Abstract

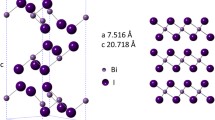

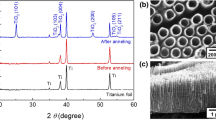

Synthesis of tubular nanomaterials has become a prolific area of investigation due to their wide range of applications. A facile solution-based method has been designed to fabricate uniform Bi2S3 nanotubes with average size of 20 nm × 160 nm using only bismuth nitrate (Bi(NO3)3·5H2O) and sulfur powder (S) as the reactants and octadecylamine (ODA) as the solvent. Powder X-ray diffraction (XRD), transmission electron microscopy (TEM), high-resolution TEM (HRTEM), and energy dispersive spectroscopy (EDX) experiments were employed to characterize the resulting Bi2S3 nanotubes and the classic rolling mechanism was applied to explain their formation process.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58.

Tenne, R.; Margulis, L.; Genut, M.; Hodes, G. Polyhedral and cylindrical structures of tungsten disulphide. Nature 1992, 360, 444–446.

Fan, S. S.; Chapline, M. G.; Franklin, N. R.; Tombler, T. W.; Cassell, A. M.; Dai, H. J. Self-oriented regular arrays of carbon nanotubes and their field emission properties. Science 1999, 283, 512–514.

Huang, Y.; Duan, X. F.; Wei, Q. Q.; Lieber, C. M. Directed assembly of one-dimensional nanostructures into functional networks. Science 2001, 291, 630–633.

Xia, Y. N.; Yang, P. D.; Sun, Y. G.; Wu, Y. Y.; Mayers, B.; Gates, B.; Yin, Y. D.; Kim, F.; Yan, Y. Q. One-dimensional nanostructures: Synthesis, characterization, and applications. Adv. Mater. 2003, 15, 353–389.

Peng, H. L.; Xie, C.; Schoen, D. T.; Mcllwrath, K.; Zhang, X. F.; Cui, Y. Ordered vacancy compounds and nanotube formation in CulnSe2 CdS core-shell nanowires. Nano Lett. 2007, 7, 3734–3738.

Wang, M. S.; Kaplan-Ashirl, I.; Wei, X. L.; Rosentsveig, R.; Wagner, H. D.; Tenne, R.; Peng, L. M. In situ TEM measurements of the mechanical properties and behavior of WS2 nanotubes. Nano Res. 2008, 1, 22–31.

Cao, Q.; Rogers, J. A. Random networks and aligned arrays of single-walled carbon nanotubes for electronic device applications. Nano Res. 2008, 1, 259–272.

Matsumoto, T.; Komatsu, T.; Arai, K.; Yamazaki, T.; Kijima, M.; Shimizu, H.; Takasawa, Y.; Nakamura, J. Reduction of Pt usage in fuel cell electrocatalysts with carbon nanotube electrodes. Chem. Commun. 2004, 840–841.

Cheng, F. Y.; Chen, J. Storage of hydrogen and lithium in inorganic nanotubes and nanowires. J. Mater. Res. 2006, 21, 2744–2757.

Shimoda, H.; Gao, B.; Tang, X. P.; Kleinhammes, A.; Fleming, L.; Wu, Y.; Zhou, O. Lithium intercalation into opened single-wall carbon nanotubes: Storage capacity and electronic properties. Phys. Rev. Lett. 2002, 88, 015502.

Dominko, R.; Arcon, D.; Mrzel, A.; Zorko, A.; Cevc, P.; Venturini, P.; Gaberscek, M.; Remskar, M.; Mihailovic, D. Dichalcogenide nanotube electrodes for Li-ion batteries. Adv. Mater. 2002, 14, 1531–1534

Wang, G. X.; Bewlay, S.; Yao, J.; Liu, H. K.; Dou, S. X. Tungsten disulfide nanotubes for lithium storage. Electrochem. Solid-State Lett. 2004, 7, A321–A323.

Miller, B.; Heller, A. Semiconductor liquid junction solar cells based on anodic sulphide films. Nature 1976, 262, 680–681.

Rabin, O.; Perez, J. M.; Grimm, J.; Wojtkiewicz, G.; Weissleder, R. An X-ray computed tomography imaging agent based on long-circulating bismuth sulphide nanoparticles. Nat. Mater. 2006, 5, 118–122.

Zhang, B.; Ye, X. C.; Hou, W. Y.; Zhao, Y.; Xie, Y. Biomolecule-assisted synthesis and electrochemical hydrogen storage of Bi2S3 flowerlike patterns with well-aligned nanorods. J. Phys. Chem. B 2006, 110, 8978–8985

Li, L. S.; Sun, N. J.; Huang, Y. Y.; Qin, Y.; Zhao, N. N.; Gao, J. N.; Li, M. X.; Zhou, H. H.; Qi, L. M. Topotactic transformation of single-crystalline precursor discs into disc-like Bi2S3 nanorod networks. Adv. Funct. Mater. 2008, 18, 1194–1201.

Ye, C. H.; Meng, G. W.; Jiang, Z.; Wang, Y. H.; Wang, G. Z.; Zhang, L. D. Rational growth of Bi2S3 nanotubes from quasi-two-dimensional precursors. J. Am. Chem. Soc. 2002, 124, 15180–15181.

Ota, J. R.; Srivastava, S. K. Low temperature micelle-template assisted growth of Bi2S3 nanotubes. Nanotechnology 2005, 16, 2415–2419.

Shen, X. P.; Yin, G.; Zhang, W. L.; Xu, Z. Synthesis and characterization of Bi2S3 faceted nanotube bundles. Solid State Commun. 2006, 140, 116–119.

Jiang, J.; Yu, S. H.; Yao, W. T.; Ge, H.; Zhang, G. Z. Morphogenesis and crystallization of Bi2S3 nanostructures by an ionic liquid-assisted templating route: Synthesis, formation mechanism, and properties. Chem. Mater. 2005, 17, 6094–6100.

Tang, J.; Alivisatos, A. P. Crystal splitting in the growth of Bi2S3. Nano Lett. 2006, 6, 2701–2706.

Comor, M. I.; Dramicanin, M. D.; Rakocevic, Z.; Zec, S.; Nedeljkovic, J. M. Preparation of Bi2S3 quantum dots by dissolution of crystalline powder in acetonitrile. J. Mater. Sci. Lett. 1998, 17, 1401–1402.

Li, Y. D.; Wang, J. W.; Deng, Z. X.; Wu, Y. Y.; Sun, X. M.; Yu, D. P.; Yang, P. D. Bismuth nanotubes: A rational low-temperature synthetic route. J. Am. Chem. Soc. 2001, 123, 9904–9905.

Feldman, Y.; Wasserman, E.; Srolovitz, D. J.; Tenne, R. High-rate, gas-phase growth of MoS2 nested inorganic fullerenes and nanotubes. Science 1995, 267, 222–225.

Chopra, N. G.; Luyken, R. J.; Cherrey, K.; Crespi, V. H.; Cohen, M. L.; Louie, S. G.; Zettl, A. Boron nitride nanotubes. Science 1995, 269, 966–967.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Wang, D., Hao, C., Zheng, W. et al. Bi2S3 nanotubes: Facile synthesis and growth mechanism. Nano Res. 2, 130–134 (2009). https://doi.org/10.1007/s12274-009-9010-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-009-9010-2