Abstract

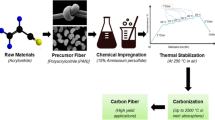

The production of polyacrylonitrile (PAN)-based carbon fiber includes two major steps, stabilization (oxidization) and carbonization. Stabilization is a slow and energy-consuming process and involves using a series of ovens that need to be carefully tuned to achieve desirable quality at the lowest cost. This usually involves meeting fiber density or cyclization levels at each zone of the oxidation furnace, often achieved through trial and error by a team of skilled operators. In this work, a simple empirical model was developed to predict density from oven system parameters and cyclization onset temperature of the PAN feedstock, parametrized as Sn, representing the oxidation depth. The relative cyclization index (RCI) and density of the fibers were analyzed after various oxidation treatments and were used to derive the model parameters. The RCI of stabilized fiber was well represented by a logistic function incorporating Sn while the fiber density was well predicted by a polynomial function of RCI. The model was verified using stabilization trials conducted on the same precursor in a continuous oven system and in a batch oven, and then on a second commercial precursor using the batch oven. Statistical analysis on these trials shows good agreement with model predictions.

Similar content being viewed by others

References

P. Morgan, “Carbon Fibers and Their Composites”, Taylor & Francis, 2005.

M. G. Dunham and D. D. Edie, Carbon, 30, 435 (1992).

M. Maghe, C. Creighton, L. C. Henderson, M. G. Huson, S. Nunna, S. Atkiss, N. Byrne, and B. L. Fox, J. Mater. Chem. A, 4, 16619 (2016).

B. A. Newcomb, Compos. Part A-Appl. Sci. Manuf., 91, 262 (2016).

M. S. A. Rahaman, A. F. Ismail, and A. Mustafa, Polym. Degrad. Stabil., 92, 1421 (2007).

Q. Ouyang, L. Cheng, H. Wang, and K. Li, Polym. Degrad. Stabil., 93, 1415 (2008).

W. Watt and W. Johnson, Nature, 257, 210 (1975).

E. Fitzer, W. Frohs, and M. Heine, Carbon, 24, 387 (1986).

E. Fitzer and D. J. Müller, Carbon, 13, 63 (1975).

J.-S. Tsai, J. Mater. Sci. Lett., 13, 1448 (1994).

S. Nunna, M. Naebe, N. Hameed, C. Creighton, S. Naghashian, M. J. Jennings, S. Atkiss, M. Setty, and B. L. Fox, Polym. Degrad. Stabil., 125, 105 (2016).

A. Takaku, T. Hashimoto, and T. Miyoshi, J. Appl. Polym. Sci., 30, 1565 (1985).

L. Peebles Jr, P. Peyser, A. Snow, and W. Peters, Carbon, 28, 707 (1990).

M. Nakatani, T. Kobayashi, Y. Imai, N. Yamamoto, and S. Sasaki, US Patent, 4,780,301 (1988).

D. U. Park, N. K. Han, J. H. Ryu, W. H. Park, and Y. G. Jeong, Fiber. Polym., 19, 2007 (2018).

S. J. Xiao, W. Y. Cao, B. Wang, L. H. Xu, and B. H. Chen, J. Appl. Polym. Sci., 127, 3198 (2013).

I. Karacan and G. Erdogan, Fiber. Polym., 13, 295 (2012).

H. Kakida and K. Tashiro, Polym. J., 29, 353 (1997).

K. Badii, J. S. Church, G. Golkarnarenji, M. Naebe, and H. Khayyam, Polym. Degrad. Stabil., 131, 53 (2016).

H. Khayyam, M. Naebe, O. Zabihi, R. Zamani, S. Atkiss, and B. Fox, IEEE Transactions on Industrial Informatics, 11, 887 (2015).

Y. Xue, J. Liu, and J. Liang, Polym. Degrad. Stabil., 98, 219 (2013).

H. Khayyam, R. N. Jazar, S. Nunna, G. Golkarnarenji, K. Badii, S. M. Fakhrhoseini, S. Kumar, and M. Naebe, Prog. Mater. Sci., 107, 100575 (2020).

D. U. Park, J. H. Ryu, N. K. Han, W. H. Park, and Y. G. Jeong, Fiber. Polym., 19, 2439 (2018).

S. Nunna, M. Maghe, R. Rana, R. J. Varley, D. B. Knorr, J. M. Sands, C. Creighton, L. C. Henderson, and M. Naebe, Materials, 12, 1069 (2019).

S. Nunna, M. Maghe, S. M. Fakhrhoseini, B. Polisetti, and M. Naebe, Energies, 11, 1145 (2018).

G. Collins, N. Thomas, and G. Williams, Carbon, 26, 671 (1988).

A. Ju, S. Guang, and H. Xu, Carbon, 54, 323 (2013).

J. S. Tsai and C. H. Lin, J. Appl. Polym. Sci., 43, 679 (1991).

D. L. Alexander, A. Tropsha, and D. A. Winkler, J. Chem. Inform. Model., 55, 1316 (2015).

B. Efron and R. J. Tibshirani, “An Introduction to the Bootstrap”, CRC Press, 1994.

Acknowledgement

The authors would like to thank Janice Hair and Lucy Cotter for fiber density testing, Nicole Phair-Sorensen and Debra Hamilton for DSC experiments, and Carbon Nexus team (Deakin University) for conducting the continuous oven processing trials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wilde, A.L., Alexander, D.L.J., Pierlot, A.P. et al. Predicting the Cyclization Index and Density of Stabilized Polyacrylonitrile Tow from Processing Conditions. Fibers Polym 22, 3241–3250 (2021). https://doi.org/10.1007/s12221-021-0011-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0011-4