Abstract

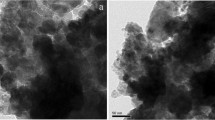

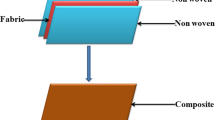

Both the chicken eggshell (ES) and rice husk (RH) represent environmental, and pollution issues. Incorporating both of them, with minimum processing procedures, in various useful applications is a major contribution in solving such problems. In this research, unsaturated polyester (UP) was doped with different percentages (5–25 wt.%) of fine (ES) to form one (UP-ES) composite system. The (UP-ES) system was reinforced with a fixed 10 wt.% of (RH), which represents an agricultural waste produced in tonnage, to fabricate the second system. X-ray diffraction (XRD) analysis emerged that the (ES) is forming from calcium carbonate (CaCO3) resembling typically the mineral one. The addition of (ES) enhanced both the mechanical characteristics of (UP) resin in terms of tensile strength, elongation %, tensile modulus, impact strength, flexural strength from 26.33 to 33.77 MPa, from 3.30 to 3.60 MPa, from 2000 to 2406.67 MPa, from 1.25 to 2.42 kJ/m2, from 64.93 to 75.07 MPa, and the thermal stability from 335.75 to 346.24 °C, respectively. This inclusion of (ES) also promoted both the limiting oxygen index (LOI) and dielectric constant (εr) of (UP) from 17.25 to 23.50 % and from 6.76 to 11.02, respectively. The addition of (RH) to (ES-UP) composite, generally, gave the same attitude for the properties like what in the (ES-UP) system other than the remarkable extra-increase in the (εr). Also, (RH) elevated the water absorption (%) of (ES-UP) composite by the action of its hydrophilic nature. It is concluded that the incorporation of both (ES) and (RH) reduces the final cost of the composite and solves one of the great environmental disposal issues.

Similar content being viewed by others

References

P. Totiger, M. Gothe, S. Nagavi, and R. Mulimani, Int. J. Res. Eng. Technol., 4, 300 (2015).

S. Sathiyamurthy, A. Thaheer, and S. Jayabal, Indian J. Fibre Text. Res., 38, 81 (2013).

K. P. Kumar and A. S. J. Sekaran, J. Reinf. Plast. Compos., 33, 1879 (2014).

A. Chauhan, P. Chauhan, and B. Kaith, J. Chem. Engineer. Process. Technol., 3, 10001323 (2012).

P. K. Mallick, “Fiber Reinforced Composites: Materials, Manufacturing and Design”, 2nd ed., Marcel Dekker Inc., New York, 1993.

A. K. Rout and A. Satapathy, Mater. Des., 41, 131 (2012).

B. J. Saradava, N. V. Rachchh, R. K. Misra, and D. G. Roychowdhary, J. Inf. Knowl. Res. Mech. Eng., 2, 472 (2013).

P. Toro, R. Quijada, M. Yazdani-Pedram, and J. L. Arias, Mater. Lett., 61, 4347 (2007).

M. Pettinato, S. Chakraborty, H. A. Arafat, and V. Calabro’, Ecotoxicol. Environ. Saf., 121, 57 (2015).

M. Mohammadi, P. Lahijani, and A. R. Mohamed, Chem. Eng. J, 243, 455 (2014).

A. Laca, A. Laca, and M. Díaz, J. Environ. Manage., 197, 351 (2017).

H. Duan, L. Zhang, J. Wang, and X. Yang, J. Wuhan Univ. Technol. Mater. Sci. Ed., 23, 460 (2008).

J. K. Fink, “Reactive Polymers: Fundamentals and Applications, A Concise Guide to Industrial Polymers”, 3rd ed., Elsevier, Oxford, 2017.

R. Malkapuram, V. Kumar, and Y. Singh Negi, J. Reinf. Plast. Compos., 28, 1169 (2009).

M. J. John and S. Thomas, Carbohydr. Polym., 71, 343 (2008).

A. K. Bledzki, V. E. Sperber, and O. Faruk, “Natural and Wood Fibre Reinforcement in Polymers”, Vol. 13, iSmithers Rapra Publishing, United Kingdom, 2002.

C. He, J. Liu, P. Xue, and H. Gu, Adv. Mat. Res., 217–218, 347 (2011).

B. S. Ndazi, S. Karlsson, J. V. Tesha, and C. W. Nyahumwa, Compos. Part A Appl. Sci. Manuf., 38, 925 (2007).

S. Arora, M. Kumar, and M. Kumar, J. Reinf. Plast. Compos., 31, 85 (2012).

H.-S. Kim, B.-H. Lee, S.-W. Choi, S. Kim, and H.-J. Kim, Compos. Part A Appl. Sci. Manuf., 38, 1473 (2007).

A. Mishra and D. Padhee, J. Mech. Civil Eng., 14, 91 (2017).

W. O. Ondiek, H. T. Ngetha, J. N. Keraita, and J. B. Byiringiro, Int. J. Compos. Mater., 8, 105 (2018).

Z. Xu, Z. Chu, L. Yan, H. Chen, H. Jia, and W. Tang, Polym. Compos., 40, 2712 (2019).

T. P. Cunha, F. B. Siqueira, and J. N. F. Holanda, Mater. Res., 22, e20180865 (2019).

I. García-Moreno, M. Á. Caminero, G. P. Rodríguez, and J. J. López-Cela, Polymers, 11, 80 (2019).

D. W. van Krevelen and K. te Nijenhuis, “Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions”, Elsevier, New York, 2009.

H. H. Xin, “A Project Report Submitted in Partial Fulfilment of the Requirements for the Award of Bachelor of Engineering (Hons.)”, Petrochemical Engineering, (FEGT), UTAR, 2016.

K. Mustapha, R. Ayinla, A. S. Ottan, and T. A. Owoseni, MRS Adv., 5, 2783 (2020).

S. Owuamanam and D. Cree, J. Compos. Sci., 4, 70 (2020).

R. Dweiri, Mater. Res., doi: https://doi.org/10.1590/1980-5373-MR-2021-0078 (2021).

N. A. N. Azman, M. R. Islam, M. Parimalam, N. M. Rashidi, and M. Mupit, Polym. Bull., 77, 805 (2020).

G. M. S. Rahman, H. Aftab, M. S. Islam, M. Z. B. Mukhlish, and F. Ali, Fiber. Polym., 17, 59 (2016).

R. N. Farahana, A. G. Supri, and P. L. Teh, J. Adv. Res. Mater. Sci., 5, 1 (2015).

S. Shuhadah and A. G. Supri, J. Phys. Sci., 20, 87 (2009).

R. A. Nasif, IJAP, 11, 25 (2015).

P. Hirematha, M. Shettara, G. Shankar, M. Ca, and N. S. Mohan, Mater. Today: Proc., 5, 3014 (2018).

B. Dholakiya in “Polyester” (H. M. Saleh), InTech, 2012.

M. C. Yew, N. H. Ramli Sulong, M. K. Yew, M. A. Amalina, and M. R. Johan, Sci. World J., doi: https://doi.org/10.1155/2014/805094 (2014).

I. Ahmad, D. R. Abu Bakar, S. N. Mokhilas, and A. Ramli, AJSTD, 22, 345 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharaf, A.M., Syala, E., Ezzat, A.A. et al. Natural Fiber Reinforced Unsaturated Polyester Resin Filled with Bio-based Calcium Carbonate: Preparation and Examination. Fibers Polym 23, 1366–1377 (2022). https://doi.org/10.1007/s12221-022-4460-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4460-1