Abstract

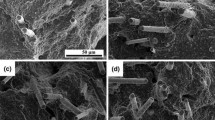

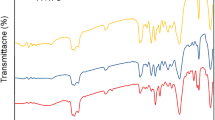

The effect of two different continuous carbon fibers (CCF1 and CCF2) with different material properties on structure-properties of continuous carbon fibers reinforced polyether-ether-ketone prepreg tapes (CCF/PEEKPT) prepared by a wet powder impregnation process were investigated. The effects of fiber content on the tensile properties, dynamic mechanical behavior, crystallization melting behavior and fracture morphology of prepared prepreg tapes were performed by the dynamic mechanical analysis (DMA), differential scanning calorimetry (DSC) and scanning electron microscope (SEM) etc. The results showed that, the tensile strength of CCF1/PEEKPT increased with increasing of the carbon fiber content within 50–75 wt%. Meanwhile, the tensile strength of 50–65 wt% CCF2/PEEKPT had the same change trend, but then decreased when the fiber content of composites was higher than 65 wt%. The storage modulus (E′) of composites increased with adding content of carbon fiber. The composites still maintained high deformation resistance when the temperature rose to 290 °C. Compared with pure PEEK, the crystallinity and crystallization rate of the composites both increased with the occurrence of fiber inducing PEEK crystallization, but the crystallization onset temperature, crystallization temperature and melting temperature of CCF/PEEKPT moved to low temperatures with adding of fiber content. In general, these observations suggested that CCF hindered the movement of the polymer chain segment and constrained the spherulites growth of PEEK for CCF/PEEKPT.

Similar content being viewed by others

References

M. Jennifer, Plast. Addit. Compound., 6, 22 (2004).

F. Chegdani and M. E. L. Mansori in “Polymer Testing”, Vol. 67, Elsevier, Netherlands, 2018.

L. Pan and U. Yapici in “Advanced Composite Materials”, Vol. 25, Over There Centuries of Scholarly Publishing, Taylor & Francis, 2015.

V. Mylläri and T. P. Ruoko in “Polymer Degradation and Stability” (J. Vuorinen and H. Lemmetyinen Eds.), Vol. 120, Applied Science Publishers, London, 2015.

A. M. Diez-Pascual, M. Naffakh, J. M. Gonzalez-Dominguez, A. Anson, Y. Martinez-Rubi, M. T. Martinez, B. Simard, and M. A. Gomez, Carbon, 48, 3485 (2010).

P. R. Monich and B. Henriques in “Materials Letters” (A. P. N. D. Oliveira, J. C. M. Souza, and M. C. Fredel Eds.), Vol. 185, Elsevier, Netherlands, 2016.

A. Avanzini, C. Petrogalli, and D. Battini in “Materials & Design”, Vol. 139, Elsevier, Netherlands, 2017.

C. Y. Chen and C. Zhang in “Composites Part B Engineering” (C. L. Liu, Y. G. Miao, S. C. Wong, and Y. L. Li Eds.), Vol. 136, Elsevier, Netherlands, 2017.

Z. Rasheva, G. Zhang, and T. Burkhart, Tribol. Int., 43, 1430 (2010).

K. Wong, U. Nirmal, and B. Lim, J. Reinf. Plast. Compos., 29, 3463 (2010).

M. H. Akonda, C. A. Lawrence, and B. M. Weager, Compos. Pt. A-Appl. Sci. Manuf., 43, 79 (2012).

D. Garcia-Gonzalez, M. Rodriguez-Millan, A. Rusinek, and A. Arias, Compos. Struct., 133, 1116 (2015).

K. Fujihara, Z. M. Huang, S. Ramakrishna, and H. Hamada, Compos. Sci. Technol., 64, 2525 (2004).

Z. Xu and M. Zhang in “Polymer Composites” (S. H. Gao, G. B. Wang, S. L. Zhang, and J. S. Luan Eds.), Society for Plastic Engineers, Connecticut, 2017.

Y. H. Zhang and W. Tao in “Composites Science & Technology” (Y. Zhang, L. Tang, J. W. Gu, and Z. H. Jiang Eds.), Vol. 165, Elsevier, England, 2018.

Y. C. Lee and R. S. Porter, Polym. Eng. Sci., 26, 633 (2010).

A. K. Mohanty, L. T. Drzal, and M. Misra, J. Adhes. Sci. Technol., 16, 999 (2002).

L. Ye, V. Klinkmuller, and K. Friedrich, J. Thermoplast. Compos., 5, 1 (1992).

A. Miller, C. Wei, and A. G. Gibson, Compos. Pt. A-Appl. Sci. Manuf., 27, 49 (1996).

A. M. Vodermayer, J. C. Kaerger, and G. Hinrichsen, Compos. Manuf., 4, 123 (1993).

M. Regis and M. Zanetti in “Materials Chemistry and Physics” (M. Pressacco and P. Bracco Eds.), Vol. 179, Elsevier, Switzerland, 2016.

M. Regis and A. Bellare in “Polymer Degradation and Stability” (T. Pascolini and P. Bracco Eds.), Vol. 136, Elsevier, England, 2017.

P. Tamás, Exp. Polym. Lett., 4, 590 (2010).

M. C. Kuo, J. C. Huang, and M. Chen, Mater. Chem. Phys., 99, 258 (2006).

L. I. Tieqi, M. Zhang, and H. Zeng, Chinese J. Mate. Res., 13, 606 (1999).

W. Wang, Z. Qi, and G. Jeronimidis, J. Mater. Sci., 26, 5915 (1991).

M. Chen and C. T. Chung, Polym. Compos., 19, 689 (1998).

M. Sattaria, A. Molazemhosseini, M. R. Naimi-Jamalb, and A. Khavandi, Mater. Chem. Phys., 147, 942 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, K., Tan, H., Wang, Y. et al. Crystallization and Mechanical Properties of Continuous Carbon Fiber Reinforced Polyether-ether-ketone Composites. Fibers Polym 20, 839–846 (2019). https://doi.org/10.1007/s12221-019-8791-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-8791-5