Abstract

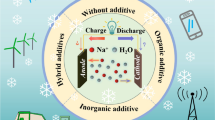

Aqueous rechargeable batteries are safe and environmentally friendly and can be made at a low cost; as such, they are attracting attention in the field of energy storage. However, the temperature sensitivity of aqueous batteries hinders their practical application. The solvent water freezes at low temperatures, and there is a reduction in ionic conductivity, whereas it evaporates rapidly at high temperatures, which causes increased side reactions. This review discusses recent progress in improving the performance of aqueous batteries, mainly with respect to electrolyte engineering and the associated strategies employed to achieve such improvements over a wide temperature domain. The review focuses on five electrolyte engineering (aqueous high-concentration electrolytes, organic electrolytes, quasi-solid/solid electrolytes, hybrid electrolytes, and eutectic electrolytes) and investigates the mechanisms involved in reducing the solidification point and boiling point of the electrolyte and enhancing the extreme-temperature electrochemical performance. Finally, the prospect of further improving the wide temperature range performance of aqueous rechargeable batteries is presented.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

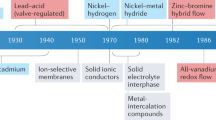

It is becoming increasingly obvious that conventional fossil-fuel-based energy sources are unable to meet global energy requirements due to the escalating global energy demands and environmental challenges. As renewable energy sources (such as wind, solar, and tidal power) are intermittent in nature, electrochemical energy storage devices will need to play a vital role in supplying consistent energy [1, 2]. Presently, lithium-ion batteries (LIBs) dominate the field and are the most extensively employed electrochemical energy storage systems [3,4,5,6]. However, LIBs are extremely expensive to produce, and Li resources are finite. In addition, the use of organic electrolytes (predominantly ethylene carbonate) in commercially available LIBs is associated with significant flammability risks and safety concerns [7,8,9,10], and organic electrolyte batteries also require stringent environmental processing. Furthermore, the burgeoning demand for flexible and wearable electronics renders organic electrolyte batteries less than ideal, as they deform under typical usage conditions [11,12,13].

Compared to organic-based LIBs, aqueous rechargeable batteries (ARBs) (comprising Li ion, sodium ion, potassium ion, and zinc ion) are considered to be safe, economical, and environmentally promising alternatives. The use of water as an electrolyte solvent in ARBs provides the following advantages: (1) intrinsic safety because water is inflammable, (2) a cheap aqueous solvent, (3) batteries that are easy to assemble and no strict manufacturing environment is required, (4) an aqueous electrolyte with high ionic conductivity that is approximately two orders of magnitude higher than that of organic electrolytes, and (5) an aqueous solvent that is non-toxic and does not pollute the environment [14,15,16]. These advantages collectively make ARBs a promising substitute for use in specific application scenarios, such as grid-scale energy storage, and in portable, flexible, wearable electronic devices [17,18,19,20].

To use of ARBs is promising in a wide range of applications and unique applications (such as polar, space, deep-sea and high-altitude exploration). Although it is expected that they can be adapted to different temperature environments, the aqueous electrolyte exhibits extreme-temperature sensitivity [21, 22]. In this respect, the high freezing point of the aqueous electrolyte is a fatal problem when operating in high-latitude cold regions. The probability of forming hydrogen bonds (HBs) becomes progressively higher than the likelihood of breaking bonds at temperatures lower than 4 °C, which leads to an increase in viscosity, and solidification can occur as the temperature lowers further. In addition, the phase transitions of the solvent water alter the physicochemical properties of the bulk electrolyte. Although the freezing point of the aqueous electrolyte is lowered by the addition of solutes according to Raoult’s law [23], the viscosity of the electrolyte gradually increases as the temperature drops and the electrolyte concentration rises [24,25,26]. Even more detrimental is the combined effect of the high viscosity and the dielectric effect, which reduces the ionic conductivity of the electrolyte (σ) (Eq. (1)) [27,28,29],

where ni is the free ion number; μi is the ionic mobility; and zi is the valence order of ions. This increases the ohmic resistance of the electrolyte and concentration polarization at the electrolyte/electrode interface, thereby causing battery failure during correct operation at low temperatures [30]. In addition, electrolyte freezing hinders the wettability of the electrode–electrolyte interface, and this also seriously affects the low-temperature performance of the ARB [31, 32]. Although increasing the solute concentration appropriately increases the boiling point (Tb) of aqueous electrolytes (Eq. (2)),

where \(\Delta {T}_{\mathrm{b}}\) is the boiling point variation; \({T}_{\mathrm{b}}^{*}\) is the boiling point of pure water (101.325 kPa); \({K}_{\mathrm{b}}\) is the boiling point decrease constant of the solvent; and m is the concentration of ions (mol/kg); the high volatility of water and the instability of the electrolyte/electrode interface at high temperatures still limit the use of ARBs in high-temperature environments [33, 34].

All these limitations are major challenges hindering the further development of ARBs. Therefore, to promote the development of high-performance electrochemical energy storage devices and to meet the requirements of real applications in various fields, it is important to develop efficient modification strategies that extend the temperature range of ARBs, and it is necessary to investigate the mechanism of action and constitutive relationships involved [35, 36].

As it is paramount to select a suitable electrolyte to give ARBs a wide temperature range performance, and it is crucial to urgently address the temperature problem of ARBs, this review systematically summarizes recent research progress made in electrolyte engineering over a wide temperature range (Fig. 1). The large amount of research based on electrolyte research demonstrates that the physical and chemical properties of the electrolyte are key factors in the mass transport, energy storage mechanism, reaction kinetics, and side reactions of ARBs at extreme temperatures. In this respect, we first discuss the strategies associated with the use of high-concentration electrolytes, electrolyte additives, and hydrogel electrolytes in lowering the freezing point of the electrolyte and improving the low-temperature performance of ARBs. We then show that the high temperature performance of ARBs can be improved by adding highly thermally stable substances into the electrolyte or by reducing the water content of the electrolyte. Finally, this review provides certain perspectives for the rational design and mechanistic investigation of electrolytes over a wide temperature range and an outlook on the future development of ARBs across a wide temperature range.

Aqueous Rechargeable Battery (ARB) at Low Temperature

In low-temperature conditions, the water-based electrolyte can constrain the ARB performance. Despite the previously mentioned notable advantages of ARBs, freezing of water at low temperatures poses practical limitations. This freezing phenomenon leads to diminished ionic conductivity, inadequate de-solvation, heightened interfacial impedance, and sluggish ion transport, which significantly impedes the functionality of aqueous batteries in low-temperature environments. The primary approach to enhancing the low-temperature performance of batteries involves improving the electrolyte’s ionic conductivity and enhancing the diffusion coefficient of ions within the electrode material under these conditions. Therefore, research efforts have been focused on lowering the freezing point of the electrolyte and augmenting its ionic conductivity. The freezing process of water is regarded as a phase transition from disordered water to ordered ice, driven by the formation of HBs; therefore, by inhibiting the formation of HBs between water molecules, it is possible to reduce the freezing point. Electrolyte modification has emerged as an effective strategy for enhancing the low-temperature performance of ARBs. In this section, we investigate how electrolyte strategies can effectively address the limitations of current ARBs in low-temperature scenarios.

Aqueous High-Concentration Electrolytes

The behavior of water molecules changes when the temperature decreases below 0 °C, which causes the formation of an additional 0.52 HBs; this leads to the reorganization of water molecules from a disordered state to an ordered one and results in the formation of solid ice [37, 38]. By weakening the HBs between water molecules, it is possible to effectively reduce the freezing point of aqueous electrolytes. In this respect, Raoult’s law states that for dilute solutions of non-electrolytes with high boiling points, the decrease in the freezing point (∆Tf) is directly proportional to the molar concentration of the solution [31, 32], and this can be expressed as

where ∆Tf represents the freezing point depression; Twater is the thermodynamic freezing point of the solvent (which is 0 °C for water); Kf is the freezing point depression constant measured in units of K·kg/mol or °C·kg/mol (with a value of 1.86 °C kg/mol for water); and the subscript m denotes the molar concentration of the solution. It is important to note that the value of Kf is solely dependent on the solvent and remains unaffected by the solute. As an illustration, a solution of ZnCl2 at a concentration of 1 mol/kg has a freezing point of − 5.58 °C. Although this equation is applicable to dilute solutions, literature reports have indicated that increasing the solute concentration to form high-concentration electrolytes is an effective approach used to reduce the freezing point of electrolytes [39].

The development of “water-in-salt” electrolytes (WiSE) has provided new possibilities for the development of high-energy ARBs, as these resemble ionic liquids and have high salt and low water concentrations [40, 41]. By utilizing electrolytes with elevated salt concentrations, the electrochemical stability window is expanded, which enhances the surface structure of the electrode materials within the aqueous environment [42]. Figure 2 shows the effect of high concentrations of ions with different charges on the HB network between water molecules. The interactions between free cations, anions, and aqueous solvents in highly concentrated electrolytes directly determine the effectiveness of lowering the freezing point of aqueous electrolytes (Fig. 2a) [43]. For instance, the strong dipole–dipole forces between Zn2+ and O in the high-concentration electrolytes cause rearrangement of the coordination structure of H2O, and as Zn2+ binding is preferential to the formation of intermolecular HBs [36], the freezing point is significantly reduced.

a Schematic illustration of mutual interactions between cations, anions, and water solvent. b Calculated interactions between ions and water and the formation energies of Zn2+ solvation configurations. c Operating temperature window of existing batteries. b and c were reproduced with permission from Ref. [24]. Copyright © 2020 Springer Nature. d Schematic illustration of the solvation structure of low-concentration 1 mol/L KOTF and high-concentration 22 mol/L KOTF electrolytes. Reproduced with permission from Ref. [44]. Copyright © 2021 American Chemical Society. e Negative ESP mapping of anions SO42−, NO3−, Cl−, I−, and CF3SO3−. a and e were reproduced with permission from Ref. [43]. Copyright © 2021 American Chemical Society

Through theoretical calculations, Zhang et al. [23] found that Zn2+–H2O possessed a higher binding energy of − 98.5 kcal/mol compared to that of H2O–H2O (Fig. 2b). Building on this insight, a high concentration of ZnCl2 (7.5 mol/L) was employed as the electrolyte in a Zn||polyaniline (PANI) cell. The abundance of Zn2+ in the electrolyte broke the HBs between water molecules, allowing the cell to operate at an ultimate temperature of − 90 °C, with a stable cycling performance at − 70 °C (84.9 mAh/g, ~ 2000 cycles), and this battery could operate at the lowest to highest recorded Earth’s surface temperatures from − 89.2 °C (Death Valley, California, USA, 1913) to 56.7 °C (Vostok Station, Antarctica, 1983). Very few cells are capable of operating at this temperature range (Fig. 2c), although a similar phenomenon is achieved with the potassium-based WiSE electrolyte.

Through Raman spectroscopy analysis, Liang et al. [44] showed that a large amount of free molecular water exists in a low concentration in a 1 mol/L KOTF electrolyte, while the weak HBs of a 22 mol/L KOTF remain unchanged, and the proportion of strong HBs is substantially reduced. These observed phenomena are attributed to the strong solvation effect of K+ ions (Fig. 2d), which effectively restricts the movement of H2O molecules within the solvation sheath of K+ [45, 46]. As a result, the freezing point of this electrolyte is significantly lowered to − 39 °C, and this antifreeze property gives the battery good stability, even at ultra-low temperatures of − 30 °C.

As mentioned above, multivalent cations can lower the freezing point of aqueous electrolytes, but anions can also significantly improve the low-temperature electrochemical properties of ARBs. Different anions in the Hofmeister sequence have been reported to have different effects on HBs. Chaotropic anions, such as I−, can reduce the density and strength of the HBs between water molecules; in contrast, kosmotropic anions, such as SO42−, increase the number of HBs and their strength. Zhang’s group [43] summarized the magnitude of the electrostatic potential (ESP) values of different anions using theoretical calculations and spectroscopic analysis techniques, and they explained the effect of anions with different ESP values on the solvation structure, HB number, and the HB strength of Zn2+ (Fig. 2e). The results showed that CF3SO3− had the highest ESP value and the lowest binding energy to the H2O/cation compared to the other ions, which indicated that this anion had the weakest interaction with Zn2+ and therefore the highest Zn–water coordination number in the Zn(CF3SO3)2 electrolyte. As a consequence, there were fewer HBs between the free water molecules, and the Fourier transform infrared spectroscopy (FTIR) results further confirmed that the lower HB strength corresponded to a lower thermodynamic freezing point. The electrochemical performance test results showed that the Zn||2 mol/L Zn(CF3SO3)2||V2O5 cell retained functionality at − 30 °C with a capacity of 194.1 mA h/g when the current density was 1 A/g, and it showed a capacity retention rate of 81.7% after 1000 cycles, compared to the rest of the low-temperature aqueous cells, which at the appropriate low-temperature conditions with higher capacity and cycling stability.

Although increasing the concentration of an electrolyte can effectively lower its freezing point, a higher concentration can be detrimental to its functionality. Indeed, when the concentration of salt in the electrolyte exceeds a certain threshold, salt crystallization becomes a concern. The solubility of electrolyte salts typically increases with temperature, meaning that lower temperatures lead to lower solubility. Different salts have distinct physical properties, and the combination of their concentrations and temperatures determines the specific crystallization zones for each salt. Therefore, the concentration of the aqueous electrolytes needs to be properly balanced to achieve optimum results at low temperatures. Becker and co-workers [47] discovered that the use of asymmetric anions in high-concentration electrolytes effectively inhibited the crystallization of highly concentrated electrolytes at low temperatures. Building on this finding, they proposed a mixed electrolyte consisting of asymmetric LiPTFSI (lithium bis(trifluoromethanesulfonyl) imide) and LiOTf (lithium trifluoromethanesulfonate). LiPTFSI exhibits exceptional solubility at room temperature, with a solubility exceeding 30 mol/L, and the addition of a second anion, LiOTf, to the electrolyte mixture resulted in an increase in the mixing entropy. Compared with 21 mol/L LiTFSI and 20 mol/L LiOTf, this increase in entropy of the mixed electrolyte (nLiTFSI/LiOTf = 15 mol/L/5 mol/L) resulted in a reduction in the liquid phase line temperature, further reducing the freezing point from ~ 20 to − 14 °C (Fig. 3a).

a Differential scanning calorimetry (DSC) curves of different ~ 20 mol/L electrolytes recorded at a scan rate of 1 K/min from 60 to 120 °C and back to 60 °C. Reproduced with permission from Ref. [47]. Copyright © 2019 Royal Society of Chemistry. b DSC curves of 35 mol/L LiFSI and mixed lithium electrolytes containing symmetric FSI and asymmetric FTFSI or symmetric TFSI anions, respectively, during scans from 60 to − 120 °C and back to 60 °C. c Cycling data of the − 10 °C cell shown in part a for a total of 500 cycles. b and c were reproduced with permission from Ref. [48]. Copyright © 2019 American Chemical Society. d Snapshot of the MD simulation of water and 4 mol/L Zn(BF4)2 electrolyte. The dashed blue line represents the HBs. e Different types of O–H⋯F HBs from the snapshot. f Raman spectra of the O–H bond and the fitted O–H stretching vibration representing the symmetric, asymmetric OH⋯O and OH⋯F HBs. g Galvanostatic charge–discharge curves of Zn||TCBQ battery at − 60 °C. d, e, f, and g were reproduced with permission from Ref. [49]. Copyright © 2021 Royal Society of Chemistry

Reber et al. [48] adopted the same strategy when using an asymmetric NaFSI/NaFTFSI electrolyte. As shown in Fig. 3b, the 25 mol/L NaFSI + 10 mol/L NaFTFSI electrolyte did not crystallize during the cooling scan and remained liquid at room temperature after six months. In addition, the asymmetric anion inhibited the formation of the long-range order and thus effectively suppressed crystallization. The NaFTFSI additive containing asymmetric anions not only inhibited the crystallization of the highly concentrated electrolyte but also lowered its freezing point. Furthermore, the NTP/NVPOF full cell with the mixed anionic electrolyte reached a total of 500 cycles at − 10 °C, maintaining a high cycle stability (Fig. 3c).

By incorporating such asymmetric anions into the electrolyte, the researchers aimed to enhance the low-temperature performance of the electrolyte and prevent salt crystallization issues arising at high concentrations. The use of highly concentrated electrolytes is logical in ARBs, as the electrochemical stability window of water can be extended, and operation can occur over a wider temperature range, which is beneficial for various battery applications.

An alternative approach is to introduce elements containing hydrogen-bonded receptors, which compete with the HBs between water molecules, resulting in a reduction in the freezing point of water. For example, Sun et al. [49] applied a 4 mol/L Zn(BF4)2 electrolyte in low-temperature aqueous zinc-ion batteries (AZIBs) and achieved an extraordinarily low freezing point of − 122 °C while maintaining a high ionic conductivity of 1.47 mS/cm at − 70 °C, and this was applied to high-performance AZIBs. Comprehensive spectral analyses and molecular dynamics (MD) simulations have shown that BF4− contains four extremely electronegative F atoms, which easily form O–H···F bonds with H2O and can efficiently break the original H-bonding network between the H2O molecules to give the electrolyte an ultra-low freezing point (Fig. 3d–f). The 4 mol/L Zn(BF4)2-based electrolyte enabled the Zn||Tetrachlorobenzoquinone (TCBQ) cell to exhibit an excellent electrochemical performance over a wide temperature range of − 95 to 25 °C, with a capacity of up to 63.5 mAh/g and an energy density of 76.2 Wh/kg at − 95 °C (Fig. 3g).

The concentrated electrolyte strategy is attracting considerable attention due to its several advantages, as follows: it (1) lowers the freezing point of the electrolyte [50], (2) extends the electrochemical stability window of the electrolyte [51, 52], (3) reduces the cathode dissolution and anode corrosion [53], (4) accelerates the electrode reactions, and (5) increases the metal ion migration number. These advantages provide ARBs with excellent low-temperature electrochemical performance. However, the disadvantages of highly concentrated electrolytes cannot be ignored, and these include low conductivity, high viscosity due to the strong cation–anion-ion coupling, salt precipitation when the temperature drops, and the high associated costs; therefore, continuous research is required to overcome these issues [54,55,56].

Hydrogel Electrolyte

In addition to tuning the concentration of the electrolyte, the development of hydrogels (cross-linked networks of hydrophilic polymer chains dispersed in water) has helped to alleviate the problem of electrode dissolution and to mitigate the electrochemical performance deteriorating at a temperature below 0 °C. Due to the development of a hydrogel that maintains good flexibility at sub-zero temperatures, flexible low-temperature quasi-solid-state batteries can now be fabricated using an anti-freezing hydrogel electrolyte. Hydrogels are commonly regarded as semi-solid electrolytes in which the solid polymer backbone retains a large amount of free water internally through hydrophilic groups [57]. Competing interactions between water molecules and the different surrounding chemical functional groups (i.e., polymers) control the antifreeze properties of hydrogels [58, 59]. Therefore, the type of terminal group of the polymer backbone is a factor determining the antifreeze capacity. The results of density flooding theory calculations (Fig. 4a) show that the interaction energy (Eint) between two water molecules (O–H···O) is − 5.75 kcal/mol [60]. The Eint achieved between polyacrylic acid (PAA) and water molecules is almost three times that of O–H···O, and this strong van der Waals force can disrupt the HBs between water molecules to increase the barrier to ice crystal formation, which maintains sufficient flexibility and ionic conductivity of the hydrogel electrolyte at low temperatures.

a Molecular models used to simulate interactions between water molecules and different terminal groups in polymers. Reproduced with permission from Ref. [60]. Copyright © 2020 Wiley. b Schematic diagram and mechanism of the anti-freezing hydrogel electrolytes. c Galvanostatic charge/discharge curves of Zn(BF4)2–PAM electrolyte-based flexible zinc-ion batteries at different temperatures. b and c were reproduced with permission from Ref. [61]. Copyright © 2023 Wiley. d Synthesis schematic and mechanisms of the antifreeze PIL-OH-based hydrogel electrolyte. Reproduced with permission from Ref. [62]. Copyright © 2021 Wiley. e Raman spectrum of polymer-free CH3COOK (KAc) gel electrolyte. f Density functional theory simulated structures of polymer-free CH3COOK (KAc) gel electrolyte when the concentration of KAc up to 48 mol/L. e and f were reproduced with permission from Ref. [63]. Copyright © 2021 Elsevier

Covalent Polymer Hydrogels

Polymer hydrogels are based on covalent cross-linking and are the most commonly employed semi-solid electrolyte type. The introduction of different concentrations of metal salt solutions in the preparation of covalent hydrogels not only improves the ionic conductivity of hydrogel electrolytes but also optimizes their flexibility and solidification points, as shown in Fig. 4. In this respect, Shi et al. [61] synthesized an antifreeze hydrogel electrolyte based on zinc tetrafluoroborate (Zn(BF4)2) and polyacrylamide (PAM). Due to the strong electronegativity of the F atom, the BF4− anion replaced the O–H···O between the free water molecules by forming O–H···F in the Zn(BF4)2–PAM hydrogel electrolyte, which remained unfrozen even at − 70 °C at low temperatures (Fig. 4b). As a result, the Zn(BF4)2–PAM electrolyte-based flexible zinc-ion batteries exhibited high adaptation to low temperatures (Fig. 4c). In addition, Hu et al. [62] developed a “two-in-one” cryoprotectant, a hydroxylated functionalized polyionic liquid (PIL-OH)-based hydrogel electrolyte, for use in aqueous LIBs. The synergistic interaction of ionic hydration and formation of HBs between PIL-OH and water molecules interrupted the water molecule's original hydrogen-bonding network (Fig. 4d) and lowered the freezing point of the water to below − 80 °C. The PIL-OH hydrogel has opened a new avenue in achieving the practical application of wearable and flexible water batteries in ultra-low-temperature environments (e.g., in the Arctic and Antarctic). However, at high salt concentrations, the freezing point decreases depending on the molar concentration of the solution. Liu et al. [63] developed a polymer-free CH3COOK (KAc) gel electrolyte with an ultra-high salt-to-water molar ratio of 1:1.16 (KAc/H2O). The Raman spectrum (Fig. 4e) showed that there was no O–H···O, and only the hydrogen band of Ac− associated with water, which indicated that all water molecules interacted with K+ and Ac−, thereby resulting in a high salt concentration gel with a low freezing point (Fig. 4f).

Noncovalent Polymer Hydrogels

The non-covalently cross-linked supramolecular polymer is another type of hydrogel that possesses distinctive self-healing, high toughness, and stretchability. The noncovalent interaction with dynamic reversibility includes interactions with multiple HBs, metal coordination, π–π interactions, and host–guest interactions. Through the modification of solvent and salt solutions, noncovalent hydrogels based on different types of interactions have also been found to exhibit different physical and chemical properties at low temperatures (Fig. 5). Recently, Mo et al. [64] designed a silk fibroin-based supramolecular hydrogel electrolyte through host–guest interactions between grafted supramolecular β-cyclodextrin and adjacent amino acid molecules on silk fibroin chains and PAA chains (Fig. 5a). Different from the self-healing mechanism through HBs, the host–guest interaction of the supramolecule is independent of temperature; therefore, the freezing point of this hydrogel is lower than that of conventional PAA hydrogel (Fig. 5b). A high salt concentration is usually introduced to modify the hydrogel and further lower the freezing point, increase water retention, and improve the reversibility of metal electrolytes. In this respect, Fu et al. [65] synthesized a polyzwitterionic hydrogel electrolyte (PZHE) using a self-catalytic nano-reinforced strategy and further formed a salt-in-water PZHE with high electrical conductivity and strong interfacial adhesion by filling it with 7.5 mol/L ZnCl2 (Fig. 5c). The colligative property of the concentrated ZnCl2, resulted in a lower water vapor pressure within this salt-in-water PZHE than that in the environment; therefore, the total mass and volume increased slightly after 120 d of storage in an open environment, exhibiting a good water retention capacity (Fig. 5d). It also provided over 420% tensile elasticity and 75% compressive strain at − 60 °C, thus accommodating rigorous deformation, including compression, folding, rolling, bending, and twisting (Fig. 5e).

a Engineering and structure of silk fibroin-based supramolecular hydrogel electrolyte through host–guest interactions. b DSC curves of silk fibroin-based supramolecular hydrogel electrolyte and PAA hydrogel electrolyte. a and b were reproduced with permission from Ref. [64]. Copyright © 2021 Wiley. c Synthesis schematic of the PZHE by a self-catalytic nano-reinforced strategy. d Weight ratio results of PZHE with different ZnCl2 concentrations. e Compressive stress–strain results for the PZHE with 7.5 mol/L ZnCl2 from − 60 to 25 °C, respectively. Inset photographs reveal that the PZHE with 7.5 mol/L ZnCl2 hydrogel electrolytes retained elasticity even when stored for over 1 d at − 60. °C c, d, and e were reproduced with permission from Ref. [65]. Copyright © 2021 American Chemical Society. f Schematic of supramolecular zwitterion hydrogel electrolytes synthesized by Fu et al. g Comparison between the ionic conductivity of this supramolecular zwitterion hydrogel and that of previously reported results. f and g were reproduced with permission from Ref. [66]. Copyright © 2023 Royal Society of Chemistry

To enhance the ion conductivity of hydrogel electrolytes at low temperatures, Fu et al. [66] synthesized supramolecular zwitterion hydrogel electrolytes by combining supramolecular betaine with nanofiber-reinforced covalently cross-linked PAA in a ZnSO4/ethylene glycol (EG) electrolyte, and this provides outstanding self-healing and anti-freezing capabilities because of the many dynamic coordination bonds and multiple HBs originating from the supramolecular betaine chains, PAA chains, and binding EG in the polymer network (Fig. 5f). In synergy with its special 3D interoperable Zn2+ transport channel, which profits from the coordination between Zn2+ and supramolecular zwitterion, this electrolyte features a record-breaking ionic conductivity of 18.6 mS/cm, even at low temperatures of − 40 °C (Fig. 5g). However, although supramolecular hydrogels provide the above advantages, their weak mechanical strength and poor processability limit their further application.

Double Network Polymer Hydrogels

Double network hydrogels consisting of covalent and noncovalent systems exhibit extraordinary mechanical properties [67]. The covalently cross-linked polymer network ensures that the hydrogel has sufficient strength and toughness, while the noncovalent cross-linked bonds dissipate energy during the loading process and improve the fatigue resistance and recovery of the double network hydrogel; this enables the requirements of high-performance flexible devices over a wide temperature range to be met (Fig. 6). The double network hydrogel possesses sufficient mechanical properties to satisfy the requirements of practical applications, due to its unique double network structure (Fig. 6a). In this respect, Sun et al. [68] simply applied covalently cross-linked polyelectrolyte-poly(2-acrylamido-2-methylpropanesulfonic acid potassium salt) and methyl cellulose to a concentrated alkaline solution and prepared an alkaline double network gel electrolyte that exhibited an extremely fast self-recovery ability and excellent fatigue resistance (Fig. 6b). In addition, the Zn-air battery assembled with this double network gel electrolyte displayed a preeminent capacity retention when the temperature was lowered from 25 to − 20 °C (Fig. 6c).

a Schematic diagram of the structure of a double network hydrogel and the traditional synthesis method. Reproduced with permission from Ref. [67]. Copyright © 2003 Wiley. b Synthesis schematic of an alkaline double network gel electrolyte prepared by covalently cross-linked polyelectrolyte-poly (2-acryl amido-2-methyl propane sulfonic acid potassium salt) and methylcellulose c Chart demonstrating the mechanical properties of the alkaline double network gel electrolyte. b and c were reproduced with permission from Ref. [68]. Copyright © 2020 American Chemical Society. d Synthetic procedure used to prepare the double network hydrogel electrolyte (PAM-CNF/KOH/KI) by polymerization and swelling. e DSC results of PAM/KOH, PAM-CNF/KOH, and PAM-CNF/KOH/KI. f Diagram of the action mechanism of PAM-CNF/KOH/KI hydrogel electrolyte. g Ionic conductivity of PAM-CNF/KOH/KI hydrogel electrolyte and its stability at 20 and − 40 °C. d, e, f, and g were reproduced with permission from Ref. [69]. Copyright © 2021 Elsevier

Ion transport kinetics are a key factor affecting electrolyte electrochemistry at low temperatures. Two effective strategies can be used to improve the ion transport rate: optimizing the dual network structure and constructing short-range ion transport channels. Zhang et al. [69] immersed an in situ polymerized PAM/cellulose nanofiber (CNF) precursor hydrogel in a mixture of KOH and KI to swell it to equilibrium and ultimately formed a novel double network hydrogel electrolyte (PAM-CNF/KOH/KI) (Fig. 6d). The hydration between K+/I− and water molecules significantly weakened the so-called “ice-like” HBs between the water molecules, thereby significantly lowering the crystallization temperature (Fig. 6e). Furthermore, as illustrated in Fig. 6f, the addition of CNF provided physical entanglement with PAM and formed an ion transport channel to improve the mechanical properties and ionic conductivity (Fig. 6g).

The design and fabrication of antifreeze hydrogel electrolytes for ARBs are based on the following principles: (1) the introduction of concentrated salt solutions, (2) the introduction of antifreeze organic additives, and (3) the synthesis or modification of hydrogels with charged or hydrophilic groups. Although these electrolytes are designed to further extend the low-temperature range of the electrolyte, it is not possible to solve the freezing problem using the hydrogel strategy alone due to the large pore sizes within the hydrogel [70]: As the pore size increases, the free water molecules play a dominant role, and the influence of polar groups on the polymer backbone are greatly diminished. The use of hydrogels in flexible device applications is extremely promising; however, special attention needs to be paid to the mechanical properties of quasi-solid hydrogels at sub-zero temperatures and to the freezing problem at low temperatures [71].

Electrolyte Additives

Electrolyte additives play a crucial role in enhancing battery performance without incurring additional production costs or altering the manufacturing process [72,73,74,75], and they can significantly improve the low-temperature performance of batteries due to their “low dose” and “fast acting” nature [76, 77]. Low-temperature aqueous electrolyte additives are often used to meet the requirements of a low melting point, miscibility with water, and high electrochemical and thermodynamic stability [78]. The use of some organic solvents (such as dimethyl sulfoxide (DMSO) [25], fluoroethylene carbonate (FEC) [79], glucose [80], 1, 3-dioxane (DOL) [81], and N, N-dimethylformamide (DMF) [82]) mixed with water in low-temperature aqueous batteries has been reported. Figure 7 shows that the electrochemical properties of the electrolyte can be effectively optimized at low temperatures by introducing functional organic additives, such as antifreeze and buffering agents.

a Schematic illustration of the LiFePO4 material’s particles in a 1 mol/L Li2SO4 aqueous electrolyte solution without and with the addition of antifreeze EG during cycling at low temperatures. Reproduced with permission from Ref. [83]. Copyright © 2019 American Chemical Society. b Schematic illustration of Zn surface evolution in electrolytes with/without CH3COONH4 additive. Reproduced with permission from Ref. [84]. Copyright © 2022 Wiley. c Schematic illustration showing the superiority of the electrolyte modified in this study. Reproduced with permission from Ref. [85]. Copyright © 2021 Elsevier. d Ionic conductivity of BSiS-D0.28 and BSiS-A0.5 hybrid electrolytes at a temperature range of − 20 to 60 °C. e Photographs showing the states of WiSE, BSiS-D0.28, and BSiS-A0.5 electrolytes at 0 and − 20 °C. d and e were reproduced with permission from Ref. [86]. Copyright © 2022 Elsevier. f Structure of eutectic solvation structure and the Zn2+ deposition process at low temperature. Reproduced with permission from Ref. [87]. Copyright © 2022 Wiley

EG is a widely used antifreeze agent [88]; the hydroxyl groups in EG can form strong HBs with water molecules, and this disrupts the hydrogen-bonding network among water molecules, inhibits the formation of ice crystals, and effectively reduces the freezing point of the electrolyte. In addition, EG is cheap, has good water solubility, a high dielectric constant (Eq. (3)), and a high flash point, which makes it a promising solvent additive for electrolytes. Tron et al. [83] used EG antifreeze additives to improve the low-temperature performance of rechargeable lithium-sulfur (Li–S) ion batteries (Fig. 7a); the antifreeze agent was found to expand the temperature range of the aqueous solution, improve the kinetics of the active material, and reduce the polarization resistance under charge and discharge cycles. Ethyl ether (Et2O) is also an effective electrolyte antifreeze additive that helps to improve the low-temperature performance of ARBs, extend their temperature range, and improve their cycling performance. In the study of Wang et al. [85], a conventional electrolyte for aqueous Zn||MnO2 cells (consisting of a 2 mol/L ZnSO4 + 0.2 mol/L MnSO4 aqueous solution) was optimized by incorporating Et2O and EG as additives (Fig. 7c). The cycling performance of the Zn||MnO2 cells was improved with the addition of Et2O, and it played a role in inhibiting the growth of Zn dendrites. The cells with an EG/30% + Et2O/1% electrolyte showed the highest capacity retention and the best cycling performance at − 10 °C and 3 A/g compared to those without the additive.

In recent years, the physical solubility limit of salt in water has been broken by the addition of acetate ions, and non-polarizing protons prevent the overgrowth and precipitation of ionic oligomers [89, 90]. Lin et al. [84] found that the addition of CH3COONH4 additive to the conventional ZnSO4 electrolyte resulted in the stable cycling of the Zn||Zn symmetric cell at − 10 °C (Fig. 7b),

According to Bjerrum’s treatment (Eq. (3)), the critical distance for ion pair formation q can be described as,

where q is the critical distance for the ion pair formation; i and j are the species of ions; z is the valence order of ions; and ε, ε0, and k are the dielectric constant of the solvent, the dielectric constant of solvent at vacuum, and Boltzmann’s constant, respectively. As the temperature drops, the larger q of the ion pair formation relates to the tendency of the anions and cations to associate more easily, and ni then decreases.

Following the Stokes–Einstein equation (Eq. (4)), the increased viscosity (η) of the electrolyte also needs to be addressed at low temperatures,

where D, r, and T are the diffusion constant, the solvation radius, and the temperature, respectively, and η and r are inversely proportional to ionic mobility, μi [29].

Chen et al. [86] reported an advanced hybrid electrolyte with the introduction of acetonitrile (AN) as a co-solvent in a 15.3 mol/L LiTFSI salt electrolyte, which exhibited an electrochemical stability window of 4.5 V. The low viscosity of AN allowed the BSiS-A0.5 electrolyte to maintain sufficient ionic conductivity at low temperatures, remaining in a liquid state even at − 20 °C (Fig. 7d, e). The LiMn2O4||Li4Ti5O12 (LMO/LTO) full cell using BSiS-A0.5 maintained a discharge capacity of 110 mAh/g after 120 cycles at 0 °C.

Due to the slow reaction kinetics, the electrochemical performance of ARBs severely deteriorates at low temperatures, and recent studies have shown that modulating the solventized structure of the aqueous electrolyte is an excellent strategy that can be employed to ameliorate this. Ma et al. [87] proposed the concept of a “eutectic solvation shell layer” for the ex-solvation shell layer of Zn2+ composed of 2-propanol. With the addition of alcohols of different carbon chain lengths and isomers, the alcohol molecules can modulate the ex-solvation shell layer by replacing water molecules to build a eutectic layer (Fig. 7g). Due to the structural advantages of the eutectic solventized shell, 150 mAh Zn||V2O5 soft pack batteries can provide remarkable performances at low temperatures of − 20 °C. This study demonstrated a new strategy that can be employed to achieve fast charging and long-term cycling capability of ARBs under extreme conditions.

Figure 8 shows that introducing electrolyte additives with organic groups that inhibit the formation of HBs is also an effective way of lowering the freezing point [91, 92]. Organic solvents containing the elements F, O, and N (alcohols, ethers, sulfones, esters, amides, nitrile) bond more strongly to water molecules and break HBs more easily, thus lowering the freezing point. Butyl sulfone is chosen for its low toxicity, high miscibility with water, high oxidative stability, and strong interactions with water molecules, and as such, it has been utilized as a co-solvent in electrolytes [93]. For example, Liu et al. [94] employed butyl sulfone to actively participate in the solvation sheath of Li ions, where its presence reinforced the O–H bonding of water and significantly disrupted the H-bonding network (Fig. 8a). The LiMn2O4||Li4Ti5O12 full cell, using the hybrid electrolyte, exhibited an outstanding performance at − 20 °C, demonstrating a high voltage (2.7 V) and a Coulomb efficiency of 98% (Fig. 8b).

a MD simulations of 12SL–4H2O–3LiClO4 electrolyte. b Cycling stability and CE of LMO/LTO full battery using 12SL–4H2O–3LiClO4 electrolyte at − 20 °C. a and b were reproduced with permission from Ref. [94]. Copyright © 2022 Wiley–VCH Verlag. c Schematic diagrams for end-capping of the H-bond network in an aqueous solvent by employing an NMP molecule that possesses an H-bond acceptor but no H-bond donor. Reproduced with permission from Ref. [95]. Copyright © 2023 Elsevier. d Conformation analysis of the system with DMSO = 0.3 from MD simulations. e Local structure of the DMSO = 0.3 system from MD simulations. d and e were reproduced with permission from Ref. [25]. Copyright © 2019 Wiley. f Schematic illustration of cell-nucleus structured electrolyte design for low-temperature aqueous Zn batteries. g Schematic modes representing H2O molecule with DAA, DDAA, DA, DDA, and non-HB. f and g were reproduced with permission from Ref. [96]. Copyright © 2023 Elsevier BV

Attention also needs to focus on the combined use of organic solvents and water and on the number of HB donors and acceptors for the solvents. In this respect, Zhao et al. [95] employed NMP (N-methyl-2-pyrrolidone) molecules as end-cap reagents to hinder proton conduction in aqueous electrolytes. The NMP structure comprises an HB acceptor but lacks an HBs donor site, which effectively impedes HB propagation and restricts the pathway for proton transport in aqueous electrolytes (Fig. 8c). This electrolyte provides excellent low-temperature performance due to the end-capping of HBs.

Insufficient ionic conductivity and freezing of the electrolyte are considered to be the main limitations for storing electrochemical energy at a low temperature. Nian’s group [25] reported an electrolyte with DMSO as an additive that had a freezing point lower than 130 °C, and MD simulations were used to understand the underlying mechanism behind the low freezing point of the electrolyte. Figure 8d, e illustrates that in the mixed water/DMSO electrolyte, an HB network is formed through the interaction between oxygen atoms in the S = O bond of DMSO and the hydrogen atoms in the O–H bond of water. When the temperature drops below 0 °C, the intermolecular HBs between DMSO and water impede the formation of the tetrahedral structure of ice, thereby enabling the electrolyte to exhibit low-temperature tolerance.

Most of the studies mentioned above employed high-polarity molecules with large additive dosages. However, the involvement of bulk organic molecules in a primary solvation sheath (PSS) inevitably enlarges the de-solvation penalty. By introducing low-polarity 1, 2-dimethoxyethane (DME) into dilute 1 mol/L trifluoromethanesulfonic acid (Zn(OTf)2) aqueous solution, Dong et al. [96] designed a cell-core structured electrolyte. The electrolyte was characterized by an inner core composed of an OTf-rich Zn2+-PSS and an outer layer consisting of a DME-modulated Zn2+-external solvation sheath (Fig. 8f). The addition of DME improved the Zn-OTf− coordination without participating in the Zn2+-PSS, thereby facilitating favorable reaction kinetics at ultra-low temperatures. Furthermore, DME disrupted the original hydrogen-bonding network of water, effectively reducing the electrolyte’s freezing point (Fig. 8g). This unique nucleus-like structure provided an ultra-low freezing point (− 52.4 °C), high ionic conductivity (1.06 mS/cm at − 40 °C), and the formation of a robust ZnF2-rich solid electrolyte interface (SEI) on the surface of the Zn electrode.

The physicochemical properties of the solvent have a considerable influence on the performance of aqueous batteries over a wide temperature range. It is evident from several methods presented above that theoretical simulations and corresponding statistical analyses can be used to obtain the relevant properties of the solvent structure, and numerous theoretical models have been developed to obtain associated information. More encouragingly, with the development of machine learning (ML) predictions, ML models can be trained based on limited MD results to construct quantitative relationships between the electrolyte formulations and the corresponding physicochemical properties [97].

Instead of adding flammable and toxic organic antifreeze additives to improve the low-temperature performance, it makes scientific sense to add common inexpensive inorganic inert additives. Certain ionic additives that contain multivalent cations have the ability to form strong interactions with water molecules and effectively lower the freezing point of aqueous solution electrolytes. Research conducted by Sun et al. and Zhu’s team [98,99,100] demonstrated the use of antifreeze double-cation electrolytes to improve the low-temperature performance of aqueous electrolyte systems. In this respect, Sun et al. [98] reported an antifreeze double-cation electrolyte with 3.5 mol/L Mg(ClO4)2 + 1 mol/L Zn(ClO4)2. By introducing the oxygen ligands, Mg2+ and ClO4−, the proportion of HBs in the water molecules was significantly reduced, and theoretical calculations confirmed the synergistic effect of cations and anions on freezing point reduction (Fig. 9a, b). The dissolution of Mg(ClO4)2 in water is a violent exothermic process, and it indicates that the bonding energy between Mg2+ and O atoms is higher than the bonding energy of HBs (Fig. 9c). Therefore, Mg2+ is more likely to combine with O atoms in water and break the arrangement of HBs to form stable hydrated ions, while ClO4− as the HB receptor can form weak HBs with H atoms in H2O. By simultaneously regulating the chemical environment of O and H atoms in H2O, the electrolyte obtained an ultra-low freezing point of 121 °C (Fig. 9d). Zhu’s team [99] reported an electrolyte system that operated at low temperatures by introducing 3.5 mol/L Mg(ClO4)2 into a 0.5 mol/L NaClO4 electrolyte. Mg2+ has a significant effect on the chemical environment of water molecules; it can effectively attract water from the water clusters, which changes the initial hydrogen-bonding network and finally lower the freezing point of the electrolyte. As shown in Fig. 9e, f, the freezing point of the mixed electrolyte was significantly reduced, and no salt precipitation or ice crystals were observed during the cooling process. This mixed electrolyte was also found to have a high ionic conductivity of 4.86 mS/cm at − 60 °C (Fig. 9g). The synergistic effect between cations and anions enabled the electrolyte to achieve an ultra-low freezing point.

Calculated formation energy and hydrated radius of a Zn2+ solvation configuration. b Mg2+ solvation configuration. c Photographs of infrared thermometry of different electrolytes. d DSC curve of 3.5 mol/L electrolyte. a, b, c, and d were reproduced with permission from Ref. [98]. Copyright © 2021 Springer Singapore. e DSC results (from − 150 to 30 °C with a heating rate of 5 °C/min) of various electrolytes. f Polarizing microscope observation of the 3.5 mol/L Mg(ClO4)2 + 0.5 mol/L NaClO4 electrolyte during the cooling process. g Ionic conductivity of 3.5 mol/L Mg(ClO4)2 + 0.5 mol/L NaClO4 electrolyte at different temperatures. e, f, and g were reproduced with permission from Ref. [99]. Copyright © 2022 Wiley. h Fitted O–H stretching vibration in the Raman spectra of 3.86 mol/L CaCl2 + 1 mol/L NaClO4 electrolyte. i Component proportions of water with different HBs for NaClO4-based electrolytes. h and i were reproduced with permission from Ref. [100]. Copyright © 2022 Wiley

In addition to Mg(ClO4)2, CaCl2 and NaClO4 have been used in electrolyte systems, and their abilities to lower the freezing point and improve the low-temperature performance have been demonstrated [100]. Low-cost CaCl2 was used as an antifreeze added to the electrolyte of 1 mol/L NaClO4 aqueous solution, and Raman spectroscopy clearly showed that CaCl2 strongly interacted with the water molecules and regulated the ratio of HBs in the electrolyte, thereby significantly lowering the freezing point of the optimized electrolyte (Fig. 9h, i). These inorganic antifreeze additives offer advantages over toxic and flammable organic co-solvents, and they provide a safer and more cost-effective approach for developing high-performance cryogenic water-based cells.

For future practical applications, the ideal additive or co-solvent needs to be capable of improving the low-temperature performance of aqueous electrolytes and also ensuring a stable interface for the metal ions phase to protect the long-term cycling of the metal anode. The formation of stable HBs between additives or co-solvents and water molecules is crucial for designing antifreeze water electrolytes [101]. Organic additives play an important role in constructing SEI that can effectively adapt to low-temperature environments, and they combine the advantages of both aqueous and non-aqueous solvents [102]. However, organic additives are toxic, and the addition of organic additives has a significant effect on the ionic conductivity of the electrolyte. There is also a continuing need to research safe organic and non-polluting inorganic additives that achieve a low-temperature performance without compromising the unique safety characteristics of ARBs.

Aqueous Rechargeable Battery (ARB) at High Temperatures

Compared to organic batteries, aqueous batteries deliver excellent thermal safety. The rise in temperature increases the ionic conductivity of the electrolyte, and the battery capacity increases accordingly. However, although aqueous electrolytes are a favorable choice for non-flammable batteries, most electrolytes suffer from poor stability at high temperatures due to the enhanced activity of water molecules. The high temperature inside the cell accelerates the water-induced side reactions of both electrodes, which may lead to structural damage, a phase change of the cathode, and depletion of the metal anode [103, 104]. Therefore, the next section discusses employing an electrolyte modification strategy for highly stable ARBs at a high temperature.

Concentrated Electrolytes

Concentrated electrolytes can inhibit electrolyte volatilization, and employing “water-in-salt” electrolytes (WiSEs) is an effective strategy for improving the high-temperature performance of ARBs. The concentration of ions in WiSEs is much higher than the moisture content, and this gives the electrolyte a wide liquid-state temperature range and a stable electrochemical window (Fig. 10). Jiang et al. [105] used 22 mol/L KCF3SO3 with a wide voltage window (3 V), which inhibited the dissolution effect and provided high conductivity and low viscosity (Fig. 10a). Furthermore, the KFeMnHCF-3565||22 mol/L KCF3SO3||PTCDI soft pack cells exhibited a superior performance at a low rate (0.5 C/0.1 C) and over a wide temperature range (− 20 °C to 60 °C) (Fig. 10b). Zhang et al. [106] proposed a new sodium-ion aqueous battery using a 17 mol/L NaClO4 electrolyte. The “water-in-salt” electrolyte had a low freezing point of − 31.3 °C and boasted high thermal stability reaching 200 °C (Fig. 10c). The complete cell benefited from the low freezing point and high thermal stability of the “water-in-salt” electrolyte and operation over a wide temperature range of − 40 °C to 100 °C was achieved (Fig. 10d), evidencing typical all-climate operation. Xia’s group [107] reported a NiHCF@CNTs||poly(1,5-NAPD) ammonium-ion battery with a 19 mol/kg CH3COONH4 electrolyte (Fig. 10e) that provided a high boiling point (140 °C) and a low freezing point (− 38 °C) and allowed the ammonium-ion battery to operate over a wide temperature range (− 40 to 80 °C) (Fig. 10f).

a Viscosity and conductivity at different temperatures for the 22 mol/L KCF3SO3 electrolyte. b Cycling performance of the KFeMnHCF-3565||22 mol/L KCF3SO3||PTCDI pouch cell at different rates (0.5°C and 0.1°C) and temperatures (− 20 °C, − 10 °C, 25 °C, and 60 °C) from 0 to 2.3 V. a and b were reproduced with permission from Ref. [105]. Copyright © 2021 American Chemical Society. c DSC measurement of the 17 mol/kg NaClO4 electrolyte. d Galvanostatic discharge–charge curves of the NiHCF||PT full cell from 25 to 100 °C at 5 A/\({\text{g}}_{{{\text{PT}}}}^{ - 1}\) c and d were reproduced with permission from Ref. [106]. Copyright © 2022 Elsevier. e Schematic of the energy storage mechanism of ammonium-ion batteries at high temperature. f DSC measurement of 19 mol/L CH3COONH4 electrolyte. e and f were reproduced with permission from Ref. [107]. Copyright © 2021 Elsevier

Solvent Modification of Electrolyte

Solvent modification of the electrolyte is an effective strategy used to inhibit a drastic water-induced side reaction and dendrite growth on the metal electrode surfaces at high temperatures. Generally, solvent additives improve the thermal stability of ARBs in the following two ways (Fig. 11): (1) preferential reduction on the electrode surface to form a highly thermally stable SEI; (2) participation in the construction of solventized structures and reconfiguration of the HB network of water, which reduces the content and activity of water and inhibits the violent decomposition of water molecules at high temperatures. Xiong et al. [82] modified the ZnSO4 electrolyte with a polar aprotic N, N-dimethylformamide (ZnSO4–H2O–DMF) (Fig. 11a), which reached a boiling point of 82 °C (Fig. 11b) and in situ formed a Zn2+-conducting Zn5(CO3)2(OH)6 SEI on the electrode surface during the cycling process. The Zn5(CO3)2(OH)6 SEI features high thermal stability due to its high thermal decomposition temperature of 250 °C (Fig. 11c), enabling it to inhibit dendrite formation at high temperatures of 70 °C. Molecular crowding is a common phenomenon in living cells where water activity is substantially suppressed by molecular crowding agents through altering the hydrogen-bonding structure [108]. Wang et al. [109] formulated a crowding agent where 1, 5-pentanediol (PD) was introduced into an aqueous electrolyte. MD simulations revealed that at 100 °C, the PD expelled a large amount of H2O from the Zn2+ solventized sheath (Fig. 11d); this modified the Zn2+ solventized structure and enhanced the O–H bonding of H2O to inhibit the reactivity of water and broaden the stable voltage window of the electrolyte to 2.35 V (Fig. 11e) while maintaining the high flame retardancy (Fig. 11f) and thermal stability of the electrolyte.

a Schemes illustrating the different reaction processes of the Zn2+ solvation structure and corresponding interfacial interaction between the Zn anode surface and electrolyte under ZnSO4–H2O–DMF electrolytes. b DSC measurement of ZnSO4–H2O–DMF electrolytes from 25 to 150 °C. c Thermogravimetry analysis (TGA) curves of the as-synthesized Zn5(OH)6(CO3)2. a, b, and c were reproduced with permission from Ref. [82]. Copyright © 2023 American Chemical Society. d The racial distribution functions of Zn(OTf)2–H2O/PD electrolyte at 100 °C obtained via MD calculations. e Linear sweep voltammetry results of ZnSO4–H2O, Zn(OTf)2–H2O, and Zn(OTf)2–H2O/PD electrolyte. f Flammability tests of different electrolytes with/without PD solvent. d, e, and f were reproduced with permission from Ref. [109]. Copyright © 2022 American Chemical Society

Hydrogels Electrolytes

Water is retained in the hydrogel structure, and hydrogels can, therefore, also be used in high-temperature applications. However, the introduction of highly concentrated salt solutions and solvent additives is typically necessary to mitigate water loss and improve the safety of hydrogels at extremely high temperatures (Fig. 11). Gu et al. [110] designed a highly stretchable and temperature-resistant hydrogel electrolyte with a guanosine G-quadruplexes, small-molecule-based, supramolecular, polymer binary network (SP-DN) structure (Fig. 12a). The developed SP-DN hydrogel electrolytes were based on a concentrated KOH aqueous solution and consisted of a series of guanosine G-tetramers interpenetrated with PAM networks. The obtained KOH (6 mol/L)-filled SP-DN hydrogels exhibited hyper stretchability (> 1600%), a wide temperature tolerance (from − 196 to 100 °C) (Fig. 12b), excellent interfacial adhesion, and ultra-high low and high-temperature conductivity (252.2 mS/cm at − 50 °C, 431.7 mS/cm at 100 °C) (Fig. 12c). Replacing water with a solvent that has a high boiling point is one way of reducing the volatility of the electrolyte. Zheng et al. [111] prepared rigid, noncombustible, spirocyclic, pentaerythritol diphosphate-based, cross-linked gel polymer electrolytes (SPDPA) by in situ thermal polymerization. The electrolyte offered favorable interfacial compatibility and thermal stability (Fig. 12d), and as shown in Fig. 12e, the addition of SPDPA effectively increased the nonflammability of the electrolyte. The NVP||GPE||Na full cell operated at a constant current density of 270 mA/g for 200 cycles at a high temperature of 60 °C and with a discharge specific capacity of 93.4 mAh/g (Fig. 12f). Hyun et al. [112] developed high-modulus ion-conductive gel electrolytes using imidazolium ionic liquids and exfoliated hexagonal boron nitride (hBN) nanoplates. The high thermal stability of the hBN nano-solid matrix facilitated the high operation rate of solid-state rechargeable Li-ion batteries at high temperatures reaching 175 °C (Fig. 12g). In addition, using both GL additives and freeze–thawing techniques, Jiang et al. [113] designed a “hydrogen bond-microstructure” dual-regulated, low-temperature-resistant, stretchable gel electrolyte (HG-F) (Fig. 12h). The freeze–thaw method allowed the PVA molecular chains to interact with each other and twist to form a three-dimensional cross-linked structure tightly bound by van der Waals and HBs, which greatly reduced the number of free water molecules and resulted in stability of the HG-F gel electrolyte over a wide temperature range. Furthermore, Hou et al. [114] reported a novel “water-in-eutectogel (WiETG)” electrolyte prepared by swelling a hydrogel polymer with a low water content DES. The three stages of weight loss that occurred are shown in Fig. 12i and are related to the evaporation of water (< 120 °C), the decomposition of acetamide or polymer species (120–400 °C), and the decomposition of LiTFSI (> 400 °C). The WiETG exhibited high thermal stability over a wide temperature range. Data about the electrochemical properties applicable to wide temperature domain electrolytes are presented in Table 1 [115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132].

a Schematic diagram of synthesis method and polymerization mechanism, and digital images of small molecule-based SP-DN hydrogel electrolytes. b Compressive stress–strain results of the G-CyBA/PAAm SP-DN and the PAAm SN hydrogels with various soaking times in aqueous KOH (6 mol/L) at temperatures from − 80 to 100 °C. c Digital images of stretchability and conductivity of the 6 mol/L KOH-filled SP-DN hydrogel electrolytes at temperatures from − 80 to 100 °C. a, b, and c were reproduced with permission from Ref. [110]. Copyright © 2021 Royal Society of Chemistry. d Burning and residue of cotton fiber wicks soaked with LE with different flame-retardant content. e Cycling performances and coulombic efficiency of the NVP/Na cells at 60 °C. f TGA curves of hBN gel electrolytes. d, e, and f were reproduced with permission from Ref. [111]. Copyright © 2020 Royal Society of Chemistry. g Cycling performance of the cell tested at 10°C at 175°C. Reproduced with permission from Ref. [112]. Copyright © 2019 American Chemical Society. h Schematic diagram of the fabrication process and principle. Reproduced with permission from Ref. [113]. Copyright © 2023 Wiley. i TGA curves of CP-131, CP-132, and CP-21 m. Reproduced with permission from Ref. [114]. Copyright © 2022 Wiley

To meet the requirements of safe and long-term cycling above room temperature, the main principle of high-temperature electrolytes is to improve thermal stability by reducing volatility and controlling decomposition. By decreasing the water content, the boiling point of the electrolyte can be increased, and various methods (such as those involving the use of high concentrations, organic/water hybrid solvents, and hydrogels) have been established based on this principle. To further enhance the high-temperature resistance of the electrolyte, the salt needs to have high thermal stability (resistance to decomposition at high temperatures). In addition, organic cathodes may dissolve in organic solvent-based electrolytes, while some inorganic cathodes may dissolve or decompose at high temperatures [133, 134]. In addition to electrolyte modification, our previously works demonstrate that the wide temperature range performance can also be improved by designing and modifying the electrode materials [135,136,137,138,139]. Therefore, it is necessary to consider the effect of the cathode on the electrolyte in the design of a suitable electrolyte or when evaluating the performance of the cell at high temperatures.

Conclusions and Prospects

Compared with conventional commercial organic batteries, ARBs are cheap to produce, easy to assemble, intrinsically safe, and environmentally friendly. They, therefore, hold great promise for use in flexible and wearable electronics and as large-scale energy storage devices. However, the temperature of ARBs and the freezing or volatility of the electrolyte greatly affect their electrochemical performance, reliability, and safety, which limits their large-scale commercial application. Nevertheless, increasing numbers of studies are being conducted, and the development of ARBs is progressing.

This review systematically summarizes the challenges and solutions associated with the use of ARBs in different temperature regions, and the following three effective electrolyte improvement strategies are proposed: (1) increasing the solute concentration of the aqueous electrolyte, (2) introducing efficient additives to the electrolyte, and (3) utilizing a hydrogel electrolyte. Based on this review, the following main conclusions and suggestions are made:

-

1.

The electrolyte is undoubtedly an important component of the battery. For non-room temperature use, it is recommended that electrolytes have high ionic conductivity, a low freezing point, low viscosity, a low free water content, and low flammability. In addition to ensuring that the electrolyte has these physical properties, it is necessary to conduct in-depth studies of the electrolyte structure to further understand its interfacial behavior at the electrode.

-

2.

Hydrogel electrolytes engineered for wearable or portable devices require the aforementioned temperature adaptation and satisfactory electrochemical properties, but the mechanical properties in different environments also need to be ascertained.

-

3.

In general, the sub-zero temperature performance of ARBs remains inferior to that of organic electrolytes because the freezing point of water is higher than that of most organic solvents. However, organic additives carry a certain degree of toxicity, and the addition of organic additives significantly reduces the ionic conductivity of the electrolyte. To maintain the competitiveness of ARBs, it is necessary to ensure their intrinsic safety and low cost, and the continued exploration of high-safety and non-polluting organic/inorganic additives is still required.

-

4.

It is also necessary to consider the compatibility of the electrolyte and electrode materials. Organic cathodes may dissolve in organic solvent-based electrolytes, while some inorganic cathodes may dissolve or decompose at high temperatures. An in-depth elucidation of the combination of electrolyte solvation structures and electrode reaction mechanisms is thus required, and advanced in situ or ex situ characterization at low and high temperatures is essential to obtain a deeper understanding of the electrochemical behavior.

-

5.

To thoroughly explain the reaction mechanism at non-room temperature, it is also necessary to use advanced and temperature-adapted characterization techniques. Examples of current techniques include variable-temperature nuclear magnetic resonance, high-resolution neutron powder diffraction, in situ liquid/solid FTIR, in situ liquid/solid Raman spectroscopy, cryo-electron microscopy, and cryo-focused ion beam (cryo-FIB). However, quantifying each component and its precise distribution at a nanoscale resolution remains a rather challenging task, and more associated in-depth studies are required.

References

Hou WH, Lu Y, Ou Y et al (2023) Recent advances in electrolytes for high-voltage cathodes of lithium-ion batteries. Trans Tianjin Univ 29(2):120–135

Wang L, Menakath A, Han F et al (2019) Identifying the components of the solid-electrolyte interphase in Li-ion batteries. Nat Chem 11(9):789–796

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Dunn B, Kamath H, Tarascon JM (2011) Electrical energy storage for the grid: a battery of choices. Science 334(6058):928–935

Luo F, Feng X, Zeng L et al (2021) In situ simultaneous encapsulation of defective MoS2 nanolayers and sulfur nanodots into SPAN fibers for high rate sodium-ion batteries. Chem Eng J 404:126430

Wang M, Meng Y, Li K et al (2022) Toward dendrite-free and anti-corrosion Zn anodes by regulating a bismuth-based energizer. eScience 2(5):509–517

Yao YX, Yao N, Zhou XR et al (2022) Ethylene-carbonate-free electrolytes for rechargeable Li-ion pouch cells at sub-freezing temperatures. Adv Mater 34(45):e2206448

Liu Z, Huang Y, Huang Y et al (2020) Voltage issue of aqueous rechargeable metal-ion batteries. Chem Soc Rev 49(1):180–232

Zhang X, Li J, Ao H et al (2020) Appropriately hydrophilic/hydrophobic cathode enables high-performance aqueous zinc-ion batteries. Energy Storage Mater 30:337–345

Zhang S, Li S, Lu Y (2021) Designing safer lithium-based batteries with nonflammable electrolytes: a review. eScience 1(2):163–177

Wang J, Wang B, Lu B (2020) Nature of novel 2D van der Waals heterostructures for superior potassium ion batteries. Adv Energy Mater 10(24):2000884

Huang Y, Li Z, Pei Z et al (2018) Solid-state rechargeable Zn/NiCo and Zn-air batteries with ultralong lifetime and high capacity: the role of a sodium polyacrylate hydrogel electrolyte. Adv Energy Mater 8(31):1802288

Wang H, Liu J, He J et al (2022) Pseudo-concentrated electrolytes for lithium metal batteries. eScience 2(5):557–565

Huang J, Guo Z, Ma Y et al (2019) Recent progress of rechargeable batteries using mild aqueous electrolytes. Small Meth 3(1):1800272

Wang D, Zhao Y, Liang G et al (2020) A zinc battery with ultra-flat discharge plateau through phase transition mechanism. Nano Energy 71:104583

Zhang Y, Zhao L, Liang Y et al (2022) Effect of electrolyte anions on the cycle life of a polymer electrode in aqueous batteries. eScience 2(1):110–115

Li H, Ma L, Han C et al (2019) Advanced rechargeable zinc-based batteries: recent progress and future perspectives. Nano Energy 62:550–587

Fang L, Cai Z, Ding Z et al (2019) Skin-inspired surface-microstructured tough hydrogel electrolytes for stretchable supercapacitors. ACS Appl Mater Interfaces 11(24):21895–21903

Ji X (2022) A perspective of ZnCl2 electrolytes: the physical and electrochemical properties. eScience 1(2):99–107

Xu CX, Jiang J (2021) Electrolytes speed up development of zinc batteries. Rare Met 40(4):749–751

Jiang L, Lu Y, Zhao C et al (2019) Building aqueous K-ion batteries for energy storage. Nat Energy 4(6):495–503

Hubble D, Brown DE, Zhao Y et al (2022) Liquid electrolyte development for low-temperature lithium-ion batteries. Energy Environ Sci 15(2):550–578

Zhu K, Sun Z, Li Z et al (2023) Design strategies and recent advancements for low-temperature aqueous rechargeable energy storage. Adv Energy Mater 13(8):2203708

Zhang Q, Ma Y, Lu Y et al (2020) Modulating electrolyte structure for ultralow temperature aqueous zinc batteries. Nat Commun 11(1):4463

Nian Q, Wang J, Liu S et al (2019) Aqueous batteries operated at −50 ℃. Angew Chem Int Ed 58(47):16994–16999

Feng Y, Zhou L, Ma H et al (2022) Challenges and advances in wide-temperature rechargeable lithium batteries. Energy Environ Sci 15(5):1711–1759

Xu K (2004) Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem Rev 104(10):4303–4417

Hou J, Yang M, Wang D et al (2020) Lithium-ion batteries: fundamentals and challenges of lithium ion batteries at temperatures between −40 and 60 ℃. Adv Energy Mater 10(18):2070079

Dong X, Wang YG, Xia Y (2021) Promoting rechargeable batteries operated at low temperature. Acc Chem Res 54(20):3883–3894

Wang M, Li T, Yin Y et al (2022) A −60 ℃ low-temperature aqueous lithium ion-bromine battery with high power density enabled by electrolyte design. Adv Energy Mater 12(25):2200728

Shang Y, Chen S, Chen N et al (2022) A universal strategy for high-voltage aqueous batteries via lone pair electrons as the hydrogen bond-breaker. Energy Environ Sci 15(6):2653–2663

Zhang X, Chen J, Xu Z et al (2022) Aqueous electrolyte with moderate concentration enables high-energy aqueous rechargeable lithium ion battery for large scale energy storage. Energy Storage Mater 46:147–154

Lu C, Chen X (2020) All-temperature flexible supercapacitors enabled by antifreezing and thermally stable hydrogel electrolyte. Nano Lett 20(3):1907–1914

Wang H, Chen Z, Ji Z et al (2021) Temperature adaptability issue of aqueous rechargeable batteries. Mater Today Energy 19:100577

Li F, Hu X (2021) Zinc metal energy storage devices under extreme conditions of low temperatures. Batter Supercaps 4(3):389–406

Ramanujapuram A, Yushin G (2018) Understanding the exceptional performance of lithium-ion battery cathodes in aqueous electrolytes at subzero temperatures. Adv Energy Mater 8(35):1802624

Liu Z, Luo X, Qin L et al (2022) Progress and prospect of low-temperature zinc metal batteries. Adv Powder Mater 1(2):100011

Tamtögl A, Bahn E, Sacchi M et al (2021) Motion of water monomers reveals a kinetic barrier to ice nucleation on graphene. Nat Commun 12(1):3120

Deng T, Zhang W, Zhang H et al (2018) Anti-freezing aqueous electrolyte for high-performance Co(OH)2 supercapacitors at −30 ℃. Energy Technol 6(4):605–612

Ma L, Li N, Long C et al (2019) Achieving both high voltage and high capacity in aqueous zinc-ion battery for record high energy density. Adv Funct Mater 29(46):1906142

Zhang H, Liu X, Li H et al (2020) High-voltage operation of a V2O5 cathode in a concentrated gel polymer electrolyte for high-energy aqueous zinc batteries. ACS Appl Mater Interfaces 12(13):15305–15312

Lukatskaya MR, Feldblyum JI, Mackanic DG et al (2018) Concentrated mixed cation acetate “water-in-salt” solutions as green and low-cost high voltage electrolytes for aqueous batteries. Energy Environ Sci 11(10):2876–2883

Zhang Q, Xia K, Ma Y et al (2021) Chaotropic anion and fast-kinetics cathode enabling low-temperature aqueous Zn batteries. ACS Energy Lett 6(8):2704–2712

Liang G, Gan Z, Wang X et al (2021) Reconstructing vanadium oxide with anisotropic pathways for a durable and fast aqueous K-ion battery. ACS Nano 15(11):17717–17728

Jiang L, Liu L, Yue J et al (2020) High-voltage aqueous Na-ion battery enabled by inert-cation-assisted water-in-salt electrolyte. Adv Mater 32(2):e1904427

Yue J, Lin L, Jiang L et al (2020) Interface concentrated-confinement suppressing cathode dissolution in water-in-salt electrolyte. Adv Energy Mater 10(36):2000665

Becker M, Kühnel RS, Battaglia C (2019) Water-in-salt electrolytes for aqueous lithium-ion batteries with liquidus temperatures below −10 ℃. Chem Commun 55(80):12032–12035

Reber D, Kühnel RS, Battaglia C (2019) Suppressing crystallization of water-in-salt electrolytes by asymmetric anions enables low-temperature operation of high-voltage aqueous batteries. ACS Mater Lett 1(1):44–51

Sun T, Yuan X, Wang K et al (2021) An ultralow-temperature aqueous zinc-ion battery. J Mater Chem A 9(11):7042–7047

Borodin O, Self J, Persson KA et al (2020) Uncharted waters: super-concentrated electrolytes. Joule 4(1):69–100

Yamada Y (2020) Concentrated battery electrolytes: developing new functions by manipulating the coordination states. Bull Chem Soc Jpn 93(1):109–118

Song M, Tan H, Chao D et al (2018) Recent advances in Zn-ion batteries. Adv Funct Mater 28(41):1802564

Yamada Y, Yaegashi M, Abe T et al (2013) A superconcentrated ether electrolyte for fast-charging Li-ion batteries. Chem Commun 49(95):11194–11196

Zhang H, Liu X, Li H et al (2021) Challenges and strategies for high-energy aqueous electrolyte rechargeable batteries. Angew Chem Int Ed 60(2):598–616

Chao D, Qiao SZ (2020) Toward high-voltage aqueous batteries: super- or low-concentrated electrolyte? Joule 4(9):1846–1851

Yu M, Lu Y, Zheng H et al (2018) New insights into the operating voltage of aqueous supercapacitors. Chem-Eur J 24(15):3639–3649

Sui X, Guo H, Chen P et al (2019) Zwitterionic osmolyte-based hydrogels with antifreezing property, high conductivity, and stable flexibility at subzero temperature. Adv Funct Mater 30(7):1907986

Wang M, Wang Q, Ding X et al (2022) The prospect and challenges of sodium-ion batteries for low-temperature conditions. Interdiscipl Mater 1(3):373–395

Huang J, Dong X, Wang N et al (2022) Building low-temperature batteries: non-aqueous or aqueous electrolyte? Curr Opin Electrochem 33:100949

Zhou W, Chen J, Chen M et al (2020) An environmentally adaptive quasi-solid-state zinc-ion battery based on magnesium vanadate hydrate with commercial-level mass loading and anti-freezing gel electrolyte. J Mater Chem A 8(17):8397–8409

Shi Y, Wang R, Bi S et al (2023) An anti-freezing hydrogel electrolyte for flexible zinc-ion batteries operating at –70 ℃. Adv Funct Mater 33(24):2214546

Hu Y, Shi R, Ren Y et al (2022) A “two-in-one” strategy for flexible aqueous batteries operated at –80 ℃. Adv Funct Mater 32(27):2203081

Liu T, Liu KT, Wang J et al (2021) Achievement of a polymer-free KAc gel electrolyte for advanced aqueous K-ion battery. Energy Storage Mater 41:133–140

Mo F, Li Q, Liang G et al (2021) A self-healing crease-free supramolecular all-polymer supercapacitor. Adv Sci 8(12):2100072

Fu Q, Hao S, Meng L et al (2021) Engineering self-adhesive polyzwitterionic hydrogel electrolytes for flexible zinc-ion hybrid capacitors with superior low-temperature adaptability. ACS Nano 15(11):18469–18482

Fu Q, Hao S, Zhang X et al (2023) All-round supramolecular zwitterionic hydrogel electrolytes enabling environmentally adaptive dendrite-free aqueous zinc ion capacitors. Energy Environ Sci 16(3):1291–1311

Gong JP, Katsuyama Y, Kurokawa T et al (2003) Double-network hydrogels with extremely high mechanical strength. Adv Mater 15(14):1155–1158

Sun N, Lu F, Yu Y et al (2020) Alkaline double-network hydrogels with high conductivities, superior mechanical performances, and antifreezing properties for solid-state zinc-air batteries. ACS Appl Mater Interfaces 12(10):11778–11788

Zhang Y, Qin H, Alfred M et al (2021) Reaction modifier system enable double-network hydrogel electrolyte for flexible zinc-air batteries with tolerance to extreme cold conditions. Energy Storage Mater 42:88–96

Zhao Y, Chen Z, Mo F et al (2020) Aqueous rechargeable metal-ion batteries working at subzero temperatures. Adv Sci 8(1):2002590

Zhou D, Chen F, Handschuh-Wang S et al (2019) Biomimetic extreme-temperature- and environment-adaptable hydrogels. ChemPhysChem 20(17):2139–2154

Zheng J, Engelhard MH, Mei D et al (2017) Electrolyte additive enabled fast charging and stable cycling lithium metal batteries. Nat Energy 2:17012

Song M, Zhong CL (2022) Achieving both high reversible and stable Zn anode by a practical glucose electrolyte additive toward high-performance Zn-ion batteries. Rare Met 41(2):356–360

Ren HT, Zhang ZQ, Zhang JZ et al (2022) Improvement of stability and solid-state battery performances of annealed 70Li2S–30P2S5 electrolytes by additives. Rare Met 41:106–114

Tang X, Zhang WC, Cao LY (2022) Multifunctional high-fluorine-content molecule with high dipole moment as electrolyte additive for high performance lithium metal batteries. Rare Met 41(3):726–729

Jin Y, Han KS, Shao Y et al (2020) Stabilizing zinc anode reactions by polyethylene oxide polymer in mild aqueous electrolytes. Adv Funct Mater 30(43):2003932

Han W, Ardhi R, Liu GC (2022) Dual impact of superior SEI and separator wettability to inhibit lithium dendrite growth. Rare Met 41(2):353–355

Guo Y, Liu J, Yang Q et al (2020) Metal-tuned acetylene linkages in hydrogen substituted graphdiyne boosting the electrochemical oxygen reduction. Small 16(10):e1907341

Xu Z, Yang J, Li H et al (2019) Electrolytes for advanced lithium ion batteries using silicon-based anodes. J Mater Chem A 7(16):9432–9446

Sun P, Ma L, Zhou W et al (2021) Simultaneous regulation on solvation shell and electrode interface for dendrite-free Zn ion batteries achieved by a low-cost glucose additive. Angew Chem Int Ed 60(33):18247–18255

Ma Z, Chen J, Vatamanu J et al (2022) Expanding the low-temperature and high-voltage limits of aqueous lithium-ion battery. Energy Storage Mater 45:903–910

Xiong P, Kang Y, Yao N et al (2023) Zn-ion transporting, in situ formed robust solid electrolyte interphase for stable zinc metal anodes over a wide temperature range. ACS Energy Lett 8(3):1613–1625