Abstract

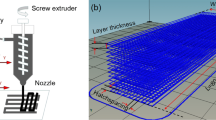

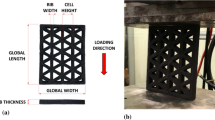

In response to the environmental problems caused by the difficulty of direct degradation of the raw materials used in traditional geogrids and the impact of different temperatures on the mechanical properties of geogrids in practical engineering applications, based on 3D printing technology, polylactic acid (PLA), carbon fiber reinforced polylactic acid (PLA/CF), and thermoplastic polyurethane (TPU) geogrids were fabricated. The 3D printed geogrids and the fiberglass geogrids used in the actual project were tested in indoor tensile tests under different temperature conditions. The mechanical properties of the geogrids of the four kinds of materials and six kinds of temperature were analyzed. The microstructure of the geogrids after tensile tests was investigated based on scanning electron microscopy technology to further analyze the effects of different materials and temperatures on the mechanical properties of the geogrids. The results showed that the tensile strength of PLA/CF geogrids and PLA geogrids decreased with increasing temperature. The tensile strength of fiberglass geogrids increased with rising temperatures. The tensile strength of PLA/CF geogrids was significantly better than PLA geogrids. Due to the addition of carbon fiber in PLA, PLA/CF can bear more tensile force at high temperatures. With the increase of temperature, the elongation at break of PLA/CF geogrids and fiberglass geogrids increased, but the elongation at break of PLA geogrids decreased. The elongation at break of PLA/CF geogrids was significantly lower than that of PLA geogrids. TPU geogrids had high tensile capacity in a high-temperature environment, and they also had high elasticity and more significant elongation at break, which was not suitable to be used as geogrid material.

Similar content being viewed by others

References

D. Leshchinsky, B. Kang, J. Han, and H. Ling, Transp. Infrastruct. Geotechnol., 1, 129 (2014).

S. Balakrishnan and B. V. S. Viswanadham, Geotext. Geomembr., 44, 95 (2016).

T. M. Allen and R. J. Bathurst, Can. Geotech. J., 51, 16 (2014).

T. M. Allen and R. J. Bathurst, J. Geotech. Geoenviron. Eng., 140, 217 (2014).

Y. Xie and B. Leshchinsky, Geotext. Geomembr., 43, 128 (2015).

H. Yuan, X. H. Bai, H. H. Zhao, and J. R.Wang, Adv. Civ. Eng., doi: https://doi.org/10.1155/2020/8839919 (2020).

Q. B. Wang, L. Xu, J. X. Zhang, R. S. Lv, T. T. Wang, Z. J. Hu, Y. Bai, Y. C. Kong, F. Xie, and L. Y. Tang, J. Test. Eval., 45, 61 (2017).

R. Hegazy, G. M. Mahmoud, and E. H. Hasan, Adv. Polym. Technol., 37, 1185 (2016).

C. W. Hsieh and C. K. Lin, Geotech. Test. J., 27, 111 (2004).

T. Chantachot, W. Kongkitkul, and F. Tatsuoka, Int. J. Geomate., 10, 1869 (2016).

H. I. Ling, Y. Mohri, and T. Kawabata, J. Geotech. Geoenviron. Eng., 124, 782 (1998).

T. Y. Liu, Y. Xin, X. Z. Liu, B. Wu, and M. C. Xiang, Chin. J. Biotechnol., doi: https://doi.org/10.13345/j.cjb.200624 (2021).

J. Chen, W. X. Fu, F. Dai, and J. H. Deng, Rock Soil Mech., 38, 174 (2017).

L. L. Zhang, H. Wen, and Z. W. Zhang, Chin. J. Rock Mech. Eng., 33, 3829 (2014).

A. Cislaghi, P. Sala, G. Borgonovo, C. Gandolfi, and G. B. Bischetti, Sustainability, doi: https://doi.org/10.3390/su13052585 (2021).

A. Hegde and T. G. Sitharam, J. Mater. Civ. Eng., 27, 04014256–1 (2015).

F. Ye and W. X. Fu, J. Mater. Civ. Eng., 30, 05017004–1 (2018).

B. Lu, D. Li, and X. Tian, Engineering, 1, 85 (2015).

D. Stathas, J. P. Wang, and H. I. Ling, Geotext. Geomembr., doi: https://doi.org/10.1016/j.geotexmem.2017.07.006 (2017).

G. J. Fowmes, N. Dixon, L. W. Fu, and C. A. Zaharescu, Geotext. Geomembr., 45, 674 (2017).

A. Lanzotti, M. Martorelli, S. Maietta, S. Gerbino, F. Penta, and A. Gloria, Procedia CIRP, 79, 143 (2019).

A. Pellis, L. Silvestrini, D. Scaini, J. M. Coburn, L. Gardossi, D. L. Kaplan, E. H. Acero, and G. M. Guebitz, Process Biochem., 59, 77 (2016).

J. Chakravarty, M. F. Rabbi, V. Chalivendra, T. Ferreira, and C. J. Brigham, Int. J. Biol. Macromol., 151, 1213 (2019).

K. Adamska, A. Voelkel, and A. Berlińska, Biomed. Anal., 127, 202 (2016).

M. Abu Ghalia and Y. Dahman, Polym. Test., 61, 114 (2017).

M. Ejaz, M. M. Azad, A. Ur, R. Shah, and J. I. Song, Fiber. Polym., 21, 2635 (2020).

Y. P. Hao, Y. Li, Z. G. Liu, X. Y. Yan, Y. Tong, and H. Zhang, Fiber. Polym., 20, 1766 (2019).

M. P. Arrieta, M. D. Sámper, J. Lopez, and A. Jiménez, Polym. Environ., 22, 460 (2014).

F. Wang, G. Wang, F. Ning, and Z. Zhang, Addit. Manuf., doi: https://doi.org/10.1016/j.addma.2020.101661 (2020).

C. Hu, J. Q. Dong, J. J. Luo, Q. H. Qin, and G. Y. Sun, Compos. Pt. B-Eng., doi: https://doi.org/10.1016/j.compositesb.2020.108400 (2020).

K. L. Zhu, H. S. Tan, Y. J. Wang, C. H. Liu, X. M. Ma, J. Wang, and H. N. Xing, Fiber. Polym., 20, 839 (2019).

L. P. Li, D. Y. Wu, and M. He, Fiber. Polym., 21, 583 (2020).

N. Maqsood and M. Rimaauskas, Compos. Part C: Open Access, doi: https://doi.org/10.1016/j.jcomc.2021.100112 (2021).

R. Matsuzaki, M. Ueda, M. Namiki, T. K. Jeong, H. Asahara, K. Horiguchi, T. Nakamura, A. Todoroki, and Y. Hirano, Sci. Rep-UK, doi: https://doi.org/10.1038/srep23058 (2016).

X. Y. Tian, T. F. Liu, C. C. Yang, Q. R. Wang, and D. C. Li, Compos. Pt. A-Appl. Sci. Manuf., 88, 198 (2016).

A. Vcg, A. Prk, and B. Hbk, Mater. Today: Proc., 23, 221 (2020).

Y. D. Shi, Y. H. Cheng, Y. F. Chen, K. Zhang, J. B. Zeng, and M. Wang, Polym. Test., 62, 1 (2017).

Q. F. Jing, Q. Liu, L. Li, Z. L. Dong, and V. V. Silberschmidt, Compos. Pt. B-Eng., 89, 1 (2016).

A. M. N. Azammi, S. M. Sapuan, M. R. Ishak, and M. T. H. Sultan, Fiber. Polym., 19, 446 (2018).

A. Huang, X. F. Peng, and L. S. Turng, Polymer, 134, 263 (2018).

K. N. Gunasekaran, V. Aravinth, C. Kumaran, K. Madhankumar, and S. P. Kumar, Mater. Today:. Proc., doi: https://doi.org/10.1016/j.matpr.2020.09.041 (2020).

N. Najafi, M. C. Heuzey, P. J. Carreau, and P. M. Wood-Adams, Polym. Degrad. Stab., 97, 554 (2012).

G. Scetta, N. Selles, P. Heuillet, M. Ciccotti, and C. Creton, Polym. Test., doi: https://doi.org/10.1016/j.polymertesting.2021.107140 (2021).

L. F. Cai, C. L. Wang, H. W. Chen, H. Qian, Z. Y. Lin, and X. C. Zhang, Appl. Nanosci., 10, 51 (2019).

A. Fk, B. Ss, B. Yk, and D. Utc, Cleaner Eng. Technol., doi: https://doi.org/10.1016/j.clet.2021.100251 (2021).

F. D. Kopinke and K. Mackenzie, J. Anal. Appl. Pyrolysis, 40–1, 43 (1997).

B. Wu, R. Wang, G. Zheng, and C. Zhou, Fiber. Polym., 21, 148 (2020).

S. Bhagia, R. R. Lowden, D. Erdman. Iii, M. Rodriguez, and A. J. Ragauskas, Appl. Mater. Today, doi: https://doi.org/10.1016/j.apmt.2020.100832 (2020).

S. C. Clarizio and R. A. Tatara, J. Polym. Environ., 20, 638 (2012).

R. L. Ferreira, I. C. Amatte, T. A. Dutra, and D. Burger, Compos. Pt. B-Eng., 124, 88 (2017).

K. K. Guduru and G. Srinivasu, Mater. Today: Proc., 33, 5403 (2020).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NO. 51778353).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, J., Zhang, H., Xie, X. et al. Study on the Mechanical Properties and Microstructure of Geogrid Under Different Materials and Temperatures. Fibers Polym 23, 1753–1762 (2022). https://doi.org/10.1007/s12221-022-4677-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4677-z