Abstract

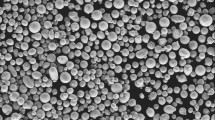

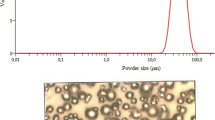

In this study, the effects of process parameters on the high temperature strength of 17-4PH stainless steel manufactured by selective laser melting (SLM) were investigated. Nine rectangular block specimens were fabricated with various process parameters. Small punch (SP) tests were conducted at 425 °C four times for each rectangular block specimens. The average maximum SP loads were measured from the tests. The fracture surfaces of SP-tested specimens were also examined. Un-melted powder was observed on the fracture surface of the specimen with the lowest average maximum SP load value, which could give rise to local cracking. Analysis of the microstructures showed that the retained austenite and amount of pore defects were the main factors that could affect SP test results. Regression surface methodology (RSM) models was applied to predict the maximum strength as a function of laser scan speed and energy density. Results showed that the energy density level of 64.29 J/mm3 and a scan speed higher than 1884 mm/s are recommended for fabricating SLM parts in the shortest time without losing material strength and with minimum metallurgical defects.

Similar content being viewed by others

Abbreviations

- P SP :

-

Maximum small punch load

- V :

-

Scan speed

- E :

-

Energy density

- a :

-

Small punch specimen thickness

- p :

-

Laser power

- d :

-

Hatching distance

- e :

-

Layer thickness

References

H. K. Rafi, D. Pal, N. Patil, T. L. Starr and B. E. Stucker, Micro-structure and mechanical behavior of 17-4 precipitation hardenable steel processed by selective laser melting, Journal of Materials Engineering and Performance, 23(12) (2014) 4421–4428.

G. Casalino, S. L. Campanelli, N. Contuzzi and A. D. Ludovico, Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel, Optics & Laser Technology, 65 (2015) 151–158.

N. Read, W. Wang, K. Essa and M. M. Attallah, Selective laser melting of AlSi10Mg alloy: process optimisation and mechanical properties development, Materials & Design, 65 (2015) 417–424.

S. Pasebani, M. Ghayoor, S. Badwe, H. Irrinki and S. V. Atre, Effects of atomizing media and post processing on mechanical properties of 17-4 PH stainless steel manufactured via selective laser melting, Additive Manufacturing, 22 (2018) 127–137.

K. N. Amato, S. M. Gaytan, L. E. Murr, E. Martinez, P. W. Shindo, J. Hernandez and F. Medina, Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting, Acta Materialia, 60(5) (2012) 2229–2239.

M. J. K. Lodhi, K. M. Deen, M. C. Greenlee-Wacker and W. Haider, Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications, Additive Manufacturing, 27 (2019) 8–19.

H. Zhang, H. Zhu, T. Qi, Z. Hu and X. Zeng, Selective laser melting of high strength Al-Cu-Mg alloys: processing, micro-structure and mechanical properties, Materials Science and Engineering: A, 656 (2016) 47–54.

R. Li, Y. S. Kim, H. Van Tho, Y. J. Yum, W. J. Kim and S. Y. Yang, Additive manufacturing (AM) of piercing punches by the PBF method of metal 3D printing using mold steel powder materials, Journal of Mechanical Science and Technology, 33(2) (2019) 809–817.

G. Miranda, S. Faria, F. Bartolomeu, E. Pinto, S. Madeira, A. Mateus and O. Carvalho, Predictive models for physical and mechanical properties of 316L stainless steel produced by selective laser melting, Materials Science and Engineering: A, 657 (2016) 43–56.

A. Yadollahi, N. Shamsaei, S. M. Thompson and D. W. Seely, Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel, Materials Science and Engineering: A, 644 (2015) 171–183.

L. E. Murr, E. Martinez, J. Hernandez, S. Collins, K. N. Amato, S. M. Gaytan and P. W. Shindo, Microstructures and properties of 17-4 PH stainless steel fabricated by selective laser melting, Journal of Materials Research and Technology, 1(3) (2012) 167–177.

L. Facchini, N. Vicente, I. Lonardelli, E. Magalini, P. Robotti and A. Molinari, Metastable austenite in 17-4 precipitation — hardening stainless steel produced by selective laser melting, Advanced Engineering Materials, 12(3) (2010) 184–188.

A. Yadollahi, N. Shamsaei, S. M. Thompson, A. Elwany and L. Bian, Mechanical and microstructural properties of selective laser melted 17-4 PH stainless steel, ASME 2015 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers (2015).

A. Yadollahi, N. Shamsaei, S. M. Thompson, A. Elwany and L. Bian, Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel, International Journal of Fatigue, 94 (2017) 218–235.

D. Croccolo, M. De Agostinis, S. Fini, G. Olmi, N. Bogojevic and S. Ciric-Kostic, Effects of build orientation and thickness of allowance on the fatigue behaviour of 15-5 PH stainless steel manufactured by DMLS, Fatigue & Fracture of Engineering Materials & Structures, 41 (2018) 900–916.

P. Edwards and M. Ramulu, Effect of build direction on the fracture toughness and fatigue crack growth in selective laser melted Ti — 6Al — 4 V, Fatigue & Fracture of Engineering Materials & Structures, 38 (2015) 1228–1236.

Z. Hu, H. Zhu, H. Zhang and X. Zeng, Experimental investigation on selective laser melting of 17-4PH stainless steel, Optics & Laser Technology, 87 (2017) 17–25.

H. Gu, H. Gong, D. Pal, K. Rafi, T. Starr and B. Stucker, Influences of energy density on porosity and microstructure of selective laser melted 17-4PH stainless steel, 2013 Solid Freeform Fabrication Symposium, 474 (2013).

A. A. Adeyemi, E. T. Akinlabi, R. M. Mahamood, K. O. Sanusi, S. Pityana and M. Tlotleng, Influence of laser power on microstructure of laser metal deposited 17-4 ph stainless steel, IOP Conference Series: Materials Science and Engineering, IOP Publishing, 225 (1) (2017).

P. Ponnusamy, S. H. Masood, D. Ruan, S. Palanisamy, R. R. Rashid and O. A. Mohamed, Mechanical performance of selective laser melted 17-4 PH stainless steel under compressive loading, Solid Freeform Fabrication 2017: Proceedings (2017) 321–331.

S. L. M. Solutions, SLM Material Data, http://www.slm-solutions.com (2012).

M. P. Manahan, A. S. Argon and O. K. Harling, The development of a miniaturized disk bend test for the determination of postirradiation mechanical properties, Journal of Nuclear Materials, 104 (1981) 1545–1550.

T. Misawa, T. Adachi, M. Saito and Y. Hamaguchi, Small punch tests for evaluating ductile-brittle transition behavior of irradiated ferritic steels, Journal of Nuclear Materials, 150(2) (1987) 194–202.

CEN, CWA 15627 Workshop Agreement: Small Punch Test Method for Metallic Materials, European Committee for Standardisation (2006).

Y. W. Ma and K. B. Yoon, Assessment of tensile strength using small punch test for transversely isotropic aluminum 2024 alloy produced by equal channel angular pressing, Materials Science and Engineering: A, 527(16–17) (2010) 3630–3638.

Z. X. Wang, H. J. Shi, J. Lu, P. Shi and X. F. Ma, Small punch testing for assessing the fracture properties of the reactor vessel steel with different thicknesses, Nuclear Engineering and Design, 238(12) (2008) 3186–3193.

P. Dymáček and K. Milička, Creep small-punch testing and its numerical simulations, Materials Science and Engineering: A, 510 (2009) 444–449.

Y. W. Ma, S. Shim and K. B. Yoon, Assessment of power law creep constants of Gr91 steel using small punch creep tests, Fatigue & Fracture of Engineering Materials & Structures, 32(12) (2009) 951–960.

P. B. Bacchewar, S. K. Singhal and P. M. Pandey, Statistical modelling and optimization of surface roughness in the selective laser sintering process, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 221(1) (2007) 35–52.

L. N. Carter, Selective laser melting of nickel superalloys for high temperature applications, Doctoral Dissertation, University of Birmingham (2013).

I. I. Cuesta and J. M. Alegre, Hardening evaluation of stamped aluminium alloy components using the small punch test, Engineering Failure Analysis, 26 (2012) 240–246.

S. P. Singh, S. Bhattacharya and D. K. Sehgal, Evaluation of high temperature mechanical strength of Cr-Mo grade steel through small punch test technique, Engineering Failure Analysis, 39 (2014) 207–220.

D. H. Lee, Evaluation of fracture strength and material degradation for weldment of high temperature service steel using advanced small punch test, KSME International Journal, 18(9) (2004) 1604–1613.

W. D. Callister, Material Science and Engineering an Introduction, New York: John Wiley & Sons Inc. (1994).

C. T. Kwok, K. I. Leong, F. T. Cheng and H. C. Man, Micro-structural and corrosion characteristics of laser surface-melted plastics mold steels, Materials Science and Engineering: A, 357(1–2) (2003) 94–103.

R. Li, J. Liu, Y. Shi, L. Wang and W. Jiang, Balling behavior of stainless steel and nickel powder during selective laser melting process, Journal of Advanced Manufacturing Technology, 59(9–12) (2012) 1025–1035.

Acknowledgments

This research was supported by Chung-Ang University Research Grants in 2020. Authors are appreciate technical support from the KMTL (Kobe Material Testing Laboratory Co).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Chongdu Cho

Ho Jun Lee received his M.S. in Mechanical Engineering from Chung-Ang University. He is currently a project researcher at KEIT (Korea Evaluation Institute of Industrial Technology). His research interests are hydrogen embrittlement and associated meatallurgical damage. He is also interested in high temperature strength and other mechanical properties of additive manufactured materials.

Van Hung Dao received his M.S. and Ph.D. degrees in Mechanical Engineering from Chung-Ang University. He is currently a postdoctoral fellow at Chung-Ang University. His research interests are microstructural analysis and application of high temperature fracture mechanics to life assessment of structural material. He is extending research to behavior of additive manufactured materials.

Young Wha Ma received his Ph.D. degree in Mechanical Engineering from Chung-Ang University, Korea in 2007. After that, he worked at Georgia Institute of Technology, U.S.A. as a postdoc. Dr. Ma is currently Senior Engineer at Doosan Heavy Industries & Construction Co. His research interests are application of high temperature fracture mechanics to residual life assessment of structural materials including anisotropic materials such as gas turbine blade.

Jong Min Yu received his M.S. in Mechanical Engineering from Chung-Ang University. He is currently a Ph.D. candidate in Chung-Ang University. His research interest is life and integrity assessment of facilities in power and process plants. He is currently involved in the study on mechanical properties of additive manufactured components with various process parameters.

Kee Bong Yoon received his B.S. in Mechanical Engineering from Seoul National University, M.S. from KAIST and Ph.D. from Georgia Institute of Technology. He is currently a Professor at Chung-Ang University. His research interests are high temperature fracture and risk based management of energy plants and semiconductor plants. He has particular interest in failures of the facilities in semiconductor companies. He is extending his research to fracture of additive manufactured materials.

Rights and permissions

About this article

Cite this article

Lee, H.J., Dao, V.H., Ma, Y.W. et al. Effects of process parameters on the high temperature strength of 17-4PH stainless steel produced by selective laser melting. J Mech Sci Technol 34, 3261–3272 (2020). https://doi.org/10.1007/s12206-020-0718-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0718-y