Abstract

In the present work, β-CD, ZnO-NPs, and several eco-friendly bioactive guests, namely, cinnamon oil, lemon oil, lavender oil, and vanillin along with environmentally benign pigment paste constituents were applied to cotton, viscose, cotton/viscose, and cotton/linen cellulosic substrates to develop durable multi-functional pigment prints in a single step using the pad-dry-thermofixation method. The developed one-step pigment coloration and multi-functionalization method resulted in a remarkable improvement in antibacterial efficacy, UV-protection ability, aroma property along with a noticeable increase in depth of the obtained pigment prints, making them very useful for a wide range of potential applications. The extent of enhancement in the above-mentioned functional and coloration properties is governed by type of cellulosic substrate, presence of β-CD/ZnO-NPs, type of bioactive agent as well as kind of pigment colorant. Among the used bioactive agents, lavender oil proved to be the best for attaining multi-functional and pigment coloration properties, keeping other parameters constant. The obtained results also demonstrated that increasing washing cycles up to 15 washes resulted in a slight decrease in the imparted functional and coloration properties, regardless of the used cellulosic substrate. Both SEM images and EDX spectra confirmed the surface modification and ZnO-NPs immobilization onto the selected fabric surfaces. Mode of interactions among the different printing paste constituents and the cellulosic substrates were also suggested.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cellulose-based textiles have many inherent desirable properties like hydrophilicity, wettability, air permeability, softness, and comfortability [1, 2]. However, they lack highly demanded functional properties, namely antimicrobial, UV-blocking, easy care, and/or water/oil repellency [3,4,5,6,7,8]. To avoid the above-mentioned drawbacks and to expand their potential applications, numerous modifications and specific functionalization have been carried out taking into consideration health risks, environmental concerns, and consumer demands [6, 9, 10].

On the other hand, several cyclodextrins (CDs), which have the ability to immobilize and host a wide range of appropriate functionalizing and active ingredients as guest molecules and to form the host–guest inclusion complexes within their hydrophobic cavities, can be used for modification and functionalization of the cellulosic substrates to impart and provide certain desirable functionalities like antimicrobial, aroma-finishing, UV-protection, better coloration properties, etc. [11,12,13,14,15,16,17].

Moreover, shifting away from conventional pigment printing and textile finishing and replacement of the harmful and non-eco-friendly pigment colorants, finishing, thickening, and binding agents with greener ones have several advantages and positive impacts like substantial water, energy, chemicals, and time savings, which in turn positively affects the product and ecology quality, and enables the development of more sustainable green textile products [18,19,20,21,22].

To date, there are few articles focused on development of multi-functional pigment printed cellulosic fabrics in a single-step process using environmentally sound functional agents and pigment formulation constituents [23,24,25]. In the present research work, we put forward an eco-friendly one-step strategy for developing antibacterial/UV-blocking/perfumed pigment prints using the following formulation: β-CD as a green modifying agent, formaldehyde-free finishing agent, water-based thickening agent, environmentally benign pigment colorants, along with ZnO-NPs alone and in combination with sustainable active ingredients namely lemon, lavender, and cinnamon essential oils or vanillin substance as active ingredients using pad-dry-cure technique. The imparted functional and coloration properties of simultaneously functionalized/printed cellulosic substrates have been investigated.

2 Experimental

2.1 Materials

Mill-scoured and bleached plain-weave cellulosic substrates namely cotton (C) (135 g/m2), viscose (V) (137 g/m2), cotton/viscose (CV) (50/50, 140 g/m2), and cotton/linen (CL) (50/50, 210 g/m2) fabrics were used in this study.

Eco-friendly lemon, lavender, and cinnamon essential oils were kindly supplied by Kalamin Co. Egypt as well as vanillin R (C8H8O3, molecular weight; 152.15, SDFCL®-India) were used in protective finish against some pathogenic bacterial strains and harmful UV-radiation.

Formaldehyde-free crosslinking agent (Arkofix® NZF, based on modified dihydroxy ethylene urea (Clariant International Ltd., Germany)), ammonium persulfate (NH4)2S2O8) catalyst, and β-cyclodextrin (β-CD, (C6H10O5)7, Sigma-Aldrich, Germany) were used as additives to enhance the extent of fixation, coloration, and functionalization of the aforementioned substrates.

Environmentally benign pigment colorants, namely Benzaprint® Orange Got, Red Got, and Blue Got (APEO- and CH2O-free aqueous pigment dispersions) were used in this work. Carbolan®DL (an eco-friendly water-based nonionic/anionic thickening agent, based on polyacrylate used as alternative to the harmful conventional kerosene emulsion thickening agent, Zschimmer & Schwarz, Germany), and Printofix® binder MTB01 EG liq. (anionic binder based on self-crosslinking acrylate copolymer, Egcodar) were of commercial grade.

ZnO-nanoparticles (ZnO-NPs, 10–30 nm) were kindly supplied by Skyspring Nanomaterials Inc., USA. All other chemicals used during this study were of reagent grade.

2.2 Simultaneous Surface Modification, Coloration, and Functionalization of the Used Cellulosic Substrates

Proper formulation guide for surface modification, coloration, and functionalization of the above-mentioned cellulosic substrates using a flat screen technique follows:

Ingredient | Content (g/kg paste) |

|---|---|

Pigment Thickener Binder Finishing agent Catalyst β-cyclodextrin additive Bioactive substance ZnO-NPs Distilled water | 20 15 100 20 2 0–15 0–20 0–10 X |

The functionalized/printed cellulosic substrates were dried at 100 °C for 5 min, thermofixed at 150 °C for 5 min, rinsed thoroughly to remove the unfixed/unreacted colorant as well as other active ingredients, and finally dried.

2.3 Testing Methods

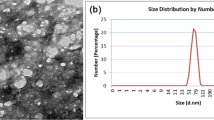

Scanning election microscopy (SEM) images and energy-dispersive X-ray spectroscopy (EDX) spectra for selected samples were obtained using a Quanta SEM 250 FEG (Field Emission Gun) equipped with an accelerating voltage of 30 kV (FEI Co., USA) for the surface composition analysis.

The nitrogen content was determined using Kjeldahl method.

The metal content was determined by a flame atomic spectrophotometer (GBC Avanta, Australia).

The imparted antibacterial activity against pathogenic Gram-positive (G + ve, Staphylococcus aureus, S. aureus) and Gram-negative (G−ve, Escherichia coli, E. coli) bacteria, expressed as zone of growth inhibition, ZI: in millimeters, was evaluated qualitatively using AATCC test method (147-2016).

Ultraviolet protection factor, UPF, value was calculated according to the AS/NZS standards (4399-1996), and ranked as follows: providing good protection, UPF:15–24, very good protection, UPF:25–39, and excellent protection, UPF: > 40. The higher the UPF value, the better UV-protecting property is.

Color strength, K/S value, of the printed fabric samples was calculated using Kubelka–Munk equation:

where K, S, and R are the absorption, scattering, and reflectance at the pigment’s maximum absorbance wavelength, respectively.

The sensorial evaluation of scent intensity was assessed according to the reported method [26], by a group of well-trained test-panel.

Fastness properties of the functionalized/pigment prints to washing, rubbing, and light were evaluated according to AATCC test methods: (61-2020), (8-2016), and (16-2004), respectively. Durability to wash was assessed according to ASTM standard test method (D737-96).

All determinations were done in triplicate and the average was taken as final results.

3 Results and Discussion

3.1 Tentative Mechanism

Incorporation of β-CD as a host biopolymer for the used bioactive guest molecules namely cinnamon oil, lemon oil, lavender oil and vanillin, along with ZnO-NPs as functional nanomaterials into the environmentally benign pigment formulations, followed by printing and subsequent thermofixation of the printed cellulosic substrates would be expected to help and facilitate pigment fixation and cellulose multi-functionalization simultaneously as shown in Scheme 1 [10, 21, 22, 25, 27,28,29].

3.2 Effect of Adding β-CD, ZnO-NPs or β-CD/ZnO-NPs to the Pigment Printing Formulation

For a given set of combined pigment coloration and multi-functionalization of CV and CL blended cellulosic fabrics, the results in Table 1 demonstrate that inclusion of β-CD (10 g/kg) into the pigment paste results in a slight decrease in %N, an improvement in antibacterial activity, expressed as ZI, against both the G + ve (S. aureus) and G-ve (E. coli) pathogenic bacteria, an enhancement in UV-protection efficacy, expressed as UPF value, along with a decrease in the depth of the obtained pigment prints, expressed as K/S values.

The decrease or increase in the aforementioned properties is governed by type of cellulosic substrate, fabric construction, its hydrophilicity, extent of modification and degree of fixation of β-CD, and accommodation of pigment molecules during the thermofixation step. The decrease in nitrogen content as well as in depth of the obtained pigment prints follows the decreasing order: CV > CL, keeping other parameters constant, which reflects the differences between the two cellulosic blends in amorphous to crystalline region, hydrophilicity, extent of penetration, location, and distribution of printing paste constituents onto/within the fabric structure which in turn affects both physico-chemical interactions and/or covalent bonding [30, 31]. On the other hand, the improvement in the antibacterial and UV-shielding capacity of the developed pigment prints could be discussed in terms of the positive role of grafted β-CD with its hydrophobic cavities onto fabric surface as well as its ability to form various inclusion complex and adducts with pigment paste constituents, e.g., finishing agent, binding agent, pigment color, etc., which may negatively impact both the growth of pathogenic bacteria as well as hinder the transmission of the harmful UV-irradiation through coating the fabric surface and minimizing the fabric porosity [21, 32].

Table 1 also demonstrates that incorporation of ZnO-NPs (10 g/kg) into the pigment printing formulation results in a decrease in both nitrogen content and K/S values of the obtained pigment prints, and the extent of decrease is determined by type of substrate.

On the other hand, inclusion of ZnO-NPs into the printing paste brings about a remarkable increase in Zn-content, antimicrobial activity as well as UV-protection efficacy regardless of the treated substrate. The increase in Zn-content reflects the positive role of the used binding agent in enhancing the extent of fixation and immobilization of ZnO-NPs onto the fabric surface, which in turn minimizes the extent of pigment molecules accommodation, i.e., lower K/S value. On the other hand, the remarkable improvement in both antibacterial activity UV-shielding ability of the developed pigment prints is attributed to its ability to generate various reactive oxygen species like ·OH, H2O−2, \({}^{ \cdot }{\text{O}}_{2}^{ - } \), [O], as follows [33,34,35,36,37,38,39,40].

which, in turn, have the ability to destruct, inhibit the growth and/or damage the harmful G + ve and G − ve bacterial cells [34]. The imparted antibacterial activity to the cellulosic pigment prints is determined by type of substrate and its Zn-content: CV > CL, as well as kind of pathogen: S. aureus > E. coli, keeping other parameters fixed.

Additionally, the remarkable improvement in the imparted UV-protection functionality to CV (UPF:130) and CL (UPF: 110) functionalized pigment prints reflect the positive role of immobilized ZnO-NPs onto printed fabrics surface on upgrading the blocking and shielding capability against the harmful UV-irradiation, especially UV-B, taking in consideration both type of fabric as well as depth of shade [5, 33, 41].

Moreover, it is worthwhile to note that incorporation of both β-CD (10 g/kg) and ZnO-NPs (10 g/kg) into the printing paste is accompanied by a noticeable increase in both antibacterial and UV-blocking functionalities along with a slight decrease in other chemical and coloration properties compared with using β-CD and ZnO-NPs individually.

As far as the changes in chemical, functional and coloration properties of the developed functionalized pigment prints as a function of additive type, the data in Table 1 demonstrate that: (i) the increase in both %N and K/S values follows the decreasing order: None > β-CD > ZnO-NPs > β-CD/ZnO-NPs, and (ii) the improvement in antibacterial and UV-protection functionality follows the decreasing order: β-CD/ZnO-NPs > ZnO-NPs > β-CD > None, keeping other parameters constant.

Finally, the imparted antibacterial activity against the tested pathogenic bacteria follows the decreasing order: S. aureus (G + ve) > E. coli (G − ve), which is attributed to their difference in cell wall structure and susceptibility to the used antibacterial agent [42,43,44].

3.3 Effect of Loading Selected Bioactive Materials onto Pigment Prints

The data in Table 1 clearly demonstrate that the highest antibacterial and UV-shielding efficacies were obtained by loading of both β-CD, with its host cavities, and ZnO-NPs onto the pigment printed substrates. Thus, all further trials were carried out using the aforementioned additives.

The data in Table 2 demonstrate that incorporation of cinnamon oil, lemon oil, lavender oil, or vanillin into the pigment printing along with other constituents results in an increase in both the Zn-content, nitrogen content, along with a significant improvement in the imparted antibacterial and UV-protection functionalities to the printed substrates, and remarkable increase in the depth of obtained pigment prints, regardless of the used cellulosic blend. The enhancement in the aforementioned properties is determined by type of cellulosic blend and follows the decreasing order: CV > CL, keeping other parameters constant.

The data in Table 2 also signify that the extent of improvement in chemical, functional, and coloration properties of simultaneously colored/finished substrates is governed by type of eco-friendly bioactive ingredient, its chemical composition, and active phytochemical constituents, like phenolics, flavonoids, tannins, terpene, etc., extent of loading into the grafted β-CD hydrophobic host-cavities and degree of releasing outside these cavities, as well as a synergistic combination of loaded ZnO-NPs and active ingredients of the greener guest bio-additives to develop multi-functional cellulosic pigment prints in one-step treatment [28, 29, 32, 45,46,47].

Moreover, as seen in Table 2, the remarkable improvement in the imparted antibacterial and UV-protection functionalities of the environmentally benign pigment prints using the listed bioactive materials along with β-CD and ZnO-NPs follows the descending order: β-CD/ZnO-NPs/lavender oil > β-CD/ZnO-NPs/lemon oil > β-CD/ZnO-NPs/vanillin > β-CD/ZnO-NPs/cinnamon oil > β-CD/ZnO-NPs, reflecting the differences among the used bioactive materials along with ZnO-NPs in inhibiting the growth, damaging and/or destroying the pathogenic bacteria cell wall, membrane function, protein synthesis, and other metabolic process [12, 29, 48,49,50], thereby upgrading the imparted antibacterial activity against both the: S. aureus (G + ve) and E. coli (G − ve) bacteria.

On the other hand, including bioactive materials along with ZnO-NPs and pigment colorant, results in enhancing the extent of reflection, absorption, transmission, and/ or blocking of the harmful UV-B radiation, thereby upgrading the UV-protecting capability of the developed printed/finished cellulosic blends.

Additionally, the remarkable increase in the depth of the obtained pigment prints, expressed as K/S values, is attributed to the enhancement in extent of ZnO-NPs fixation, inclusion compounds immobilization, and pigment molecules accommodation via formation of a three-dimensional network coat with the help of the added binding and crosslinking agents during thermofixation step [33, 51,52,53].

3.4 Effect of Using Different Pigment Colorants

As far as the variation in the chemical and functional properties, and color strength of the simultaneously printed and functionally finished CV and CL blended fabrics as a function of the type of pigment colorant, and for a given set of treatment conditions, the data in Table 3 demonstrate that: (i) the imparted functional properties expressed as ZI and UPF values, and the depth of the obtained pigment prints, expressed as K/S values, are determined by type of printing paste constituents and follows the same decreasing order as mentioned in case of using Benzaprint® Blue (data in Table 2), (ii) the noticeable variation in Zn-content, nitrogen-content, in the imparted antibacterial and UV-protection functionalities and in the extent of pigment coloration, expressed as K/S, is affected by the kind of pigment colorant, e.g. chemical structure, molecular size, hue, degree of fixation, and extent of accumulation as well as mode of interaction among different paste constituents and the treated cellulosic blend, and (iii) the most successful printing/finishing formulation for attaining the best functional/coloration properties were β-CD/ZnO-NPs/lavender oil formulations, regardless of the included pigment colorant.

3.5 SEM and EDX Analysis

Figure 1 shows the surface morphology and EDX spectra, respectively, of untreated and simultaneously functionalized/pigment printed viscose fabric samples using various pigment printing constituents. A close view of Fig. 1c, e, g clearly demonstrates that SEM images of selected viscose prints show remarkable change in their morphological structures compared with smooth surface of unprinted ones (Fig. 1a). The extent of coating, printing, and surface deposition of the used ingredients is governed by printing paste constituents, ability to form a three-dimensional network, and polymeric film to immobilize and affix the β-CD, pigment molecules, ZnO-NPs onto the fabric structure and to encapsulate the lavender oil into the hydrophobic cavities of grafted β-CD.

Additionally, EDX pattern of pigment prints, without addition of β-CD, ZnO-NPs, and lavender oil to the printing paste, shows peaks of C, O, and N elements related to the cellulose component, binding agent along with finishing agent constituents, respectively. On the other hand, EDX elemental analysis of the simultaneously pigment printed/multifunctionalized viscose substrate confirms the presence of Zn and Cu-elements (Fig. 1h), along with other elements namely C, O, and N, onto the developed pigment prints as a direct consequence of fixation and immobilization of ZnO-NPs, and inclusion of Cu-containing blue pigment molecules and lavender constituents [54, 55] within the hydrophobic cavities of grafted β-CD onto the fabric surface.

3.6 Effect of Type of Cellulosic Substrate and Durability to Wash

As far as the change in Zn and nitrogen contents, antibacterial activity (ZI), UV- protection ability (UPF), and scent intensity (SI) of the developed pigment printed/functionalized cellulosic fabrics as a function of type of substrate, keeping other parameters constant, the data in Table 4 demonstrate that: (i) both the Zn-content and the nitrogen content of the simultaneously printed/functionalized substrates follow the decreasing order: V > CV > C > CL, (ii) the imparted antibacterial activity against the harmful S. aureus (G + ve) and E. coli (G − ve) bacteria follows the above-mentioned order, (iii) the improvement in UV-protection property, UPF, follows the decreasing order: CV > V > CL > C, (iv) The variation in K/S of the developed pigment prints follows the descending order: V > CV > C > CL, and (v) using different cellulosic substrates has practically no effect on both scent intensity (SI:5), and on the wash, rubbing, and light fastness properties of the developed pigment prints.

On the other hand, the given data in Table 4 signify that increasing the number of washing cycles from one to 15 results in a slight decrease in the imparted functional and coloration properties, i.e., high extent of durability. All simultaneously printed/functionalized fabric samples acquired an outstanding antibacterial activity against the tested pathogens, i.e., S. aureus and E. coli bacteria, a pronounced UV-protection efficacy (> 50+, excellent) and a noticeable fragrance functional property (SI:4), irrespective of the treated cellulosic substrate.

The marginal or slight decrease in the chemical, color, and functional properties of the laundered blended fabrics, after 15 laundering cycles, in comparison with unwashed ones is a direct consequence of removal of untreated, physically bonded, surface deposited, entrapped, chemically unfixed constituents, and/or soluble adducts during the repeated laundering cycles.

Additionally, the variation in the aforementioned properties, before and after washing, reflects the variation in the treated cellulosic substrate in fabric construction, type of cellulosic component, availability and accessibility of active sites, i.e.–OH– groups, amorphous/crystalline area, extent of modification, functionalization, immobilization, and accommodation of both ZnO-NPs and pigment molecules as well as attachment of β-CD with its hydrophilic cavities onto fabric structure and subsequent inclusion of the used guest molecules [33].

4 Conclusion

This article successfully presented a greener and facile strategy for synergistic combination of β-CD, ZnO-NPs, various essential oils namely cinnamon, lemon, lavender and vanillin as guest molecules along with environmentally benign pigment paste constituents to fabricate durable multi-functional cellulosic pigment prints in one step. The imparted functional and coloration properties followed the decreasing order: β-CD/ZnO-NPs/bioactive ingredients > β-CD/ZnO-NPs alone, keeping other parameters constant. The imparted: antibacterial activity against both S. aureus (G + ve) and E. coli (G − ve) bacteria, UV-shielding capability against the harmful UV-B radiation and fragrant functional properties, the depth of the developed pigment prints, and their noticeable durability to repeated washing cycles confirmed the positive role of the modified pigment printing formulation in enhancing and facilitating the combined functionalization/coloration process, taking into consideration both the energy and material consumption, product quality as well as environmental concerns. Type of additive, kind of bioactive guest molecule, type of cellulosic substrate as well as nature of pigment colorant affected both extent of coloration and functionalization of the nominated cellulosic substrates. The appropriate conditions for attaining the highest functionality and printability were: β-CD (10 g/kg), ZnO-NPs (10 g/kg), lavender oil (10 g/kg), pigment colorant (20 g/kg), binding agent (100 g/kg), thickening agent (15 g/kg), crosslinking/fixing agent (20 g/kg), catalyst (2 g/kg), drying of printed fabric samples at 100 °C/5 min., then thermofixed at 150 °C/5 min., keeping other parameters constant. The unique combination of eco-friendly pigment coloration and functionalization of cellulosic substrates could be adopted and implemented on large scale to develop durable and sustainable protective cellulosic printed products. Further research work is underway to investigate, confirm, and demonstrate the mechanism proposed using FTIR analysis as well as to report the impart of the suggested strategy for surface modification, coloration, and multi-functionalization of cellulosic blends on some physico-chemical, mechanical, and thermal properties of the developed substrates in comparison with the unreacted once.

References

S. Islam, M. Shahid, F. Mohammad, J. Cleaner Prod. 57, 2 (2013)

A.K. Roy Choudhury, Text. Prog. 45, 3 (2013)

N.A. Ibrahim, B. Eid, E.A. El-Aziz, T.M. Abou Elmaaty, S.M. Ramadan, RSC Adv. 7, 33219 (2017)

N.A. Ibrahim, B.M. Eid, S.M. Sharaf, in Textiles and clothing. ed. by M. Shabbir (John Wiley & Sons, Inc, and Scrivener Publishing LLC, Hoboken, USA, 2019), pp.131–190

Y.-L. Lam, C.-W. Kan, C.-W.M. Yuen, Text. Prog. 44, 175 (2012)

M. Shahid, F. Mohammad, Ind. Eng. Chem. Res. 52, 5245 (2013)

R. Dastjerdi, M. Montazer, Colloids Surf. B: Biointerfaces 79, 5 (2010)

M. Montazer, T. Harifi, Nanofinishing of textile materials (Woodhead Publishing, Sawston, 2018)

S.B. Moore, L.W. Ausley, J. Cleaner Prod. 12, 585 (2004)

I. Holme, Color. Technol. 123, 59 (2007)

N.A. Ibrahim, B.M. Eid, in Handbook of sustainable polymers. ed. by V.K. Thakur, M.K. Thakur (Pan Stanford Publishing, CRC Press, Boca Raton, 2016), pp.215–264

N.A. Ibrahim, N.A. Abd El-Ghany, B.M. Eid, E.M. Mabrouk, Int. J. Biol. Macromol. 111, 526 (2018)

N.A. Ibrahim, H.M. Khalil, B.M. Eid, T.M. Tawfik, Fibers Polym. 19, 1655 (2018)

N. Singh, O. Sahu, in The impact and prospects of green chemistry for textile technology. ed. by Shahid-ul-Islam, B.S. Butola (Woodhead Publishing, Sawston, 2019), pp.83–105

A. Haji, in Frontiers of textile materials. ed. by M. Shabbir, S. Ahmed, J.N. Sheikh (Scrivener Publishing, Wiley, Beverly, USA, 2020), pp.87–116

S. Khanna, J. Chakraborty, Fash. Text. 5, 9 (2018)

P.L. Nostro, L. Fratoni, P. Baglioni, J. Incl. Phenom. Macrocycl. Chem. 44, 423 (2002)

A. Gürses, in The impact and prospects of green chemistry for textile technology. ed. by Shahid-ul-Islam, B.S. Butola (Woodhead Publishing, Elsevier, Sawston, 2018), pp.21–56

N.A. Ibrahim, B.M. Eid, H. Kafafy, in Advances in functional and protective textiles. ed. by Shahid-ul-Islam, B.S. Butola (Woodhead Publishing, Elsevier, Sawston, 2020), pp.569–630

R.S. Lodhi, N. Lal, Dyes Pigm. 4, 121 (2017)

B. Mahltig, J. Zhang, L. Wu, D. Darko, M. Wendt, E. Lempa, M. Rabe, H. Haase, J. Coat. Technol. Res. 14, 35 (2017)

N.A. Ibrahim, M.R. El-Zairy, S. Zaky, H.A. Borham, Polym. Plast. Technol. Eng. 44, 111 (2005)

N.A. Ibrahim, E. Abd El-Aziz, B.M. Eid, T.M. Abou Elmaaty, J. Text. Inst. 107, 1022 (2016)

N.A. Ibrahim, B.M. Eid, H.M. Khalil, Carbohydr. Polym. 115, 559 (2015)

F. Uddin, M. Lomas, Color. Technol. 121, 158 (2005)

C.X. Wang, S.L. Chen, J. Ind. Text. 34, 157 (2005)

N.A. Ibrahim, A.A. Aly, B.M. Eid, H.M. Fahmy, Fibers Polym. 19, 2298 (2018)

N.A. Ibrahim, B.M. Eid, E.M. El-Zairy, E. Emam, S. Barakat, Int. J. Biol. Macromol. 135, 88 (2019)

R.K. Sarkar, D. Purushottam, P.D. Chauhan, J. Fibre Text. Res. 28, 322 (2003)

J. Park, Colourage 57, 41 (2010)

N. Yaman, E. Ozdogan, N. Seventekin, J. Eng. Fibers Fabr. 7(2), 40 (2012)

N.A. Ibrahim, B.M. Eid, E.R. El-Zairy, Carbohydr. Polym. 86, 1313 (2011)

N.A. Ibahim, B.M. Eid, E. Abd El-Aziz, T.M. Abou Elmaaty, Carbohydr. Polym. 97, 537 (2013)

N.A. Ibrahim, A.A. Nada, B.M. Eid, M. Al-Moghazy, A.G. Hassabo, N.Y. Abou-Zeid, Adv. Nat. Sci.: Nanosci. Nanotechnol. 9, 035014 (2018)

A. Becheri, M. Dürr, P. Lo Nostro, P. Baglioni, J. Nanopart. Res. 10, 679 (2008)

B.S. Butola, A. Garg, A. Garg, I. Chauhan, J. Inst. Eng. (India): E 99, 93 (2018)

M. Ibanescu, V. Musat, T. Textor, V. Badilita, B. Mahltig, J. Alloys Compd. 610, 244 (2014)

A. Arputharaj, V. Nadanathangam, S.R. Shukla, Cellulose 24, 3399 (2017)

H.F. Moafi, A.F. Shojaie, M.A. Zanjanchi, Thin Solid Films 519, 3641 (2011)

S.W. Kim, Y.-J. An, Appl. Microbiol. Biotechnol. 95, 243 (2012)

R. Pandimurugan, S. Thambidurai, Int. J. Biol. Macromol. 105, 788 (2017)

N.A. Ibrahim, A.A. Aly, M. Gouda, J. Ind. Text. 37, 203 (2008)

V. Prasad, A. Arputharaj, A.K. Bharimalla, P.G. Patil, N. Vigneshwaran, Appl. Surf. Sci. 390, 936 (2016)

S. Riaz, M. Ashraf, in Advances in Functional Finishing of Textiles. ed. by M. Shahid, R. Adivarekar (Springer, Singapore, 2020), p.129

C. Panisello, B. Peña, G. Gilabert Oriol, M. Constantí, T. Gumí, R. Garcia-Valls, Ind. Eng. Chem. Res. 52, 9995 (2013)

A. Sharkawy, I.P. Fernandes, M.F. Barreiro, A.E. Rodrigues, T. Shoeib, Ind. Eng. Chem. Res. 56, 5516 (2017)

S. Ghayempour, M. Montazer, J. Microencapsul. 33, 497 (2016)

Y. El Atki, I. Aouam, F. El Kamari, A. Taroq, K. Nayme, M. Timinouni, B. Lyoussi, A. Abdellaoui, J. Adv. Pharm. Technol. Res. 10, 63 (2019)

M. Viuda-Martos, Y. Ruiz-Navajas, J. Fernández-López, J. Perez-Álvarez, J. Food Saf. 28, 567 (2008)

K.A. Hammer, C.F. Carson, T.V. Riley, J. Appl. Microbiol. 86, 985 (1999)

L. Rizzello, R. Cingolani, P.P. Pompa, Nanomedicine 8, 807 (2013)

T. Harifi, M. Montazer, Carbohydr. Polym. 88, 1125 (2012)

M. Montazer, M.G. Afjeh, J. Appl. Polym. Sci. 103, 178 (2007)

R. Prusinowska, K.B. Śmigielski, Herba Polonica 60(2), 56 (2014)

CHT-group, Pigments for Printing-Bezaprint. CHT Smart Chemistry with Character, Germany

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interests

None.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ibrahim, N.A., El-Zairy, E.M., Allah, S.S.A. et al. A Greener Facile Approach to Develop Durable Multifunctional Cellulosic Pigment Prints Using β-CD, ZnO-NPs and Several Bioactive Guest Molecules. Fibers Polym 24, 109–118 (2023). https://doi.org/10.1007/s12221-023-00087-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00087-x