Abstract

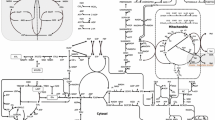

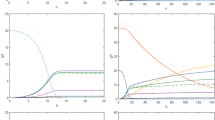

This study presents a detailed in silico analysis of bioethanol production from glucose/xylose mixtures of various compositions by fed-batch co-culture and mono-culture fermentation of specialized microbes. The mono-culture consists of recombinant Saccharomyces cerevisise that can metabolize both hexose and pentose sugars while the co-culture system consists of substrate-selective microbes. Dynamic flux balance models based on available genome-scale reconstructions of the microorganisms have been used to analyze bioethanol production in fed-batch culture with constant feed rates and the maximization of ethanol productivity is addressed by computing optimal aerobic-anaerobic switching times. The simulation results clearly point to the superior performance of fed-batch fermentation of microbial co-culture against fed-batch fermentation of mono-culture for bioethanol production from glucose/xylose mixtures. A set of potential genetic engineering strategies for enhancement of S. cerevisiae and Escherichia coli strains performance have been identified. Such in silico predictions using genome-scale models provide valuable guidance for conducting in vivo metabolic engineering experiments.

Similar content being viewed by others

References

Dien, B. S., M. A. Cotta, and T. W. Jeffries (2003) Bacteria engineered for fuel ethanol production: Current status. Appl. Microbiol. Biotechnol. 63: 258–266.

Ghim, C. M., T. Kim, R. J. Mitchell, and S. K. Lee (2010) Synthetic biology for biofuels: Building designer microbes from the scratch. Biotechnol. Bioproc. Eng. 15: 11–21.

Krahulec, S., B. Petschacher, M. Wallner, K. Longus, M. Klimacek, and B. Nidetzky (2010) Fermentation of mixed glucosexylose substrates by engineered strains of Saccharomyces cerevisiae: Role of the coenzyme specificity of xylose reductase, and effect of glucose on xylose utilization. Microb. Cell Fact. 9: 16.

Ma, Y., H. Dong, S. Zou, J. Hong, and M. Zhang (2012) Comparison of glucose/xylose co-fermentation by recombinant Zymomonas mobilis under different genetic and environmental conditions. Biotechnol. Lett. 34: 1297–1304.

Bader, J., E. M. Gerlach, M. K. Popovic, R. Bajpai, and U. Stahl (2010) Relevance of microbial coculture fermentations in biotechnology. J. Appl. Microbiol. 109: 371–387.

Chen, Y. (2011) Development and application of co-culture for ethanol production by co-fermentation of glucose and xylose: A systematic review. J. Ind. Microbiol. Biotechnol. 38: 581–597.

Kim, T. Y., S. B. Sohn, Y. B. Kim, W. J. Kim, and S. Y. Lee (2012) Recent advances in reconstruction and applications of genome-scale metabolic models. Curr. Opin. Biotechnol. 23: 617–623.

Mahadevan, R., A. P. Burgard, I. Famili, S. V. Dien, and C. H. Schilling (2005) Applications of metabolic modelling to drive bioprocess development for the production of value-added chemicals. Biotechnol. Bioproc. Eng. 10: 408–417.

Varma, A. and B. O. Palsson (1994) Metabolic flux balancing: Basic concepts, scientific and practical use. Nat. Biotechnol. 12: 994–998.

Orth, J. D., I. Thiele, and B. O. Palsson (2010) What is flux balance analysis? Nat. Biotechnol. 28: 245–248.

Kauffman, K. J., P. Prakash, and J. S. Edwards (2003) Advances in flux balance analysis. Curr. Opin. Biotechnol. 14: 491–496.

Martinez, I. B., A. G. Garcia, E. S. Manjarrez, and J. S. A. Barradas (2011) A simple metabolic flux balance analysis of biomass and bioethanol production in Saccharomyces cerevisiae fedbatch cultures. Biotechnol. Bioproc. Eng. 16: 13–22.

Mahadevan, R., J. S. Edwards, and F. J. Doyle (2002) Dynamic flux balance analysis of diauxic growth in Escherichia coli. Biophys. J. 83: 1331–1340.

Mahadevan, R. and M. A. Henson (2012) Genome-based modelling and design of metabolic interactions in microbial communities. Comput. Struct. Biotechnol. J. 3: e201210008.

Antoniewicz, M. R. (2013) Dynamic metabolic flux analysistools for probing transient states of metabolic networks. Curr. Opin. Biotechnol. 24: 973–978.

Hjersted, J. L. and M. A. Henson (2006) Optimization of fedbatch Saccharomyces cerevisiae fermentation using dynamic flux balance models. Biotechnol. Prog. 22: 1239–1248.

Hjersted, J. L., M. A. Henson, and R. Mahadevan (2007) Genome-scale analysis of Saccharomyces cerevisiae metabolism and ethanol production in fed-batch culture. Biotechnol. Bioeng. 97: 1190–1204.

Hjersted, J. L. and M. A. Henson (2009) Steady-state and dynamic flux balance analysis of ethanol production by Saccharomyces cerevisiae. IET Syst. Biol. 3: 167–179.

Hanly, T. J. and M. A. Henson (2011) Dynamic flux balance modeling of microbial co-cultures for efficient batch fermentation of glucose and xylose mixtures. Biotechnol. Bioeng. 108: 376–385.

Hanly, T. J., M. Urello, and M. A. Henson (2012) Dynamic flux balance modeling of S. cerevisiae and E. coli co-cultures for efficient consumption of glucose/xylose mixtures. Appl. Microbiol. Biotechnol. 93: 2529–2541.

Hanly, T. J. and M. A. Henson (2013) Dynamic metabolic modeling of a microaerobic yeast co-culture: Predicting and optimizing ethanol production from glucose/xylose mixtures. Biotechnol. Biofuels 6: 44.

Lisha, K. P. and D. Sarkar (2014) Dynamic flux balance analysis of batch fermentation: Effect of genetic manipulations on ethanol production. Bioproc. Biosyst. Eng. 37: 617–627.

Bro, C., B. Regenberg, J. Forster, and J. Nielsen (2006) In silico aided metabolic engineering of Saccharomyces cerevisiae for improved bioethanol production. Metab. Eng. 8: 102–111.

Duarte, N. C., M. J. Herrgard, and B. O. Palsson (2004) Reconstruction and validation of Saccharomyces cerevisiae iND750, a fully compartmentalized genome-scale metabolic model. Genome Res. 14: 1298–1309.

Feist, A. M. (2007) A genome-scale metabolic reconstruction for Escherichia coli K-12 MG1655 that accounts for 1260 ORFs and thermodynamic information. Mol. Syst. Biol. 3: 1–1.

Schuetz, R., L. Kuepfer, and U. Sauer (2007) Systematic evaluation of objective functions for predicting intracellular fluxes in Escherichia coli. Mol. Syst. Biol. 3: 1–9.

Edwards, J. S., R. U. Ibarra, and B. O. Palsson (2001) In silico predictions of Escherichia coli metabolic capabilities are consistent with experimental data. Nat. Biotechnol. 19: 125–130.

Gianchandani, E. P., M. A. Oberhardt, A. P. Burgard, C. D. Maranas, and J. A. Papin (2008) Predicting biological system objectives de novo from internal state measurements. BMC Bioinformatics 9: 43.

Becker, S. A., A. M. Feist, M. L. Mo, G. Hannum, B. O. Palsson, and M. J. Herrgard (2007) Quantitative prediction of cellular metabolism with constraint-based models: The COBRA Toolbox. Nat. Protoc. 2: 727–738.

Chen, J., W. Zhang, L. Tan, Y. Wang, and G. He (2009) Optimization of metabolic pathways for bioconversion of lignocellulose to ethanol through genetic engineering. Biotechnol. Adv. 27: 593–598.

Liu, T. and C. Khosla (2010) Genetic engineering of Escherichia coli for biofuel production. Annu. Rev. Genet. 44: 53–69.

Kim, J. and J. L. Reed (2010) OptORF: Optimal metabolic and regulatory perturbations for metabolic engineering of microbial strains. BMC Syst. Biol. 4: 53.

Kuyper, M., M. J. Toirkens, J. A. Diderich, A. A. Winkler, J. P. vanDijken, and J. T. Pronk (2005) Evolutionary engineering of mixed-sugar utilization by a xylose-fermenting Saccharomyces cerevisiae strain. FEMS Yeast Res. 5: 925–934.

Eslamloueyan, R. and P. Setoodeh (2011) Optimization of fedbatch recombinant yeast fermentation for ethanol production using a reduced dynamic flux balance model based on artificial neural networks. Chem. Eng. Comm. 198: 1309–1338.

Guo, Z., L. Zhang, Z. Ding, and G. Shi (2011) Minimization of glycerol synthesis in industrial ethanol yeast without influencing its fermentation performance. Metab. Eng. 13: 49–59.

Trinh, C. T., P. Unrean, and F. Srienc (2008) Minimal Escherichia coli cell for the most efficient production of ethanol from hexoses and pentoses. Appl. Environ. Microbiol. 74: 3634–3643.

Eiteman, M. A., S. A. Lee, and E. Altman (2008) A co-fermentation strategy to consume sugar mixtures effectively. J. Biol. Eng. 2: 3.

Kanehisa, M. and S. Goto (2000) KEGG: Kyoto encyclopedia of genes and genomes. Nucleic Acids Res. 28: 27–30.

Govindaswamy, S. and L. M. Vane (2007) Kinetics of growth and ethanol production on different carbon substrates using genetically engineered xylose-fermenting yeast. Bioresour. Technol. 98: 677–685.

Toivari, M. H., A. Aristidou, L. Ruohonen, and M. Penttila (2001) Conversion of xylose to ethanol by recombinant Saccharomyces cerevisiae: Importance of xylulokinase (XKS1) and oxygen availability. Metab. Eng. 3: 236–249.

Roca, C., J. Nielsen, and L. Olsson (2003) Metabolic engineering of ammonium assimilation in xylose-fermenting Saccharomyces cerevisiae improves ethanol production. Appl. Env. Microbiol. 69: 4732–4736.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lisha, K.P., Sarkar, D. In silico analysis of bioethanol production from glucose/xylose mixtures during fed-batch fermentation of co-culture and mono-culture systems. Biotechnol Bioproc E 19, 879–891 (2014). https://doi.org/10.1007/s12257-014-0320-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-014-0320-1