Abstract

In this study, we developed a strategy for using the Scoggins procedure in the synthesis of acetamidines as novel CO2-triggered switchable surfactants via acetimidates by effectively tuning the chemical equilibrium. The as-synthesized N’-alkyl-N,N-diethylacetamidines exhibit excellent CO2/N2 switchability and their bicarbonate salts have the ability to emulsify oil–water mixtures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Surfactants, whose amphiphilic structures enable the stabilization of emulsions with two immiscible phases, are widely applied in many processes such as cleaning [1], viscous oil transportation [2], and enhancing oil recovery [3]. Excellent stabilization is required in these processes, usually followed by a subsequent emulsion-destabilization step to effectively recover the two immiscible phases. However, this remains a challenging task for most commonly used surfactants. To tackle this problem, it is necessary for the surfactants that can be “switched on and off” to reversibly stabilize/destabilize the emulsion under certain trigger conditions. The switchable surfactants reported in the literature can undergo reversible interconversions from surface-active to surface-inactive forms upon command, and their switchability can usually be triggered by altering the external conditions, such as pH [4], electrochemical redox [5], magnetic-field intensity [6], or light source (UV or visible light) [7]. Compared with these triggers, CO2 is environmentally benign, inexpensive, and renewable, and more important, it does not accumulate in a system after repeated cycles. Therefore, it has been identified as an innovative and ideal “trigger” for stimuli-responsive surfactants and has recently been studied for use in reversible solvents [8,9,10], switchable Pickering emulsions [11, 12], and repeatable polymer-based materials [13, 14], particularly for application in enhanced oil recovery [15, 16].

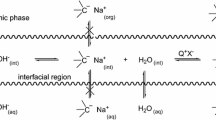

Thus far, the majority of CO2/N2 reversible surfactants include guanidines, imidazoles, tertiary amines, and amidines. In their inactive forms, these surfactants can be protonated to form charged bicarbonates that become active upon the addition of CO2 in aqueous media, increasing their solubility in water. The bicarbonate ions can then be deprotonated by bubbling with N2 or air [17]. However, these common CO2/N2 reversible surfactants have some inherent drawbacks that hinder their wide application. The headgroup of imidazole surfactants limits their triggering efficiency due to their hydrolysis in aqueous media [18]. Surfactants containing a hydrophilic headgroup of guanidine are generally basic and require more rigorous conditions to achieve deprotonation (such as high temperature, long reaction time, or heavy flow rate of bubbling gas) [19]. With respect to tertiary amines, their basicity is so weak that stable emulsions can hardly be formed [20]. As such, compounds containing an amidine head [21, 22] are attracting more attention due to their mild basicity and superior stability. In addition, the exceptional demulsifying ability of amidines in their neutral form is an unexpected advantage. Scheme 1 illustrates the protonation and deprotonation processes of amidines stimulated by CO2 and N2 (or air), respectively, in aqueous media, where R represents a long-chain alkyl or ethoxylated groups. Amidine surfactants can easily and reversibly transform into bicarbonate salts.

Amidines can be synthesized using various strategies, such as the nucleophilic addition of amines to nitriles [23], reaction of catalytic three-component coupling [24], displacement reaction of imidates with amines [25, 26], and the Scoggins procedure [27, 28]. Of these synthetic methods, the Scoggins procedure involving primary amines and N,N-dimethylacetamide dimethyl acetal can synthesize long-chain aliphatic amidines and aromatic amidines with a high yield of 90% accompanied by the formation of a small amount of imidates as a by-product [27, 28]. This is particularly attractive since an encouraging acetamidines yield of 99% was achieved by Jessop et al. [21] when they added an excess amount of dimethylamine to the reaction system. However, the types of amidines used in this synthesis method have been fairly limited thus far, due to the limitation of commercially available reactants. The structure of amidines generated by this method differed from those in the hydrophobic tail group, which are mainly long-chain alkyl or ethoxylated groups, or both [16, 21], and the hydrophilic head is bonded only with the dimethyl group.

As stated earlier, imidates were the only by-product of the Scoggins procedure. At the same time, the potent electrophilicity of imidates supports the synthesis of amidines through displacement reactions with amines. Therefore, imidates have potential for use in the synthesis of new CO2/N2 switchable amidines if various imidates can be generated as the main product by modifying the Scoggins procedure. We also believe it is important to gain insight into the reaction path of the Scoggins procedure to facilitate the development of this novel synthesis strategy. In this study, we mainly investigated the reaction path of the Scoggins procedure for use in developing a new approach for the synthesis of novel CO2/N2 switchable surfactants.

Experimental Section

Materials and Methods

To avoid light and moisture, we conducted all the reactions in the dark environment. We purchased N,N-dimethylacetamide dimethyl acetal (> 90%, stabilized by 5–10% methanol) and a series of primary amines (dodecylamine (AR) > 98%, tetradecylamine (AR) > 96%, hexadecylamine (AR) > 95%, octadecylamine (GC) > 98%) from Aladdin Reagent Company (Shanghai, China) without further purification. We prepared N’-dodecyl-N,N-dimethylacetamidine (1b) in experiments 1 and 2, as shown in Table 1, according to methods reported in Refs. [21, 28]. We recorded the proton nuclear magnetic resonance (1H NMR) and carbon-13 nuclear magnetic resonance (13C NMR) of the reaction products on a Varian Inova spectrometer (Varian, America, 500 MHz), for which all the chemical shift values refer to CDCl3 (δ(1H), 7.26 ppm; δ(13C), 77.16 ppm). We obtained high-resolution electrospray ionization mass spectrometry (ESI-HRMS) data on a Bruker micrOTOF-QII mass spectrometer (Bruker, America) and infrared (IR) spectra on a Nicolet Avatar 320 spectrometer (Thermo Fisher, America) with a smart miracle accessory.

General Procedure for the Synthesis of N-alkyl-O-Methylacetimidates

We put N,N-dimethylacetamide dimethyl acetal (1.72 g, 0.012 mol) and dodecyl amine (1.89 g, 0.01 mol) into a three-neck round-bottom brown flask in a dark environment and an oil bath, to which we then added methanol (40 mL). We kept this mixture at 68 °C for 2 h with a methanol reflux in the condenser. To determine when the conversion of the dodecylamine was complete, we used the thin-layer chromatography method (Merck TLC plates, silica gel 60 F254, with chloroform and methanol as developing solvents, VCHCl3/VCH3OH = 3:1). Then, we removed the methanol and dimethylamine from the reaction mixture by rotary evaporation at 50 °C and − 0.1 MPa for 20 min, obtaining a light-yellow liquid product consisting of N-dodecyl-O-methylacetimidate (1a, 71.7% yield) and N’-dodecyl-N,N-dimethylacetamidine (1b, 28.3% yield). We calculated the yield based on its 1H NMR spectrum. Then, we subjected the resulting mixture to flash column chromatography on aluminum oxide (active, neutral, 200–300 mesh) using ethyl acetate and dichloromethane (VCH3COOCH2CH3/VCH2Cl2 = 1:2) as mobile phases to obtain purified N-dodecyl-O-methylacetimidate (1a) as a colorless liquid. We also synthesized other N-alkyl-O-methylacetimidates, including N-tetradecyl-O-methylacetimidate (2a), N-hexadecyl-O-methylacetimidate (3a), and N-octadecyl-O-methylacetimidate (4a), by the same method, using different primary amines as the reactants, i.e., tetradecylamine (0.22 g), hexadecylamine (0.25 g), and octadecylamine (0.28 g), respectively.

N-dodecyl-O-methylacetimidate (1a): Colorless oil, 1H NMR (500 MHz, CDCl3) δ = 7.27 (s, 1H), 3.60 (s, 3H), 3.18 (t, 2H), 1.86 (s, 3H), 1.54–1.49 (m, 2H), 1.33–1.26 (m, 18H), 0.88 (t, 3H); 13C NMR (125 MHz, CDCl3) δ = 161.10, 77.67–76.74, 52.07, 49.40, 32.13, 31.74, 29.90, 29.87, 29.86, 29.77, 29.57, 27.54, 22.89, 14.59, 14.28; HRMS m/z (ESI) calcd for C15H31NO (M + H)+ 242.2478, found 242.2512. IR absorption W–N=C– at 1685.48 cm−1, W–C–O–C– at 1253.50 cm−1.

N-tetradecyl-O-methylacetimidate (2a): Colorless oil, 1H NMR (500 MHz, CDCl3) δ = 7.27 (s, 1H), 3.60 (s, 3H), 3.18 (t, 2H), 1.86 (s, 3H), 1.55–1.49 (m, 2H), 1.30–1.26 (m, 22H), 0.88 (t, 3H); 13C NMR (125 MHz, CDCl3) δ = 161.02, 77.67–76.74, 52.07, 49.50, 32.04, 31.57, 29.81, 29.78, 29.68, 29.49, 27.51, 22.79, 14.47, 14.17; HRMS m/z (ESI) calcd for C17H35NO (M + H)+ 270.2791, found 270.2811; IR absorption W–C=N– at 1685.48 cm−1, W–C–O–C– at 1253.50 cm−1.

N-hexadecyl-O-methylacetimidate (3a): Colorless oil, 1H NMR (500 MHz, CDCl3) δ = 7.27 (s, 1H), 3.60 (s, 3H), 3.17 (t, 2H), 1.86 (s, 3H), 1.59–1.49 (m, 2H), 1.30–1.26 (m, 26H), 0.88 (t, 3H); 13C NMR (125 MHz, CDCl3) δ = 161.17, 77.67–76.74, 52.21, 49.53, 32.16, 31.68, 29.94, 29.90, 29.89, 29.79, 29.61, 27.63, 22.91, 14.63, 14.30; HRMS m/z (ESI) calcd for C19H39NO (M + H)+ 298.3104, found 298.3128; IR absorption W–C=N– at 1685.48 cm−1, W–C–O–C– at 1253.50 cm−1.

N-octadecyl-O-methylacetimidate (4a): Colorless oil, 1H NMR (500 MHz, CDCl3) δ = 7.27 (s, 1H), 3.58 (s, 3H), 3.17 (t, 2H), 1.85 (s, 3H), 1.54–1.49 (m, 2H), 1.30–1.25 (m, 30H), 0.88 (t, 3H); 13C NMR (125 MHz, CDCl3) δ = 161.01, 77.67–76.74, 52.14, 49.51, 32.16, 31.71, 29.94, 29.90, 29.79, 29.61, 27.63, 22.91, 14.56, 14.28; HRMS m/z (ESI) calcd for C21H43NO (M + H)+ 326.3417, found 326.3444; IR absorption W–C=N– at 1685.48 cm−1, W–C–O–C– at 1253.50 cm−1.

General Procedure for Reaction Pathway Studies Using 1H NMR

Experimental Process for the Results Shown in Fig. 1

We added N,N-dimethylacetamide dimethyl acetal (1.72 g) and dodecyl amine (1.89 g) to a three-neck round-bottom brown flask in a dark environment, to which we added 40 mL of methanol. Then we maintained the mixture at 68 °C for 2 h by controlling the temperature of the oil bath with a methanol reflux in the condenser. We extracted 1 mL samples at intervals and immediately transferred them into an ice bath. Then, we removed the methanol and dimethylamine from the samples using a rotary evaporator at 10 °C and − 0.1 MPa. The remaining product was a mixture of N-dodecyl-O-methylacetimidate (1a) and N’-dodecyl-N,N-dimethylacetamidine (1b). Based on their 1H NMR spectra, we calculated the selectivities of 1a and 1b at different reaction times.

Experimental Process for the Results Shown in Fig. 2

First, we prepared a certain amount of purified N’-dodecyl-N,N-dimethylacetamidine (1b) using the method developed by Jessop et al. [21]. We added about 0.012 mol of N,N-dimethylacetamide dimethyl acetal (1.72 g) and 76.4 mmol of Me2NH (38 mL, 2 mol/L solution in tetrahydrofuran) into a three-neck round-bottom brown flask and stirred the mixture (100 r/min) at 25 °C. After that, we added about 0.01 mol dodecylamine (1.89 g) dropwise to this mixture at room temperature, stirred it for 10 min, and then left it for 18 h in the dark. To remove most of the tetrahydrofuran and Me2NH, we kept the mixture at 55 °C and − 0.1 MPa in a rotary evaporator for 8 h, which yielded a yellow liquid consisting of N’-dodecyl-N,N-dimethylacetamidine (1b, yield = 97.6%) and a trace impurity of N-dodecyl-O-methylacetimidate (1a, yield = 2.4%), which we identified based on its 1H NMR spectrum. We then reacted the above product (2.54 g) with methanol (40 mL) in a three-neck round-bottom brown flask with a condenser and thermometer and kept this mixture at 68 °C for 2 h. We extracted 1 mL samples at intervals, which we immediately transferred into an ice bath. Then, we removed the methanol and dimethylamine from the samples using a rotary evaporator at 10 °C and −0.1 MPa. By 1H NMR, we identified the remaining product as a mixture of N-dodecyl-O-methylacetimidate (1a) and N’-dodecyl-N,N-dimethylacetamidine (1b). Based on their 1H NMR spectra, we calculated the normalized concentrations of 1a and 1b at different reaction times.

General Synthesis of N’-Alkyl-N,N-Diethylacetamidines

We obtained purified N-hexadecyl-O-methylacetimidate (3a) and N-octadecyl-O-methylacetimidate (4a) by the method described above in section “General Procedure for the Synthesis of N-alkyl-O-Methylacetimidates”. We put the obtained N-hexadecyl-O-methylacetimidate (1.48 g, 0.005 mol) into a three-neck round-bottom brown flask and reacted it with diethylamine (7.31 g, 0.1 mol) in the solvents triethylamine (20 mL) and dioxane (30 mL) at 85 °C (reaction temperature) for 36 h. After the reaction, we removed the volatile components from the mixture, including diethylamine and the solvents triethylamine and dioxane, using a rotary evaporator at 60 °C and −0.1 MPa for 30 min, obtaining N’-hexadecyl-N,N-diethylacetamidine (3c, 60.5% yield) as a yellow liquid. We also synthesized N’-octadecyl-N,N-diethylacetamidine (4c, 53.7% yield) by the same method, using 1.63 g N-octadecyl-O-methylacetimidate (0.005 mol) as the reactant.

N’-hexadecyl-N,N-diethylacetamidine (3c): Yellow oil, 1H NMR (500 MHz, CDCl3) δ = 7.27 (s, 1H), 3.29 (q, 4H), 3.17 (t, 2H), 1.87 (s, 3H), 1.52–1.47 (m, 2H), 1.30–1.26 (m, 26H), 1.08 (t, 6H), 0.88 (t, 3H); 13C NMR (125 MHz, CDCl3) δ = 156.57, 49.73, 41.68, 32.31, 31.46, 29.68–27.38, 22.65, 14.34, 14.04, 13.67; HRMS m/z (ESI) calcd for C22H46NO (M + H)+ 339.3733, found 339.3752; IR absorption W–N=C–N– at 1620.76 cm−1.

N’-octadecyl-N,N-diethylacetamidine (4c): Yellow oil, 1H NMR (500 MHz, CDCl3) δ = 7.27 (s, 1H), 3.29 (q, 4H), 3.17 (t, 2H), 1.88 (s, 3H), 1.53–1.48 (m, 2H), 1.30–1.26 (m, 30H), 1.08 (t, 6H), 0.88 (t, 3H); 13C NMR (125 MHz, CDCl3) δ = 156.55, 49.77, 41.63, 32.32, 31.89, 29.67– 26.94, 22.64, 14.34, 14.03, 13.67; HRMS m/z (ESI) calcd for C22H46NO (M + H)+ 367.4046, found 367.4064; IR absorption W–N=C–N– at 1621.46 cm−1.

General Procedure for the Switchable Characterization Tests on N’-Octadecyl-N,N-Diethylacetamidine

We determined the conductivity of the solution bubbled by CO2 or N2 using a DDSJ-308F conductivity meter (Shanghai Leici, China) and controlled the gas-flow rate using a mass flow controller (Beijing Shengye, China). We bubbled the solution of DMSO and water (VDMSO/Vwater = 45 mL/5 mL) with N’-octadecyl-N,N-diethylacetamidine (4c, 0.22 g) by CO2, followed by N2 at 65 °C, during which we recorded the conductivity. We obtained four reversible cycles by bubbling CO2 (400 mL/min) for 40 min and then N2 (800 mL/min) for 40 min. We also determined the conductivity of the solution containing purified N-octadecyl-O-methylacetimidate (4a, 0.08 g) using the same method as that in the blank experiment. We examined the capability of stabilizing an emulsion by mixing dodecane and water (5 mL, v/v = 1:1) containing N’-octadecyl-N,N-diethylacetamidine (4c, 0.022 g) and observed the state of the oil–water emulsion layers formed by the bubbling CO2 at different stages.

Results and Discussion

Consecutive Reactions of Scoggins Procedure in the Presence of Excess Methanol

To effectively regulate product distribution in the Scoggins procedure, we conducted this reaction by varying the organic additives. Table 1 summarizes the reaction results based on the 1H NMR characterization. Compared with the results (Fig. S2) obtained in experiment 1 using the Oszczapowicz’ method [28] without any additives, we obtained a high N’-dodecyl-N,N-dimethylacetamidine (1b) yield of about 97.6% (Fig. S3) when using NH(CH3)2 as the additive, as developed by the Jessop et al. [21]. It seems that NH(CH3)2 can inhibit the formation of N-dodecyl-O-methylacetimidate. Interestingly, the addition of methanol (experiment 3) led to a dramatic decrease in the yield of 1b, which represents only 28.3% of the total conversion of dodecylamine, whereas we found 1a to be the only by-product with a yield of 71.7% (Fig. S4). This remarkable decline in the acetamidine yield and the formation of such a large amount of acetimidate demonstrates that the presence of methanol may control the product distribution to a great extent.

To further understand the reaction path of the Scoggins procedure in the presence of excess methanol, we designed an experiment (experiment 3), in which we performed interval sampling during the reaction process to obtain a detailed product distribution as a function of the reaction time. We used 1H NMR to analyze the relative selectivity of acetamidine and acetimidate during the reaction. Figure 1 shows plots of the evolution of the selectivities of 1a and 1b versus reaction time. In Fig. 1, we can see that the selectivity of 1b increases rapidly to its peak within 2 min and then decreases slowly until reaching a constant selectivity of 28.1%, whereas the selectivity of 1a increases gradually until reaching 71.9% at 120 min. These results indicate that the process is likely a consecutive reaction, in which 1b is easily formed as an intermediate in the first step and then reacts with methanol to generate 1a in the second step. The fact that 1b is readily generated in this reaction may be due to a bimolecular nucleophilic substitution reaction (SN2) between N,N-dimethylacetamide dimethyl acetal with high electrophilicity and the nucleophilic reagent dodecylamine. This reaction may be constrained by a thermodynamic equilibrium, in which the excess methanol in the mixture promotes the generation of acetimidates.

To better confirm the consecutive reaction pathway of this reaction system, we performed a reaction between 1b (synthesized during experiment 2 in advance) and methanol. Using 1H NMR analysis, we identified only 1a and 1b in the resulting mixture by after removing the volatile phase from the samples in high vacuum conditions. Figure 2 shows the normalized concentrations of 1a and 1b in the samples as a function of reaction time. We can see that the normalized concentration of 1b significantly decreases with reaction time, reaching a constant value of about 28.3% after about 90 min. The normalized concentration of 1a shows the opposite trend at first and ultimately remains constant at 71.7%. The time required to reach the equilibrium concentration is about 90 min, which is shorter than that of the Scoggins procedure (120 min) in the conditions described above. These results indicate that 1a is generated from the reaction between 1b and methanol, thereby providing further evidence that the Scoggins procedure involves a consecutive reaction. In addition, the higher selectivity of 1b at the beginning stage of the Scoggins procedure and the lower equilibrium yield of 1b due to the limiting effect of the thermodynamic equilibrium prove that the reaction of 1b with methanol in the second step is the control step for the formation of 1a.

Based on the above findings, we successfully synthesized a class of N-alkyl-O-methylacetimidates (A, Fig. S1) by enhancing the Scoggins procedure with the excess methanol (using the same reaction conditions as experiment 3 in Table 1). As listed in Table 2, all the yields of A are around 70% (Figs. S4–S7), which means that all these reactions reach roughly the same level of equilibrium regardless of the different hydrophobic groups of the primary amines. Next, we purified a series of product A to colorless liquids using flash column chromatography with Al2O3 as the stationary phase and ethyl acetate/hexane (v/v, 2:3) as the eluent. We then confirmed the resulting structures by HRMS (Figs. S8–S11), 1H NMR (Figs. S14, S17, S20, S23), 13C NMR (Figs. S15, S18, S21, S24), and IR spectroscopy (Figs. S32–S35). Taking into consideration the characteristic of the equilibrium reaction, these acetimidates might have potential for use as precursors in the preparation of novel acetamidines via reactions with different primary or secondary amines.

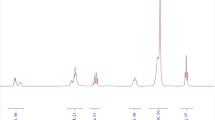

Synthesis of Novel Acetamidines via Acetimidates

To verify the feasibility of generating new acetamidines from acetimidates, we performed a series of reactions between purified A and NH(CH2CH3)2. As expected, we successfully produced two N’-alkyl-N,N-diethylacetamidines (C) with a diethyl group linked to the amidine group for the first time via a displacement reaction (Table 3) with an extremely high selectivity of nearly 100%. We confirmed the structures of N’-hexadecyl-N,N-diethylacetamidine (3c) and N’-octadecyl-N,N-diethylacetamidine (4c) by HRMS (Figs. S12, S13), 1H NMR (Figs. S26, S29), 13C NMR (Figs. S27, S30) and IR spectroscopy (Figs. S36, S37). The quartets at δH = 3.29 in the 1H NMR spectra and at δC = 41.68 in the 13C NMR spectra indicate methylene in the -N(CH2CH3)2 group. We also detected solution peaks of trace 1,4-dioxane at δH = 3.70 and δC = 67.03 [30]. This strategy opens a new possible way to design and efficiently synthesize novel acetamidines with various terminal alkyl groups by simply replacing NH(CH2CH3)2 with other dialkylamines.

CO2-Triggered Switchable Characterization of Novel Acetamidines

Next, we examined the CO2/N2 switchability of N’-octadecyl-N,N-diethylacetamidine by monitoring the conductivity in wet dimethyl sulfoxide. As shown in Fig. 3, N’-octadecyl-N,N-diethylacetamidine (4c) exhibited excellent switchability when CO2 and then N2 were bubbled through the solution over four cycles, which indicates the reversible transformation between neutral amidine and bicarbonate ions. We also examined the capability of N’-octadecyl-N,N-diethylacetamidine bicarbonates salts to stabilize an emulsion by mixing dodecane and water containing 4c. As shown in Fig. 4, the two immiscible phases became a homogeneous emulsion after the bubbling of CO2. When kept at room temperature for 12 h, the emulsion volume still accounted for about 90% of the oil–water system, including a thin cloudy liquid at the bottom of the measurement cylinder (Fig. 4c). Then, bubbling N2 rapidly breaks the emulsion into two separate phases (Fig. 4d). The conductivity and emulsification tests containing only 4a evidenced that the rest of 4a had little effect and can be ignored. These results demonstrate that the synthesized N’-alkyl-N,N-diethylacetamidines have CO2/N2 switchability in the emulsification and demulsification of the oil–water system.

Conductivity of wet DMSO solution containing 4c and purified 4a as a function of time during four cycles of treatment with CO2 followed by N2. Conditions: T = 65 °C, VDMSO/Vwater = 45 mL/5 mL, FCO2 = 400 mL/min, 40 min, FN2 = 800 mL/min, 40 min; 4c: 0.22 g/50 mL; 4a: 0.08 g/50 mL (as blank experiment)

Photographs of dodecane/water system (5 mL, v/v = 1:1) containing 4c (0.022 g) at different stages. a Sample a after shaking for 5 min without CO2 at 25 °C; b sample b bubbled with CO2 at 25 °C; c sample c standing for 12 h at 25 °C; d sample d bubbled with N2 for 30 min at 45 °C; e dodecane/water containing 4a (0.011 g) after bubbling CO2 for 5 min at 25 °C

Conclusions

In conclusion, in this study, we developed a new approach for synthesizing CO2-triggered switchable surfactants by the reaction between amines and imidates, produced using an enhanced Scoggins procedure. This reaction process consists of two reactions in a series, and the yield of acetimidates can be significantly improved by shifting the reaction equilibrium using excess methanol as an additive. This method provides an effective route for synthesizing varieties of CO2/N2 switchable acetamidines with the desired functional groups bonded to the amidine group.

References

Behera MR, Varade SR, Ghosh P et al (2014) Foaming in micellar solutions: effects of surfactant, salt, and oil concentrations. Ind Eng Chem Res 53(48):18497–18507

Huang C, Karimi IA (2006) Scheduling tanker-lightering operations in crude oil transportation. Ind Eng Chem Res 45(24):8063–8082

Sharma T, Iglauer S, Sangwai JS (2016) Silica nanofluids in an oilfield polymer polyacrylamide: interfacial properties, wettability alteration and applications for chemical enhanced oil recovery. Ind Eng Chem Res 55(48):12387–12397

Ren G, Wang L, Chen Q et al (2017) PH switchable emulsions based on dynamic covalent surfactants. Langmuir 33(12):3040–3046

Feng A, Peng L, Liu B et al (2016) Electrochemical redox switchable dispersion of single-walled carbon nanotubes in water. ACS Appl Mater Interfaces 8(17):11024–11030

Melle S, Lask M, Fuller GG (2005) Pickering emulsions with controllable stability. Langmuir 21(6):2158–2162

Li L, Rosenthal M, Zhang H et al (2012) Light-switchable vesicles from liquid-crystalline homopolymer-surfactant complexes. Angew Chem Int Ed 51(46):11616–11619

Jessop PG, Mercer SM, Heldebrant DJ (2012) CO2-triggered switchable solvents, surfactants, and other materials. Energy Environ Sci 5(6):7240–7253

Jessop PG, Heldebrant DJ, Li X et al (2005) Green chemistry: reversible nonpolar-to-polar solvent. Nature 436(7054):1102

Samorì C, Cespi D, Blair P et al (2017) Application of switchable hydrophilicity solvents for recycling multilayer packaging materials. Green Chem 19(7):1714–1720

Jiang J, Zhu Y, Cui Z et al (2013) Switchable pickering emulsions stabilized by silica nanoparticles hydrophobized in situ with a switchable surfactant. Angew Chem Int Ed Engl 52(47):12373–12376

Jiang J, Ma Y, Cui Z et al (2016) Pickering emulsions responsive to CO2/N2 and light dual stimuli at ambient temperature. Langmuir 32(34):8668–8675

Darabi A, Jessop PG, Cunningham MF (2016) CO2-responsive polymeric materials: synthesis, self-assembly, and functional applications. Chem Soc Rev 45(15):4391–4436

Su X, Jessop PG, Cunningham MF (2017) Preparing artificial latexes using a switchable hydrophilicity solvent. Green Chem 19(8):1889–1894

Liu Y, Jessop PG, Cunningham M et al (2006) Switchable surfactants. Science 313(5789):958–960

Liang C, Harjani JR, Robert T et al (2012) Use of CO2-triggered switchable surfactants for the stabilization of oil-in-water emulsions. Energy Fuels 26(1):488–494

Arthur T, Harjani JR, Phan L et al (2012) Effects-driven chemical design: the acute toxicity of CO2-triggered switchable surfactants to rainbow trout can be predicted from octanol-water partition coefficients. Green Chem 14(2):357–362

Qiao W, Zheng Z, Shi Q (2012) Synthesis and properties of a series of CO2 switchable surfactants with imidazoline group. J Surfactants Deterg 15(5):533–539

Fowler CI, Jessop PG, Cunningham MF (2012) Aryl amidine and tertiary amine switchable surfactants and their application in the emulsion polymerization of methyl methacrylate. Macromolecules 45(7):2955–2962

Zhang Y, Guo S, Wu W et al (2016) CO2-triggered pickering emulsion based on silica nanoparticles and tertiary amine with long hydrophobic tails. Langmuir 32(45):11861–11867

Harjani JR, Liang C, Jessop PG (2011) A synthesis of acetamidines. J Org Chem 76(6):1683–1691

Cunningham MF, Jessop PG, Darabi A et al (2016) In carbon dioxide switchable polymers and processes in polymer reaction engineering. Macromol Symp 370(1):92–98

Veer SD, Katkar KV, Akamanchi KG (2016) Sulfated tungstate catalyzed activation of nitriles: addition of amines to nitriles for synthesis of amidines. Tetrahedron Lett 57(36):4039–4043

Bae I, Han H, Chang S (2005) Highly efficient one-pot synthesis of N-sulfonylamidines by Cu-catalyzed three-component coupling of sulfonyl azide, alkyne, and amine. J Am Chem Soc 127(7):2038–2039

Patai S, Rappoport Z (1975) The chemistry of amidines and imidates. Wiley, New York, pp 363–364

Caron S, Wei L, Douville J et al (2010) Preparation and utility of trihaloethyl imidates: useful reagents for the synthesis of amidines. J Org Chem 75(3):945–947

Scoggins MW (1975) A rapid gas chromatographic analysis of diastereomeric diamines. J Chromatogr Sci 13(3):146–148

Oszczapowicz J, Raczyńska E (1984) Amidines. Part 13. Influence of substitution at imino nitrogen atom on pK a values of N 1 N 1-dimethylacetamidines. J Chem Soc Perkin Trans 2(10):1643–1646

Åke P, Alf R, Kurt T (1969) Preparation and properties of N-monoalkylated imidic esters. Acta Chem Scand 23(3):818–824

Fulmer GR, Miller AJM, Sherden NH et al (2010) NMR chemical shifts of trace impurities: common laboratory solvents, organics, and gases in deuterated solvents relevant to the organometallic chemist. Organometallics 29(9):2176–2179

Acknowledgements

This study was supported by the China National Petroleum Corporation (RIPED-2017-JS-87).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Xu, Y., Wang, F., Hou, Q. et al. Strategy for Synthesizing Novel Acetamidines as CO2-Triggered Switchable Surfactants via Acetimidates. Trans. Tianjin Univ. 25, 237–244 (2019). https://doi.org/10.1007/s12209-018-0169-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-018-0169-z