Abstract

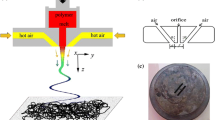

In the present work, approaches of the Computational Fluid Dynamics (CFD) simulation, the Particle Image Velocimetry (PIV) measurement, and the spinning experiment were applied to investigate the phenomenon of air recirculation in blunt-die melt-blown airflow. Firstly, the characteristics of air recirculation were explored by CFD simulation. The simulation results predicted that the air recirculation generated a lateral air velocity along the nose-piece direction. Then, the air circulation was experimental verified by using PIV technique. The PIV results confirmed the predicted conclusions of CFD simulation. Finally, the effect of air recirculation on the microfiber spinning during the melt-blown process was experimentally investigated by a spinning experiment using a blunt die with nose-piece width of 2.56 mm. The spinning results indicated that the air circulation had a tendency of splitting the normal polymeric stream, which played negative effect on the continuity of microfiber spinning. This work is expected to provide some clues to melt-blown die design and the quality control of nonwoven products.

Similar content being viewed by others

References

J. Drabek and M. Zatloukal, Phys. Fluids, 31, 091301 (2019).

N. P. Deng, H. S. He, J. Yan, Y. X. Zhao, E. B. Ticha, Y. Liu, W. M. Kang, and B. W. Cheng, Polymer, 165, 174 (2019).

C. Burger, B. S. Hsiao, and B. Chu, Annu. Rev. Mater. Res., 36, 333 (2006).

R. Nanjundappa and G. S. Bhat, J. Appl. Polym. Sci., 98, 2355 (2005).

D. Hietel and N. Marheineke, Proc. Appl. Math. Mech., 5, 667 (2005).

W. L. Han and X. H. Wang, J. Appl. Polym. Sci., 123, 2511 (2012).

K. Meng, X. H. Wang, and X. B. Huang, J. Appl. Polym. Sci., 108, 2523 (2008).

K. L. Jin, A. Banerji, D. Kitto, F. S. Bates, and C. J. Ellison, ACS Appl. Mater. Inter., 11, 12863 (2019).

L. Cui, C. L. Zhou, P. Zhu, C. H. Tsou, W. J. Yang, and J. T. Yeh, J. Appl. Polym. Sci., 125, E158 (2012).

J. Song, F. Lu, B. W. Cheng, X. Y. Hu, and C. Ma, Fiber. Polym., 15, 291 (2014).

H. M. Xiao, J. Y. Gui, G. J. Chen, and C. P. Xiao, J. Appl. Polym. Sci., 132, 42807 (2015).

M. A. J. Uyttendaele, and R. L. Shambaugh, Ind. Eng. Chem. Res., 28, 1735 (1989).

B. Majumdar and R. L. Shambaugh, Ind. Eng. Chem. Res., 30, 1300 (1991).

B. D. Tate and R. L. Shambaugh, Ind. Eng. Chem. Res., 37, 3772 (1998).

A. S. Harpham and R. L. Shambaugh, Ind. Eng. Chem. Res., 35, 3776 (1996).

S. Xie, W. L. Han, G. J. Jiang, and C. Chen, J. Mater. Sci., 53, 6991 (2018).

Y. F. Sun, B. W. Liu, X. H. Wang, and Y. C. Zeng, J. Appl. Polym. Sci., 122, 3520 (2011).

H. M. Krutka, R. L. Shambaugh, and D. V. Papavassiliou, Ind. Eng. Chem. Res., 41, 5125 (2002).

H. M. Krutka, R. L. Shambaugh, and D. V. Papavassiliou, Ind. Eng. Chem. Res., 42, 5541 (2003).

E. M. Moore, R. L. Shambaugh, and D. V. Papavassiliou, J. Appl. Polym. Sci., 94, 909 (2004).

H. M. Krutka, R. L. Shambaugh, and D. V. Papavassiliou, Ind. Eng. Chem. Res., 46, 655 (2007).

Y. F. Sun and X. H. Wang, J. Appl. Polym. Sci., 115, 1540 (2010).

X. B. Hao, H. Huang, and Y. C. Zeng, Text. Res. J., 89, 3221 (2018).

Y. L. Cheng, L. L. Wu, and T. Chen, Heat Transf. Res., 44, 473 (2013).

M. A. Hassan, N. Anantharamaiah, S. A. Khan, and B. Pourdeyhimi, Ind. Eng. Chem. Res., 55, 2049 (2016).

Y. D. Wang and X. H. Wang, Ind. Eng. Chem. Res., 52, 4597 (2013).

Y. D. Wang and X. H. Wang, Polym. Eng. Sci., 54, 110 (2014).

D. H. Tan, P. K. Herman, A. Janakiraman, F. S. Bates, S. Kumar, and C. W. Macosko, Chem. Eng. Sci., 80, 342 (2012).

L. Jarecki, S. Blonski, A. Blim, and A. Zachara, J. Appl. Polym. Sci., 125, 4402 (2012).

S. Xie, G. J. Jiang, B. L. Ye, and B. Q. Shentu, Polymers, 12, 279 (2020).

S. Xie and Y. C. Zeng, Ind. Eng. Chem. Res., 52, 2116 (2013).

Acknowledgement

This research was supported by the National Natural Science Foundation of China (Grant 11702113 and 51805210), China Postdoctoral Science Foundation (Grant 2019M652075), the Open Project Program of Key Laboratory of Yarn Materials Forming and Composite Processing Technology, Zhejiang Province, Jiaxing University (Grant MTC2020-15), and Jiaxing Program of Science and Technology (Grant 2019AD32005).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xie, S., Jiang, G., Wu, X. et al. Air Recirculation and Its Effect on Microfiber Spinning in Blunt-Die Melt Blowing. Fibers Polym 22, 703–710 (2021). https://doi.org/10.1007/s12221-021-0225-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0225-5