Abstract

Solid-state batteries (SSBs) have been considered the most promising technology because of their superior energy density and safety. Among all the solid-state electrolytes (SEs), Li7La3Zr2O12 (LLZO) with high ionic conductivity (3 × 10−4 S/cm) has been widely investigated. However, its large-scale production in ambient air faces a challenge. After air exposure, the generated Li2CO3 layer deteriorates the ionic conductivity and interfacial wettability, thus greatly compromising the electrochemical performance of SSBs. Many works aim to eliminate this layer to recover the pristine LLZO surface. Unfortunately, few articles have emphasized the merits of Li2CO3. In this review, we focus on the two-sidedness of Li2CO3. We discuss the various characteristics of Li2CO3 that can be used and recapitulate the strategies that utilize Li2CO3. Insulating Li2CO3 is no longer an obstacle but an opportunity for realizing intimate interfacial contact, high air stability, and outstanding electrochemical performance. This review aims to offer insightful guidelines for treating air-induced Li2CO3 and lead to developing the enhanced air stability and electrochemical performance of LLZO.

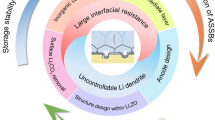

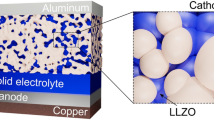

Graphical Abstract

Reproduced with permission from Ref. [19]. Copyright 2020 Elsevier. b TEM image. Reproduced with permission from Ref. [18]. Copyright 2018 Elsevier. c Raman spectra. Reproduced with permission from Ref. [19]. Copyright 2020 Elsevier. d FT-IR spectra. e C 1 s spectrum of XPS. Reproduced with permission from Ref. [20]. Copyright 2019 Elsevier. f TG-DSC curves of LLZTO@Li2CO3. Reproduced with permission from Ref. [18]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [28]. Copyright 2017 The Royal Society of Chemistry

Reproduced with permission from Ref. [21]. Copyright 2017 American Chemical Society

Reproduced with permission from Ref. [38]. Copyright 2020 American Chemical Society. c XPS analysis of the C 1 s and O 1 s peaks of LLZT (bottom) and Li6.5La3Zr1.5Ta0.5O12-C (LLZT-C) (top). Reproduced with permission from Ref. [54]. Copyright 2015 American Chemical Society. d Rapid acid treatment. Reproduced with permission from Ref. [20]. Copyright 2019 Elsevier

Reproduced with permission from Ref. [59]. Copyright 2019 The Royal Society of Chemistry. Schematic of the roles of b NH4F treatment. Reproduced with permission from Ref. [60]. Copyright 2020 John Wiley and Sons. c Schematic of the CS deposition process: (I) reduction of the Li2CO3 passivation layer by CS molecules, (II) aggregation of radical particles on the ceramic surface, and (III) uniform coverage of the CS layer on the Li6.5La3Zr1.5Ta0.5O12 (LLZTO) pellet. Reproduced with permission from Ref. [49]. Copyright 2020 American Chemical Society

Reproduced with permission from Ref. [62]. Copyright 2021 Wiley. b Dopamine polymerized on the surface of LLZTO particles to form a polydopamine coating layer. Reproduced with permission from Ref. [65]. Copyright 2019 Royal Society of Chemistry. c Schematic comparison of the Li-ion interface transfer across a continuous Li2CO3 layer and a broken Li2CO3 network wetted with LM. Reproduced with permission from Ref. [69]. Copyright 2020 Springer Nature. Schematic of the roles of d Li2.3C0.7B0.3O3. Reproduced with permission from Ref. [18]. Copyright 2018 Elsevier. e Co3O4. Reproduced with permission from Ref. [68]. Copyright 2020 Springer Nature

Similar content being viewed by others

References

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414(6861):359–367

Lu WZ, Xue MZ, Zhang CM (2021) Modified Li7La3Zr2O12 (LLZO) and LLZO-polymer composites for solid-state lithium batteries. Energy Storage Mater 39:108–129

Heo K, Song YW, Hwang D et al (2022) Effect of a self-assembling La2(Ni0.5Li0.5)O4 and amorphous garnet-type solid electrolyte composite on a layered cathode material in all-solid-state batteries. RSC Adv 12(22):14209–14222

Weiss M, Simon FJ, Busche MR et al (2020) From liquid- to solid-state batteries: ion transfer kinetics of heteroionic interfaces. Electrochem Energy Rev 3(2):221–238

Samson AJ, Hofstetter K, Bag S et al (2019) A bird’s-eye view of Li-stuffed garnet-type Li7La3Zr2O12 ceramic electrolytes for advanced all-solid-state Li batteries. Energy Environ Sci 12(10):2957–2975

Reddy MV, Julien CM, Mauger A et al (2020) Sulfide and oxide inorganic solid electrolytes for all-solid-state Li batteries: a review. Nanomaterials (Basel) 10(8):1606

Deiseroth HJ, Kong ST, Eckert H et al (2008) Li6PS5X: a class of crystalline Li-rich solids with an unusually high Li+ mobility. Angew Chem Int Ed 47(4):755–758

Zhang WB, Weber DA, Weigand H et al (2017) Interfacial processes and influence of composite cathode microstructure controlling the performance of all-solid-state lithium batteries. ACS Appl Mater Interfaces 9(21):17835–17845

Manthiram A, Yu XW, Wang SF (2017) Lithium battery chemistries enabled by solid-state electrolytes. Nat Rev Mater 2:16103

Thangadurai V, Kaack H, Weppner W (2003) Novel fast lithium ion conduction in garnet-type Li5La3M2O12 (M = Nb, Ta). J Am Ceram Soc 86:437–440

Murugan R, Thangadurai V, Weppner W (2007) Fast lithium ion conduction in garnet-type Li7La3Zr2O12. Angew Chem 46:7778–7781

Du FM, Zhao N, Li YQ et al (2015) All solid state lithium batteries based on lamellar garnet-type ceramic electrolytes. J Power Sour 300:24–28

Monroe C, Newman J (2005) The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J Electrochem Soc 152(2):A396

Cao DX, Sun X, Li Q et al (2020) Lithium dendrite in all-solid-state batteries: growth mechanisms, suppression strategies, and characterizations. Matter 3(1):57–94

Ma C, Rangasamy E, Liang CD et al (2015) Excellent stability of a lithium-ion-conducting solid electrolyte upon reversible Li+/H+ exchange in aqueous solutions. Angew Chem Int Ed Engl 54(1):129–133

Cheng L, Crumlin EJ, Chen W et al (2014) The origin of high electrolyte-electrode interfacial resistances in lithium cells containing garnet type solid electrolytes. Phys Chem Chem Phys 16(34):18294–18300

Galven C, Dittmer J, Suard E et al (2012) Instability of lithium garnets against moisture. Structural characterization and dynamics of Li7-xHxLa3Sn2O12 and Li5-xHxLa3Nb2O12. Chem Mater 24(17):3335–3345

Han FD, Yue J, Chen C et al (2018) Interphase engineering enabled all-ceramic lithium battery. Joule 2(3):497–508

Huo HY, Li XN, Sun YP et al (2020) Li2CO3 effects: new insights into polymer/garnet electrolytes for dendrite-free solid lithium batteries. Nano Energy 73:104836

Huo HY, Chen Y, Zhao N et al (2019) In-situ formed Li2CO3-free garnet/Li interface by rapid acid treatment for dendrite-free solid-state batteries. Nano Energy 61:119–125

Sharafi A, Kazyak E, Davis AL et al (2017) Surface chemistry mechanism of ultra-low interfacial resistance in the solid-state electrolyte Li7La3Zr2O12. Chem Mater 29(18):7961–7968

Truong L, Thangadurai V (2011) Soft-chemistry of garnet-type Li5+xBaxLa3-xNb2O12 (x = 0, 0.5, 1): reversible H+↔Li+ ion-exchange reaction and their X-Ray, 7Li MAS NMR, IR, and AC impedance spectroscopy characterization. Chem Mater 23:3970–3977

Nyman M, Alam TM, McIntyre SK et al (2010) Alternative approach to increasing Li mobility in Li-La-Nb/Ta garnet electrolytes. Chem Mater 22(19):5401–5410

Jin Y, McGinn PJ (2013) Li7La3Zr2O12 electrolyte stability in air and fabrication of a Li/Li7La3Zr2O12/Cu0.1V2O5 solid-state battery. J Power Sour 239:326–331

Larraz G, Orera A, Sanjuán ML (2013) Cubic phases of garnet-type Li7La3Zr2O12: the role of hydration. J Mater Chem A 1(37):11419–11428

Wang YX, Lai W (2015) Phase transition in lithium garnet oxide ionic conductors Li7La3Zr2O12: the role of Ta substitution and H2O/CO2 exposure. J Power Sour 275:612–620

Xia WH, xu BY, Duan HN, et al (2017) Reaction mechanisms of lithium garnet pellets in ambient air: the effect of humidity and CO2. J Am Ceram Soc 100(7):2832–2839

Sharafi A, Yu S, Naguib M et al (2017) Impact of air exposure and surface chemistry on Li-Li7La3Zr2O12 interfacial resistance. J Mater Chem A 5(26):13475–13487

Williams DD, Miller RR (1970) Effect of water vapor on the LiOH-CO2 reaction. Ind Eng Chem Fundam 9:454–457

Busche MR, Drossel T, Leichtweiss T et al (2016) Dynamic formation of a solid-liquid electrolyte interphase and its consequences for hybrid-battery concepts. Nat Chem 8(5):426–434

Liu T, Ren YY, Shen Y et al (2016) Achieving high capacity in bulk-type solid-state lithium ion battery based on Li6.75La3Zr1.75Ta0.25O12 electrolyte: interfacial resistance. J Power Sour 324:349–357

Xu BY, Duan HN, Liu HZ et al (2017) Stabilization of garnet/liquid electrolyte interface using superbase additives for hybrid Li batteries. ACS Appl Mater Interfaces 9:21077–21082

Fu XJ, Wang TT, Shen WZ et al (2020) A high-performance carbonate-free lithium|garnet interface enabled by a trace amount of sodium. Adv Mater 32(26):2000575

Cheng L, Wu CH, Jarry A et al (2015) Interrelationships among grain size, surface composition, air stability, and interfacial resistance of Al-substituted Li7La3Zr2O12 solid electrolytes. ACS Appl Mater Interfaces 7(32):17649–17655

Brugge RH, Hekselman AKO, Cavallaro A et al (2018) Garnet electrolytes for solid state batteries: visualization of moisture-induced chemical degradation and revealing its impact on the Li-ion dynamics. Chem Mater 30(11):3704–3713

Feng JR, Gao ZH, Sheng L et al (2021) Progress and perspective of interface design in garnet electrolyte-based all-solid-state batteries. Carbon Energy 3:385–409

Guo Y, Wu SC, He YB et al (2022) Solid-state lithium batteries: safety and prospects. eScience 2(2):138–163

Huo HY, Luo J, Thangadurai V et al (2019) Li2CO3: a critical issue for developing solid garnet batteries. ACS Energy Lett 5(1):252–262

Aguesse F, López del Amo JM, Roddatis V et al (2014) Enhancement of the grain boundary conductivity in ceramic Li0.34La0.55TiO3Electrolytes in a moisture-free processing environment. Adv Mater Interfaces 1(7):1300143

Guo YX, Cheng J, Zeng Z et al (2022) Li2CO3: insights into its blocking effect on Li-ion transfer in garnet composite electrolytes. ACS Appl Energy Mater 5:2853–2861

Chen RS, Li QH, Yu XQ et al (2020) Approaching practically accessible solid-state batteries: stability issues related to solid electrolytes and interfaces. Chem Rev 120(14):6820–6877

Geiger CA, Alekseev E, Lazic B et al (2011) Crystal chemistry and stability of “Li7La3Zr2O12” garnet: a fast lithium-ion conductor. Inorg Chem 50(3):1089–1097

Rettenwander D, Geiger CA, Amthauer G (2013) Synthesis and crystal chemistry of the fast Li-ion conductor Li7La3Zr2O12 doped with Fe. Inorg Chem 52(14):8005–8009

Rettenwander D, Geiger CA, Tribus M et al (2014) A synthesis and crystal chemical study of the fast ion conductor Li7–3xGaxLa3Zr2O12 with x = 0.08 to 0.84. Inorg Chem 53(12):6264–6269

Abrha LH, Hagos TT, Nikodimos Y et al (2020) Dual-doped cubic garnet solid electrolytes with superior air stability. ACS Appl Mater Interfaces 12(23):25709–25717

Xia W, Xu B, Duan H, Guo Y, Kang H, Li H, Liu H (2016) Ionic conductivity and air stability of Al-doped Li7La3Zr2O12 sintered in alumina and Pt crucibles. ACS Appl Mater Interfaces 8(8):5335–5342

Luo YL, Li XY, Zhang YL et al (2018) Electrochemical properties and structural stability of Ga- and Y- co-doping in Li7La3Zr2O12 ceramic electrolytes for lithium-ion batteries. Electrochim Acta 294:217–225

Leo CJ, Subba Rao GV, Chowdari BVR (2003) Effect of MgO addition on the ionic conductivity of LiGe2(PO4)3 ceramics. Solid State Ion 159(3–4):357–367

Zhang Y, Meng JW, Chen KY et al (2020) Behind the candelabra: a facile flame vapor deposition method for interfacial engineering of garnet electrolyte to enable ultralong cycling solid-state Li-FeF3 conversion batteries. ACS Appl Mater Interfaces 12(30):33729–33739

Li YQ, Cao Y, Guo XX (2013) Influence of lithium oxide additives on densification and ionic conductivity of garnet-type Li6.75La3Zr1.75Ta0.25O12 solid electrolytes. Solid State Ion 253:76–80

Duan HN, Zheng HP, Zhou Y et al (2018) Stability of garnet-type Li ion conductors: an overview. Solid State Ion 318:45–53

Li YT, Xu BY, Xu HH et al (2017) Hybrid polymer/garnet electrolyte with a small interfacial resistance for lithium-ion batteries. Angew Chem Int Ed Engl 56(3):753–756

Xu BY, Li WL, Duan HN et al (2017) Li3PO4-added garnet-type Li6.5La3Zr1.5Ta0.5O12 for Li-dendrite suppression. J Power Sour 354:68–73

Prasada RR, Gu WY, Sharma N et al (2015) In situ neutron diffraction monitoring of Li7 La3 Zr2 O12 formation: toward a rational synthesis of garnet solid electrolytes. Chem Mater 27(8):2903–2910

Li YT, Chen X, Dolocan A et al (2018) Garnet electrolyte with an ultra-low interfacial resistance for Li-metal batteries. J Am Chem Soc 140(20):6448–6455

Wu JF, Pu BW, Wang D et al (2019) In situ formed shields enabling Li2CO3-free solid electrolytes: a new route to uncover the intrinsic lithiophilicity of garnet electrolytes for dendrite-free Li-metal batteries. ACS Appl Mater Interfaces 11(1):898–905

Cheng L, Liu M, Mehta A et al (2018) Garnet electrolyte surface degradation and recovery. ACS Appl Energy Mater 1(12):7244–7252

Cheng L, Chen W, Kunz M et al (2015) Effect of surface microstructure on electrochemical performance of garnet solid electrolytes. ACS Appl Mater Interfaces 7(3):2073–2081

Ruan YD, Lu Y, Huang X et al (2019) Acid induced conversion towards robust and lithiophilic interface for Li-Li7La3Zr2O12 solid-state battery. J Mater Chem A 7(24):14565–14574

Duan H, Chen WP, Fan M et al (2020) Building an air stable and lithium deposition regulable garnet interface from moderate-temperature conversion chemistry. Angew Chem Int Ed Engl 59(29):12069–12075

Zhang SS, Zhao HL, Wang J et al (2020) Enhanced densification and ionic conductivity of Li-garnet electrolyte: efficient Li2CO3 elimination and fast grain-boundary transport construction. Chem Eng J 393:124797

Zhang JX, Yu RH, Li J et al (2021) Transformation of undesired Li2CO3 into lithiophilic layer via double replacement reaction for garnet electrolyte engineering. Energy Environ Mater 5:962–968

Shen ZC, Cheng YF, Sun SH et al (2021) The critical role of inorganic nanofillers in solid polymer composite electrolyte for Li+ transportation. Carbon Energy 3:482–508

Chen H, Zheng MT, Qian SS et al (2021) Functional additives for solid polymer electrolytes in flexible and high-energy-density solid-state lithium-ion batteries. Carbon Energy 3:929–956

Huang ZY, Pang WY, Liang P et al (2019) A dopamine modified Li6.4La3Zr1.4Ta0.6O12/PEO solid-state electrolyte: enhanced thermal and electrochemical properties. J Mater Chem A 7(27):16425–16436

Su SM, Ma JB, Zhao L et al (2021) Progress and perspective of the cathode/electrolyte interface construction in all-solid-state lithium batteries. Carbon Energy 3(2):866–894

Mijung N, Lee Y, Cho J (2006) Water adsorption and storage characteristics of optimized LiCoO2 and LiNi1∕3Co1∕3Mn1∕3O2 composite cathode material for Li-ion cells. J Electrochem Soc 153(5):A935

Yang YN, Li YX, Li YQ et al (2020) On-surface lithium donor reaction enables decarbonated lithium garnets and compatible interfaces within cathodes. Nat Commun 11:5519

Meng JW, Zhang Y, Zhou XJ et al (2020) Li2CO3-affiliative mechanism for air-accessible interface engineering of garnet electrolyte via facile liquid metal painting. Nat Commun 11(1):3716

You Y, Celio H, Li JY et al (2018) Modified high-nickel cathodes with stable surface chemistry against ambient air for lithium-ion batteries. Angew Chem 130(22):6590–6595

Jung R, Morasch R, Karayaylali P et al (2018) Effect of ambient storage on the degradation of Ni-rich positive electrode materials (NMC811) for Li-ion batteries. J Electrochem Soc 165(2):A132–A141

Kong D, Hu J, Chen Z, Song K, Li C, Weng M, Pan F (2019) Ti-gradient doping to stabilize layered surface structure for high performance high-Ni oxide cathode of Li-ion battery. Adv Energy Mater 9(41):1901756

Xie Q, Li WD, Manthiram A (2019) A Mg-doped high-nickel layered oxide cathode enabling safer, high-energy-density Li-ion batteries. Chem Mater 31(3):938–946

Song BH, Li WD, Oh SM et al (2017) Long-life nickel-rich layered oxide cathodes with a uniform Li2ZrO3 surface coating for lithium-ion batteries. ACS Appl Mater Interfaces 9(11):9718–9725

Kim J, Lee J, Ma H et al (2018) Controllable solid electrolyte interphase in nickel-rich cathodes by an electrochemical rearrangement for stable lithium-ion batteries. Adv Mater 30(5):1704309

Xie Q, Manthiram A (2020) Long-life, ultrahigh-nickel cathodes with excellent air storage stability for high-energy density lithium-based batteries. Chem Mater 32:7413–7424

Guo JL, Cai YJ, Zhang SJ et al (2016) Core-shell structured o-LiMnO2@Li2CO3 nanosheet array cathode for high-performance, wide-temperature-tolerance lithium-ion batteries. ACS Appl Mater Interfaces 8(25):16116–16124

Tian N, Hua CX, Wang ZX et al (2015) Reversible reduction of Li2CO3. J Mater Chem A 3(27):14173–14177

Acknowledgements

The authors appreciate the support from the National Natural Science Foundation of China (Nos. U2001220 and 51902223), the Haihe Laboratory of Sustainable Chemical Transformations, the Fundamental Research Funds for the Central Universities, the National Key Research and Development Program of China (Nos. 2021YFF0500600 and 2019YFE0118800), and the Natural Science Foundation of Tianjin (No. 20JCYBJC00850).

Author information

Authors and Affiliations

Contributions

Shichao Wu and Quan-Hong Yang proposed the concept, Xuerui Yi and Yong Guo completed the manuscript. All authors participated in the interpretation of the results and discussions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yi, X., Guo, Y., Pan, S. et al. Duality of Li2CO3 in Solid-State Batteries. Trans. Tianjin Univ. 29, 73–87 (2023). https://doi.org/10.1007/s12209-022-00351-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-022-00351-w