsevier Ltd., pp 125–157

Arul GP, Shanmugam S, Veerappan AR, Kumar P (2019) Mathematical modeling and experimental studies on a dual inclined oscillating bed with double pass solar dryer for drying of non - parboiled paddy grains. Energy Sources A: Recovery Util Environ Eff 43(22):2935–2946. https://doi.org/10.1080/15567036.2019.1670754

Ziegler V, Paraginski RT, Ferreira CD (2021) Grain storage systems and effect of moisture, temperature and time on grain quality – A review. J Stored Prod Res 91:101770. https://doi.org/10.1016/j.jspr.2021.101770

Jodicke K, Arendta S, Hofachera W, Speckleb W (2019) The influence of process parameters on the quality of dried agricultural products determined using the cumulated thermal load. Drying Technol. https://doi.org/10.1080/07373937.2019.1568254

Beigi M, Tohidi M, Torki-Harchegani M (2017) Exergetic analysis of deep-bed drying of rough rice in a convective dryer. Energy 140:374–382. https://doi.org/10.1016/j.energy.2017.08.100

ASAE D245.7 (2021) Moisture relationships of plant-based agricultural products American Society of Agricultural Engineers St. Joseph, USA

Nguyen VH, Duong HT, Gummert M (2016) Building a model for the paddy columnar dryer of solar powered air dryer for white oyster mushroom drying. Int Agric Eng J 25(1):64–73

Dai A, Zhou X, Liu X, Liu J, Zhang C (2018) Intelligent control of a grain drying system using a GA-SVM-IMPC controller. Drying Technol 36(12):1413–1435. https://doi.org/10.1080/07373937.2017.1407938

Quequeto WD, Resende, O, Tfouni SAV, Leme Gomes FM, Borges AX, Santos MRB, Costa ER, Junior WNF, Glasenapp M, Quirino JR, Rosa ES (2021) Drying of soybean grains with direct-fired furnace using wood chips: Performance, quality and polycyclic aromatic hydrocarbons. Drying Technol 1–11. https://doi.org/10.1080/07373937.2021.1929293

Hii CL, Ong SP, Yap JY, Putranto A, Mangindaan D (2021) Hybrid drying of food and bioproducts: a review. Drying Technol 39(11):1554–1576. https://doi.org/10.1080/07373937.2021.1914078

Onwude DI, Iranshahi K, Rubinetti D, Schudel S, Schemminger J, Martynenko A, Defraeye T (2022) How much do process parameters affect the residual quality attributes of dried fruits and vegetables for convective drying? Food Bioprod Process 131(November):176–190. https://doi.org/10.1016/j.fbp.2021.11.005

Prawiranto K, Carmellet J, Defraeye T (2020) Identifying: In silico how microstructural changes in cellular fruit affect the drying kinetics. Soft Matter 16(43):9929–9945. https://doi.org/10.1039/d0sm00749h

Singh A, Sarkar J, Sahoo RR (2020) Experimental energy, exergy, economic and exergoeconomic analysis of batch-Type solar-assisted heat pump dryer. Renew Energy 156, 1107–116. https://doi.org/10.1016/j.renene.2020.04.100

Bala BK (2017) Deep-bed and continuous flow drying deep-bed drying models. In: Dry Storage Cereal Grains, 2nd edn. John Wiley Sons, Ltd., pp 147–194

Jia C, Wang L, Li R, Liu C (2017) Experimental study on drying characteristics of wheat by low-field nuclear magnetic resonance. Drying Technol 35(10):1258–1265. https://doi.org/10.1080/07373937.2016.1242492

Hu X, Wu P, Zhang S, Chen S, Wang L (2019) Moisture conversion and migration in single-wheat kernel during isothermal drying process by LF-NMR. Drying Technol 37(7):803–812. https://doi.org/10.1080/07373937.2018.1459681

Hammami F, Ben Mabrouk S, Mami A (2016) Modelling and simulation of heat exchange and moisture content in a cereal storage silo. Math Comput Model Dyn Syst 22(3):207–220. https://doi.org/10.1080/13873954.2016.1157823

Golpour I, Guine RPF, Golpour H, Amiri R, Poncet S, Parian JA (2021) Evaluating the heat and mass transfer effective coefficients during the convective drying process of paddy (Oryza sativa L.). Food Process Eng 1–14. https://doi.org/10.1111/jfpe.13771

Zhao L, Yang J, Du T, Wu Z (2019) A 3-dimensional body-fitted simulation of heat and mass transfer in rice kernel during hot air-drying process. Int J Food Eng 15(3–4):1–11. https://doi.org/10.1515/ijfe-2018-0382

Golpour I, Nejad MZ, Chayjan RA, Nikbakht AM, Guine RPF, Dowlati M (2017) Investigating shrinkage and moisture diffusivity of melon seed in a microwave assisted thin layer fluidized bed dryer. Food Measure 11:1–11. https://doi.org/10.1007/s11694-016-9365-5

Jian F, Jayas DS (2018) Characterization of isotherms and thin-layer drying of red kidney beans, part i: choosing appropriate empirical and semitheoretical models. Drying Technol 36(14):1696–1706. https://doi.org/10.1080/07373937.2017.1422515

Wang J, Zhu K, Wang Y, Dai B, Liu S, Li Y (2020) Moisture diffusion and shrinkage characteristics of broad bean during low-temperature vacuum drying. Int J Food Prop 23(1):2217–2230. https://doi.org/10.1080/10942912.2020.1849277

Amantea RP, Fortes M, Ferreira WR, Santos GT (2018) Energy and exergy efficiencies as design criteria for grain dryers. Drying Technol 36(4):491–507. https://doi.org/10.1080/07373937.2017.1409232

Gao S, Ming B, Lu-lu L, Yin X, Xue J, Wang K, Xie R, Li S (2021) Relationship and distribution of in-field dry-down and equilibrium in corn grain moisture content. Agric For Meteorol 304–305

Islam MA, Mondal MHT, Akhtaruzzaman M, Sheikh MAM, Islam MM, Haque MA, Sarker MSH (2021) Energy, exergy, and milling performance of parboiled paddy: an industrial LSU dryer. Drying Technol 0(0):1–15. https://doi.org/10.1080/07373937.2021.1919701

Shen L, Wang L, Zheng C, Liu C, Zhu Y, Liu H, Liu C, Shi Y, Zheng X, Xu H (2019) Continuous microwave drying of germinated brown rice: effects of drying conditions on fissure and color, and modeling of moisture content and stress inside kernel. Drying Technol 39(5):669–697. https://doi.org/10.1080/07373937.2019.1705331

Thuwapanichayanan R, Kumklam P, Soponronnarit S, Prachayawarakorn S (2022) Mathematical model and energy utilization evaluation of a coaxial impinging stream drying system for parboiled paddy. Drying Technol 40(1):158–174. https://doi.org/10.1080/07373937.2020.1775640

Yogendrasasidhar D, Pydi-setty Y (2018) Drying kinetics, exergy, and energy analysis of Kodo millet grains and fenugreek seeds using a wall heated fluidized bed dryer. Energy 151:799–811. https://doi.org/10.1016/j.energy.2018.03.089

Mitsiri A, Prachayawarakorn S, Devahastin S, Rordprapat W, Soponronnarit S (2021) Alternative economic and shortened method for the production of dried germinated rice. Drying Technol 1–15. https://doi.org/10.1080/07373937.2021.1945619

Akhtaruzzaman M, Biswas MHT, M, Sheikh AM, Khatun AA, Sarker MSH, (2021) Evaluation of drying performance, energy consumption, and quality of two-stage dried maize grain. J of Biosyst Eng. https://doi.org/10.1007/s42853-021-00095-w

Mondal MHT, Hossain MA, Sheikh MAM, Akhtaruzzaman M, Sarker MSH (2021) Energetic and exergetic investigation of a mixed flow dryer: a case study of maize grain drying. Drying Technol 39(4):466–480. https://doi.org/10.1080/07373937.2019.1709077

Ergun A, Ceylan I, Acar B, Erkaymaz H (2017) Energy–exergy–ANN analyses of solar-assisted fluidized bed dryer. Drying Technol 35(14):1711–1720. https://doi.org/10.1080/07373937.2016.1271338

Abdoli B, Zare D, Jafari A, Chen G (2018) Evaluation of the air-borne ultrasound on fluidized bed drying of shelled corn: effectiveness, grain quality, and energy consumption. Drying Technol 36(14):1749–1766. https://doi.org/10.1080/07373937.2018.1423568

Kumar M, Kumar R, Tiwari S, Manchanda H, Kumar A (2021) Enviro-economical feasibility of groundnut drying under greenhouse and indoor forced convection hot air dryers. J Stored Prod Res 93:101848. https://doi.org/10.1016/j.jspr.2021.101848

Kaveh M, Abbaspour-Gilandeh Y, Fatemi H, Chen G (2021) Impact of different drying methods on the drying time, energy, and quality of green peas. J Food Process Preserv 00:1–16. https://doi.org/10.1111/jfpp.15503

Nosrati M. Zare D, Nassiri SM, Chen G, Jafari A (2021) Experimental and numerical study of intermittent drying of rough rice in a combined FIR-dryer. Drying Technol 1–13. https://doi.org/10.1080/07373937.2021.1898418

Behera G, Sutar PP (2021) Starch gelatinization and drying of paddy using microwave rotary drum dryer: Optimization, kinetics, and cooking studies. Drying Technol 39(7):965–981. https://doi.org/10.1080/07373937.2020.1741605

Mondal MHT, Shiplu KSP, Sen KP, Roy J, Sarker MSH (2019) Performance evaluation of small scale energy efficient mixed flow dryer for drying of high moisture paddy. Drying Technol 37(12):1541–1550. https://doi.org/10.1080/07373937.2018.1518914

Epstein A, Lubitz W, Dineen G, Dyck J (2020) Performance evaluation of a non-equilibrium model for low temperature grain drying and simulation of seasonal dryer operation. Drying Technol 0(0):1–17. https://doi.org/10.1080/07373937.2020.1832511

Kaveh M, Abbaspour-Gilandeh Y (2020) Impacts of hybrid ( convective-infrared-rotary drum ) drying on the quality attributes of green pea. Food Process Eng 1–15. https://doi.org/10.1111/jfpe.13424

Defendi RO, Paraíso PR, Jorge LM, de-M, (2017) Optimization study of soybean intermittent drying in fixed-bed drying technology. Drying Technol 35(1):125–137. https://doi.org/10.1080/07373937.2016.1162171

Atungulu GG, Sadaka S (2018) Postharvest technology: rice drying. In Rice: Chem Technol. https://doi.org/10.1016/B978-0-12-811508-4.00015-0

Batey I (2017) Maintaining grain quality during storage and Transport. In: Cereal Grains: assessing and management quality, 2nd edn. Elsevier Ltd. https://doi.org/10.1016/B978-0-08-100719-8.00020-6

Narwal S, Gupta OP, Pandey V, Kumar D, Ram S (2020) Effect of storage and processing conditions on nutrient composition of wheat and barley. In: Wheat and Barley Grain Biofortification. Elsevier Inc., pp 229–256. https://doi.org/10.1016/b978-0-12-818444-8.00009-2

Vishwakarma RK, Kumar N, Sharma K, Kumar Y, Kumar C (2022) Storage. In: Sharma HK, Kumar N (eds) Agro-processing and food engineering: operational and application aspects. Springer Nature, Singapore, pp 353–413. https://doi.org/10.1007/978-981-16-7289-7_9

FAO (2011). Grain crop drying, handling and storage. In: Januarius OA, Lawrence OG, Geoffrey CM, Chepete HJ (eds) Rural structure in the tropics: design and development. Food and Agricultural Organization of United Nation, Rome, Italy, pp 363–386. https://www.fao.or/3/i2433e/i2433e10.pdf

Kumar N, Sharma HK (2022). Drying. In: Sharma HK, Kumar N (eds) Agro-processing and food engineering: operation and application aspects. Springer Nature. Singapore, pp 147–216. https://doi.org/10.1007/978-981-16-7289-7_5

Szabo V, Poos T (2021) Modeling of heat and mass transfer in fluidized bed dryers using the volumetric heat transfer coefficient. Part 2: calculation algorithm based on the heat and mass transfer model. Drying Technol 1–15. https://doi.org/10.1080/07373937.2021.1938111

Ostrikov A, Ospanov A, Shevtsov A, Vasilenko V, Timurbekova A (2021) An empirical-mathematical modelling approach to explore the drying kinetics of cereals under variable heat supply using the stitched method. Acta Agric Scand Sect B Soil Plant Sci 71(9):762–771. https://doi.org/10.1080/09064710.2021.1947360

Celik E, Parlak N, Cay Y (2021) Experimental and numerical study on drying behaviour of corn grain. Heat Mass Transf 57:321–332. https://doi.org/10.1007/s00231-020-02954-2

Rudobashta SP, Zueva GA (2019) On-farm heat pump - assisted fluidized bed dryer and its kinetics calculation. Drying Technol 38(1–2):6–18. https://doi.org/10.1080/07373937.2019.1591436

Coradi PC, Nunes MT, Bellochio SDC, Camilo LJ, Teodoro PE (2021). Effects of drying temperatures and storage conditions on the levels of lipids and starches in corn grains for yield ethanol industry. Biofuels 0(0):1–10. https://doi.org/10.1080/17597269.2021.1904674

De Faria R, dos Santos ARP, Gariepy Y, da Silva EAA, Sartori MMP, Raghavan V (2020) Optimization of the process of drying of corn seeds with the use of microwaves. Drying Technol 38(5–6):676–684. https://doi.org/10.1080/07373937.2019.1686009

De Groote H, Githinji PG, Munya BG, Ricker-Gilbert JE (2021) Economics of open-air sun drying in the maize value chain of Kenya. J Agric Food Res 5:100185. https://doi.org/10.1016/j.jafr.2021.100185

Zhou J, Yang X, Zhu H, Yuan J, Huang K (2019) Microwave drying process of corns based on double-porous model. Drying Technol 37(1):92–104. https://doi.org/10.1080/07373937.2018.1439952

Chavan A, Vitankar V, Shinde N, Thorat B (2021) CFD simulation of solar grain dryer. Drying Technol 39(8):1101–1113. https://doi.org/10.1080/07373937.2020.1863422

Jin Y, Wong KW, Yang D, Zhang Z, Wu W, Yin J (2021) A neural network model used in continuous grain dryer control system. Drying Technol 1–22. https://doi.org/10.1080/07373937.2021.1891930

Luthra K, Sadaka S (2021) Investigation of rough rice drying in fixed and fluidized bed dryers utilizing dehumidified air as a drying agent. Drying Technol 39(8):1059–1073. https://doi.org/10.1080/07373937.2020.1741606

Atungulu GG, Olatunde GA, Sadaka S (2018) Impact of rewetting and drying of rough rice on predicted moisture content profiles during in-bin drying and storage. Drying Technol 36(4):468–476. https://doi.org/10.1080/07373937.2017.1345933

Jittanit W, Angkaew K (2021) Effect of drying schemes using superheated-steam and hot-air as drying media on the quality of parboiled chalky rice compared to conventional parboiling. Drying Technol 39(16):2218–2233. https://doi.org/10.1080/07373937.2020.1761375

Ghasemi A, Sadeghi M, Mireei SA (2018) Multi-stage intermittent drying of rough rice in terms of tempering and stress cracking indices and moisture gradients interpretation. Drying Technol 36(1):109–117. https://doi.org/10.1080/07373937.2017.1303777

Jiazheng W, Zhang H, Li F (2017) A study on drying models and internal stresses of the rice kernel during infrared drying. Drying Technol 35(6):680–688. https://doi.org/10.1080/07373937.2016.1201834

De-Mattosb R, Martínez Garreiro J, Meghirditchian G, Ferrari A, Zecchi B (2020) Effect of modeling simplifications on behavior and computational cost for simulation of fixed bed wheat drying process. Drying Technol 0(0):1–18. https://doi.org/10.1080/07373937.2020.1867564

Wang L, Zhao Y, Ma W, Shen L, Liu C, Liu C, Li S (2021) Utilization efficiency of microwave energy for granular food in continuous drying: From propagation properties to technology parameters. Drying Technol 1–20. https://doi.org/10.1080/07373937.2021.1890770

Chen J, Tang L, Shi P, Yang B, Sun T, Cao W, Zhu Y (2017) Effects of short-term high temperature on grain quality and starch granules of rice (Oryza sativa L.) at post-anthesis stage. Protoplasma 254:935–943. https://doi.org/10.1007/s00709-016-1002-y

Srimitrungroj T, Soponronarit S, Prachayawarakorn S, Nathakaranakule A (2018) Evaluation of new parboiled rice process using humidified hot air fluidized bed drying. Drying Technol 37(8):1–9. https://doi.org/10.1080/07373937.2018.1485692

Iheonye A, Gariepy Y, Raghavan V (2019) Computer vision for real-time monitoring of shrinkage for peas dried in a fluidized bed dryer. Drying Technol 1–17. https://doi.org/10.1080/07373937.2019.1649277

Gonzalez M, Alvarez-Ramirez J, Vernon-Carter E J, Reyes I, Alvarez-Poblano L (2020) Effect of the drying temperature on color, antioxidant activity and in vitro digestibility of green pea (Pisum sativum L.) flour. Starch - Starke 72(9–10):1900228. https://doi.org/10.1002/star.201900228

Zare D, Akbarzadeh S, Nematollahi MA, Loghavi M (2020) Simulation of hot air infrared-assisted green peas drying using finite element method. Food Process Eng e13500:1–12. https://doi.org/10.1111/jfpe.13500

Yang Z, Li X, Tao Z, Luo N, Yu F (2018) Ultrasound-assisted heat pump drying of pea seed. Drying Technol 1–12. https://doi.org/10.1080/07373937.2018.1430041

Yu Z, Fan Y, Wang X, Xia M, Cai Y (2020) In vitro and in vivo digestibility of pea and chickpea powder prepared by cooking and drying treatment. Int J Food Prop 23(1):1187–1199. https://doi.org/10.1080/10942912.2020.1792925

Zhang X, Zhu K, Wang Y, Li Y, Zhang Y (2020) Coupling effect of dehydration characteristics and microstructure of broad bean seeds under low-temperature vacuum environment. Drying Technol 40(2):230–242. https://doi.org/10.1080/07373937.2020.1783550

Cao X, Zhang M, Fang Z, Mujumdar AS, Jiang H, Qian H, Ai H (2017) Drying kinetics and product quality of green soybean under different microwave drying methods. Drying Technol 35(2):240–248. https://doi.org/10.1080/07373937.2016.1170698

Jian F, Jayas DS (2018) Characterization of isotherms and thin-layer drying of red kidney beans, part ii: three-dimensional finite element models to estimate transient mass and heat transfer coefficients and water diffusivity. Drying Technol 36(14):1707–1718. https://doi.org/10.1080/07373937.2017.1422514

Mukwevho P, Emmambux MN (2022) Effect of infrared and microwave treatments alone and in combination on the functional properties of resulting flours from bambara groundnut seeds. LWT Food Sci Technol 153:112448

Sahdev RK, Kumar M, Dhingra AK (2018a) Forced convection greenhouse groundnut drying: an experimental study. Heat Transfer Research 49(4):309–325. https://doi.org/10.1615/HeatTransRes.201801321

Sahdev RK, Kumar M, Dhingra AK (2018b) Development of empirical expression for groundnuts drying inside a greenhouse. Int Food Res J 25(5):1853–1862

Ren X, Wang L, Xu B, Wei B, Liu Y, Zhou C, Ma H, Wang Z (2018) Influence of microwave pretreatment on the flavor attributes and oxidative stability of cold-pressed rapeseed oil. Drying Technol 1–12. https://doi.org/10.1080/07373937.2018.1459682

Xu B, Wei B, Ren X, Liu Y, Jiang H, Zhou C, Ma H (2018) Dielectric pretreatment of rapeseed 1: influence on the drying characteristics of the seeds and physico-chemical properties of cold-pressed oil. Food Bioprocess Technol 11:1236–1247

Brito RC, Zacharias MB, Forti VA, Freire JT (2021) Physical and physiological quality of intermittent soybean seeds drying in the spouted bed. Drying Technol 39(6):820–833. https://doi.org/10.1080/07373937.2020.1725544

Atungulu GG, Olatunde GA (2018) Assessment of new in-bin drying and storage technology for soybean seed. Drying Technol 36(4):383–399. https://doi.org/10.1080/07373937.2017.1335751

Coradi PC, Dubal ITP, Bilhalva NS, Nunes, CF, Teodoro PE (2020) Correlation using multivariate analysis and control of drying and storage conditions of sunflower grains on the quality of the extracted vegetable oil. J Food Process Preserv 44(12):e14961. https://doi.org/10.1111/jfpp.14961

Sahdev RK, Kumar M, Dhingra AK (2017a) Effect of mass on the convective heat transfer coefficient during open sun drying of groundnut. J Food Sci Technol 54(13):4510–4516. https://doi.org/10.1007/s13197-017-2858-3

Sahdev RK, Kumar M, Dhingra AK (2017b) Forced convection drying of Indian groundnut: an experimental study. Facta Univ-Ser Mech Eng 15(3):467–477. https://doi.org/10.22190/FUME160812011S

Funding

The authors acknowledge the financial support of the Ministry of Higher Education, Malaysia, through the Transdisciplinary Research Grant Scheme Project (TRGS/1/2020/UPM/02/7).

Author information

Authors and Affiliations

Contributions

The study was conceptualized by Kabiru Ayobami Jimoh and Norhashila Hasim. Original draft was writing by Kabiru Ayobami Jimoh. The manuscript was critically revised and edited by Norhashila Hashim, Rosnah Shamsudin, Hasfalina Che Man, Mahirah Jahari and Daniel I. Onwude. The final manuscript was read and approved by all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information