Abstract

The basis of this study is to identify the versatility of N,N,N′-trimethyl-N′-tallow-1,3-diaminopropane (DTTM) surfactant in high saline environments. The surfactant was examined with sodium chloride, NaCl, to understand how triggers such as salt, pH, temperature, and surfactant concentration influences the viscoelastic response of the surfactant solution. The DTTM surfactant and salt (NaCl) concentrations used in steady-state shear viscosity analysis range from 0.2 wt% to 2 wt% and 5 wt% to 25 wt%, respectively. Along with DTTM results, three similar chemical structures are investigated to understand how viscosity changes with alterations in tail and head group composition. It was found that DTTM surfactant has the capability of transitioning from a foam-bearing to viscoelastic state at low surfactant concentrations under moderate to high saline conditions. A longer tail length promotes viscoelasticity and shear-thinning behavior. Terminals consisting of hydroxides or ethoxylates have a lower viscosity than that of methyl terminals. A head group consisting of two nitrogen atoms has a higher viscosity than those containing one nitrogen atom. The rheological characterization of DTTM presented in this paper is part of a larger study in determining the capability of this surfactant to foam CO2 for improving mobility control in CO2 enhanced oil recovery in high saline oil formations.

Similar content being viewed by others

1 Introduction

Microstructural aggregation and morphology of surfactant micelles impart changes in macroscopic behavior and flow properties of the surfactant solution under certain conditions (Gaudino et al. 2015; Schramm 2000; Trickett and Eastoe 2008; van Zanten 2011). In general, the packing parameter classifies the structure of the micelles under four divisions; spherical, cylindrical/wormlike, vesicles, or lamellar micelles (Lequeux 1996). Solutions with spherical or short-rod micelles tend to have Newtonian behavior at low viscosities. Depending on internal and external parameters, the morphology can transition from one division to another. When the micelles organize into cylindrical aggregates or entangle wormlike structures, the solution transforms into a viscoelastic state (Hull et al. 2015; Koehler et al. 2000).

Viscoelastic surfactants (VES) are characterized as having viscous and elastic properties that deform under applied shear, stress, and/or strain. However, unlike polymers, the removal of force allows VES solutions to quickly recover and reform back to their natural state at a specified relaxation time (Cates and Candau 1990). In addition, depending on the type of surfactant, adjustments in salinity, temperature, surfactant concentration, and pH can fine-tune the viscoelastic response and macroscopic fluid behavior of the solution (Nasr-El-Din et al. 2009). These reasons make viscoelastic surfactants attractive and practical for subsurface applications in the realm of matrix acidizing, conformance control (gel and foam treatment) and chemical enhanced oil recovery (fluid diversion and gas-flood mobility control).

The article reflects one of the works completed to bulk characterize N,N,N′-trimethyl-N′-tallow-1,3-diaminopropane, DTTM, by understanding the chemical’s viscoelastic properties and rheological behavior when exposed to various environmental conditions. In the literature, many types of surfactants, especially ionic-type, display a viscoelastic response. Notable surfactants are listed in Table 1. Comparable to the surfactants listed in the table, DTTM exhibits striking rheological properties that can be modified by salinity, while fine-tuning temperature, pH, and surfactant concentration can adjust the viscous strength to a desirable condition. Modifying pH changes the protonation level of the molecules, electrolytes or counterions induce microstructural transformation of micelles by reducing electrostatic repulsion, temperature controls the minimization of free energy by breaking, reformation, and branching of micellar networks, while surfactant concentration controls the aggregation density. The ability to fine-tune viscoelasticity and rheological behavior is an engineering novelty, optimizing performance and efficiency for subsurface applications. The rheological characterization of DTTM presented in this paper is part of a larger study in determining the capability of this surfactant to foam CO2 for improving mobility control and sweep efficiency in CO2 enhanced oil recovery in high temperature, pressure and saline conditions, particularly in carbonate reservoirs.

In our previous work, we have shown that this particular type of surfactant is a good foaming agent and has good solubility in high pressure CO2 (Liebum 2016). These are favorable properties for robust conformance control with foam and good surfactant transport in the reservoir, which improve sweep efficiency during CO2 foam flooding (Ren et al. 2014, 2017). In particular, the alkyl diamine surfactant studied in this work is also an important alternative to commercially available polymers that have been used to enhance foam performance in porous media (Romero et al. 2002; Ye et al. 1997). This surfactant overcomes several disadvantages of polymer enhanced foam such as:

-

(1)

Undesired chromatographic separation of polymer and a foaming surfactant in the reservoir,

-

(2)

Additional surface facilities for polymer hydration,

-

(3)

Limited temperature and salinity tolerance and pH sensitivity of most commercially available polymers used for enhancing foam performance.

Therefore, we report in this work, for the first time, the rheology of an alkyl diamine surfactant and influencing factors including salinity, concentration, pH, temperature, and molecular structure. Such rheological characterization would greatly advance our understanding of surfactant and foam transport in porous media with applications in fluid (gas and water) mobility control in gas enhanced oil recovery.

2 Experimental description

2.1 Materials

N,N,N′-trimethyl-N′-tallow-1,3-diaminopropane (DTTM), tris(2-hydroxyethyl)-N-tallowalkyl-1,3-diaminopropane (EDM), dimethyl cocoalkylamine (ARM), and ethoxylated cocoalkylamine (ECA) were gifts from AkzoNobel and were used as received. Chemical structure and aqueous stability of 1 wt% DTTM are shown in Figs. 1 and 2, respectively. Figure 2 shows that this surfactant exhibits good aqueous stability at high temperatures in a 20 wt% NaCl solution.

Aqueous stability results at 1 wt% DTTM in a 20 wt% NaCl solution under variable temperature conditions. Filled circles represent unstable solutions that appear opaque or experience aqueous phase separation in the solution, hatch circles represent transition solutions that appear translucent and open circles represent stable solutions that appear clear

Samples tested for effects of salinity, surfactant concentration and temperature were prepared using deionized (DI) water, sodium chloride (NaCl), and 11 wt% DTTM bulk solution where the pH was adjusted to 5.21 by using hydrochloric acid (HCl). The average pH of the final samples is 6.01 and slightly variates (± 2%) depending on salt concentration. On the other hand, samples testing how protonation influences viscosity were individually prepared by adding NaCl and a known volume of bulk surfactant solution into a solution of various DI water and HCl mixtures.

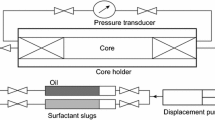

2.2 Analysis

A TA instrument AR-G2 rheometer with smart swap was used to analyze all samples. The Couette concentric cylinder was selected based on the solution’s fluid behavior ranging from Newtonian to nonlinear viscoelasticity. About 19 mL of solution was dispensed into the cylinder and preconditioned for 1 min before starting the steady-state shear rate analysis from 1 to 100 s−1 with 4 points per decade. Additionally, all samples were tested at 40 °C, with the exception of decoupling temperature effects, which spanned from 25 to 80 °C.

The DTTM surfactant and salt (NaCl) concentrations used in steady-state shear viscosity analysis range from 0.2 wt% to 2 wt% and 5 wt% to 25 wt%, respectively. Rheological measurements insinuate changes in the macroscopic and microscopic behavior of the solution, as well as indicate critical degrees of freedom to prompt viscoelasticity. Note, no critical micelle concentration (CMC) measurements were tested under different environmental conditions for surfactants analyzed. Finally, along with DTTM results, investigation of three similar chemical structures, illustrated in Fig. 1, EDM, ARM and ECA, will be studied to see how viscosity changes with alterations in tail and head group composition at high salinities of 20 wt% and 25 wt% NaCl.

2.3 Theoretical structure-rheological property relationship

Rheological behavior links both the microstructure and morphology elements of a solution (Rounds 1994). Employed in this study, a classical qualitative model called Israelachvili’s packing parameter, “P,” characterizes the micellar morphology where thermodynamics and free energy conditions of the system provoke micellar structural transformations (Collura et al. 2001; Hull et al. 2015; Raghavan 2009).

This model’s packing parameter value, “P” in Eq. (1), is influenced by the volume (v) and maximum length (l) of the tail, as well as the “effective” head group area (a) of the surfactant molecules and relates these factors to various micellar structures categorized as either spherical (P < 1/3), cylindrical (1/3 < P < 1/2), vesicle (1/2 < P < 1), or lamellar (P = 1) shown in Table 2.

Salt, pH, chloride ions, temperature, and other external factors can influence the micellar structure and alter the packing parameter value. For instance, upon the addition of total dissolved solids (TDS), comprised of salt and/or chloride ions, the effective head group size, “a,” shrinks due to a reduction of electrostatic repulsion among the head groups causing “P” to increase, resulting in a transformation of the self-assembled micellar structures and enhancement of the solution’s viscous properties. Additionally, an increase in H+ ions, principally responsible for altering the solution’s pH and protonation of amine-based surfactants, will enlarge the “a” parameter by increasing the ionic repulsion among molecules, leading to a decrease in “P.” This results in a viscosity buildup going from the nonprotonated to half-protonated state followed by a decline in viscosity when approaching the fully protonated state of the solution. These parameters will be discussed in more detail in the results and discussion section.

In general, applying the packing parameter relationship, as the salt concentration increases in the solution, the effective head group size shrinks, leading to a rise in the packing parameter value. This increase can facilitate micellar growth from spherical to cylindrical then entangling and elongating of cylindrical micelles to form wormlike structures (Kalur and Raghavan 2005). In other words, the addition of salt reduces the critical micelle concentration, thereby allowing lower surfactant concentrations to transform into a viscoelastic state (Lee et al. 2010). Additionally, high NaCl concentrations promote micellar flexibility of the system, providing a favorable environment for the growth of wormlike micelles (Maeda et al. 2001; Truong and Walker 2002).

Maeda et al. (2001) stated for tetradecyldimethylamine oxides, the half-ionized state, where half of the nitrogen atoms are protonated in the solution (α = 0.5), can have viscosities that are magnitudes greater than solutions at other protonation states (Maeda et al. 2001). At the half-ionized state, partially protonated molecules have mix ionic charge, making them prone to self-assemble into larger micellar aggregates, such as cylindrical to globular, due to the hindrance of electrostatic repulsion among the surfactant molecules. Moreover, Wang et al. (2008) also contributed by describing the pH and protonation effects of a multi-amine surfactant, bis (amidoethyl-carbamoylethyl)-octadecylamine (Wang et al. 2008). It was concluded that at the fully ionized state, where all nitrogen atoms are protonated (α = 1), the surfactant solution forms smaller micelles at low pH because of increasing repulsion between similar-charged head groups. On the other hand, with little to no ionization, the micelles transform to a globular morphology at neutral pH due to deprotonation and reduction of molecular repulsion leading to large, low-viscous micellar aggregates. The degree of protonation as a function of the pH and viscosity relationship for amine-based surfactants will be discussed in Sect. 3.3.

3 Results and discussion

3.1 Effects of salinity and surfactant concentration

The type and amount of salt play a significant role in developing viscoelastic solutions. The Cl− ions shrink the double layer and screen electrostatic repulsion around each head group, allowing surfactant molecules to aggregate and gradually transform into various micellar structures. To attain viscoelasticity, a higher concentration is required if using a weak, nonbinding salt, such as NaCl, since this type of salt shields the surface of the micelles unlike strong hydrotropic salts, for instance sodium salicylate and sodium tosylate, that penetrate into the micellar structure initiating viscoelasticity at lower salt concentrations (Trickett and Eastoe 2008; Hoffmann 1994; Calabrese et al. 2015). To define, hydrotropic salts are amphiphilic compounds that cannot form aggregates, like micelles, yet can solubilize organic compounds in water (Hill et al. 2014).

As shown in Fig. 3, the addition of NaCl significantly affects viscosity, notably for solutions with high surfactant concentrations. For all surfactant concentrations at a shear rate of 10 s−1, a transition slope is present suggesting that the fluid behavior changes from low-viscous to shear thinning at a fixed range of salinities, in other words this region defines the micellar crossover concentration transitioning from the dilute to semi-dilute regime and the onset of wormlike micelles entangling (Shashkina et al. 2005). This means that the crossover surfactant concentration or transition region occurs at higher salinities when surfactant concentration decreases, consequently delaying viscoelasticity and shear-thinning behavior. It can be seen in Fig. 3 that all the curves converge at the lowest salinity analyzed of 5 wt% NaCl, signifying that surfactant concentration becomes an important factor when the concentration is under the semi-dilute regime at a given salt concentration. In all, this figure displays how salinity triggers the growth of micellar structures thereby increasing the apparent viscosity of the solution, while the surfactant concentration magnifies and enhances the salinity’s impact on viscosity. It is important to note that in high saline environments, the viscosity appears to approach a plateau as salinity continues to increase, supposedly resulting in maximum entanglement or growth of the micelles due to thermodynamic and hydrodynamic limitations or micellar branching (Mu and Li 2001).

3.2 Effect of shear rate

Figure 4 displays how shear rate imposes significant changes in viscosity. Four surfactant concentrations were selected to illustrate viscosity profiles against shear rate at five different salinities: 25 wt%, 20 wt%, 17.5 wt%, 15 wt%, and 10 wt% NaCl. At a shear rate of 1 s−1, the viscosity drops nearly an order of magnitude when the surfactant concentrations are halved at a salinity of 20 wt% NaCl. This observation suggests that micellar growth and viscosity depends on the aggregation density and micellar size, which is associated with surfactant concentration. As the surfactant concentration increases, the micelles are more prone to overlap and entangle into a transient network due to a larger presence of surfactant molecules in the solution (Collura et al. 2001).

In addition, shear thinning at higher salt concentrations suggests disentanglement of the system and alignment of the wormlike micelles under shear flow (Acharya and Kunieda 2006; Shchipunov and Hoffmann 2000; Trickett and Eastoe 2008). This alignment causes viscosity degradation since the micellar structure orients in a way that minimizes resistance to flow, causing the solution to move as a single object (Lin et al. 2001). Furthermore, a slight degree of shear thickening occurs at lower salt concentrations and/or dilute solutions, leading to a fractional viscosity increase of 0.2 mPa s from 1 to 100 s−1. This can indicate hydrodynamic instabilities above a critical shear rate in the solution, most likely attributed to the formation of nonequilibrium, shear-induced, micellar phase transitions (Barentin and Liu 2001; Berret 2006; Hu et al. 1998). In addition, shear thickening under steady shear can occur when the surfactant concentration is close to the critical micelle concentration (Koehler et al. 2000). To confirm this statement, future experiments will be conducted to determine the critical micelle concentration of DTTM at various conditions.

It has been reported that many viscoelastic surfactant solutions display shear banding, where the micellar solution becomes unstable and splits into shear bands with spatial heterogeneities of different viscosities, velocities and/or internal structure (Anderson et al. 2006; Cates 1994; Rehage and Hoffmann 1991). According to Kalur et al. (2005), shear banding and shear-thinning behavior are the result of the existence of wormlike micelles due to the dynamics of relaxation, breakage and recombination of the micellar structure as well as the alignment of the chains and disentanglement with respect to the flow gradient (Hu and Lips 2005; Kalur et al. 2005). These listed references provide more information about the relation between shear banding and wormlike micelle structures (Britton and Callaghan 1999; Britton et al. 1999; Calabrese et al. 2015; Cappelaere and Cressely 1997; Delgado et al. 2009; Dhont and Briels 2008; Fardin et al. 2015; Helgeson et al. 2009; Hu and Lips 2005; Hu et al. 2008; Liberatore et al. 2009; Manneville 2008; Miller and Rothstein 2007; Pipe et al. 2010; Thareja et al. 2011; Yesilata et al. 2006).

It can be observed in Fig. 4 that solutions at 1 wt% and 2 wt% DTTM and salinities at 20 wt% and 25 wt% NaCl display a stress plateau, perhaps signifying the presence of wormlike micelles. In this regime, the flow becomes strongly time dependent as stress fluctuates between a maximum and minimum value at a given shear rate (Yesilata et al. 2006). The time for stress to equilibrate in the plateau region can be two or more orders of magnitudes higher than the viscoelastic relaxation time of the fluid, causing uncertainty of the plateau’s slope, curvature and reproducibility of the data (Yesilata et al. 2006). Moreover, no apparent stress plateau is detected at lower salt and surfactant concentrations, as stress remains linear. In other words, at shear rates above or below the shear banding or stress plateau regime, the stress coincides linearly with the changes in shear rate.

Nonetheless, a stress plateau can be due to other causes rather than shear banding when interpreting solely shear rate rheological measurements, for instance wall and stick slip, elastic instabilities, geometry, uncertainty from stress measurements, and inherent stress gradient from the device can cause similar responses (Hu et al. 2008). According to Manneville (2008), a plateau in shear stress provides insufficient evidence of the shear banding presence since the Couette geometry only measures global measurements and shear banding requires more localized characterization tools to allow the organization and microstructure of the bands (Manneville 2008). Further investigation is required to confirm the presence of shear banding at a wider range of shear rates (10−2 to 1000 s−1).

3.3 Effect of pH

DTTM is characterized as a nonionic surfactant or amine at high pH, but protonates into a cationic surfactant under acidic conditions due to the degree of protonation (α) of the amine head group. Effects of protonation on viscosity have been well established for amine-based surfactants and discussed in Sect. 2.3 and displays in Fig. 5. The presence of hydrogen ions in the solution increases the protonation and ionic repulsion of the surfactant molecules leading to smaller micelle formations near the fully ionized state, while the addition of chloride ions provides electrostatic screening among surfactant molecules, resulting in the ability to transform micelles into transient networks. Therefore, micellar morphology is based on both pH and chloride ions present in the solution.

As shown in Fig. 6, viscosity data were measured as a function of shear rate at a constant temperature in solutions consisting of 1 wt% DTTM and 20 wt% NaCl. This figure displays how viscosity evolves with pH, based on the addition of HCl from 0.21 wt% to 0.85 wt% with pH values spanning from 6.2 to 0, respectively. From the results, at a shear rate of 1 s−1, the viscosity profiles are widely distributed from 520 to 1275 mPa s, suggesting pH has a significant contribution to fine-tuning viscous effects. When the shear rate increases, the viscosity profiles converge near 10 s−1, suggesting that the pH effect is limited to low shear rates. Two mechanisms, i.e., TDS (NaCl and Cl− ions from HCl) and pH contribute to this protonation-viscosity dependence. Based on the linear interpolation of Fig. 3 at a fixed surfactant concentration, even though an increase in TDS will increase the viscosity of the solution from screening electrostatic interaction as well as maintaining and inducing the micellar network, the addition of H+ ions is the most dominant factor in modifying the viscosity profile by varying the protonation process, ionic charge of the aggregates and pH of the solution. It can be concluded that viscosity decreases as pH approaches the fully ionized state of the solution.

3.4 Effect of temperature

As shown in Fig. 7, viscosity data were measured as a function of steady-state shear rate and temperature for 1 wt% DTTM and 20 wt% NaCl solutions. This figure characterizes how temperature changes, from 25 to 80 °C, impact the shear-thinning behavior at steady-state shear rate conditions. It can be seen that at low shear rates, the viscosity is more dispersed with temperatures ranging from 1076 mPa s at 50 °C to 109.4 mPa s at 80 °C, then as the shear rate increases, the fluid shear thins resulting in a concentrated viscosity range at all temperatures. This suggests that temperature plays an important role in altering apparent viscosity at low shear rates, which displays representative behavior of wormlike micelles (Kalur et al. 2005).

Steady-state shear viscosity at 1 wt% DTTM, 20 wt% NaCl solution at temperatures ranging from 25 °C to 80 °C with a pH value of 6.14 (room temperature). The left plot represents how viscosity increases with respect to temperature and the right plot shows an opposite trend where the viscosity of DTTM declines with increasing temperature

Similar temperature effects are reported for other amine-based surfactants where wormlike micelles can spontaneously form at ambient temperatures based on the addition of salts, counterions, cosurfactants, surfactant mixtures, block copolymers, and/or organic solvents to the solution (Berret 2006; Hu and Lips 2005; Li et al. 2011; Rabie and Nasr-El-Din 2015; Shashkina et al. 2005; Wang et al. 2012). In particular, as temperature increases, the viscosity initially rises to an inflection point then begins degrading afterward and this process can repeat at higher temperatures (Rabie and Nasr-El-Din 2015). This viscosity “enhancement” suggests that not all of the micelles entangled to form wormlike micelles at low temperatures (Raghavan and Kaler 2001). As temperature increases, the wormlike micelles grow to a lesser extent thereby reducing the micellar length and leading to a decrease in rheological properties (Kalur et al. 2005).

At high salt concentrations, micellar branching can occur at high end-cap energies, where less energy is required to form branches than to form end-caps, leading to a decrease in viscosity with respect to increasing temperatures (Zana and Kaler 2007). Kalur et al. (2005) and Zhao et al. (2015) stated that when temperature increases, the salt ions desorb from the micelles leading to a decline in surface charge and a promotion in viscoelasticity. Moreover, at high salinities, thermo-induced thickening behavior due to hydrogen bonding and thermal stability of the viscoelastic solution could increase viscosity (Zhang et al. 2016).

Researchers have noted micelles grow and entangle before the inflection point due to the minimization of free energy, but after the inflection point, the onset of micellar branching occurs leading to a decrease in viscosity (Calabrese et al. 2015; Koehler et al. 2000; Trickett and Eastoe 2008). Trickett and Eastoe (2008) observed only a range of surfactant concentrations display this viscosity enhancement phenomenon and the critical temperature where the turning point exists is a function of surfactant concentration and shear rate. Thus, in conclusion, as the temperature increases, micelles elongate and entangle into chains until the competing effect of temperature surpasses the entanglement process and initiates micellar branching. When this happens, the inflection point occurs, and the viscosity starts to decline.

From another perspective shown in Fig. 8, at fixed shear rates of 1 and 10 s−1 for 1 wt% and 0.5 wt% DTTM in 20 wt% NaCl solutions, the increase in viscosity at low temperatures can be seen for all three curves followed by an inflection point resulting in a viscosity drop-off afterward. Three prominent factors alter the location of the inflection point and viscosity profile of a solution; surfactant concentration, salinity/additives, and shear rate. First, at a fixed surfactant concentration comparing two different shear rates, the inflection point shifts to higher temperatures as the shear rate increases. The difference in temperature is around 10 °C, but higher shear rates display a lower margin of viscosity enhancement as mentioned in Fig. 7. Second, comparing different surfactant concentrations at a rate of 10 s−1, as the surfactant concentration decreases the inflection point translates to a lower temperature for the 0.5 wt% surfactant solution. It is conceivable that the inflection point will disappear at a low surfactant concentration concluding that viscosity enhancement is limited to a fixed surfactant concentration range for a given salinity. Further test to explore the impact of salinity and surfactant concentration for this type of chemical is advisable.

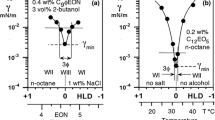

3.5 Effect of chemical structure

Rheological properties were conducted and compared for four cationic surfactants: ARM, DTTM, ECA, and EDM. With diverse combinations of hydrophobic tail lengths, head group terminals, and number of nitrogen atoms available in the head group, it is apparent that each surfactant will interact uniquely in the presence of NaCl. This section will analyze all four chemicals at two different salinities, 20 wt% and 25 wt% NaCl, to investigate the onset of viscoelastic/shear-thinning behavior, if any, for each chemical composition at 40 °C. Figure 9 illustrates the viscosity and fluid profile of solutions composed of 20 wt% and 25 wt% NaCl at 1 wt% fixed surfactant concentration. It can be shown that strong shear thinning occurs only with DTTM at both salinities, while EDM and ARM display weaker shear thinning at 25 wt% NaCl. ECA shows no signs of shear thinning for both salinities tested.

Discussed below is how modifications of the tail and head group influences the shear-thinning response of the solution:

3.5.1 Tail group modification

The length and composition of the tail are of primary importance when it comes to altering rheological properties of the solution (Raghavan and Kaler 2001). In this case, surfactants with coco-based tails, such as ARM and ECA, typically contain 12–16 carbon atoms, while surfactants with tallow-based tails, such as DTTM and EDM, consist of 14–18 carbons. According to Raghavan et al. (2002), as the alkyl tail length lessens, synergism in self-assembly decreases, leading to weak micellar growth and a small rise in viscosity. When the tail length increases, the interaction among the tail groups becomes stronger and more entangled causing a dramatic growth of micellar chains and a rise in viscosity (Raghavan et al. 2002).

3.5.2 Head group modification

Head group terminals can also contribute to the variations in rheological properties. Terminals consisting of hydroxides or ethoxylates are more hydrophilic when compared to methyl terminals. The hydrophilicity induces a more hydrating atmosphere for the surfactant molecule and aids its dissolution in water. The presence of hydrophobic terminals, such as methyl groups found in DTTM and ARM, can dehydrate the surfactant molecules with excess salt in the aqueous solution. This hydrophobicity favors the growth of long micelles, since hydrophobic molecules have higher end-cap energies, and end-cap energy is exponentially proportional to the micellar length (Berret 2006; Raghavan and Kaler 2001; Raghavan et al. 2002). End-cap energy represents the excess packing energy for surfactants with preferential cylindrical aggregation and is defined as the energy required to create two new chain ends for neutral micelles (Berret 2006). Large end-cap energy drives the transformation of cylindrical micelles to long and entangled wormlike or branched micelles, while low end-cap energy is achieved by forming closed loops or rings (Zana and Kaler 2007).

3.5.3 Monoamine versus diamine modification

The number of nitrogen atoms present in the head group can contribute to the growth of micellar structure due to changes in molecular interactions based on the degree of protonation. The protonation process ionizes each nitrogen one-by-one in a two-step process for diamines, while monoamines ionize in a one-step process. This means surfactants with a single nitrogen atom will fully protonate at a higher pH than molecules with two nitrogen atoms due to the number of hydrogen ions required to ionize them completely. Since monoamines are at a more protonated state than diamines at a higher pH, the micellar structures for each type should be dissimilar due to differences in ionic repulsion among similarly charged head groups. When the surfactant molecules are fully protonated, the micelles tend to self-assembled into smaller spherical aggregates since they all possess the same ionic charge resulting in an increase in electrostatic repulsion and effective head group size of the molecules. On the other hand, molecules that are partially protonated have mixed ionic charge making them prone to self-assemble into larger micellar aggregates, such as cylindrical to globular, due to the hindrance of electrostatic repulsion among the surfactant molecules.

In all, chemical structures play a role in the viscous strength and onset of shear thinning, and this is important when screening chemicals for a particular fluid mobility control application.

4 Conclusions

In this work, we have mainly investigated the viscoelastic behavior of DTTM at different salinities, concentrations, pH, and temperatures. From the decoupled results, salinity is the main factor for inducing viscoelasticity since salt triggers the growth of micellar structures by reducing electrostatic repulsion among the molecules.

DTTM exhibits a pH and viscosity relationship associated with the protonation and deprotonation evolution of the molecules. The effect of pH is much more pronounced at lower shear rates. This finding suggests that the rheological behavior of DTTM is stable in an acidic environment such as in CO2 flooded reservoirs.

For changes in temperature, the viscosity initially increases as the temperature ramps up then decreases after the inflection point. This temperature effect occurs prominently at lower shear rates and lessens at higher shear rates above 10 s−1. This ramp up in viscosity implies the entanglement of the wormlike micelles until the competing effect of temperature initiates micellar branching.

Furthermore, three similarly structured alkyl amine surfactants along with DTTM were studied to analyze how changes in the head and tail groups influence the viscoelastic response of a solution. At high salt concentrations, DTTM can sustain viscosity 1–2 orders of magnitudes higher than the other three chemical structures. A longer tail length, such that of DTTM and EDM promotes viscoelasticity and shear-thinning behavior due to efficient entanglement abilities compared to shorter tails. Terminals consisting of hydroxides or ethoxylates have a lower viscosity than that of methyl terminals. Finally, it was observed that a head group consisting of two nitrogen atoms has a higher viscosity than those containing one nitrogen atom due to the slower protonation process of the diamine surfactant molecules.

In all, the results suggest that DTTM can be used as a foaming and water viscosification agent. Similar to polymer enhanced foam, viscosification is a means to increase foam stability, and thereby the effective viscosity of aqueous foams for gas mobility control. The surfactant can be injected in CO2 or brine to generate foam in situ for reducing gas mobility in excessively gas processed zones (thief zones). Foam stability and propagation can be enhanced as the formation brine is viscosified in situ.

References

Acharya DP, Kunieda H. Wormlike micelles in mixed surfactant solutions. Adv Colloid Interface Sci. 2006;123–126:401–13. https://doi.org/10.1016/j.cis.2006.05.024.

Anderson VJ, Pearson JRA, Boek ES. The rheology of worm-like micellar fluids. In: Rheology Review, 2006. The British Society of Rheology. 2006. pp. 217–253.

Aryanpanah S, Nasr-El-Din HA. Rheological properties of an amine oxide viscoelastic surfactant with application in well stimulation. In: SPE Latin America and Caribbean petroleum engineering conference, 21–23 May, Maracaibo, Venezuela. 2014. https://doi.org/10.2118/169242-MS.

Barentin C, Liu AJ. Shear thickening in dilute solutions of wormlike micelles. Europhys Lett. 2001;55(3):432–8.

Berret JF. Rheology of wormlike micelles: equilibrium properties and shear banding transition. Mol Gels. 2006. https://doi.org/10.1007/1-4020-3689-2_20.

Brinchi L, Germani R, Di Profio P, Marte L, Savelli G, Oda R, et al. Viscoelastic solutions formed by wormlike micelles of amine oxide surfactant. J Colloid Interface Sci. 2010;346(1):100–6. https://doi.org/10.1016/j.jcis.2010.02.035.

Britton MM, Callaghan PT. Shear banding instability in wormlike micellar solutions. Eur Phys J B Condens Matter Complex Syst. 1999;7:237–49. https://doi.org/10.1007/s100510050610.

Britton MM, Mair RW, Lambert RK, Callaghan PT. Transition to shear banding in pipe and Couette flow of wormlike micellar solutions. J Rheol. 1999;43(4):897–909. https://doi.org/10.1122/1.551008.

Calabrese MA, Rogers SA, Murphy RP, Wagner NJ. The rheology and microstructure of branched micelles under shear. J Rheol. 2015;59:1299. https://doi.org/10.1122/1.4929486.

Cappelaere E, Cressely R. Shear banding structure in viscoelastic micellar solutions. Colloid Polym Sci. 1997;275(5):407–18. https://doi.org/10.1007/s003960050098.

Cates ME, Candau SJ. Statics and dynamics of worm-like surfactant micelles. J Phys: Condens Matter. 1990;2(33):6869–92.

Cates M. Theoretical modeling of viscoelastic phases. In: Structure and flow in surfactant solutions. ACS symposium series 578. Washington, DC: American Chemical Society; 1994. pp. 32–50.

Collura JS, Harrison DE, Richards CJ, Kole TK, Fisch MR. The effects of concentration, pressure, and temperature on the diffusion coefficient and correlation length of SDS micelles. J Phys Chem B. 2001;105(21):4846–52. https://doi.org/10.1021/jp004572h.

Delgado J, Kriegs H, Castillo R. Flow velocity profiles and shear banding onset in a semidilute wormlike micellar systems under Couette flow. J Phys Chem B. 2009;113(47):15485–94. https://doi.org/10.1021/jp9027996.

Dhont JK, Briels WJ. Gradient and vorticity banding. Rheol Acta. 2008;47(3):257–81. https://doi.org/10.1007/s00397-007-0245-0.

Fardin MA, Radulescu O, Morozov A, Cardoso O, Browaeys J, Lerouge S. Stress diffusion in shear banding wormlike micelles. J Rheol. 2015;59(6):1335–62. https://doi.org/10.1122/1.4930858.

Farn RJ. Chemistry and technology of surfactants. Oxford: Wiley-Blackwell. 2006.

Gaudino D, Pasquino R, Grizzuti N. Adding salt to a surfactant solution: linear rheological response of the resulting morphologies. J Rheol. 2015;59(6):1363–75. https://doi.org/10.1122/1.4931114.

Helgeson ME, Vasquez PA, Kaler EW, Wagner NJ. Rheology and spatially resolved structure of cetyltrimethylammonium bromide wormlike micelles through the shear banding transition. J Rheol. 2009;53(3):727. https://doi.org/10.1122/1.3089579.

Hill JP, Shrestha LK, Ishihara S, Ji Q, Ariga K. Self-assembly: from amphiphiles to chromophores and beyond. Molecules. 2014;19(6):8589–609. https://doi.org/10.3390/molecules19068589.

Hoffmann H. Viscoelastic surfactant solutions. In: Structure and flow in surfactant solutions. ACS symposium series. Washington, DC: American Chemical Society; 1994. pp. 2–31.

Hu YT, Lips A. Kinetics and mechanism of shear banding in an entangled micellar solution. J Rheol. 2005;49(5):1001–27. https://doi.org/10.1122/1.2008295.

Hu YT, Boltenhagen P, Pine DJ. Shear thickening in low-concentration solutions of wormlike micelles. I. Direct visualization of transient behavior and phase transitions. J Rheol. 1998;42(5):1185–208. https://doi.org/10.1122/1.550926.

Hu YT, Lips A, Palla C. Comparison between shear banding and shear thinning in entangled micellar solutions. J Rheol. 2008;52(2):379–400. https://doi.org/10.1122/1.2836937.

Hull KL, Sayed M, Al Muntasheri GA. Recent advances in viscoelastic surfactant for improved production from hydrocarbon reservoirs. In: SPE international symposium on oilfield chemistry, 13–15 April, The Woodlands, Texas, USA. 2015. https://doi.org/10.2118/173776-MS.

Kalur GC, Raghavan SR. Anionic wormlike micellar fluids that display cloud points: rheology and phase behavior. J Phys Chem B. 2005;109(18):8599–604. https://doi.org/10.1021/jp044102d.

Kalur GC, Frounfelker BD, Cipriano BH, Norman AI, Raghavan SR. Viscosity increase with temperature in cationic surfactant solutions due to growth of wormlike micelles. Langmuir. 2005;21(4):10998–1004. https://doi.org/10.1021/la052069w.

Koehler RD, Raghavan SR, Kaler EW. Microstructure and dynamics of wormlike micellar solutions formed by mixing cationic and anionic surfactants. J Phys Chem B. 2000;104(47):11035–44. https://doi.org/10.1021/jp0018899.

Kuperkar KC, Mata JP, Bahadur P. Effect of 1-alkanols/salt on the cationic surfactant micellar aqueous solutions: a dynamic light scattering study. Colloids Surf A Physiochem Eng Asp. 2011;380(1–3):60–5. https://doi.org/10.1016/j.colsurfa.2011.02.019.

Lee HY, Diehn KK, Ko SW, Tung SH, Raghavan SR. Can simple salts influence self-assembly in oil? Multivalent cations as efficient gelators of lecithin organosols. Langmuir. 2010;26(17):13831–8. https://doi.org/10.1021/la1019108.

Lequeux F. Structure and rheology of wormlike micelles. Curr Opin Colloid Interface Sci. 1996;1(3):341–4. https://doi.org/10.1016/S1359-0294(96)80130-0.

Li L, Nasr-El-Din HA, Cawiezel KE. Rheological properties of a new class of viscoelastic surfactant. SPE Prod Oper. 2010;25(3):355–66. https://doi.org/10.2118/121716-PA.

Li L, Nasr-El-Din HA, Crews JB, Cawiezel KE. Impact of organic acids/chelating agents on the rheological properties of an amidoamine oxide surfactant. SPE Prod Oper. 2011;26(1):30–40. https://doi.org/10.2118/128091-PA.

Liberatore MW, Nettesheim F, Vasquez PA, Helgeson ME, Wagner NJ, Kaler EW, et al. Microstructure and shear rheology of entangled wormlike micelles in solution. J Rheol. 2009;53(2):441–58. https://doi.org/10.1122/1.3072077.

Liebum M. Characterization of an alkyl diamine surfactant for gas mobility control in gas enhanced oil recovery and conformace control. Ph.D dissertation. Univeristy of Texas. 2016.

Lin Z, Zakin JL, Talmon Y, Zheng Y. Influence of surfactant concentration and counterion to surfactant ratio on rheology of wormlike micelles. J Colloid Interface Sci. 2001;239(2):543–54. https://doi.org/10.1006/jcis.2001.7618.

Maeda H, Yamamoto A, Souda M, Kawasaki H, Hossain KS, Norio N, et al. Effects of protonation on the viscoelastic properties of tetradecyldimethylamine oxide micelles. J Phys Chem B. 2001;105(23):5411–8. https://doi.org/10.1021/jp0101155.

Manneville S. Recent experimental probes of shear banding. Rheol Acta. 2008;47(3):301–18. https://doi.org/10.1007/s00397-007-0246-z.

Miller E, Rothstein JP. Transient evolution of shear-banding wormlike micellar solutions. J Non Newton Fluid Mech. 2007;143(1):22–37. https://doi.org/10.1016/j.jnnfm.2006.12.005.

Mu JH, Li GZ. The formation of wormlike micelles in anionic surfactant aqueous solutions in the presence of bivalent counterion. Chem Phys Lett. 2001;345(1–2):100–4. https://doi.org/10.1016/S0009-2614(01)00799-0.

Nasr-El-Din H, Al-Nakhli AR, Al-Driweesh SM, Welton TD, Sierra L, van Domelen MS. Application of cationic surfactant-based fluids for acid diversion. SPE Prod Oper. 2009;24(1):124–34. https://doi.org/10.2118/107687-PA.

Pipe CJ, Kim NJ, Vasquez PA, Cook LP, McKinley GH. Wormlike micellar solutions: II. comparison between experimental data and scission model predictions. J Rheol. 2010;54(4):881–913. https://doi.org/10.1122/1.3439729.

Rabie AI, Nasr-El-Din HA. Effect of acid additives on the reaction of stimulating fluids during acidizing treatments. In: SPE North Africa technical conference and exhibition, 14–16 September, Cairo, Egypt. 2015. https://doi.org/10.2118/175827-MS.

Raghavan S. Distinct character of surfactant gels: a smooth progression from micelles to fibrillar networks. Langmuir. 2009;25(15):8382–5. https://doi.org/10.1021/la901513w.

Raghavan S, Kaler EW. Highly viscoelastic wormlike micellar solutions formed by cationic surfactants with long unsaturated tails. Langmuir. 2001;17(2):300–6. https://doi.org/10.1021/la0007933.

Raghavan S, Fritz G, Kaler EW. Wormlike micelles formed by synergistic self-assembly in mixtures of anionic and cationic surfactants. Langmuir. 2002;18(10):3797–803. https://doi.org/10.1021/la0115583.

Rehage H, Hoffmann H. Viscoelastic surfactant solutions, model systems for rheological research. Mol Phys. 1991;74(5):933–73. https://doi.org/10.1080/00268979100102721.

Ren G, Sanders AW, Nguyen QP. New method for the determination of surfactant solubility and partitioning between CO2 and brine. J Supercrit Fluids. 2014;91:77–83. https://doi.org/10.1016/j.supflu.2014.04.010.

Ren G, Nguyen QP. Understanding aqueous foam with novel CO2-soluble surfactants for controlling CO2 vertical sweep in sandstone reservoirs. Pet Sci. 2017;14(2): 330–361. https://doi.org/10.1007/s12182-017-0149-2.

Rojas MR, Muller AJ, Saez AE. Shear rheology and porous media flow of wormlike micelle solutions formed by mixture of surfactants of opposite charge. J Colloid Interface Sci. 2008;326(1):221–6. https://doi.org/10.1016/j.jcis.2008.07.022.

Romero C, Alvarez JM, Müller AJ. Micromodel studies of polymer-enhanced foam flow through porous media. In: SPE/DOE improved oil recovery symposium, 13–17 April, Tulsa, Oklahoma. 2002. https://doi.org/10.2118/75179-MS.

Rounds RS. Shear effects in surfactant solutions. In: Structure and flow in surfactant solutions. ACS symposium series. Washington, DC: American Chemical Society. 1994. pp. 260–77.

Schramm LL. Surfactants fundamental and applications in the petroleum industry. Cambridge: Cambridge University Press. 2000.

Shashkina JA, Philippova OE, Zaroslov YD, Khokhlov AR, Pryakhina TA, Blagodatskikh IV. Rheology of viscoelastic solutions of cationic surfactant: effect of added associating polymer. Langmuir. 2005;21:1524–30. https://doi.org/10.1021/la0482756.

Shchipunov YA, Hoffmann H. Thinning and thickening effects induced by shearing in lecithin solution of polymer-like micelles. Rheol Acta. 2000;39(6):542–53. https://doi.org/10.1007/s003970000097.

Thareja P, Hoffmann IH, Liberatore MW, Helgeson ME, Hu YT, Gradzielski M, et al. Shear-induced phase separation (SIPS) with shear banding in solutions of cationic surfactant and salt. J Rheol. 2011;55(6):1375–97. https://doi.org/10.1122/1.3641517.

Trickett K, Eastoe J. Surfactant-based gels. Adv Colloid Interface Sci. 2008;144(1–2):66–74. https://doi.org/10.1016/j.cis.2008.08.009.

Truong MT, Walker LM. Quantifying the importance of micellar microstructure and electrostatic interactions on the shear-induced structural transition of cylindrical micelles. Langmuir. 2002;18(6):2024–31. https://doi.org/10.1021/la015551x.

Tung SH, Huang YE, Raghavan SR. Contrasting effects of temperature on the rheology of normal and reverse wormlike micelles. Langmuir. 2007;23(2):372–6. https://doi.org/10.1021/la063037r.

van Zanten R. Stabilizing viscoelastic surfactants in high-density brines. SPE Drill Complet. 2011;26(4):499–505. https://doi.org/10.2118/141447-PA.

Wang W, Lu W, Jiang L. Influence of pH on the aggregation morphology of a novel surfactant with single hydrocarbon chain and multi-amine headgroups. J Phys Chem B. 2008;112(5):1409–13. https://doi.org/10.1021/jp075535u.

Wang G, Nasr-El-Din HA, Zhou J, Holt S. A new viscoelastic surfactant for high temperature carbonate acidizing. In: SPE Saudi Arabia section technical symposium and exhibition, 8–11 April, Al-Khobar, Saudi Arabia. 2012. https://doi.org/10.2118/160884-MS.

Ye Z, Pu W, Zhang S, Chen T. Laboratory study on profile modification by using foamed polymer solution. In: Annual technical meeting, June 8–11, Calgary, Alberta, Petroleum Society of Canada. 1997. https://doi.org/10.2118/97-128.

Yesilata B, Clasen C, McKinley GH. Nonlinear shear and extensional flow dynamics of wormlike surfactant solutions. J Non Newton Fluid Mech. 2006;133:73–90. https://doi.org/10.1016/j.jnnfm.2005.10.009.

Zana R, Kaler EW. Giant micelles: properties and applications. Florida: CRC Press. 2007.

Zhang YM, Zhou D, Ran H, He S. Rheology behaviors of C22-tailed carboxylbetaine in high-salinity solution. J Dispers Sci Technol. 2016;37(4):496–503. https://doi.org/10.1080/01932691.2015.1045601.

Zhao Y, Haward SJ, Shen AQ. Rheological characterizations of wormlike micellar solutions containing cationic surfactant and anionic hydrotropic salt. J Rheol. 2015;59(5):1229–58. https://doi.org/10.1122/1.4928454.

Acknowledgements

This work was supported by the Abu Dhabi National Oil Company and the University of Texas at Austin.

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Yan-Hua Sun

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Liebum, M.M., Hirasaki, G. & Nguyen, Q.P. A systematic rheological study of alkyl amine surfactants for fluid mobility control in hydrocarbon reservoirs. Pet. Sci. 15, 538–551 (2018). https://doi.org/10.1007/s12182-018-0217-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-018-0217-2