Abstract

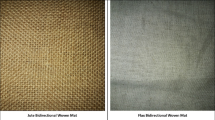

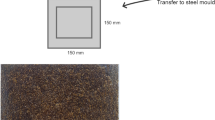

Synthetic plastic pollution has focussed the attention of material scientist and researchers towards the development of non-toxic biodegradable composite materials. To develop bio-composites, sustainable products and materials should be encouraged with involvement of non-toxic raw materials. Exploration of bio-composites development imparts the attention of researchers towards nature-based resources. This study gives a brief role of natural fibers, animal and plant wastages, and polymer to develop composite materials. In this study, fabrication of bio-composites was done by the reinforcement of ramie and kenaf fibers with eggshell and coconut shell powders with epoxy polymer matrix using hand lay-up technique. Present research includes moisture uptake capacity, density and surface roughness measurement, and mechanical characterization of developed composite specimens. Kenaf/coconut shell powder/epoxy composite absorbed more water than other developed specimens. Similarly, kenaf reinforced nanocomposite has slightly higher surface roughness than ramie reinforced nanocomposite with eggshell and coconut shell powders. Ramie/epoxy/coconut shell had the highest tensile strength of 42.3 MPa. Kenaf/epoxy/coconut shell achieved the highest tensile modulus of 1.97 MPa, and kenaf/epoxy/eggshell had highest elongation at break of 3.6% as compared to all other developed specimens. Flexural strength was highest for ramie/epoxy/coconut shell at 30.5 MPa. Impact strength was also highest for ramie/epoxy/coconut shell at 8.9 kJ/m2. From the SEM analysis, it was found that kenaf fiber reinforced specimens are more damaged when compared to ramie fiber reinforced specimens due to rough surface and better wettability of ramie fiber which provided better interfacial adhesion between fiber and matrix phase hence. Thus, it was observed that ramie fiber reinforced with coconut shell and eggshell powder achieved better performance during mechanical analysis.

Similar content being viewed by others

Data availability

Not applicable.

References

Alemdar A, Sain M (2008) Biocomposites from wheat straw nanofibers: morphology, thermal and mechanical properties. Compos Sci Technol 68(2):557–565. https://doi.org/10.1016/J.COMPSCITECH.2007.05.044

Chichane A, Boujmal R, El Barkany A (2023) Bio-composites and bio-hybrid composites reinforced with natural fibers: review. Mater Today Proc 72:3471–3479. https://doi.org/10.1016/J.MATPR.2022.08.132

Radhakrishnan S, Das PP, Chaudhary V (2022) Deciphering the pathways for evaluation of nanofillers for polymer composites: biodegradability, sustainability, and emerging applications. Biomass Convers Biorefin 2022:1–32. https://doi.org/10.1007/S13399-022-03548-0

Chaudhary V, Ahmad F (2020) A review on plant fiber reinforced thermoset polymers for structural and frictional composites. Polym Test 91. https://doi.org/10.1016/j.polymertesting.2020.106792

Vinod A, Sanjay MR, Suchart S, Jyotishkumar P (2020) Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites. J Clean Prod 258:120978. https://doi.org/10.1016/J.JCLEPRO.2020.120978

Das PP, Chaudhary V, Ahmad F, Manral A (2021) Effect of nanotoxicity and enhancement in performance of polymer composites using nanofillers: a state-of-the-art review. Polym Compos 42(5) John Wiley and Sons Inc:2152–2170. https://doi.org/10.1002/pc.25968

Fortunati E, Peltzer M, Armentano I, Torre L, Jiménez A, Kenny JM (2012) Effects of modified cellulose nanocrystals on the barrier and migration properties of PLA nano-biocomposites. Carbohydr Polym 90(2):948–956. https://doi.org/10.1016/J.CARBPOL.2012.06.025

Krishna JS, Chaudhary V, Mehta J, Malhotra P, Gupta S, Gupta P (2022) Synergistic reinforcement of nanofillers in biocomposites developed by additive manufacturing techniques. Biomass Convers Biorefin:1–16. https://doi.org/10.1007/S13399-022-03395-Z/METRICS

Nagalakshmaiah M et al (2019) Biocomposites: present trends and challenges for the future. Green Compos Automot Appl:197–215. https://doi.org/10.1016/B978-0-08-102177-4.00009-4

Radhakrishnan S et al (2023) Studies on mechanical, thermal, and water immersion of plant and animal wastage nanofiller–based bio-fiber-reinforced composites. Biomass Convers Biorefin 2023:1–22. https://doi.org/10.1007/S13399-023-04788-4

Ridho MR et al (2022) Lignin as green filler in polymer composites: development methods, characteristics, and potential applications. Adv Mater Sci Eng 2022. https://doi.org/10.1155/2022/1363481

Das PP, Chaudhary V, Ahmad F, Manral A, Gupta S, Gupta P (2022) Acoustic performance of natural fiber reinforced polymer composites: influencing factors, future scope, challenges, and applications. Polym Compos 43(3):1221–1237. https://doi.org/10.1002/PC.26455

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58(11):80–86. https://doi.org/10.1007/S11837-006-0234-2/METRICS

Moudood A, Rahman A, Khanlou HM, Hall W, Öchsner A, Francucci G (2019) Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos B Eng 171:284–293. https://doi.org/10.1016/J.COMPOSITESB.2019.05.032

Natrayan L, Merneedi A, Bharathiraja G, Kaliappan S, Veeman D, Murugan P (2021) Processing and characterization of carbon nanofibre composites for automotive applications. https://doi.org/10.1155/2021/7323885

Suhaily M, Che Hassan CH, Jaharah AG, Afifah MA, Nor Khairusshima MK (2018) Analysis and modeling of delamination factor in drilling of woven kenaf fiber reinforced epoxy using Box Behnken experimental design. IOP Conf Ser Mater Sci Eng 290(1). https://doi.org/10.1088/1757-899X/290/1/012033

He L, Xia F, Wang Y, Yuan J, Chen D, Zheng J (2021) Mechanical and dynamic mechanical properties of the amino silicone oil emulsion modified ramie fiber reinforced composites. Polymers (Basel) 13(23). https://doi.org/10.3390/POLYM13234083

Jha MK, Das PP, Pandey V, Gupta P, Chaudhary V, Gupta S (2022) Water immersion aging of polymer composites: architectural change of reinforcement, mechanical, and morphological analysis. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-03622-7

Chaudhary V, Bajpai PK, Maheshwari S (2020) Effect of moisture absorption on the mechanical performance of natural fiber reinforced woven hybrid bio-composites. J Nat Fibers 17(1):84–100. https://doi.org/10.1080/15440478.2018.1469451

Chaudhary V, Sahu R, Manral A, Ahmad F (2020) Comparative study of mechanical properties of dry and water aged jute/flax/epoxy hybrid composite. Mater Today Proc 25:857–861. https://doi.org/10.1016/J.MATPR.2019.11.053

Radhakrishnan S, Chaudhary V, Das PP, Sharma B, Sharma R (2023) Deterioration of polymer composites after water ageing of chemically treated and untreated biomass. Biomass Convers Biorefin 2023:1–32. https://doi.org/10.1007/S13399-023-04086-Z

Chaudhary V, Bajpai PK, Maheshwari S (2017) Studies on mechanical and morphological characterization of developed jute/hemp/flax reinforced hybrid composites for structural applications. J Natur Fibers 15(1):80–97. https://doi.org/10.1080/15440478.2017.1320260

Djafar Z, Renreng I, Jannah M (2020) Tensile and bending strength analysis of ramie fiber and woven ramie reinforced epoxy composite. J Natur Fibers 18(12):2315–2326. https://doi.org/10.1080/15440478.2020.1726242

Sapiai N, Jumahat A, Jawaid M, Midani M, Khan A (2020) Tensile and flexural properties of silica nanoparticles modified unidirectional kenaf and hybrid glass/kenaf epoxy composites. Polymers 12(11):2733. https://doi.org/10.3390/POLYM12112733

Syafri E et al (2018) Synthesis and characterization of cellulose nanofibers (CNF) ramie reinforced cassava starch hybrid composites. Int J Biol Macromol 120:578–586. https://doi.org/10.1016/J.IJBIOMAC.2018.08.134

Abd El-baky MA, Attia MA, Abdelhaleem MM, Hassan MA (2020) Mechanical characterization of hybrid composites based on flax, basalt and glass fibers. J Compos Mater 54(27):4185–4205. https://doi.org/10.1177/0021998320928509

Zainol I, Asyraf MRM (2018) Preparation and characterisation of epoxy/silica/kenaf composite using hand lay-up method. Safety and Health of Biocomposites View project natural hydroxyapatite and collagen for wound dressing View project. [Online]. Available: https://www.researchgate.net/publication/331927907. Accessed 8 Aug 2023

Kumar R, Anand A (2019) Fabrication and mechanical characterization of Indian ramie reinforced polymer composites. Mater Res Express 6(5):055303. https://doi.org/10.1088/2053-1591/AAFF12

Sosiati H, Firmansyah F, Rahman MBN (2022) The role of silica in improving the properties of kenaf/silica/epoxy hybrid composites. AIP Conf Proc 2499(1). https://doi.org/10.1063/5.0104978/2827119

Thiyagu C, NarendraKumar U (2023) Effect of ammonium polyphosphate on fire-retardant, mechanical, and vibrational analysis of epoxy/glass/ramie hybrid composite. Polym Compos 44(1):621–631. https://doi.org/10.1002/PC.27123

Wang H, Memon H, Hassan EAM, Miah MS, Ali MA (2019) Effect of jute fiber modification on mechanical properties of jute fiber composite. Materials 12(8):1226. https://doi.org/10.3390/MA12081226

Boopalan M, Niranjanaa M, Umapathy MJ (2013) Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Compos B Eng 51:54–57. https://doi.org/10.1016/J.COMPOSITESB.2013.02.033

Verma D, Goh KL (2021) Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: mechanical and morphological studies. J Compos Sci 5(7):175. https://doi.org/10.3390/JCS5070175

Ramasubbu R, Madasamy S (2020) Fabrication of automobile component using hybrid natural fiber reinforced polymer composite. J Natur Fibers 19(2):736–746. https://doi.org/10.1080/15440478.2020.1761927

Asumani O, Paskaramoorthy R (2020) Fatigue and impact strengths of Kenaf fibre reinforced polypropylene composites: effects of fibre treatments. Adv Compos Mater 30(2):103–115. https://doi.org/10.1080/09243046.2020.1733308

Yahaya R, Sapuan SM, Jawaid M, Leman Z, Zainudin ES (2016) Water absorption behaviour and impact strength of Kenaf-Kevlar reinforced epoxy hybrid composites. Adv Compos Lett 25(4):98–102. https://doi.org/10.1177/096369351602500403/ASSET/IMAGES/LARGE/10.1177_096369351602500403-FIG3.JPEG

Yu T, Jiang N, Li Y (2014) Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos Part A Appl Sci Manuf 64:139–146. https://doi.org/10.1016/J.COMPOSITESA.2014.05.008

Choi HY, Lee JS (2012) Effects of surface treatment of ramie fibers in a ramie/poly(lactic acid) composite. Fibers Polym 13(2):217–223. https://doi.org/10.1007/S12221-012-0217-6

Mahapatra SK, Satapathy A (2023) Development and characterization of titanium oxide filled ramie fiber based hybrid composites. Polym Compos. https://doi.org/10.1002/PC.27590

Taj A, Swamy RP, Naik K, Bharath KN (2023) An evaluation on mechanical properties of vacuum bagging processed kenaf epoxy nano aluminium oxide and nanographene composites. Eng Res Exp 5(2):025007. https://doi.org/10.1088/2631-8695/ACC996

Sai Krishnan G, Shanmugasundar G, Vanitha M, Pradhan R, Sivam SPSS (2021) Performance analysis on mechanical/morphological properties of ramie-kenaf hybrid polymer composites. AIP Conf Proc 2417(1). https://doi.org/10.1063/5.0072635/611245

Chaudhary V, Bajpai PK, Maheshwari S (2018) An investigation on wear and dynamic mechanical behavior of jute/hemp/flax reinforced composites and its hybrids for tribological applications. Fibers Polym 19(2):403–415. https://doi.org/10.1007/s12221-018-7759-6

Author information

Authors and Affiliations

Contributions

SR and JSK: writing—original manuscript; VC, PG, and SG: ideas, conceptualization, supervision; AK: writing—SPD.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Radhakrishnan, S., Krishna, J.S., Dwivedi, S.P. et al. Experimental investigation of mechanical and physical properties of coconut shell and eggshell filler-based bio-fiber reinforced epoxy hybrid composites. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05037-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05037-4