Abstract

Padded clothing (shoulder padding) is worn in Rugby Union to give players an opportunity to protect themselves. A performance specification for padded clothing has been set out by World Rugby™, with the intention that padded clothing only protects against lacerations and abrasions. Test protocols in this specification provide an assessment of the impact force attenuative properties of the material, this itself will not indicate what injuries they may have the potential to prevent or lessen the severity of. The current study has used previously established biomechanical parameters to develop a mechanical test procedure to assess the ability of padded clothing to prevent or lessen the severity of stud-induced laceration and abrasion injuries. A synthetic skin and soft tissue surrogate was developed and validated to mimic human anatomy. Without the addition of padded clothing, both wearing (abrasion) and tearing (laceration) of the synthetic tissue surrogate were seen. The addition of padded clothing saw no sign of stud-induced injury, even after six repeated trials of the same product, showing padded clothing can prevent or lessen the severity of lacerations and abrasions. The developed testing protocols could be used to assess the safety of any sports stud designs in relation to skin injury as well as the effectiveness of various protective clothing products across the sports industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In Rugby Union, padded clothing, commercially known as shoulder padding, is worn to dissipate a certain amount of impact energy. It is reported that 70% of players will wear shoulder padding to reduce the perceived risk of injury [1]. However, the injuries that padded clothing has the ability to prevent or reduce the severity of has not been quantitatively defined. Rugby Union’s governing body World Rugby™ (WR) has set regulations to limit its impact attenuation potential, and as such, they do not view shoulder padding as a form of significant protection from injuries like fractures and dislocations. It is, nonetheless, considered to reduce the risk of superficial injuries like lacerations and abrasions. However, this aspect has never been quantitatively assessed.

A recent survey study found that 71% of rugby players have received a laceration injury caused by a rugby stud resulting in them having to leave the field of play [2]. Although laceration and skin injury is generally uncommon in Rugby Union, (approximately 5% of the total incidence of all injuries [3]) players will frequently require stitching and be exposed to infections [4, 5]. There is, therefore, a potential benefit of wearing padded clothing if its ability to prevent these types of injuries can be proven. Regulation 12 [6] governed by WR sets certain provisions related to shoulder padding. At the time of writing, padding must have a density no greater than 45 kg/m3 ± 15 kg/m3; therefore, manufacturers will generally make them from foam products. Shoulder padding is subjected to an impact test involving a rigid 5 kg striker with a flat surface impacting a cylindrical steel anvil that has the shoulder pad mounted on it, the padding’s impact attenuative capabilities are limited. This testing only provides information on the impact force attenuation properties of the material rather than quantifying which specific injuries the padding may protect from. In a stud impact, shoulder padding is not sandwiched between two rigid bodies but between one or more nonlinear viscoelastic human bodies.

Recent research has developed test protocols for the assessment of skin injury risk from stud contacts in rugby [7]. Within this research, the kinetic and kinematic parameters of stamping and raking impacts in Rugby Union were measured. Raking velocity, load and, therefore, coefficient of friction (COF) were impact factors. When testing padded clothing, it is vital these game-representative contact conditions are used. Another potential constraint to the effectiveness of testing padded clothing is the use of an unrepresentative surrogate body that the padded clothing is mounted on, usually this body is rigid, unlike human tissue. This can lead to an inaccurate response to impact causing differences in the magnitude of stress and strain absorbed by padded clothing, as well as not represent the extent of the damage that may be caused to the human body segment [8].

Human surrogates are commonly used in the automotive, defence, and medical industries to perform a range of functions including training aids (e.g., synthetic skin for medical graft training) [9]. Their use in the impact testing domains to assess the ability of injury preventative measures (i.e., shoulder padding) is also prevalent [8, 10]. Silicone elastomers have been used in the past to represent human soft tissue structures (muscle, adipose) because of their similarities in density, response to load, and repeatability [11, 12]. Synthetic chamois leather has previously been used as a cost-effective method of simulating the skin in impact testing environments due to its similar penetration resistance properties [13]. Validation of these surrogate materials is vital; this is usually done with ex vivo animal (often Porcine) tissue or with post-mortem human tissue [14]. The use of these surrogate materials does, however, have clear ethical implications. Ex vivo animal tissues also lack tonicity and do not always offer a representative mechanical response to load, for example, Porcine skin is slightly tougher than human skin due to its higher collagen content and increased thickness [15,16,17]. Because of the need for human surrogates in many industries, companies like Syndaver® have developed state-of-the-art human tissue simulants with similar mechanical properties to their human equivalent [18]. However, these products are costly, especially if a bespoke product needs to be developed.

The purpose of this research was, therefore, to develop a new test procedure using appropriate loading conditions to assess the effectiveness of rugby shoulder padding to reduce the severity of lacerations and abrasions induced by stud raking contacts.

2 Design of rig

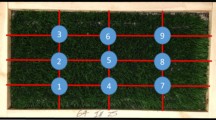

To simulate rugby stud raking, a rig initially developed to assess shoe–surface interactions [19] was adapted to include a rugby stud attachment as pictured in Fig. 1. This rig allowed for the replication of rugby stud raking conditions previously investigated by Oudshoorn [20]. Both vertical and horizontal force can be applied using pneumatic cylinders, the pressure can be altered to modify loads to suit. The rig is instrumented with load cells and linear variable differential transformers so that force, COF, displacement, and acceleration in both the vertical and horizontal directions can be measured. A schematic of the rig is displayed in Fig. 2. The rig had a minimum vertical force (~ 500 N); therefore, four studs (Gilbert, 18 mm, aluminum (Conforming to regulation 12, schedule 2 [6])) were used in a configuration that matched the front four studs of rugby boot (Adidas, Kakari, SG), so that similar pressures to Oudshoorn’s [20] parameters (one stud) could be achieved.

A synthetic tissue surrogate was developed to replicate the human soft tissue response to stud raking (Fig. 3). It consisted of two layers, simulating muscle and skin. The dermal and epidermal layer of skin combined is 1.93–2.35 mm thick [21]. The trapezius, which is where shoulder padding sits on the rugby player ranges from 4.1 to 14.26 mm in thickness [22, 23]. A 2 mm skin layer and an 8 mm muscle layer (10 mm total) were, therefore, used for the synthetic tissue surrogate. Both the validation simulants (Porcine tissue and Syndaver® skin simulant) were also 10 mm thick. The muscle simulant was made from silicone (Silastic™ 3481, Dow Corning, UK) set as a rectangular slab (200 × 150 × 8 mm). The reason a flat rectangular shape and not a shoulder shape was chosen was so the surrogate was repeatable, easy to fabricate, and fitted into the test rig. The silicone was a three-part blend with the addition of a catalyst and deadener (PlatSil® Gel 25 Deadener, Mouldlife, UK) in a 10:1:4 (base: catalyst: deadener) weight ratio. The blend was thoroughly mixed and fully degassed before being poured into rectangular moulds (200 × 150 mm). Its compressive properties matched that of Porcine muscle tissue, with previous research [12] outlining how this was achieved. The skin layer was made from synthetic chamois (2 mm) cross-woven polyvinyl acetate (PVA) (KCIC200, Kent Car Care, Manchester, UK) due to its similar penetration resistance to the skin as found in previous studies [13, 20, 24]. The skin covered the soft tissue layer to create a dual-layered testbed (10 mm thick in total). The synthetic chamois was added to the silicone while it was setting so they bonded together. A bespoke clamp held the skin–tissue system in place during the testing (Fig. 3b). Padded rugby clothing (shoulder padding) can also be clamped in place over the synthetic tissue surrogate. The test rig operates in a two stage process. A vertical load applies pre-compression to the surrogate following which a horizontal load is applied to create a raking action with the vertical load maintained.

3 Validation of protocol

3.1 Test parameters

Using the adaptations described to the rig and the surrogate, similar loading conditions developed by Oudshoorn [7] were achieved (Table 1). It should be acknowledged that maximum vertical force (Fz) and therefore, pressure per stud (MPa) is higher in the current test. However, this is still within 95% CI of Oudshoorn’s study. The horizontal force (Fx) at the maximum vertical force is also displayed. The mean COF was calculated from the full duration of the raking movement.

3.2 Synthetic tissue surrogate

To validate the synthetic tissue surrogate, tests were run on, (i) a slab of 10 mm thick ex vivo Porcine tissue (belly) acclimatized to room temperature (stored in a fridge (4 °C)) and (ii) a slab of commercially available synthetic skin and subcutaneous tissue (“Basic” 5 mm thick tissue plate, Syndaver®, Florida) covering a 5 mm thick silicone muscle layer (same as muscle layer in synthetic tissue surrogate). The procurement and storage of the Porcine tissue followed all of the University of Sheffield's ethical guidelines and risk assessment policies. This approach offered a multi-factor validation of the surrogate. Porcine tissue and Syndaver® products have been reported to display similar mechanical properties to human tissue, especially when comparing penetration resistance of the skin [25]. While Syndaver® skin is considered to be a state-of-the-art product, chamois leather offers a low-cost and frangible alternative that is suitable for this project.

Raking tests (without the addition of shoulder padding) following the parameters in Table 1 were performed on the Synthetic tissue surrogate. And then, the Porcine tissue and Syndaver® skin simulant for validation. When comparing post-test photographic images (taken from a fixed camera position) (Fig. 4), similar signs of wear/ abrasion were seen between the synthetic tissue surrogate and Porcine tissue, as well as this, there was tearing/laceration in the Syndaver® product, as seen in the synthetic tissue surrogate. A tear/laceration was defined when the silicone soft tissue layer could be seen through the chamois layer. The reason the Porcine skin did not tear could be because it is slightly tougher due to its higher collagen content [15, 16], and slightly higher thickness when compared with human skin [17]. When comparing vertical load against horizontal displacement plots (Fig. 5) similar traces can be seen between the synthetic tissue surrogate and the Syndaver® skin simulant, the Porcine tissue surrogate follows a similar trace at the end of the raking movement but the loads are smaller at the beginning, possibly due to the irregularities seen in organic tissues. The mean COF was also calculated throughout the raking duration, a mean COF of 0.61 and 0.59 was exhibited by the Porcine Tissue and Syndaver® skin simulant. A slightly higher COF was exhibited by the synthetic tissue surrogate of 0.63; however, it was concluded this was a close comparison to the validation surrogates. After validation, the synthetic tissue surrogate was used for the assessment of padded clothing.

4 Assessment of padded clothing

Testing was completed with the addition of PlastaZote foam (PlastaZote LD60, 12 mm thick) used as a control material, as done in a previous impact testing of shoulder padding study [26], and two commercial shoulder padding materials clamped over the synthetic tissue surrogate. Images of the Synthetic tissue surrogate were taken before and after one raking trial. After this, a further five (six in total) raking trials were performed to see if the padding degraded. There was clear degradation of both the padding, and the material that encompasses the padding, but no wear or tear marks on the underlying Synthetic tissue surrogate (Fig. 6a). The maximum vertical force applied without padding was 21 N (3%) higher than the overall mean with padding, the mean horizontal velocity was 0.11 m/s (12%) lower than the mean with padding; however, these differences were not significant (t test, p = 0.137) (Table 2).

Figure 7b displays a difference map created by comparing images of the synthetic tissue surrogate before and after raking (ImageDiff, Ionforge). The software uses a color scale to highlight differences between the pixels in images (purple < blue < green < orange < yellow). The wear mark seen in Fig. 7a totalled 1108 mm2 (left) and 988 mm2 (right). The green areas are where a visible tear occurred (Fig. 6a), as can be seen on the original image taken after raking (Fig. 7c). There was minimal difference between the images taken before and after testing with the control material (Fig. 7b), providing further evidence to suggest padding can prevent, or reduce the severity of, stud-induced lacerations or abrasions.

5 Discussion

The study set out to develop a testing mechanism using appropriate loading conditions to assess the effectiveness of rugby shoulder padding’s ability to prevent or lessen the severity of lacerations and abrasions. The investigation showed that rugby shoulder padding can prevent stud lacerations and abrasions using representative stud raking parameters. The study also developed a test method that can be used to assess both the safety of any sport’s studs as well as the effectiveness of various protective clothing across the sports industry.

Some limitations should be acknowledged when referring to both the test methods and results. Issues arise when using skin and human tissue simulants in an attempt to replicate the mechanical behavior (frictional properties, breaking loads) of the human tissue it is representing. The current test method validates the developed skin and human tissue simulant using Porcine tissue, a state-of-the-art skin simulant (Syndaver®), and past literature. Using this validation process the most replicable and affordable simulant was developed, this adding to Oudshoorn’s [20] previously developed test method. However, unless live human tissue is used, the exact mechanical response to stud impacts cannot be known. Porcine tissue is easy to obtain and is used because of its similarity to human tissue [27]. However, biological samples are unhygienic if not stored and transported correctly, quickly degrade, and are highly variable from sample to sample. Their inconsistency in mechanical properties is shown in Fig. 5. The surrogate developed was flat to ensure repeatability in testing, although layer thicknesses were similar to that of a human shoulder, the surrogate’s anatomical geometries were not; therefore, the surrogate was not shaped like a shoulder. This may have affected the severity of the tears at different points in the surrogate. However, it is suggested the same conclusions on the effectiveness of padding to prevent laceration and abrasion injuries would be found. The purpose of the surrogate was to test shoulder padding’s ability to prevent laceration and abrasion injuries in a repeatable way, which it successfully does; however, the addition of a surrogate with more representative geometries could further validate the flat synthetic tissue surrogate. Furthermore, the muscle thickness parameters were taken from a general population. Rugby players will tend to have a larger muscle mass than the general population [28].

Oudshoorn’s [20] impact parameters were based on a data set of participants with a mean mass of 76.2 kg. This is far lighter than the average professional rugby player (99.2 kg) [29]. Stud raking forces in professional rugby may then be greater; however, slightly higher stud pressures were used for the current test which may act to balance this out. Future studies should increase the stud pressures to a point where an abrasion or laceration is caused when shoulder padding is added. The protective limits of current shoulder padding could, therefore, be established.

Quantitative assessment of the amount of damage to the Synthetic tissue surrogate also poses a limitation. Many similar studies only qualitatively assess the difference in images, i.e., is there a tear or not. The current study looks to bridge this gap through the use of an image difference software. However, this could be improved, three-dimensionally scanning the surface of the Synthetic tissue surrogate before and after stud raking would allow for the size of a tear to be quantitatively assessed, a similar method was used by Kalbermatten et al. [30] where a laser scanner was used to measure the percentage change in skin surface area of facial lacerations. If future tests were completed and tearing occurred, classifying each tear following a skin tear classification system like the Skin Tear Audit Research [31] would lead to an improved assessment of the results. This could be the case if the padded material was of worse quality, or the stud used for testing was sharper. The results from the current study do, however, mean that each tear did not need to be classified as the addition of padding did not cause a tear at all. With this in mind, the effect of stud design could also be explored in the future. The study focused on laceration and abrasion injuries only. Other superficial injuries caused by studs like bruising should also be considered in the future.

Mechanical test setups like this also allow for the comparison of results measured from different shoulder pads; therefore, meaning the test could be implemented in test houses as part of regulations and standards [32]. World Rugby’s™ current test method assesses the impact attenuative abilities of the material and not its injury prevention capacity. Coupled with this, the test has not been based on any biomechanical parameters. However, when designing mechanical tests in regulations and standards it is important to consider their practicality for test houses. The current study would not be appropriate for use in a test house due to the number of replicable skin and soft tissue simulants that would need to be used, and the bespoke nature of the mechanical testing device. Further work could consider whether standardized test methods for cut-resistant materials (e.g., ISO 13997 and BS 388) can be applied to rugby padding, by comparing outputs from such standards with those from the tests presented here.

Future studies are needed to identify how different shoulder padding designs, different materials as well as the addition of the player's jersey can affect their ability to protect from stud injury. This information could then be used by manufacturers, as well as in the development of regulations associated with shoulder padding.

6 Conclusions

In this research, a test method was developed, which assessed rugby shoulder padding’s ability to prevent or lessen the severity of rugby stud injuries. Previous research was used to reproduce game-relevant loading conditions for stud raking in Rugby Union. A validated skin and soft tissue simulant was used, advancing previous research. The test method also can be modified to assess various items of padded clothing across multiples sports. Future research can use this test method to quantify the protective abilities in regards to stud injuries of various shoulder padding designs.

References

Marshall SW, Waller AE, Dick RW, Pugh CB, Loomis DP, Chalmers DJ (2002) An ecologic study of protective equipment and injury in two contact sports. Int J Epidemiol 31:587–592

Oudshoorn BY, Driscoll HF, Dunn M, James D (2016) Causation events of stud laceration injuries in rugby union. Procedia Eng 147:496–500. https://doi.org/10.1016/j.proeng.2016.06.227

Oudshoorn BY, Driscoll H, Kilner K, Dunn M, James D (2017) Prevalence of laceration injuries in professional and amateur rugby union: a systematic review and meta- analysis. BMJ Open Sport Exerc Med 3:e000239. https://doi.org/10.1136/bmjsem-2017-000239

van den Eijnde WAJ, Peppelman M, Lamers EAD, van de Kerkhof PCM, van Erp PEJ (2014) Understanding the acute skin injury mechanism caused by player-surface contact during soccer. Orthop J Sports Med 2:232596711453348. https://doi.org/10.1177/2325967114533482

Gibbs N (1993) Injuries in professional rugby league. Am J Sports Med 21:696–700. https://doi.org/10.1177/036354659302100510

World Rugby (2015) Regulation 12. http://playerwelfare.worldrugby.org/reg12. Accessed 29 July 2021

Oudshoorn B (2018) Development of a test method to evaluate laceration risk of studded footwear. Doctoral Thesis. Sheffield Hallam University

Payne T (2015) Improved human soft tissue thigh surrogates for superior assessment of sports personal protective equipment. Doctoral Thesis. Loughborough University

Ustbas B, Kilic D, Bozkurt A, Aribal ME, Akbulut O (2018) Silicone-based composite materials simulate breast tissue to be used as ultrasonography training phantoms. Ultrasonics 88:9–15. https://doi.org/10.1016/j.ultras.2018.03.001

Hrysomallis C (2009) Surrogate thigh model for assessing impact force attenuation of protective pads. J Sci Med Sport 12:35–41. https://doi.org/10.1016/j.jsams.2007.07.013

Payne T, Mitchell S, Bibb R, Waters M (2014) Initial validation of a relaxed human soft tissue simulant for sports impact surrogates. Procedia Eng 72:533–538. https://doi.org/10.1016/j.proeng.2014.06.092

Hughes A, Driscoll H, Carré M (2020) Development of Silicone Elastomer for Use in the Assessment of Padded Clothing in Rugby Union. Proceedings 49:77. https://doi.org/10.3390/proceedings2020049077

Ankersen J, Birkbeck AE, Thomson RD, Vanezis P (1999) Puncture resistance and tensile strength of skin simulants. P I Mech Eng 213:493–501. https://doi.org/10.1243/0954411991535103

Payne T, Mitchell S, Bibb R (2013) Design of human surrogates for the study of biomechanical injury: a review. Crit Rev Biomed Eng 41:51–88

Shergold OA, Fleck NA (2005) Experimental investigation into the deep penetration of soft solids by sharp and blunt punches, with application to the piercing of skin. J Biomech Eng 127:838–848. https://doi.org/10.1115/1.1992528

Lim J, Hong J, Chen WW, Weerasooriya T (2011) Mechanical response of pig skin under dynamic tensile loading. Int J Impact Eng 38:130–135. https://doi.org/10.1016/j.ijimpeng.2010.09.003

Pramudita JA, Shimizu Y, Tanabe Y, Ito M, Watanabe R (2014) Tensile properties of porcine skin in dorsal and ventral regions. JSEM 14:s245–s250

Sakezles C (2009) Synthetic human tissue models can reduce the cost of device development. Med Device Technol 20:32–34

Clarke J, Carré MJ, Damm L, Dixon S (2013) The development of an apparatus to understand the traction developed at the shoe–surface interface in tennis. P I Mech Eng 227:149–160. https://doi.org/10.1177/1754337112469500

Oudshoorn B, Driscoll H, Dunn M, Senior T, James D (2018) Development of a test method for assessing laceration injury risk of individual cleats during game-relevant loading conditions. Footwear Sci 10:1–10. https://doi.org/10.1080/19424280.2017.1403969

Akkus O, Oguz A, Uzunlulu M, Kizilgul M (2012) Evaluation of skin and subcutaneous adipose tissue thickness for optimal insulin injection. J Diabetes Metab 3:1000216

Day JM, Uhl T (2013) Thickness of the lower trapezius and serratus anterior using ultrasound imaging during a repeated arm lifting task. Man Ther 18:588–593

Jeong J-R, Han JH, Cho J-E, Lee W-h (2016) Reliability and validity of a personal computer based muscle viewer for measuring upper trapezius and transverses abdominis muscle thickness. Phys Ther Rehabil Sci 5:155–161

Bir CA, Resslar M, Stewart S (2012) Skin penetration surrogate for the evaluation of less lethal kinetic energy munitions. Forensic Sci Int 220:126–129. https://doi.org/10.1016/j.forsciint.2012.02.008

Barbero AM, Frasch HF (2009) Pig and guinea pig skin as surrogates for human in vitro penetration studies: a quantitative review. Toxicol In Vitro 23:1–13. https://doi.org/10.1016/j.tiv.2008.10.008

Imam S, Driscoll H, Winwood K, Venkatraman P, Allen T (2020) Efficacy of density in predicting the protective properties of padded clothing in rugby. Proceedings 49:38. https://doi.org/10.3390/proceedings2020049038

Falland-Cheung L, Pittar N, Tong D, Waddell JN (2015) Investigation of dental materials as skin simulants for forensic skin/skull/brain model impact testing. Forensic Sci Med Pathol 11:552–557. https://doi.org/10.1007/s12024-015-9718-0

Geeson-Brown T, Jones B, Till K, Chantler S, Deighton K (2020) Body composition differences by age and playing standard in male rugby union and rugby league: a systematic review and meta-analysis. J Sports Sci 38:2161–2176. https://doi.org/10.1080/02640414.2020.1775990

Reardon C, Tobin DP, Tierney P, Delahunt E (2017) The worst case scenario: locomotor and collision demands of the longest periods of gameplay in professional rugby union. PLoS ONE 12:e0177072. https://doi.org/10.1371/journal.pone.0177072 (PMID: 28510582)

Kalbermatten DF, Wettstein R, Erba P, Schumacher R, Dagorov P, Pierer G (2007) Laser scanner analysis in reconstruction of traumatic laceration of the facial nerve. Laser Phys Lett 4:476–479. https://doi.org/10.1002/lapl.200710012

Carville K, Lewin G, Newall N, Haslehurst P, Michael R, Santamaria N, Roberts P (2007) STAR: a consensus for skin tear classification. Primary Intention 15:18

Moritz EF, Haake S, Odenwald S (2006) Test methods in the development of sports equipment. N Y. https://doi.org/10.1007/978-0-387-46051-2_54

Acknowledgements

This project is funded by World Rugby™ and the Engineering and Physical Sciences Research Council (EPSRC).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results. The editor in chief of the journal, who is part of the project, was blinded from the submission.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hughes, A.C., Dixon, J., Driscoll, H.F. et al. Padded rugby clothing to prevent laceration and abrasion injuries from stud raking: a method of assessment. Sports Eng 25, 3 (2022). https://doi.org/10.1007/s12283-022-00369-2

Accepted:

Published:

DOI: https://doi.org/10.1007/s12283-022-00369-2