Abstract

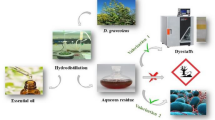

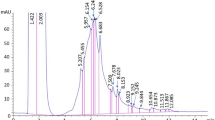

Natural dyes have become an appealing ecological source for textile dyeing and present a potential alternative of the synthetic dye. The main objective of this current study was aimed towards possible valorization of aqueous effluent in natural phytodyeing process. The hydrodistillation process of the liquid waste of Centaurea Kroumeriensis was studied for its re-use in the dyeing of wool fabrics. The studied dye bath was analyzed by physicochemical methods pointing out the presence of flavonoids and condensed tannins. The phytodyeing process was optimized using mathematical modeling based on full factorial design. The obtained dyeing performances were assessed by the measurement of color strength (K/S) and colorimetric coordinates. In addition, color fastness to light, washing, and rubbing was evaluated. The dyed fabrics showed shades between beige and brown and exhibited, overall, good fastness properties. In other respects, the wastewater effluent residual from the dyeing process was characterized and compared to that of the initial dye bath. The polluting load was reduced for both chemical oxygen demand and biochemical oxygen demand. On balance, the liquid waste of Centaurea Kroumeriensis exhibited remarkable coloring performances proving its use as a promising natural resource for textile fabrics natural dyeing. Hence, the suitable waste management concept in essential oil production extraction could lead to achieving a low-cost sustainable dyeing process.

Similar content being viewed by others

References

M. J. Melo, “Handbook of Natural Colorants”, pp.3–20, John Wiley & Sons, New York, 2009.

P. S. Vankar and D. Shukla, “New Trends in Natural Dyes for Textiles”, Elsevier, Woodhead Publishing, 2019.

P. M. dos S. Silva, T. R. Fiaschitello, R. S. de Queiroz, H. S. Freeman, S. A. da Costa, P. Leo, A. F. Montemor, and S. M. da Costa, Dyes Pigm., 173, 107953 (2020).

K. Yamjala, M. S. Nainar, and N. R. Ramisetti, Food Chem., 192, 813 (2016).

A. Fröse, K. Schmidtke, T. Sukmann, I. Juhász Junger, and A. Ehrmann, Optik, 181, 215 (2019).

N. Nasirizadeh, H. Dehghanizadeh, M. E. Yazdanshenas, M. R. Moghadam, and A. Karimi, Ind. Crops Prod., 40, 361 (2012).

L. Pattanaik, P. Duraivadivel, P. Hariprasad, and S. N. Naik, Bioresour. Technol., 301, 122721 (2020).

M. Yusuf, A. Ahmad, M. Shahid, M. I. Khan, S. A. Khan, N. Manzoor, and F. Mohammad, J. Cleaner Prod., 27, 42 (2012).

M. Yusuf, F. Mohammad, and M. Shabbir, J. King Saud. Univ. Sci., 29, 137 (2017).

S. A. Khan, M. I. Khan, M. Yusuf, M. Shahid, F. Mohammad, and M. A. Khan, Colourage, 58, 38 (2011).

M. Yusuf, M. Shabbir, and F. Mohammad, Nat. Prod. Bioprospect., 71, 23 (2017).

M. Andriamanantena, P. Danthu, D. Cardon, R. F. Fawbush, B. Raonizafinimanana, V. E. Razafintsalama, S. R. Rakotonandrasana, A. Ethève, T. Petit, and Y. Caro, Chem. Biodivers., 16, e1900442 (2019).

F. S. Ghaheh, S. M. Mortazavi, F. Alihosseini, A. Fassihi, A. S. Nateri, and D. Abedi, J. Cleaner Prod., 72, 139 (2014).

M. Ben Ticha, N. Meksi, H. E. Attia, W. Haddar, A. Guesmi, H. Ben Jannet, and M. F. Mhenni, Dyes Pigm., 141, 103 (2017).

N. Baaka, M. Ben Ticha, and A. Guesmi, Fiber. Polym., 20, 2522 (2019).

M. Kilinc, S. Canbolat, N. Merdan, H. Dayioglu, and F. Akin, Procedia Soc. Behav. Sci., 195, 2152 (2015).

M. Yusuf in “Agro-industrial Waste Materials and Their Recycled Value-Added Applications: Review” (L. Martínez, O. Kharissova, and B. Kharisov Eds.), pp.1–11, Handbook of Ecomaterials, Springer, Cham. Switzerland, 2019.

J. A. Bennett, K. Wilson, and A. F. Lee, J. Mater. Chem. A, 4, 3617 (2016).

A. Shahid, N. Amin, T. Ahmad, F. Batool, A. Hassan, “Recycling from Waste in Fashion and Textiles: A Sustainable and Circular Economic Approach”, p.363, Scrivener Publishing LLC, Wiley, 2020.

N. Dhouibi, S. Manuguerra, R. Arena, A. Madhi, M. M. Concetta, A. Santulli, and H. Dhaouadi, Appl. Sci., 10, 2267 (2020).

J. B. Harborne and C. A. Williams, Nat. Prod. Rep., 18, 310 (1995).

I. Moussa, N. Baaka, R. Khiari, A. Moussa, G. Mortha, and M. F. Mhenni, J. Renew. Mater., 6, 55 (2018).

S. C. Liu, J. T. Lin, C. K. Wang, H. Y. Chen, and D. J. Yang, Food Chem., 114, 577 (2009).

W. Haddar, M. Ben Ticha, A. Guesmi, F. Khoffi, and B. Durand, J. Cleaner Prod., 68, 114 (2014).

E. W. Rice, R. B. Baird, and A. D. Eaton, “Standard Methods for the Examination of Water and Wastewater”, 23rd ed., American Public Health Association, USA, 2017.

Y. Zhao, J. Zhao, Y. Yan, Z. Li, and J. Huang, Soft Matter, 14, 3282 (2010).

O. Deveoğlu and R. Karadağ, Int. J. Adv. Eng. Pure Sci., 3, 188 (2019).

G. Zengin, G. Bulut A. Mollica, C. M. N. Picot-Allain, and M. F. Mahomoodally, Comput. Biol. Chem., 73, 120 (2018).

F. Hentati, C. Delattre, A. V. Ursu, J. Desbrières, D. Le Cerf, C. Gardarin, S. Abdelkafi, P. Michaud, and G. Pierre, Carbohydr. Polym., 198, 589 (2018).

N. Dhouibi, H. Binous, H. Dhaouadi, and S. Dridi-Dhaouadi, J. Cleaner Prod., 261, 121106 (2020).

N. Meksi, W. Haddar, S. Hammami, and M. F. Mhenni, Ind. Crops Prod., 40, 103 (2012).

E. G. Tsatsaroni and I. C. Eleftheriadis, J. Soc. Dye. Colour., 110, 313 (1994).

N. Baaka, A. Mahfoudhi, W. Haddar, M. F. Mhenni, and Z. Mighri, Nat. Prod. Res., 31, 22 (2017).

K. Phan, E. Van Den Broeck, V. Van Speybroeck, K. De Clerck, K. Raes, and S. De Meester, Dyes Pigm., 176, 108180 (2020).

S. A. Khan, A. Ahmad, M. I. Khan, M. Yusuf, M. Shahid, N. Manzoor, and F. Mohammed, Dyes Pigm., 95, 206 (2012).

M. Souissi, A. Guesmi, and A. Moussa, J. Cleaer Prod., 204, 1143 (2018).

L. J. Rather, Shahid-ul-Islam, and F. Mohammad, Fiber. Polym., 16, 1497 (2015).

Y. Ren, J. Gong, F. Wang, Z. Li, J. Zhang, R. Fu, and J. Lou, Dyes Pigm., 134, 334 (2016).

Acknowldgments

This project is carried out under the MOBIDOC scheme, funded by the EU through the EMORI program and managed by the ANPR. The authors also would like to thank the Tunisian Higher Education and Scientific Research Ministry for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhouibi, N., Ben Ticha, M., Raddaoui, H. et al. Valorization and Reuse of Centaurea Kroumeriensis Hydrodistillation Effluent: A Sustainable Phytodyeing Process for Wool Fabrics. Fibers Polym 22, 2238–2250 (2021). https://doi.org/10.1007/s12221-021-0727-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0727-1