Abstract

Two-dimensional (2D) transition metal dichalcogenides (TMDs) have attracted extensive attention due to their unique electronic and optical properties. In particular, TMDs can be flexibly combined to form diverse vertical van der Waals (vdWs) heterostructures without the limitation of lattice matching, which creates vast opportunities for fundamental investigation of novel optoelectronic applications. Here, we report an atomically thin vertical p–n junction WSe2/MoS2 produced by a chemical vapor deposition method. Transmission electron microscopy and steady-state photoluminescence experiments reveal its high quality and excellent optical properties. Back gate field effect transistor (FET) constructed using this p–n junction exhibits bipolar behaviors and a mobility of 9 cm2/(V·s). In addition, the photodetector based on MoS2/WSe2 heterostructures displays outstanding optoelectronic properties (R = 8 A/W, D* = 2.93 × 1011 Jones, on/off ratio of 104), which benefited from the built-in electric field across the interface. The direct growth of TMDs p–n vertical heterostructures may offer a novel platform for future optoelectronic applications.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the past decades, two-dimensional (2D) transition metal dichalcogenides (TMDs) layered semiconductors have been considered as promising candidates for next-generation electronics and optoelectronics. This is due to their unique properties such as atomically thin thickness, and to their electronic, photonic, and mechanical properties [1,2,3,4,5,6]. Moreover, the heterostructures that are composed of various 2D layered TMDs materials have attracted more and more attention as a consequence of their diversified band alignments [5]. For example, type-I materials are usually used for light-emitting diodes [7], type-II have an important application in photovoltaic devices [8, 9], and type-III are widely used in the tunneling field effect transistors [10]. Until now, there have been diverse ways to synthesize the heterostructures, including mechanical stacking, the solution method, and chemical vapor deposition (CVD) [12,13,14], in which the CVD approach can easily synthesize materials with high production yield and large area. Many van der Waals heterostructures have been successfully composed by the CVD method and can be used in integrated optoelectronic applications [15,16,17]. For instance, Li et al. reported high-performance optoelectronic devices based on van der Waals vertical MoS2/MoSe2 heterostructures with enhanced photoresponsivity of 36 A/W and a remarkable detectivity of 4.8 × 1011 Jones [16]. Wu et al. demonstrated the vapor growth of WSe2/WS2 heterostructures with distinct nonlinear optical properties by controlling crystallographic alignments in the form of AA and AB stacking [15]. However, although there is demand for mass production of high-quality vertical p–n heterostructures for use in integrated devices, there are still few reports on them because synthesizing the non-alloyed heterojunctions with sharp interface by CVD method is difficult. Most of the devices developed so far are based on single-material [18,19,20,21], but their performance is limited by defects and small light absorption cross-sections [21, 22]. Therefore, the controllable synthesis of vertical p–n heterostructures is very important for future integrated electronic and optoelectronic applications.

In this work, we report production of vertical MoS2/WSe2 p–n heterojunctions through a two-step CVD method and explore its application in photoelectric devices. The optical measurements and scanning transmission electron microscopy (STEM) demonstrate that the heterostructures are of high quality, without alloying. Electrical measurements exhibit considerable photon-electron conversion efficiency, photoresponsivity, detectivity, and stable light response. The study thus provides an alternative approach to design various TMDs heterostructures for future optoelectronic applications.

2 Experimental details

2.1 Synthesis of MoS2/WSe2 vertical heterostructures

The vertical MoS2/WSe2 heterostructures were synthesized by a two-step growth CVD approach. In the first step, MoS2 template was synthetized using a salt-assisted method, Salt could reduce the evaporation temperature of MoO3, thereby reducing the difficulties for production of MoS2 with large-area. An alumina boat containing S powder was placed at upstream of a furnace. Then, another boat with mixed powder of NaCl and MoO3 (99.99%, Alfa Aesar) was positioned at the central region of furnace, on top of which three pieces of SiO2/Si substrates was placed for deposition. Before heating, the system was cleaned by pure Ar flow for 30 min at a rate of 80 standard cubic centimeters per minute (sccm). The furnace was heated to 810 ℃ within 30 min at 60 sccm, with Ar as the carrier gas, then maintained at that temperature for a further 10 min. Finally, the furnace naturally cooled down to room temperature. For the second step, to synthesize vertical WSe2/MoS2 heterostructures, a boat with as-grown MoS2 templates was placed at downstream of furnace for subsequent deposition of WSe2. The WSe2 source powder (99.99%, Alfa Aesar) was put at the central heating area of the furnace. After the cleaning procedure as described above, the furnace was heated to 1020 ℃ within 30 min at 60 sccm and maintained at that temperature for 3 min. After the reaction, the furnace cooled down to room temperature naturally.

2.2 Characterizations

The morphologies of heterostructures were characterized using an optical microscopy (Zeiss Axio Scope A1), an atomic force microscope (AFM, Bruker Multimode 8), and a scanning transmission electron microscope (JEM ARM200F). The optical measurements (Photoluminescence and Raman) were conducted using a confocal microscope (WITec, alpha-300) with a 532 nm laser focused by an objective.

2.3 Device fabrication and optoelectronic measurements

Standard e-beam lithography (EBL, Raith 150) and metal thermal evaporation were performed to fabricate the Au/Cr (10 nm/50 nm) electrodes on the as-grown heterostructures with a lift-off approach. The electric and optoelectronic properties of the heterostructures were measured in vacuum with Lake Shore Probe Station and Agilent B1500A semiconductor analyzer at room temperature.

3 Results and discussion

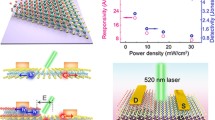

The MoS2/WSe2 heterostructures were grown by a two-step CVD method. Figure 1a shows a schematic diagram of the atomic growth model, and Fig. 1b exhibits a picture of the heterostructure under the optical microscope. The schematic view and optical image of MoS2 grown on SiO2/Si substrate are shown in Figs. 1ai and 1bi (Additional file 1: Fig. S1 for detail) respectively. The lateral size of monolayer MoS2 triangles ranged from 20 to 200 μm. The red square in Fig. 1bii indicates the small WSe2 triangles that was grown on MoS2 in the second step, and the area marked by the green spots is the underlying MoS2. The evolution of morphology of WSe2 on MoS2 after 2, 4, and 6 min growth is shown in Figs. 1aii–aiv and 1bii–biv, respectively, with the whole WSe2 covered eventually. The optical image clearly indicated that WSe2 on MoS2 had only 0° and 60° stacking modes. Atomic force microscopy showed that MoS2 and WSe2 were both monolayers (Additional file 1: Fig. S2). Figure 1c shows the photoluminescence (PL) spectra of MoS2 and MoS2/WSe2 heterostructures. The peaks at 680 and 755 nm correspond to the A excitons of MoS2 and WSe2, respectively. The PL intensity of MoS2 becomes quenched in the heterostructure because of the charge transfer in the MoS2/WSe2 interface, with type-II band alignment, as shown in Fig. 4f. Figure 1d shows the Raman spectra of MoS2 and MoS2/WSe2heterostructure. The peak positions of MoS2 locate at 379 cm−1 (E2g(S-Mo)) and 397 cm−1 (A1g(S-Mo)), respectively, while that of the heterostructure locate at 270 cm−1 (A1g(W-Se)), 372 cm−1 (E2g(S-Mo)), and 400 cm−1 (A1g(S-Mo)). PL and Raman results are consistent with MoS2 and WSe2 properties previously reported, proving the successful synthesis of MoS2/WSe2 heterostructure.

Growth morphology and the optical characterizations of as-grown MoS2/WSe2 heterostructures. Schematic views of heterostructure growth (ai–aiv) and their corresponding optical images (bi–biv). Scale bar: 20 µm. c PL spectra of monolayer MoS2 and MoS2/WSe2 heterostructure. d Raman spectra of MoS2 and MoS2/WSe2 heterostructure

The MoS2/WSe2 heterostructure grown on SiO2/Si was transferred to a copper net (see the supporting information for the detail transfer method), and then the microstructure and chemical composition of the MoS2/WSe2 heterostructure were analyzed by transmission electron microscopy (TEM). Figure 2a gives the low-resolution scanning transmission electron microscope (TEM) image of MoS2/WSe2 vertical heterostructure. The triangular area marked by green dash line is the bottom layer of MoS2, and the red triangle is the heterojunction area. Figure 2b is the high-resolution transmission electron microscope (HRTEM) image of the bottom MoS2, with a lattice spacing of 2.7 Å, corresponding to the (100) crystal plane of the 2H phase MoS2. The inset is the selected area electron diffraction (SAED) pattern of MoS2. The SAED of the MoS2/WSe2 heterostructure is shown in Fig. 2c. Two sets of regular hexagon diffraction pattern are displayed clearly. The polygonal diffraction patterns marked by green and red lines have a crystal plane spacing of 2.7 Å and red 2.8 Å, corresponding to MoS2 and WSe2 (100) crystal planes, respectively. Figure 2d shows the area at the interface of the heterostructure under the HRTEM. The right side is MoS2, and the left side is the heterostructure. The atomic structure is clear, which proves that the high-quality MoS2/WSe2 vertical heterojunction with a clear interface was successfully synthesized. The TEM energy-dispersive X-ray photoelectron spectroscopy (EDS) of different regions is shown in Fig. 2e. The red line shows several peaks for elements such as W, Se, Mo, S, and Cu (from the copper mesh), corresponding to the MoS2/WSe2 heterojunction. The green line only shows Mo, S, and Cu peaks, corresponding to the MoS2. The results agrees with The X-ray photoelectron spectroscopy (XPS) measurement of the heterojunction given in Additional file 1: Fig. S3. Figure 2f is the HRTEM image in the heterojunction region, the moiré patterns can be clearly observed due to the interlayer coupling between MoS2 and WSe2. This observation further demonstrates the successful synthesis of the high-quality, well-defined MoS2/WSe2 heterostructure.

High-resolution atomic characterizations of MoS2/WSe2 heterostructure. a Low-resolution TEM image of transferred MoS2/WSe2 heterostructure on a Cu grid. Scale bar: 1 μm. b HRTEM image of MoS2. Scale bar: 1 nm. c SAED patterns of MoS2/WSe2 heterostructure. d Atomic resolution scanning TEM image of the heterostructure interface. Scale bar: 2 nm. e EDS spectra of the MoS2/WSe2 vertical heterostructure. f HRTEM image of heterostructure region. Scale bar: 2 nm

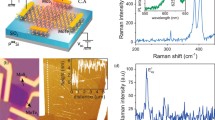

To further investigate the charge transport properties of the vertically stacked MoS2/WSe2 van der Waals heterostructures, back-gate field-effect transistors (FET) were fabricated based on MoS2/WSe2 p–n heterojunctions. Figure 3a displays the device structure in which Ti/Au electrodes are deposited on WSe2, as the drain and source electrodes. The transport characteristic of the heterostructure device given in Fig. 3b shows ambipolar behavior, which is attributed to the p-type WSe2 and the n-type MoS2. Figure 3b shows that, when a negative gate voltage (Vg) is applied, the WSe2 layer is turned on and the device exhibits p-type behavior. Conversely, when the MoS2 layer is on state and the device shows n-type behavior while the gate voltage was positive. At the same time, the current increases when the drain-source voltage Vds changes from 0.2 to 1 V. The diagram indicates that the threshold voltage is − 10 V, and the on/off ratio is 104. The mobility could be obtained using the expression μ = gmL/(WC0Vds), where gm represents the transconductance, L = 17.3 μm and W = 54.5 μm are the length and the width of the device, respectively. C0 is the capacitance per unit area for the 280 nm thick SiO2. Based on the data shown in Fig. 3b, the calculated mobility is 9 cm2/(V·s). Figure 3c, d show the corresponding output characteristics of MoS2/WSe2 heterostructure. The inset in Fig. 3c is the enlarged view of the region marked by the red circle. The drain-source current Ids decreases as the Vg varies from − 60 to − 20 V, and increases as Vg raises from 0 to 60 V. All the device measurements were conducted under vacuum at room temperature.

Benefiting from the large built-in electric field at the p–n heterojunction interface and the resulting high separation efficiency of photogenerated carriers, p–n heterostructures are widely used in optoelectronic applications. Under illumination of 633 nm laser light, the photovoltaic and photoresponse characteristics of the MoS2/WSe2 vertical heterostrutures were examined further. The photodetector based on MoS2/WSe2 vertical heterjunction is schematically illustrated in Fig. 4a, with drain-source voltage Vds applied to the heterojunction device. Figure 4b shows the Ids−Vds curves at various illumination intensities ranging from 0 to 63.69 mW/cm2 (Vg = 20 V). More electron–hole pairs are generated as the illumination intensity increases, resulting in a greater photocurrent. In Fig. 4c, the photocurrent intensities are evaluated at a gate bias of 20 V. Other photocurrent data under different gate voltages are shown in Additional file 1: Fig. S4a. The photocurrent intensity (Iph) is defined as Iph = Ilight − Idark, where Ilight (Idark) is current measured under light (dark state). The relation between Iph and laser power density P can be expressed as Iph = aPα. The fitted parameters of a and α obtained from Fig. 4c are 9.43 × 10–9 and 0.41, respectively. The responsivity (R) can be calculated using R = Iph/(PA), where A is the effective area of the device channel. The calculated responsivity of the device is up to 8 A/W (P = 0.05 mW/cm2, Vds = 1 V, device area of 943.85 μm2), which is greater than that of monolayer MoS2 and WSe2 devices previously reported [24,25,26]. In addition, the value of R can reach up to 41 A/W at 60 V gate voltage (Additional file 1: Fig. S4b). To characterize the sensitivity of a photodetector, the device detectivity (D*) is used. D* can be calculated using the formula D* = RA1/2/ (2eIdark)1/2, where e is the electron charge, assuming D* is primarily affected by the shot noise of the dark current [26, 27]. According to this formula, D* can reach a maximum value of 2.93 × 1011 Jones as shown in Fig. 4d. Detectivity at various gate voltages can be found in Additional file 1: Fig. S4c. The photoresponse speed of the MoS2/MoSe2 heterostructure photodetector was investigated further by turning on and off the laser beam (633 nm, 63.69 mW/cm2). Figure 4e displays exemplary photocurrent curves for the photodetector, showing excellent stability and reliability of on/off switching behavior (Vds = 1 V, Vg = 0 V, P = 63.69 mW/cm2). Figure 4f exhibits the band structure of the MoS2/WSe2. It is shown that a typical type-II heterostructure is formed. When the laser beam was focused on the heterojunction, the electrons in WSe2 were transferred to MoS2, whereas the holes in MoS2 were transferred to WSe2. This results in the photogating effect, wherein the charges modify the conductance of the WSe2 channel. The high responsivity and the excellent reliability indicate that the designed MoS2/WSe2 p–n heterojunction may achieve ultrasensitive photodetection in the future.

Optoelectronic device performance of MoS2/WSe2 vertical heterostructure. a Schematic illustration of the device. b Ids–Vds curves across the heterojunction under 633 nm laser illumination with different incident powers. Vds ranges from – 1 to 1 V. c Dependence of device photocurrent on illumination power densities. d Photoresponsivity and detectivity of the photodetector at various illumination power densities ranging from 0 to 63.69 mW/cm2. e Photocurrent response of the device; the laser excitation is turned on and off by a chopper working at 1 Hz (Vds = 1 V, Vg = 0 V, P = 63.69 mW/cm2). f Band structures and the charge transfer process at the interface of the MoS2/WSe2 p–n heterojunction

4 Conclusions

In this work, we developed a controllable two-step growth method to prepare vertically stacked MoS2/WSe2 heterostructures. Furthermore, PL Spectroscopy, Raman spectroscopy, and HRTEM were used to characterize the obtained p–n heterojunctions. The results indicate that the samples are of high crystal quality. A p–n field effect transistor was fabricated based on the heterostructures. The bipolar behavior was observed and the device exhibited high carrier mobility of up to 9 cm2/(V·s). Under the laser illumination, excellent photodetection properties was obtained with the photoresponsivity approaching 8 A/W and detectivity of 2.93 × 1011 Jones. Meanwhile, stable on/off photoswitching was also demonstrated. All the results show that the achieved MoS2/WSe2 p–n heterojunctions have great potential in integrated optoelectronic applications.

References

Zeng, H., Dai, J., Yao, W., Xiao, D., Cui, X.: Valley polarization in MoS2 monolayers by optical pumping. Nat. Nanotechnol. 7(8), 490–493 (2012)

Duan, X., Wang, C., Pan, A., Yu, R., Duan, X.: Two-dimensional transition metal dichalcogenides as atomically thin semiconductors: opportunities and challenges. Chem. Soc. Rev. 44(24), 8859–8876 (2015)

Seyler, K.L., Schaibley, J.R., Gong, P., Rivera, P., Jones, A.M., Wu, S., Yan, J., Mandrus, D.G., Yao, W., Xu, X.: Electrical control of second-harmonic generation in a WSe2 monolayer transistor. Nat. Nanotechnol. 10(5), 407–411 (2015)

Li, H., Wang, X., Zhu, X., Duan, X., Pan, A.: Composition modulation in one-dimensional and two-dimensional chalcogenide semiconductor nanostructures. Chem. Soc. Rev. 47(20), 7504–7521 (2018)

Zheng, W., Zheng, B., Yan, C., Liu, Y., Sun, X., Qi, Z., Yang, T., Jiang, Y., Huang, W., Fan, P., Jiang, F., Ji, W., Wang, X., Pan, A.: Direct vapor growth of 2D vertical heterostructures with tunable band alignments and interfacial charge transfer behaviors. Adv. Sci. 6(7), 1802204 (2019)

Luo, Z., Zheng, W., Luo, N., Liu, B., Zheng, B., Yang, X., Liang, D., Qu, J., Liu, H., Chen, Y., Jiang, Y., Chen, S., Zou, X., Pan, A.: Photoluminescence lightening: extraordinary oxygen modulated dynamics in WS2 monolayers. Nano. Lett. 22(5), 2112–2119 (2022)

Lu, Z.H., Baribeau, J.M., Lockwood, D.J.: Quantum confinement and light emission in SiO2/Si superlattices. Nature 378(6554), 258–260 (1995)

Liu, H., Zhu, X., Sun, X., Zhu, C., Huang, W., Zhang, X., Zheng, B., Zou, Z., Luo, Z., Wang, X., Li, D., Pan, A.: Self-powered broad-band photodetectors based on vertically stacked WSe2/Bi2Te3 p–n heterojunctions. ACS Nano 13(11), 13573–13580 (2019)

Yuan Y., Zhang, X., Liu, H., Yang, T., Zheng, W., Zheng, B., Jiang, F., Li, L. Li, D., Zhu, X., Pan, A.: Growth of CdSe/MoS2 vertical heterostructures for fast visible-wavelength photodetectors. J. Alloys Compd. 815, 152309 (2020)

Jeon, H.B., Shin, G.H., Lee, K.J., Choi, S.Y.: Vertical-tunneling field‐effect transistor based on WSe2-MoS2 heterostructure with ion gel dielectric. Adv. Electron. Mater. 6(7), 2000091 (2020).

Gong, Y., Lin, J., Wang, X., Shi, G., Lei, S., Lin, Z., Zou, X., Ye, G., Vajtai, R., Yakobson, B.I., Terrones, H., Terrones, M., Tay, B.K., Lou, J., Pantelides, S.T., Liu, Z., Zhou, W., Ajayan, P.M.: Vertical and in-plane heterostructures from WS2/MoS2 monolayers. Nat. Mater. 13(12), 1135–1142 (2014)

Li, M.Y., Shi, Y., Cheng, C.C., Lu, L.S., Lin, Y.C., Tang, H.L., Tsai, M.L., Chu, C.W., Wei, K.H., He, J.H., Chang, W.H., Suenaga, K., Li, L.J.: NANOELECTRONICS. Epitaxial growth of a monolayer WSe2-MoS2 lateral p–n junction with an atomically sharp interface. Science 349(6247), 524–528 (2015)

Li, F., Feng, Y., Li, Z., Ma, C., Qu, J., Wu, X., Li, D., Zhang, X., Yang, T., He, Y., Li, H., Hu, X., Fan, P., Chen, Y., Zheng, B., Zhu, X., Wang, X., Duan, X., Pan, A.: Rational kinetics control toward universal growth of 2D vertically stacked heterostructures. Adv. Mater. 31(27), e1901351 (2019)

Yang, T., Zheng, B., Wang, Z., Xu, T., Pan, C., Zou, J., Zhang, X., Qi, Z., Liu, H., Feng, Y., Hu, W., Miao, F., Sun, L., Duan, X., Pan, A.: Van der Waals epitaxial growth and optoelectronics of large-scale WSe2/SnS2 vertical bilayer p–n junctions. Nat. Commun. 8(1), 1906 (2017)

Wu, X., Wang, X., Li, H., Zeng, Z., Zheng, B., Zhang, D., Li, F., Zhu, X., Jiang, Y., Pan, A.: Vapor growth of WSe2/WS2 heterostructures with stacking dependent optical properties. Nano Res. 12(12), 3123–3128 (2019)

Li, F., Xu, B., Yang, W., Qi, Z., Ma, C., Wang, Y., Zhang, X., Luo, Z., Liang, D., Li, D., Li, Z., Pan, A.: High-performance optoelectronic devices based on van der Waals vertical MoS2/MoSe2 heterostructures. Nano Res. 13(4), 1053–1059 (2020)

Zhang, W., Chiu, M.H., Chen, C.H., Chen, W., Wee, A.: Role of metal contacts in high-performance phototransistors based on WSe2 monolayers. ACS Nano 8(8), 8653–8661 (2014)

Huang, Y., Deng, H.X., Xu, K., Wang, Z.X., Wang, Q.S., Wang, F.M., Wang, F., Zhan, X.Y., Li, S.S., Luo, J.W., He, J.: Highly sensitive and fast phototransistor based on large size CVD-grown SnS2 nanosheets. Nanoscale 7(33), 14093–14099 (2015)

Sanne, A., Ghosh, R., Rai, A., Yogeesh, M.N., Shin, S.H., Sharma, A., Jarvis, K., Mathew, L., Rao, R., Akinwande, D., Banerjee, S.: Radio frequency transistors and circuits based on CVD MoS2. Nano. Lett. 15(8), 5039–5045 (2015)

Kwon, H., Garg, S., Park, J.H., Jeong, Y., Yu, S., Kim, S.M., Kung, P., Im, S.: Monolayer MoS2 field-effect transistors patterned by photolithography for active matrix pixels in organic light-emitting diodes. NPJ 2D Mater. Appl. 3(1), 9 (2019)

Shidpour, R., Manteghian, M.: A density functional study of strong local magnetism creation on MoS2 nanoribbon by sulfur vacancy. Nanoscale 2(8), 1429–1435 (2010)

Komsa, H.-P., Krasheninnikov, A.V.: Effects of confinement and environment on the electronic structure and exciton binding energy of MoS2 from first principles. Phys. Rev. B 86(24), 241201 (2012)

Gong, F., Fang, H., Wang, P., Su, M., Li, Q., Ho, J.C., Chen, X., Lu, W., Liao, L., Wang, J., Hu, W.: Visible to near-infrared photodetectors based on MoS2 vertical Schottky junctions. Nanotechnology. 28(48), 484002 (2017)

Chen, Y., Wang, X., Wu, G., Wang, Z., Fang, H., Lin, T., Sun, S., Shen, H., Hu, W., Wang, J., Sun, J., Meng, X., Chu, J.: High-performance photovoltaic detector based on MoTe2/MoS2 van der Waals heterostructure. Small 14(9), 1870038 (2018)

Liu, B., Tang, B., Lv, F., Zeng, Y., Liao, J., Wang, S., Chen, Q.: Photodetector based on heterostructure of two-dimensional WSe2/In2Se3. Nanotechnology 31(6), 065203 (2020)

Wang, P., Liu, S., Luo, W., Fang, H., Gong, F., Guo, N., Chen, Z.G., Zou, J., Huang, Y., Zhou, X., Wang, J., Chen, X., Lu, W., Xiu, F., Hu, W.: Arrayed van der Waals broadband detectors for dual-band detection. Adv. Mater. 29(16), 1604439 (2017)

Li, C., Yan, X., Song, X., Bao, W., Ding, S., Zhang, D.W., Zhou, P.: WSe2/MoS2 and MoTe2/SnSe2 van der Waals heterostructure transistors with different band alignment. Nanotechnology 28(41), 415201 (2017)

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Grant Nos. 62090035, U19A2090, and 61905071), the Key Program of the Hunan Provincial Science and Technology Department (Nos. 2019XK2001 and 2020XK2001), and the International Science and Technology Innovation Cooperation Base of Hunan Province (No. 2018WK4004).

Author information

Authors and Affiliations

Contributions

YX, SLC, and ALP conceived the idea and participated in the data analysis. YX performed the material growth, optical characterization and drafted the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Supplementary Information

Below is the link to the electronic supplementary material.

Additional file 1

: Fig. S1. Schematic view of CVD growth of MoS2/WSe2 vertical heterostructures. Fig. S2 Atomic force microscopy (AFM) image of the MoS2 and the MoS2/WSe2 heterostructures. (a) AFM image of MoS2. (b) AFM image of WSe2. (c) AFM image of single WSe2 triangle. Fig. S3. Chemical states of Mo, S, W and Se in the MoS2/WSe2 heterostructures, measured by X-ray photoelectron spectroscopy. Fig. S4. (a) Photocurrent plots under different values of power and gate voltage (Vds=1 V). (b) Photoresponsivity of the photodetector at various gate voltages ranging from 0 to 60 V (Vds=1 V). (c) Detectivity of the photodetector at various gate voltages ranging from 0 to 60 V (Vds=1 V).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xiao, Y., Qu, J., Luo, Z. et al. Van der Waals epitaxial growth and optoelectronics of a vertical MoS2/WSe2 p–n junction. Front. Optoelectron. 15, 41 (2022). https://doi.org/10.1007/s12200-022-00041-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12200-022-00041-4